An ultra-short cartridge mechanical seal and its working method

An ultra-short cartridge and cartridge technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of shortened service life of mechanical seals, complex structures, improper installation, etc., and reduce the sealing pressure , better sealing effect, and prevent the spring from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

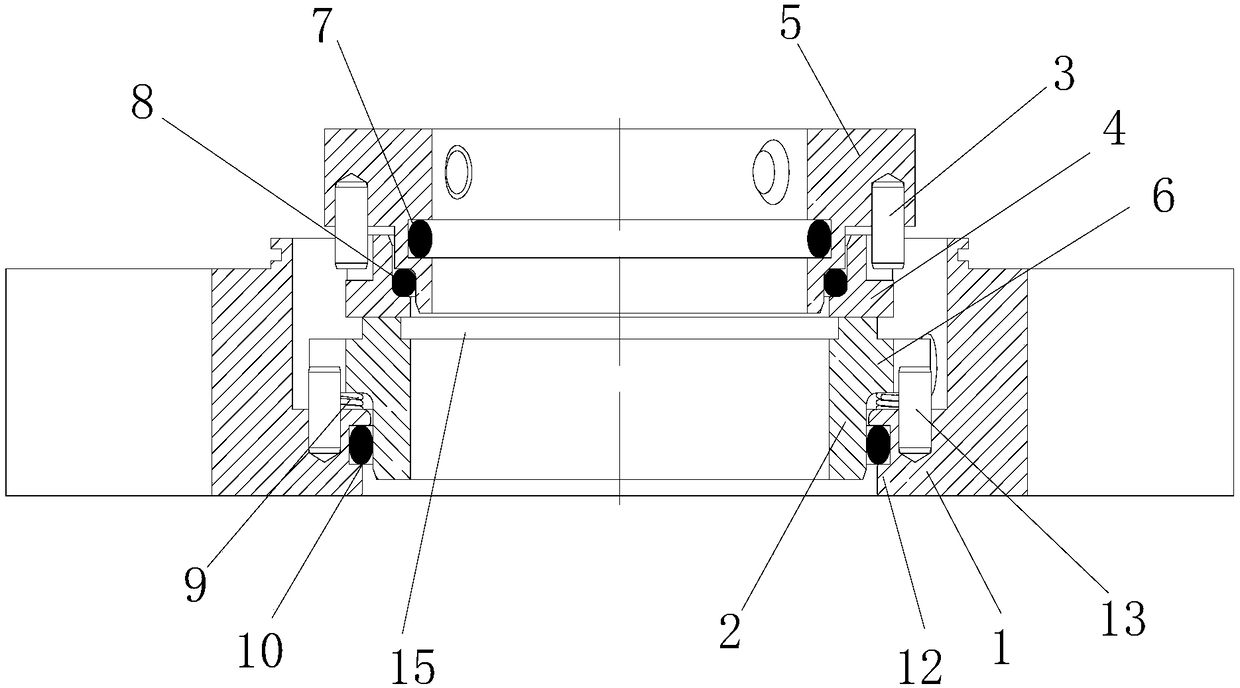

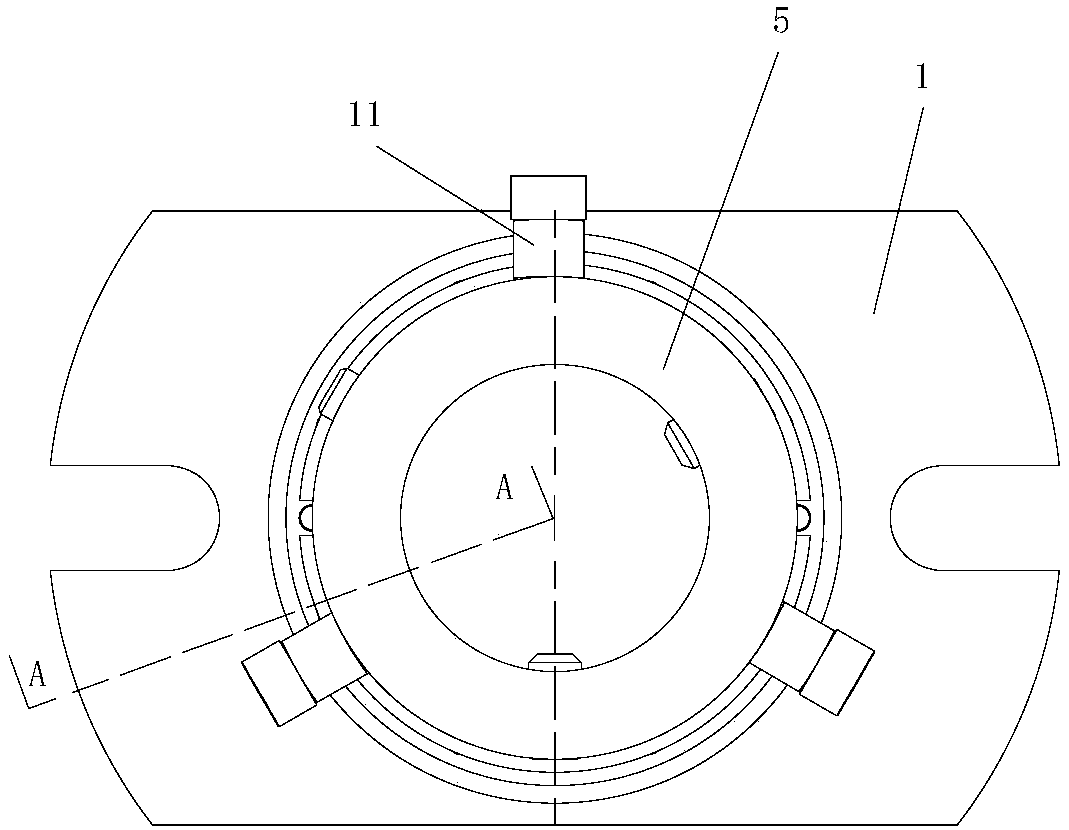

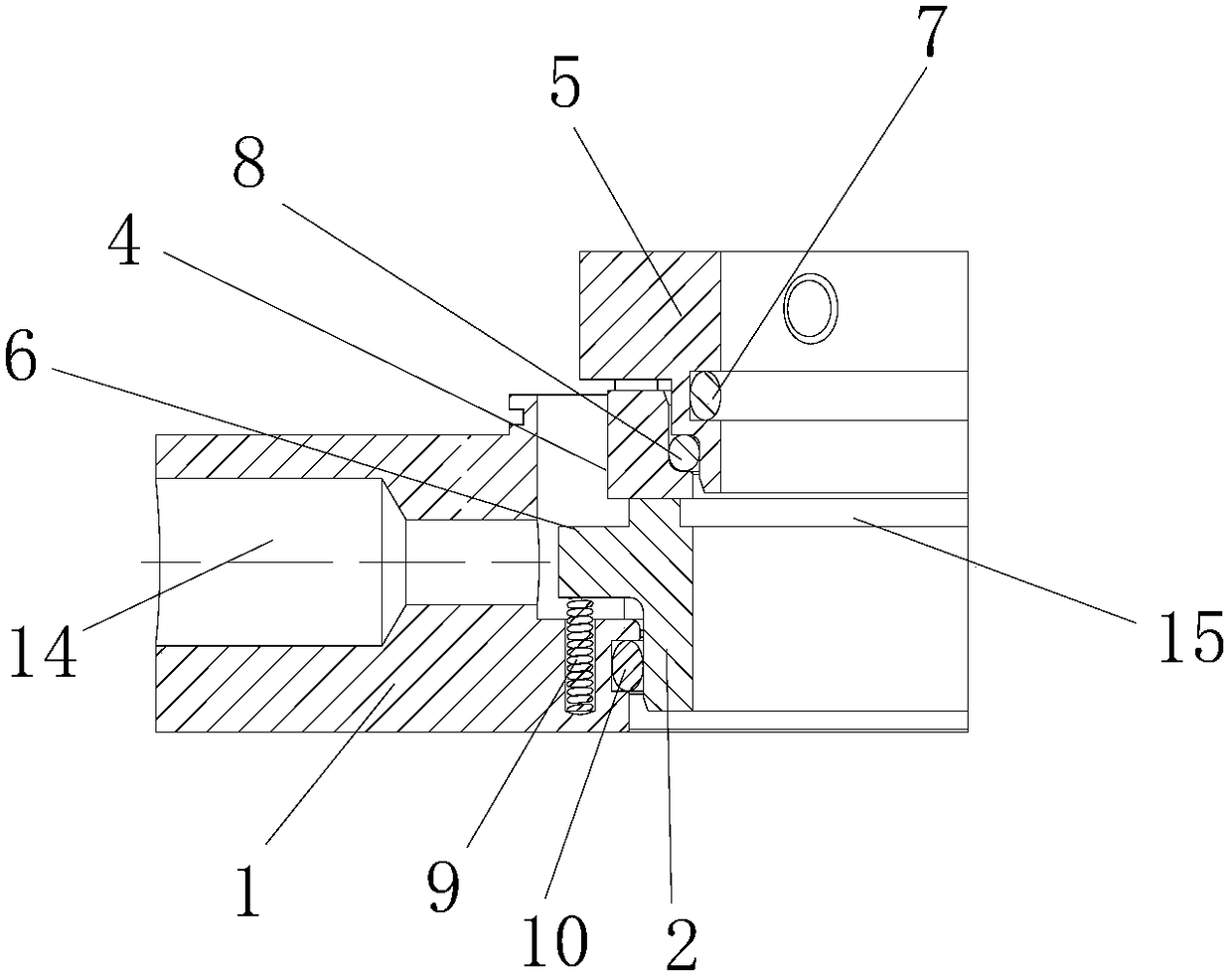

[0020] Example 1 as Figure 1 to Figure 3 As shown, the ultra-short cartridge mechanical seal of this embodiment includes: a flange 1, a static ring 2, a moving ring 4, and a clamping ring 5 for connecting with the package to be packaged, and the bottom of the inner wall of the flange 1 is along its An annular boss 12 is arranged in the circumferential direction, and a flange 6 is arranged on the outer wall of the static ring 2 along its circumference. An annular groove is set, and a third O-ring 10 is arranged in the annular groove to obtain a better sealing effect; and the flange 6 of the static ring 2 is placed above the flange annular boss 12, the flange 6 and A plurality of limit pins 13 for transmission and guidance are arranged between the bosses 12, so that the static ring 2 can be axially displaced along the flange 1, and at the same time the static ring 2 can rotate synchronously with the flange 1; the annular boss 12 The upper end surface is provided with a plurali...

Embodiment 2

[0023] The working method of the above-mentioned ultra-short cartridge type mechanical seal comprises the following steps:

[0024] A. The moving ring 4 and the clamping ring 5 are fixedly connected to the rotating shaft, the static ring 2 is fixedly connected to the container, and the rotating shaft is introduced into the container.

[0025] B. Pull out the positioning block 11 so that the moving ring 4 is in contact with the static ring 2 and forms a seal.

[0026] C. Rotate the rotating shaft to drive the clamping ring 5 and the moving ring 4 to rotate, so that the dynamic cooperation between the sealing surface of the moving ring 4 and the sealing surface of the static ring 2 is achieved. For sealing, the second O-ring 8 seals between the clamping ring 5 and the moving ring 4, and the third O-ring 10 seals between the static ring 2 and the flange 1; along the static ring 2 When the liquid flowing out from the inner wall and the outer wall of the rotating shaft is sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com