Solid cartridge for ultrasonic atomization electronic cigarette and manufacturing method of solid cartridge

A technology of ultrasonic atomization and ultrasonic atomization tablets, which is applied in the direction of smokers' supplies, applications, tobacco, etc., which can solve the problem of odor caused by ultrasound or fragmentation directly by ultrasound, unclear aroma of suction smoke, and oral comfort Not good enough and other problems, to avoid the risk of harmful substances and odors, enhance the sense of experience, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

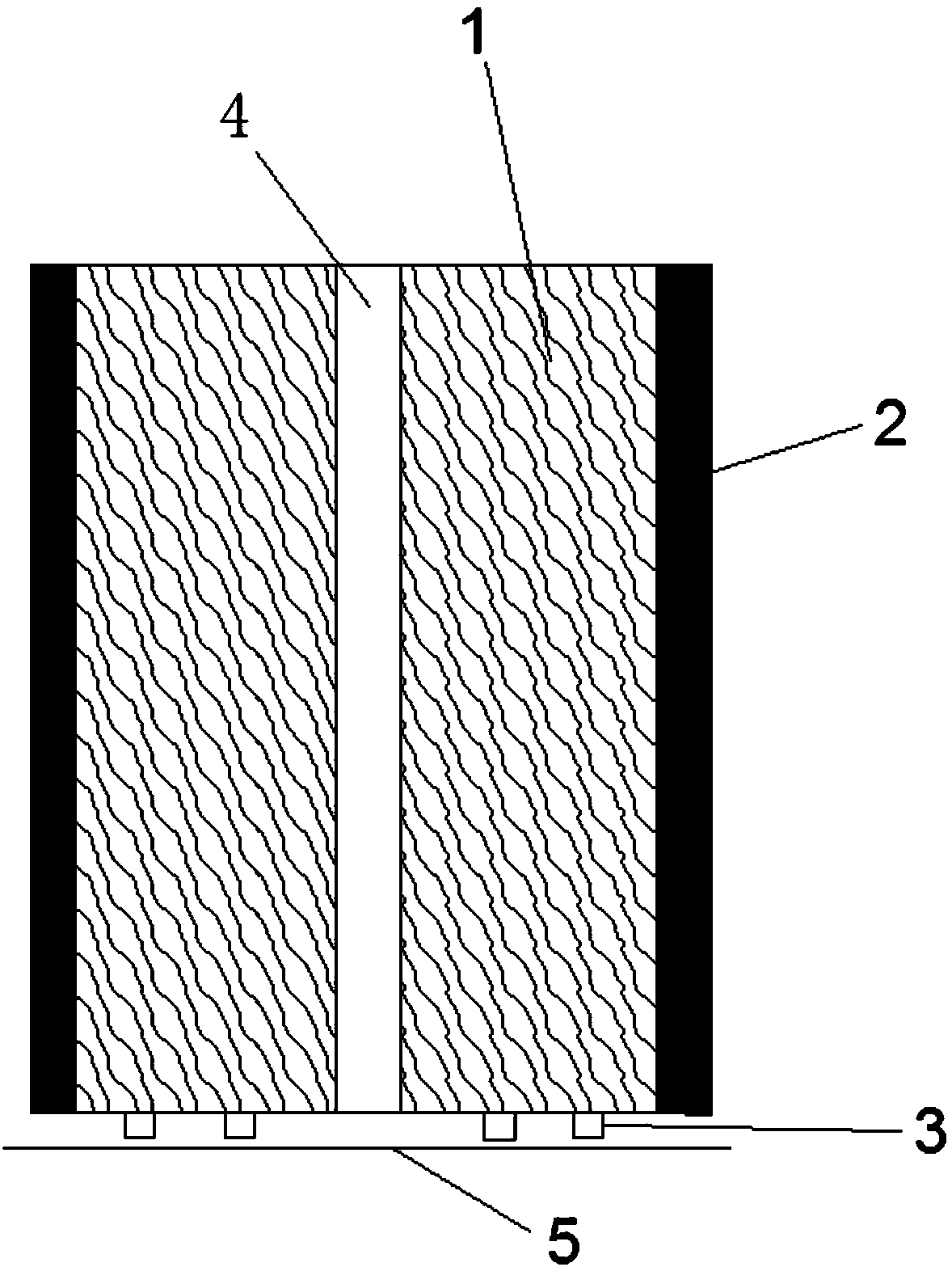

Image

Examples

Embodiment 1

[0034] The preparation method of the solid-state cartridge for ultrasonically atomized electronic cigarettes in this embodiment includes the following steps:

[0035] (1) In parts by mass, weigh 50 parts of tobacco stem fiber, 30 parts of flax fiber, 5 parts of 60-mesh flue-cured tobacco powder, 3 parts of food glue, 10 parts of puffing agent, 2 parts of 5A molecular sieve 40-mesh powder, add An appropriate amount of water is mixed and stirred evenly to obtain a mixed slurry of raw materials in the liquid storage part;

[0036] (2) Inject the mixed slurry of raw materials in the liquid storage part into a bar-shaped concave with a center column (for making a smoke channel, the same below) and a bottom with an interval of 2mm, a length of 2mm, a width of 1.8mm, and a depth of 1mm. groove (the groove is used to form the protrusion at the bottom of the pod), after filling the mold, put them together in an oven at 105°C for drying, then take out the green body and trim it slightly...

Embodiment 2

[0040] The preparation method of the solid-state cartridge for ultrasonically atomized electronic cigarettes in this embodiment includes the following steps:

[0041] (1) In parts by mass, weigh 35 parts of tobacco stem fiber, 25 parts of sisal fiber, 12 parts of shredded cotton fiber, 8 parts of flue-cured tobacco powder of 80 mesh, 5 parts of food glue, and 15 parts of puffing agent, Add an appropriate amount of water to mix and stir evenly to obtain a mixed slurry of raw materials in the liquid storage part;

[0042] (2) Fill the mixed slurry of raw materials in the above-mentioned liquid storage part with a cylindrical concave column with a center column and a bottom with a distance of 3mm, a diameter of 1mm, and a depth of 2mm (the concave column is used to form the protrusion at the bottom of the pod) ) in the mold, quickly dried in an environment of 140°C and trimmed slightly, and then wrapped in an anti-seepage plastic cylinder to obtain a finished solid pod.

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com