Automobile rear axle case

An automobile rear axle and axle housing technology, applied in the field of auto parts, can solve the problems of poor sealing performance of the rear cover and axle housing assembly, poor weld quality stability, etc., to reduce the number of weld seams, reduce production costs, reduce Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

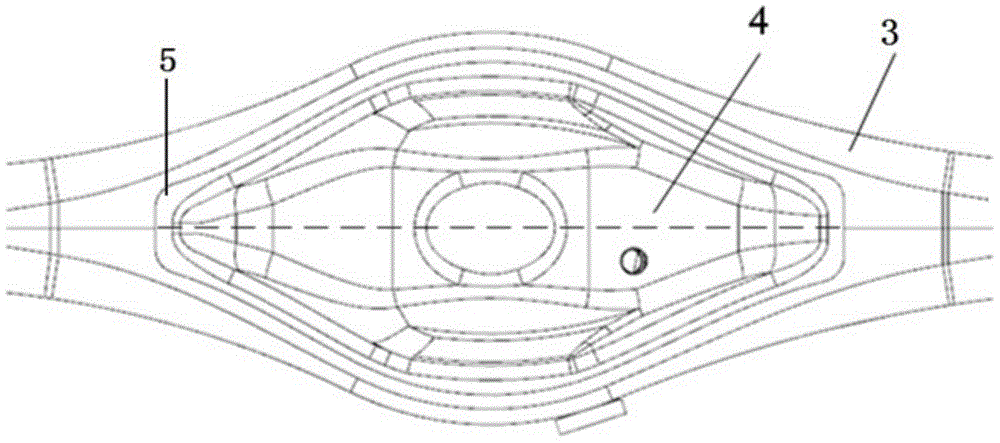

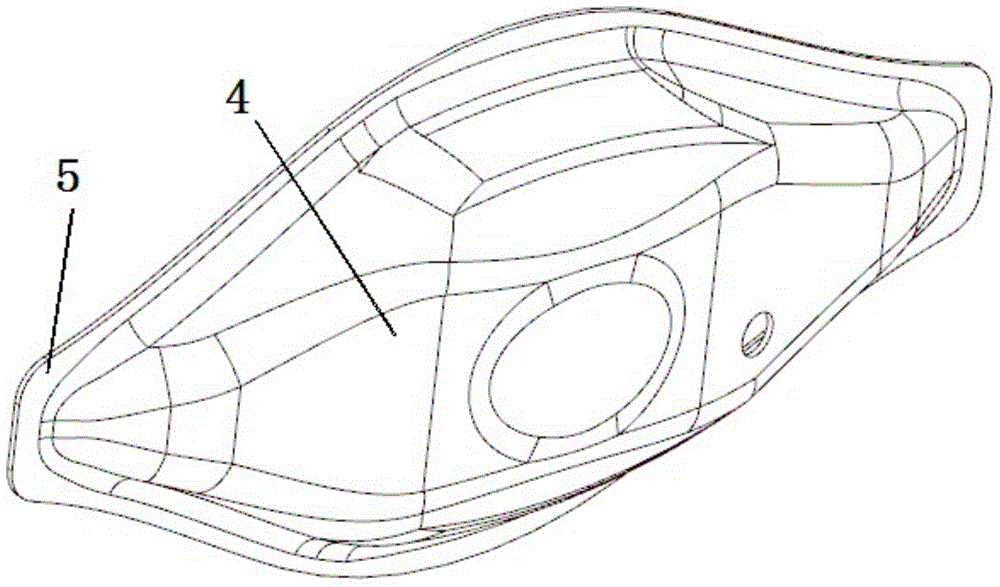

[0017] Such as figure 2 Shown, a kind of automobile rear axle housing, comprises axle housing assembly 3 and rear cover 4, and described rear cover 4 is a whole and is rhombus, and its middle part protrudes outwards, has formed a cavity; The rear cover 4 is connected to the axle housing assembly 3 , and the diagonals of the two smaller inner corners of the rear cover 4 are parallel to the axis of the axle housing assembly 3 . The middle part of the rear cover 4 protrudes toward the opposite direction of the axle housing assembly 3, and the protrusion is composed of an outwardly protruding curved surface at the center of the rear cover and a plurality of inclined surfaces around the curved surface.

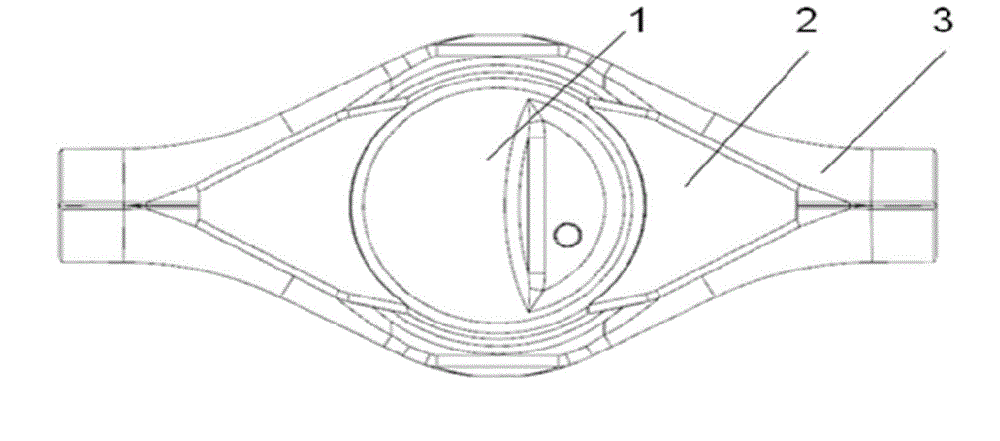

[0018] Such as figure 1 As shown, compared with the prior art, the diamond-shaped rear cover 4 is a part integrated with the circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com