Anti-blocking and anti-corrosion structure for junction of horn pipe and backflow groove

A trumpet tube and anti-blocking technology, which is applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of easy corrosion at the connection between the horn tube and the return flow tank, and reduce the frequency of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

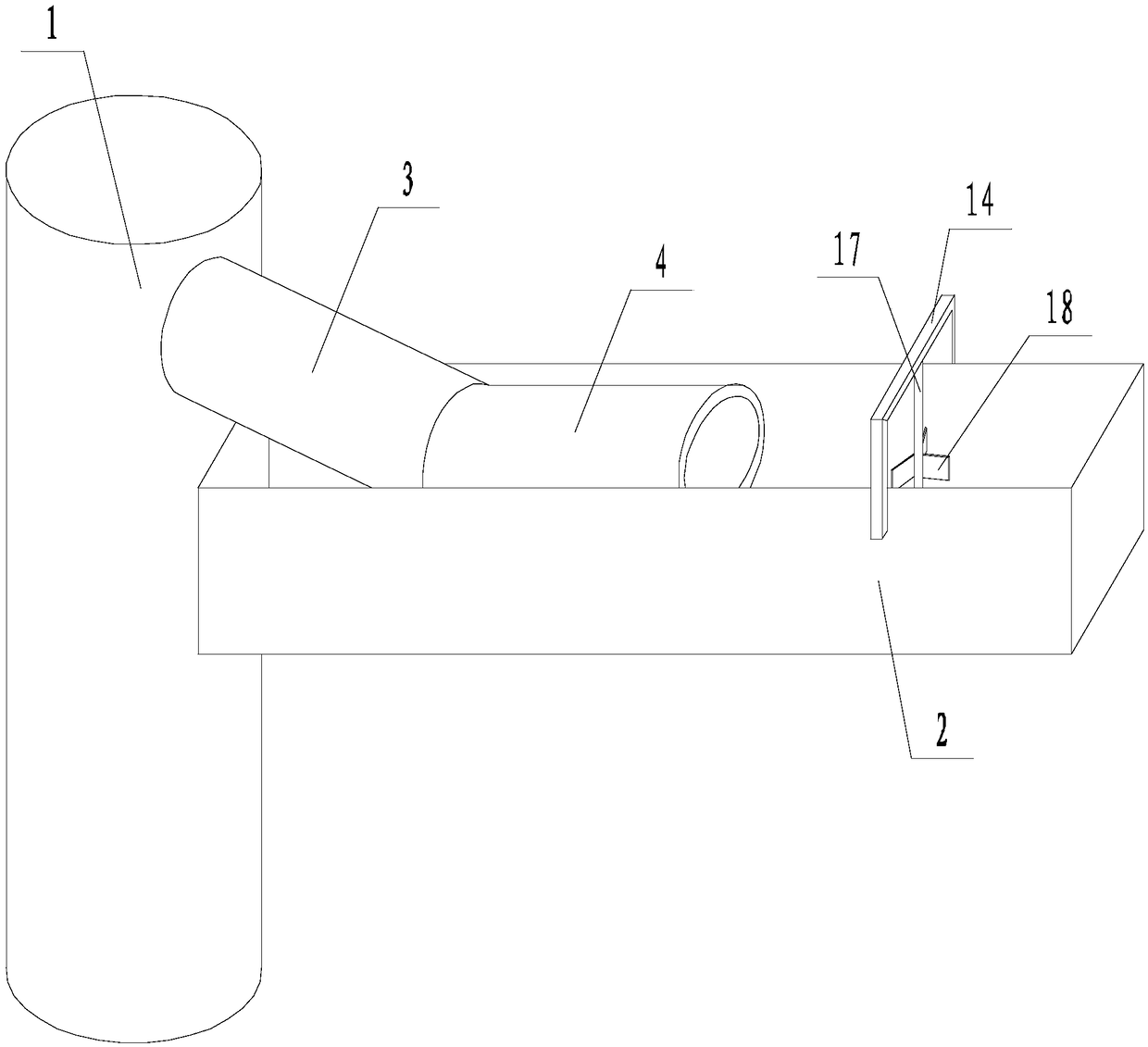

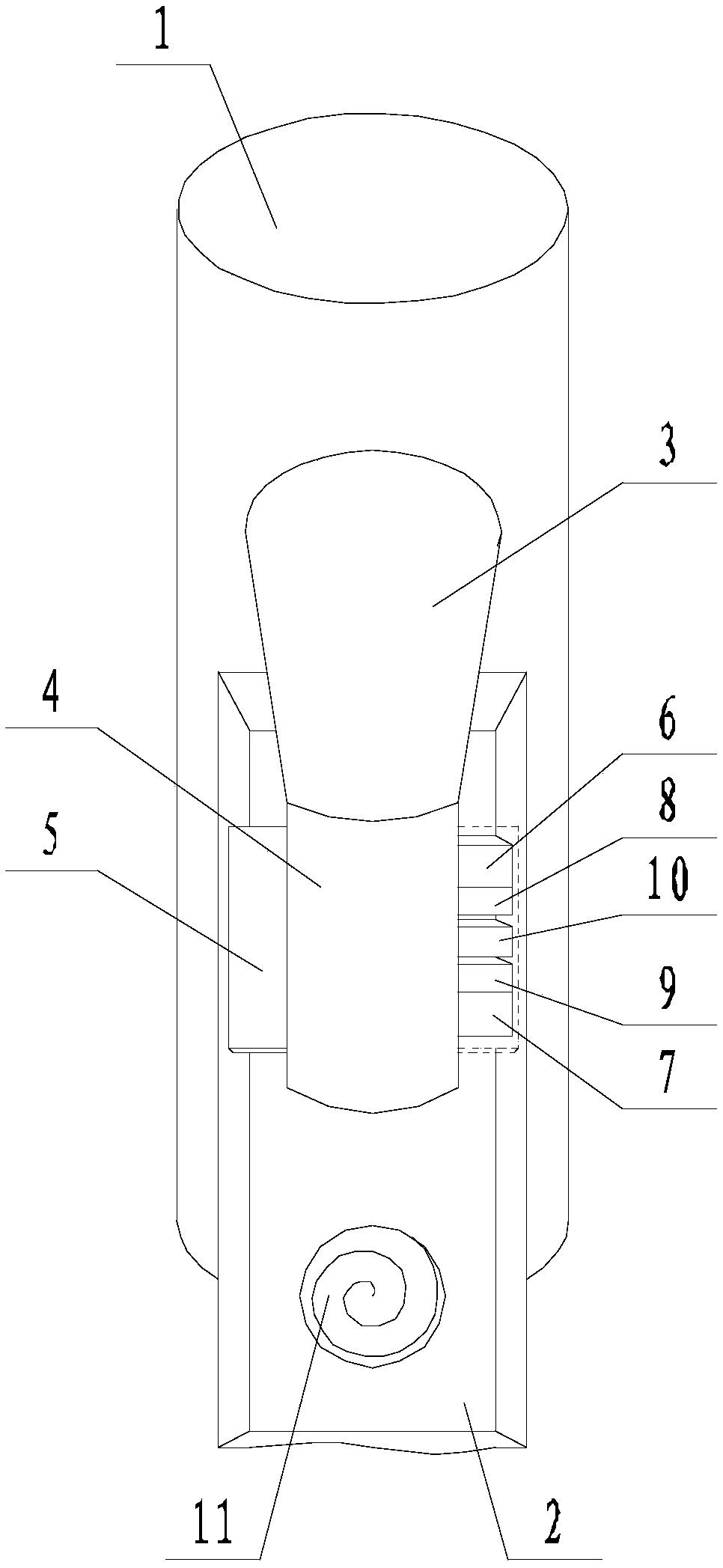

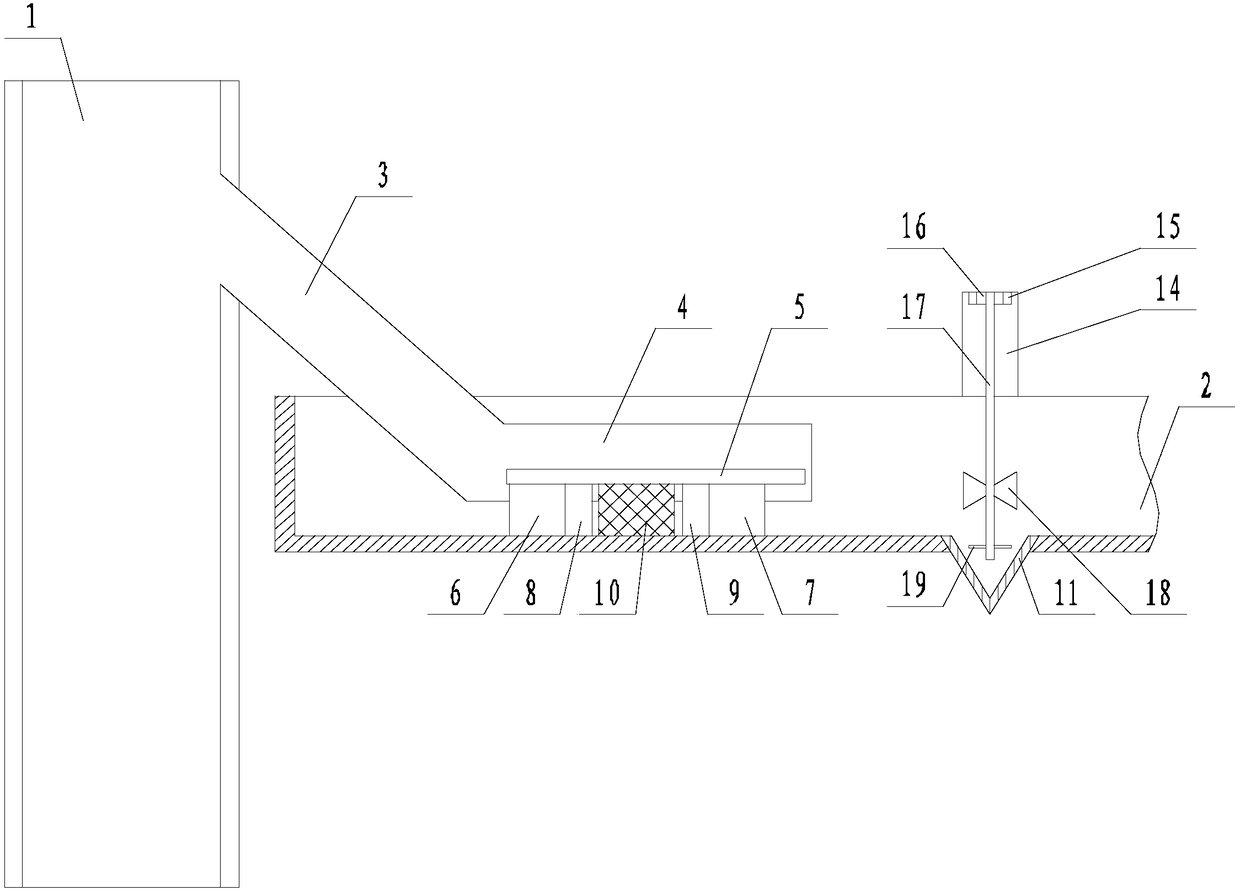

[0028] like Figure 1 to Figure 7 The anti-blocking and anti-corrosion structure used for the connection between the trumpet tube and the reflux tank is shown. For the convenience of display, in figure 2 The ceramic mounting plate 5 on the right side and the gantry frame 14 have been hidden as a whole, including the trumpet pipe 1 provided with the return port, the back flow tank 2 connected to the return port of the trumpet pipe 1, and the back flow tank 2 The outer surface is not in contact with the trumpet tube 1, and the height of the reflux groove 2 is lower than the height of the return port of the trumpet tube 1. The horn tube 1 is fixedly connected with an inclined conduit 3 communicated with the return port, and the inclined conduit 3 faces the return port. The direction of the launder 2 is inclined downward, and the end of the inclined conduit 3 away from the trumpet tube 1 is fixedly connected to the parallel conduit 4. The parallel conduit 4 is located in the refl...

Embodiment 2

[0030] like Figure 1 to Figure 7 The shown anti-blocking and anti-corrosion structure for the connection between the horn tube and the reflux tank, on the basis of the embodiment, the materials of the horn tube 1, the inclined conduit 3, and the parallel conduit 4 are the same; the reflux tank 2 , the tapered protrusion 11, the deflector 12, the baffle 18, and the blade 19 are made of the same material. A number of blind holes 20 are evenly distributed on the surface of the second ceramic pad 7 facing the direction of the conical protrusion 11 , and the opening diameter of the blind holes 20 is 2.5 cm. The first ceramic spacer 6, the first rubber gasket 8, the bearing frame 10, the second rubber gasket 9, and the second ceramic spacer 7 are all square structures with an arc groove 13 on the upper part. The radius of the arc groove 13 is equal to the outer diameter of the parallel conduit 4; the opposite sides of the bearing frame 10 along the length direction of the backflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com