Pressurizing cylinder

A pressurized cylinder and pressurized piston technology, applied in the field of hydraulic pressurized cylinders, can solve the problems of complex structure, large size and weight, difficult manufacture and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

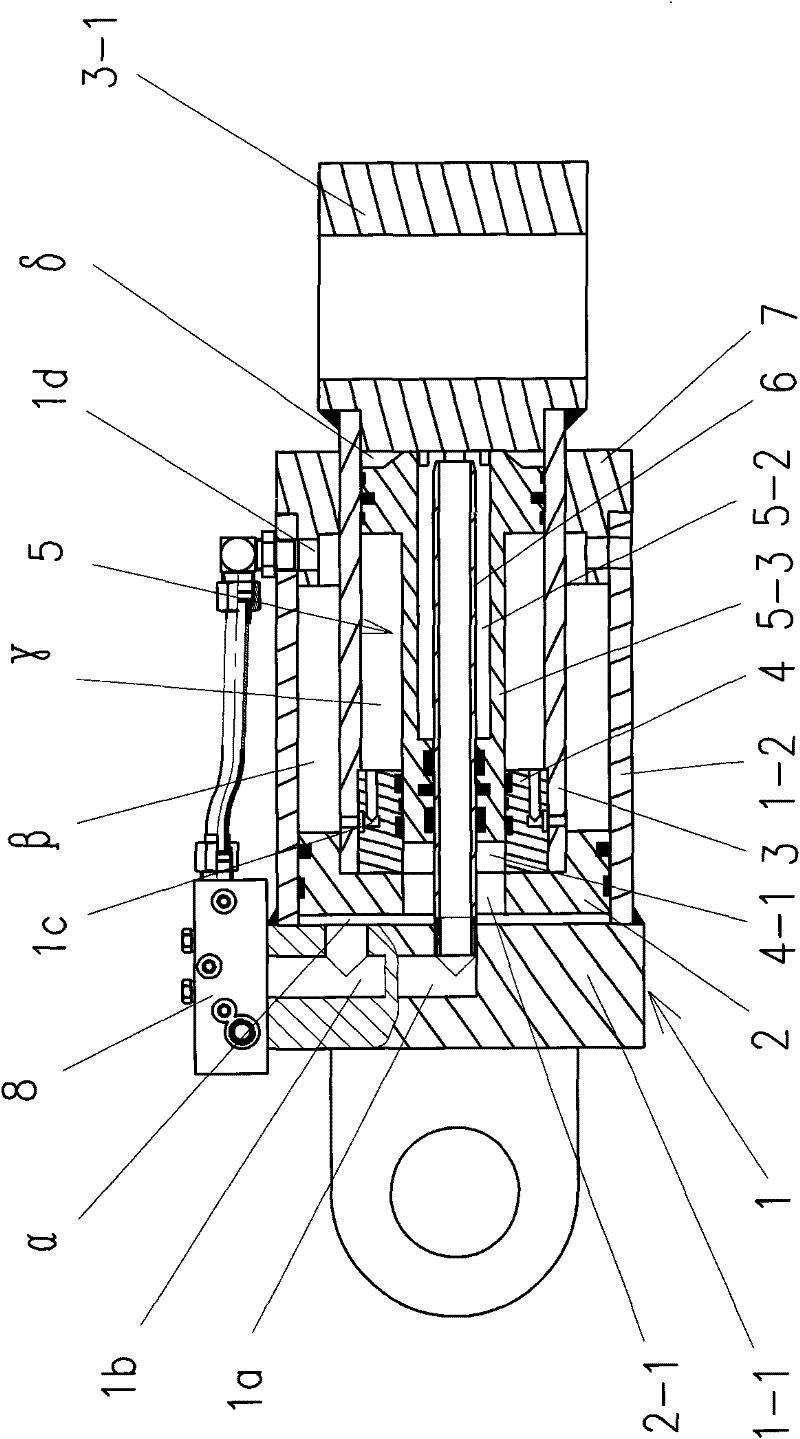

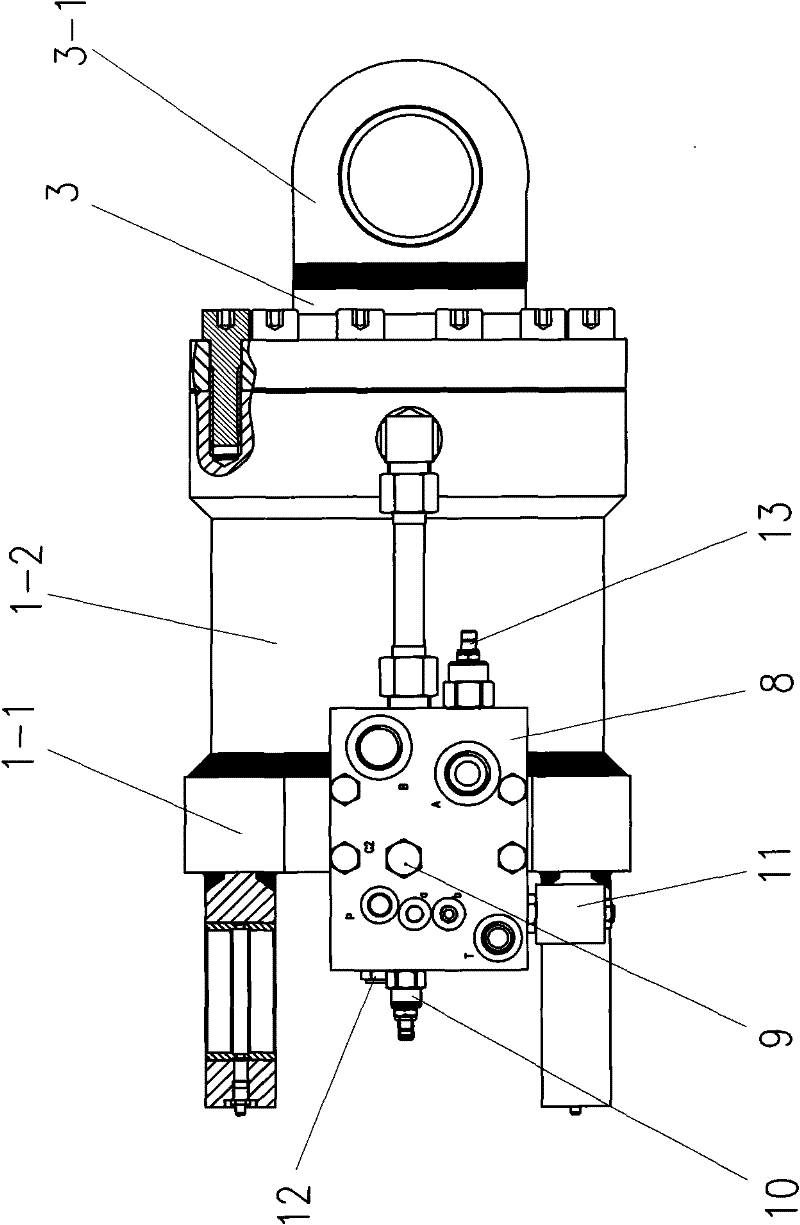

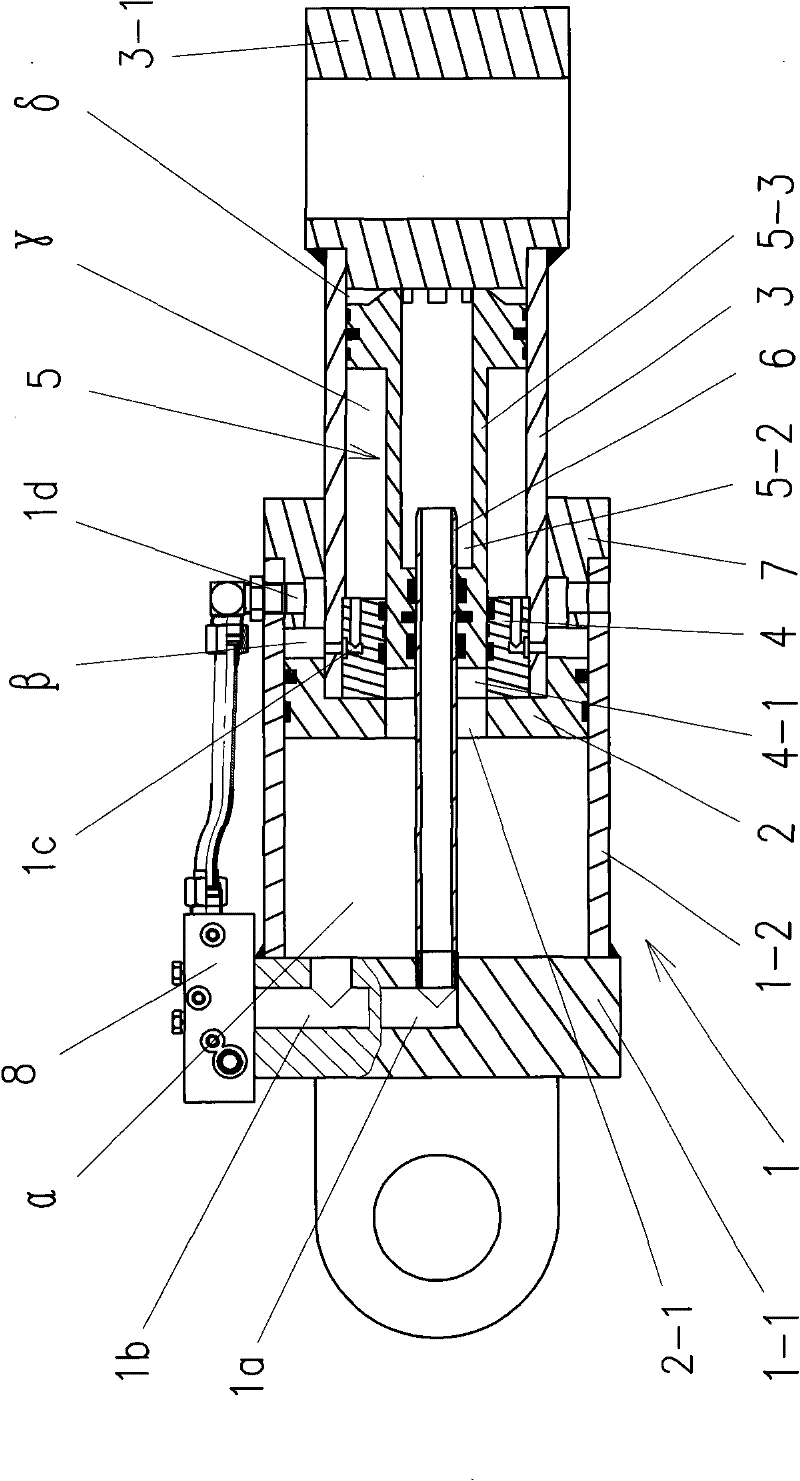

[0021] Such as figure 1 , 2 , 3, and 5 are the first embodiment of the present invention, a pressurized oil cylinder, including cylinder 1, piston 2, piston rod 3, piston rod end connector 3-1 and end cover 7, cylinder 1 The inner cavity of the piston 2 is divided into a first cavity α and a second cavity β, the piston rod 3 is equipped with a booster piston 5, and the inner cavity of the piston rod 3 is divided into a third cavity γ and a fourth cavity δ by the booster piston 5. The second cavity β and the third cavity γ are communicated through the oil passage 1c, and the piston 2 has an opening 2-1. One end of the booster piston 5 can penetrate through the opening 2-1 of the piston 2 and extend into the cylinder 1 The first cavity α, the booster piston 5 has a through hole 5-2, the through hole 5-2 communicates with the fourth cavity δ of the inner cavity of the piston rod 3, and the end 1-1 of the cylinder 1 has a first oil passage 1a and The second oil circuit 1b is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com