Oil-proof device for sewing machine needle bar

A sewing machine needle and oil-proof technology, applied in the field of sewing machines, can solve the problems of increased oil leakage, unguaranteed service life and reliability, and weakened oil-proof ability, achieving stable suction, eliminating the risk of oil leakage, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

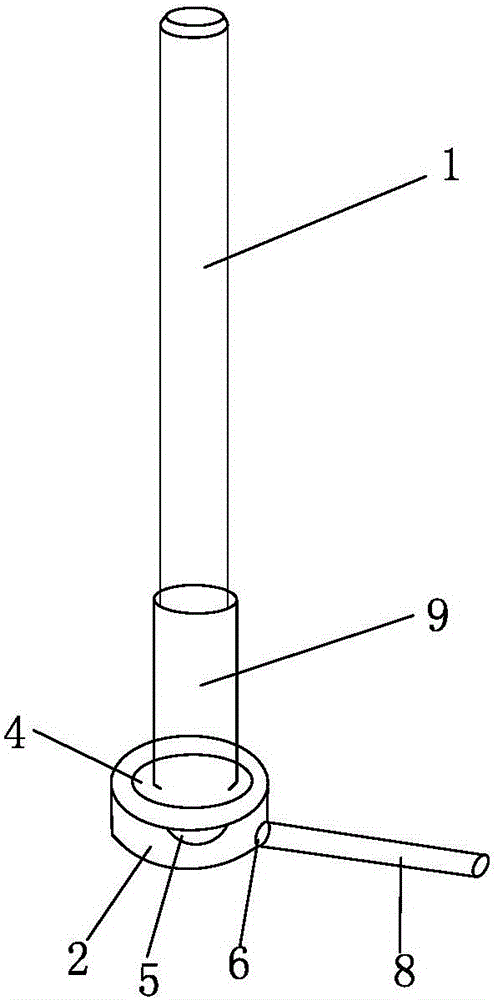

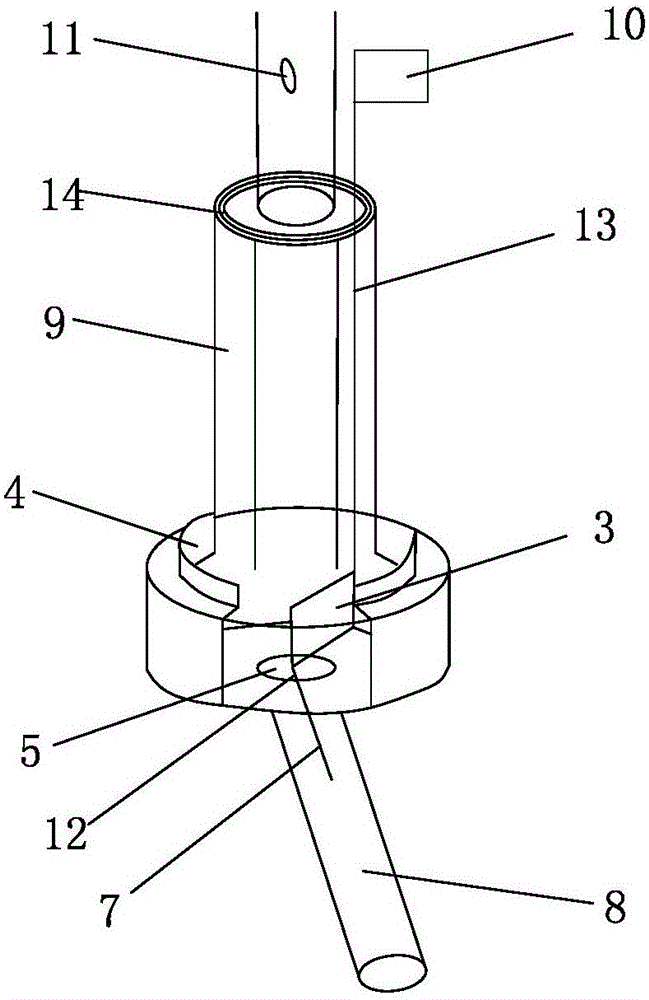

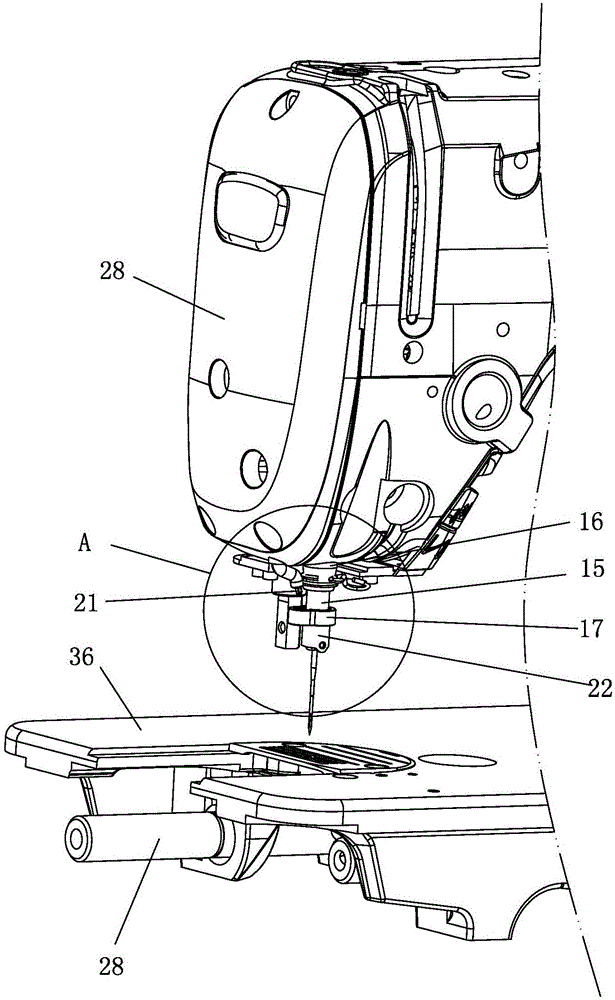

[0037] The present invention will be further described below with specific embodiment, see image 3 -10:

[0038] A sewing machine needle bar oil prevention device, including a needle bar 15, on the needle bar 15 is provided with an oil return reservoir 17 that can collect lubricating oil leaking from between the needle bar 15 and the needle bar lower bushing 16, on the needle bar 15 One side of the rod 15 is provided with an oil return pipe 18, the oil suction end of the oil return pipe 18 is located above the oil return storage 17, the oil return pipe 18 is connected with the oil return device, the needle bar 15 drives the oil return storage 17 to move up and down during the up and down movement, The oil return accumulator 17 moves into contact with the oil suction end of the oil return pipe 18, and the oil return pipe 18 absorbs the lubricating oil in the oil return accumulator 17 through the oil return device and returns the oil. The oil suction end of the oil return pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com