Patents

Literature

32results about How to "Reduce the probability of oil spills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

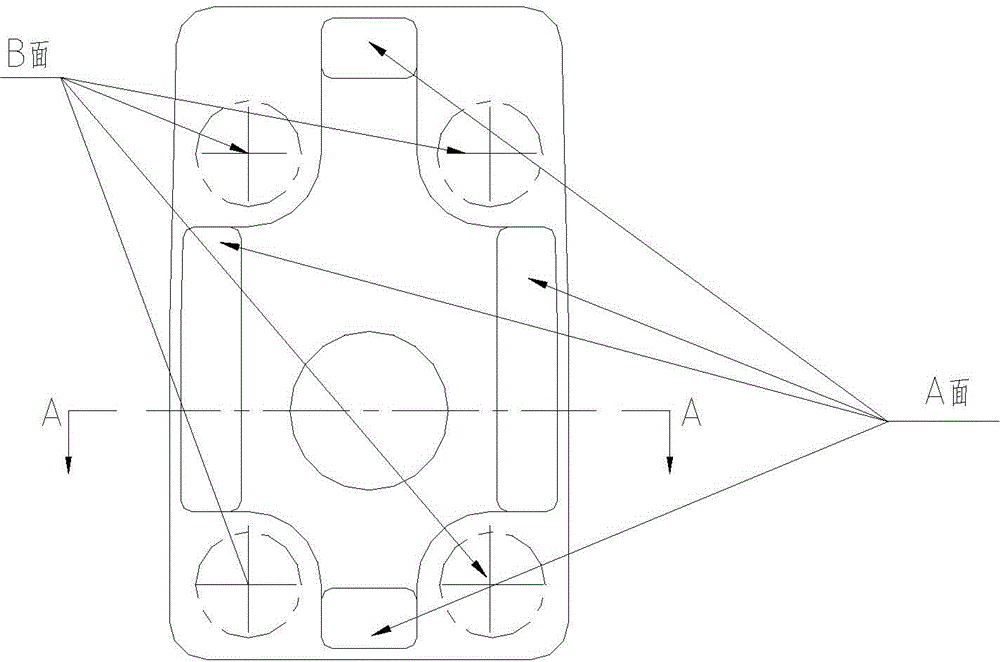

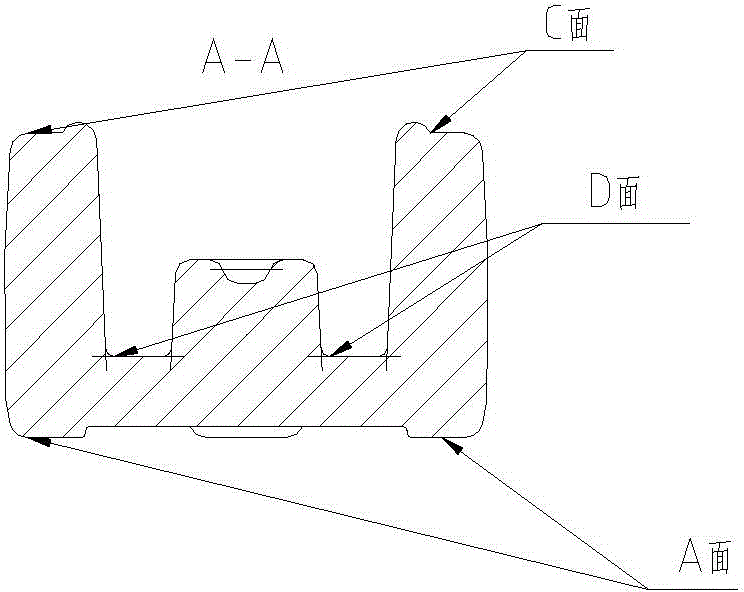

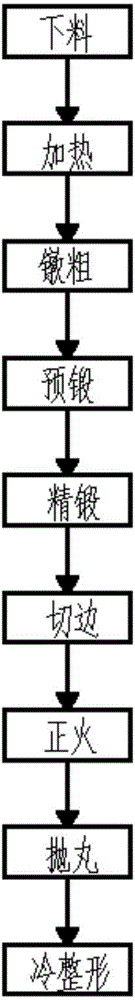

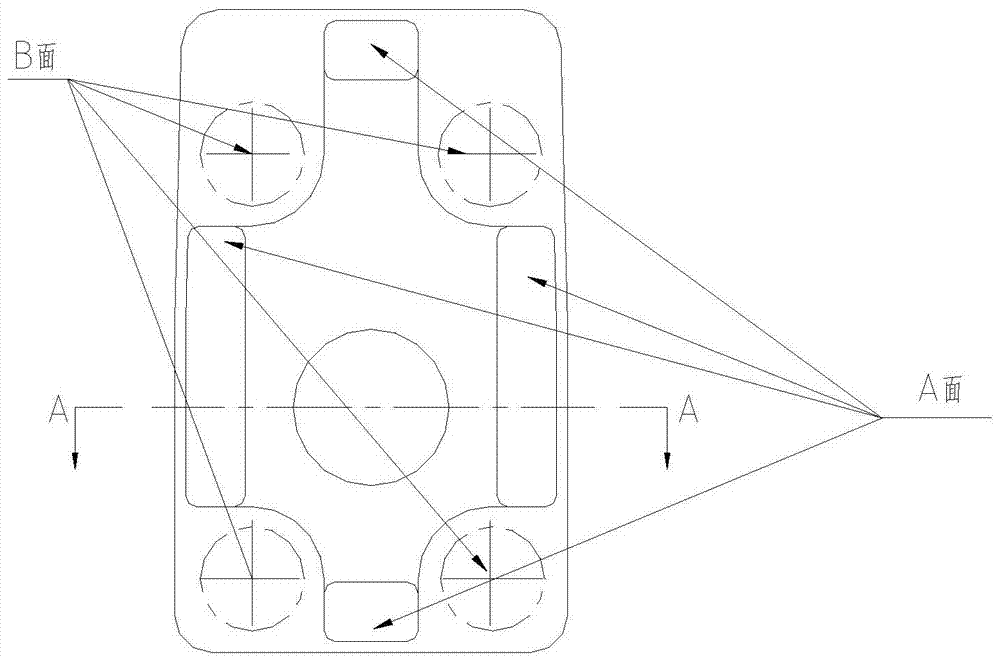

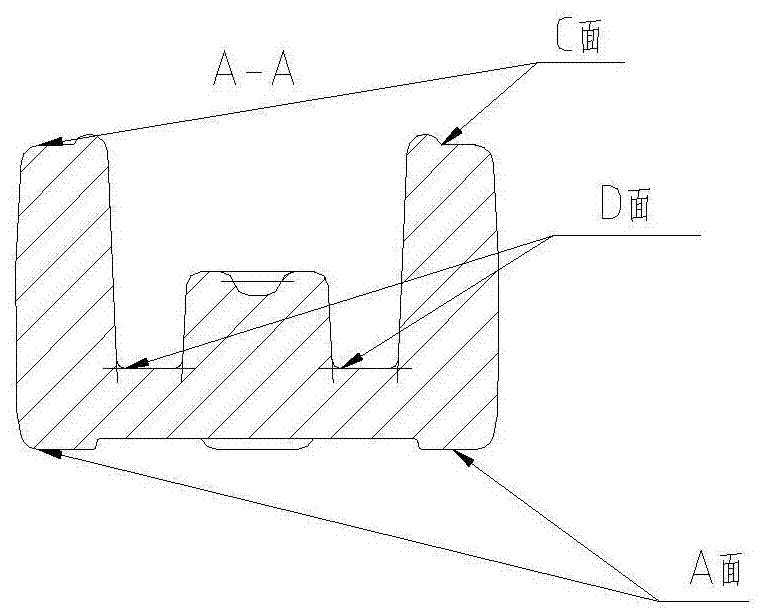

Hydraulic valve cover manufacturing process

The invention relates to a hydraulic valve cover manufacturing process. The process includes the following steps of a, discharging, wherein the required raw material is prepared according to weight and size, b, heating, wherein heating is conducted on the raw material in a heating furnace, c, upsetting, wherein the heated raw material is placed in an upsetting die, unsetting is conducted on the raw material to form a workblank, and the oxide skin on the surface of the workblank is removed; d, dummying, wherein performing is conducted on the workblank generated after the oxide skin is removed to form a pre-forging piece, e, precision forging, wherein fine machining is conducted on the preformed workblank to form a precision forging piece, f, burr cutting, wherein burrs of the precision forging piece are cut on a punching machine, g, normalizing, wherein the precision forging piece generated after burr cutting is conducted is placed in a furnace, and normalizing is conducted on the precision forging piece, h, shot blasting, wherein the oxide skin on the surface of the precision forging piece generated after normalizing is conducted is removed and i, cold sizing, wherein local cold sizing is conducted on the precision forging piece on a cold forging machine. According to the hydraulic valve cover manufacturing process, the workblank is formed through hot forging, then cold-extrusion is conducted on a key face, the plane degree and parallel degree are guaranteed, traditional machinery machining is replaced, the production cost is saved, and the forged piece is high in mechanical strength and stable in size accuracy.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

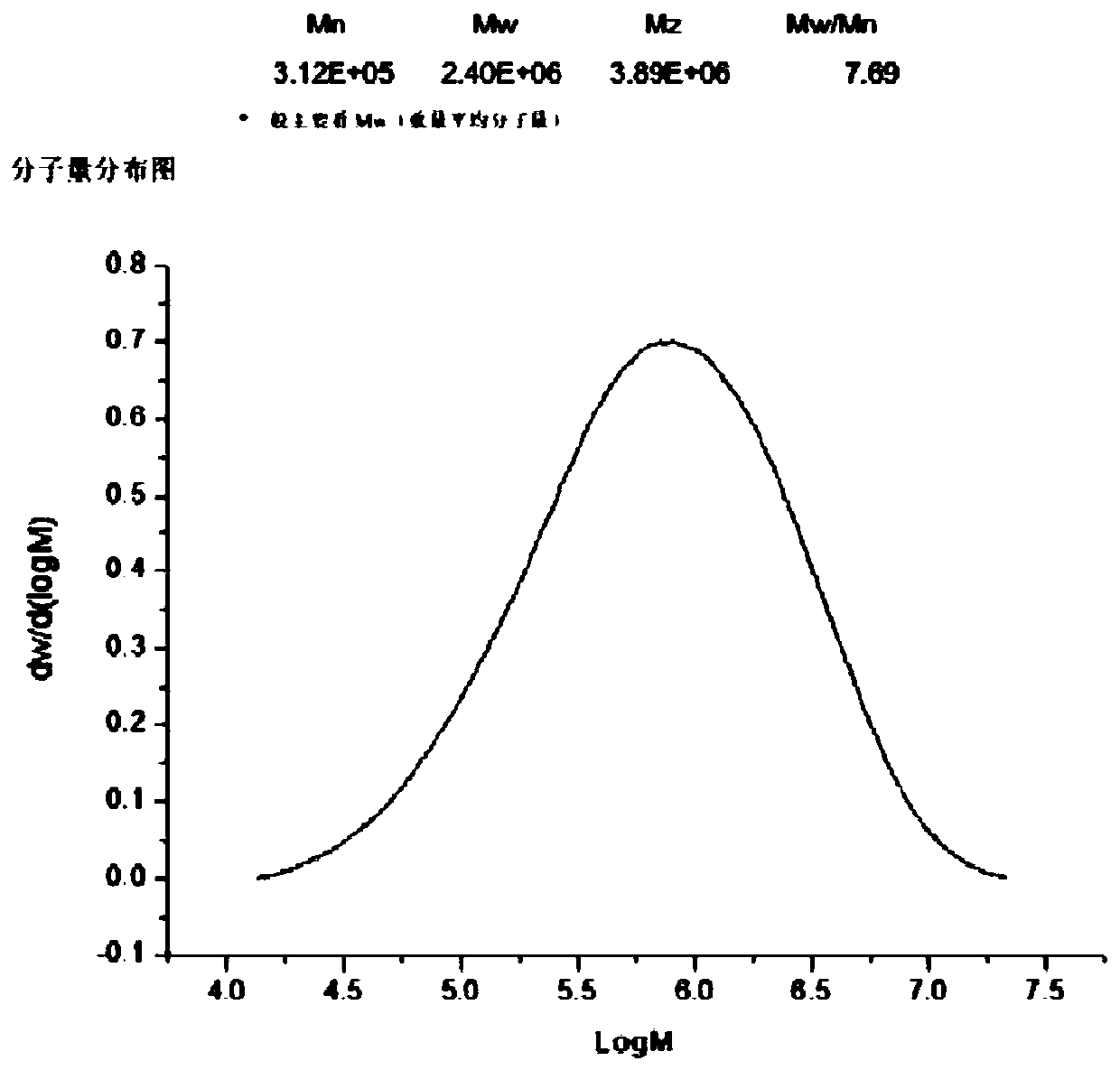

Plant soft capsule and preparation method and application thereof

PendingCN110075081ASimple ingredientsReduce manufacturing costTeaPharmaceutical non-active ingredientsCarrageenanActive component

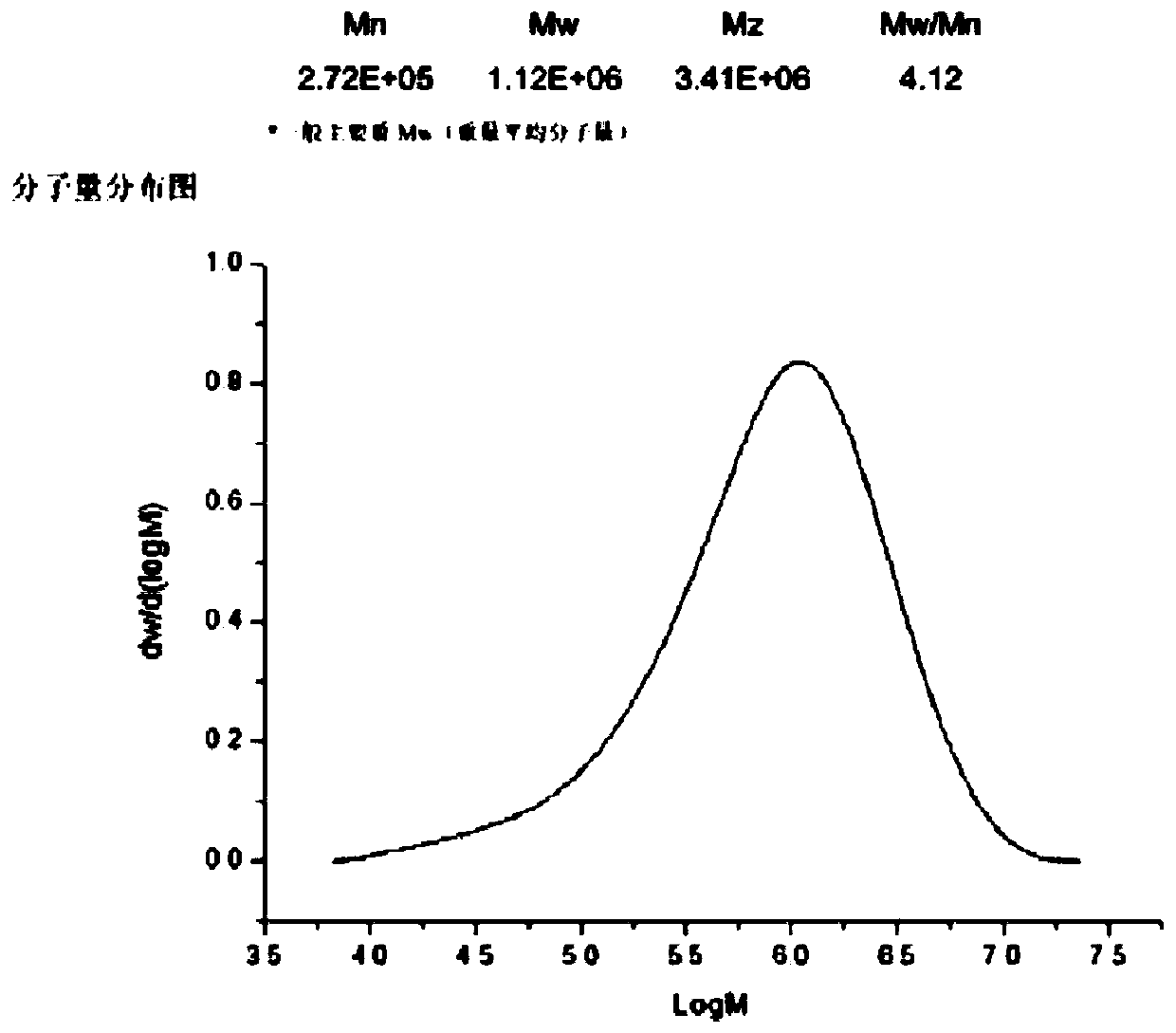

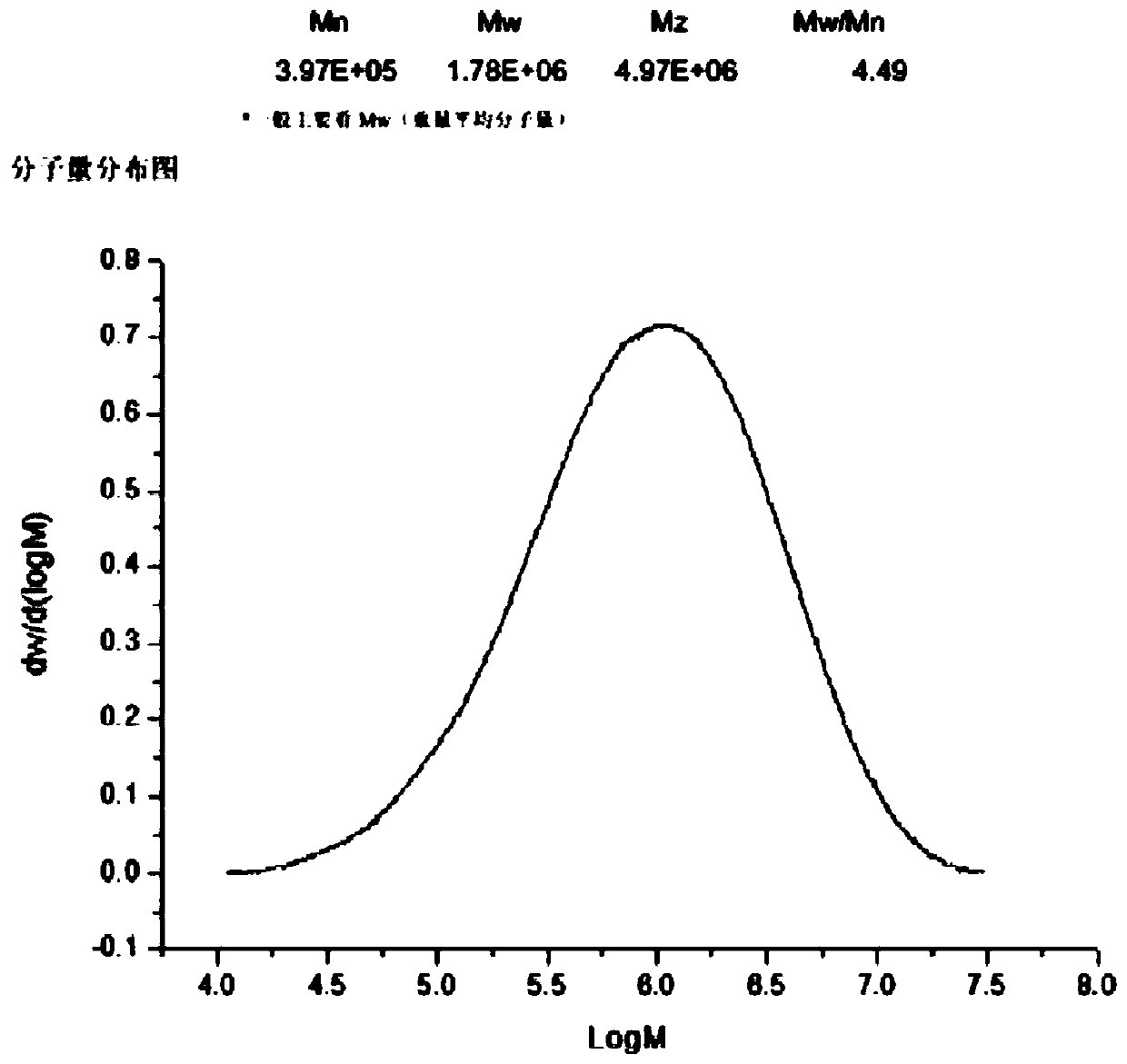

The invention belongs to the technical field of soft capsules, and particularly relates to a plant soft capsule and a preparation method and application thereof. By controlling weight-average molecular weight of carrageenan to be 1.2*10<6>-2.0*10<6>, the plant soft capsule with excellent performance is prepared with starch, a plasticizer and water; compared with a plant soft capsule in the prior art, the plant soft capsule provided by the invention is lower in production cost, and the product quality reaches the requirements of a gelatin soft capsule; under the premise of high production efficiency, low oil leaking rate is realized and fracture time reaches the standard of United States Pharmacopeia (USP). The plant soft capsule prepared by the preparation method provided by the inventioncan be filled with active components as contents, and is used for preparing multiple drugs, functional foods or dietary nutrition supplements.

Owner:JIANGSU ALAND NOURISHMENT

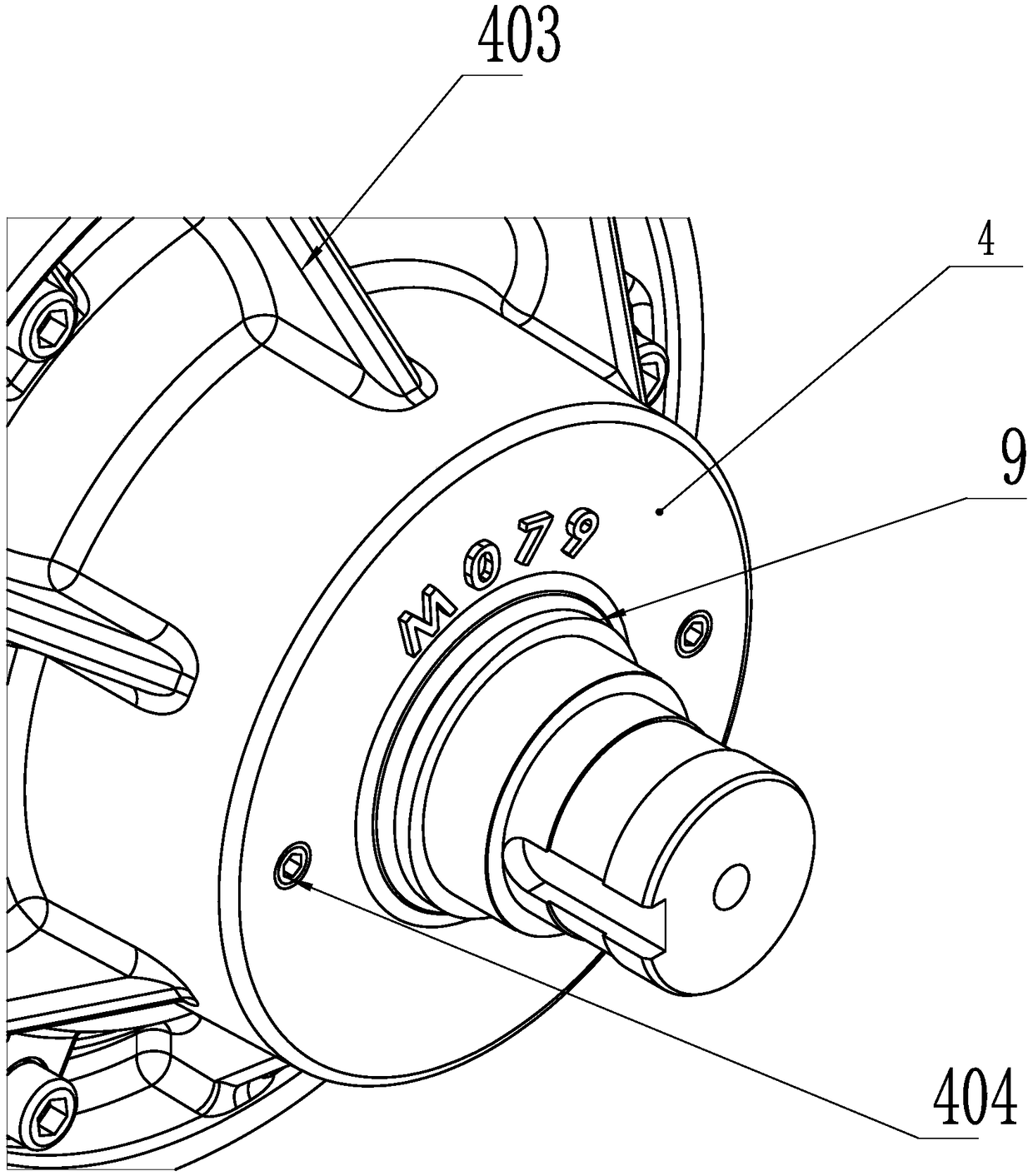

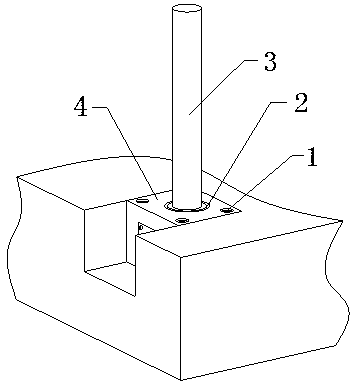

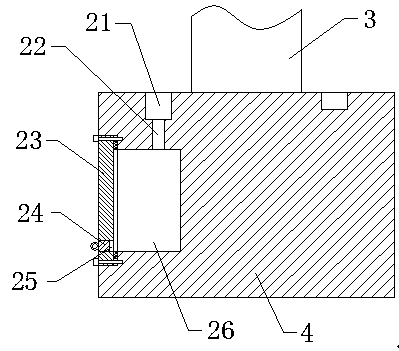

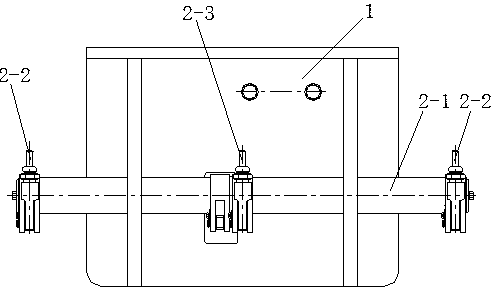

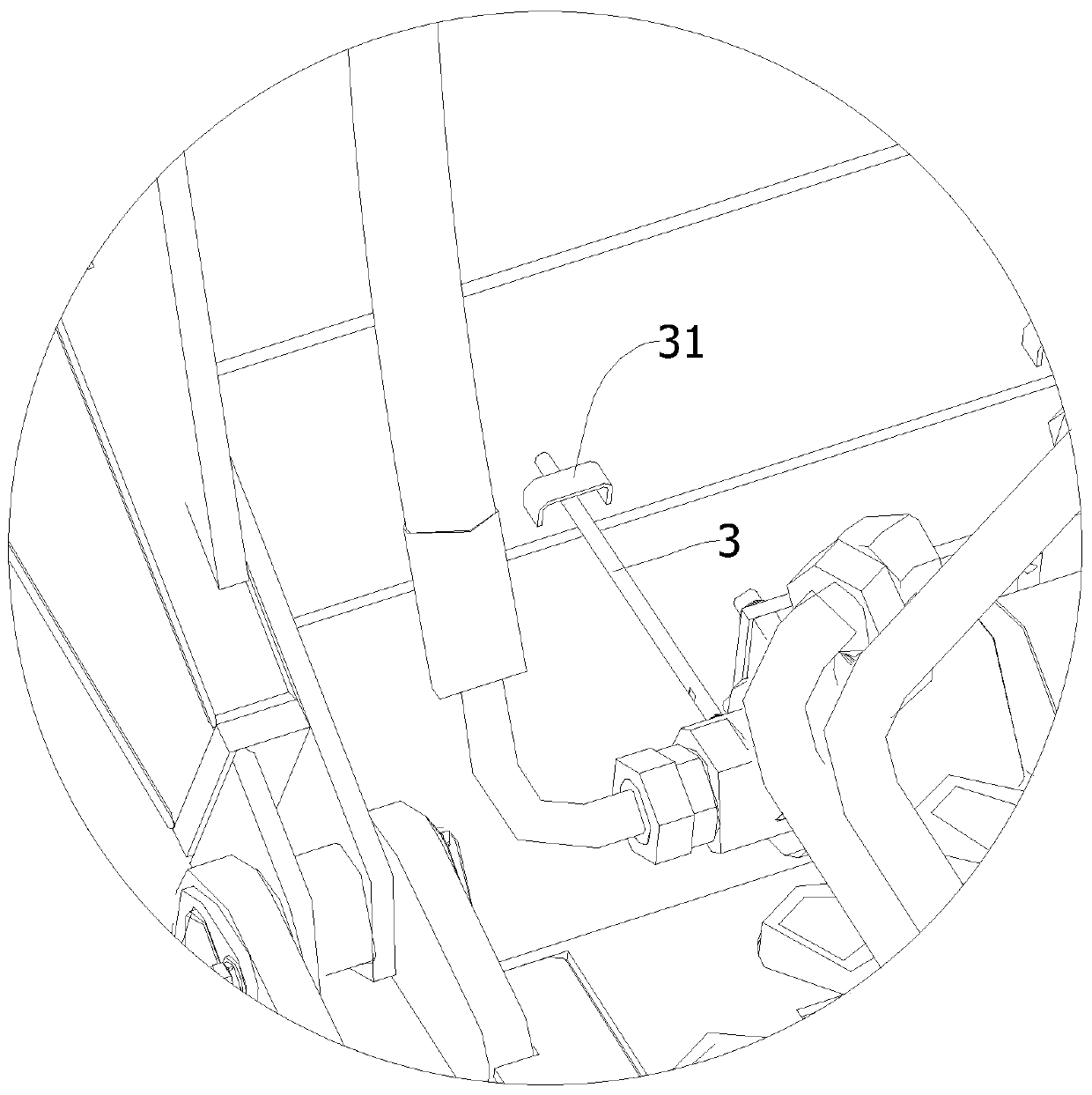

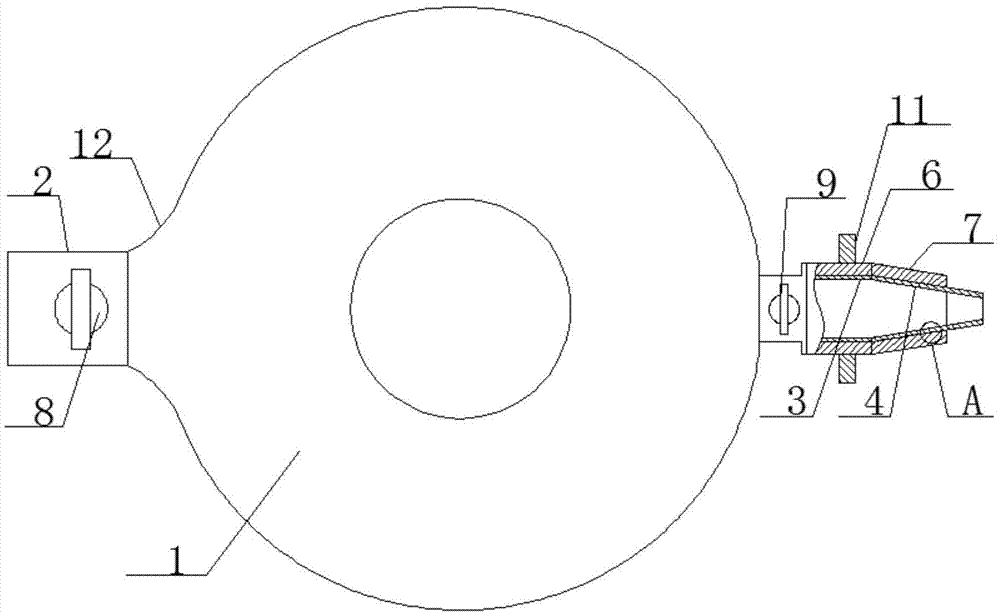

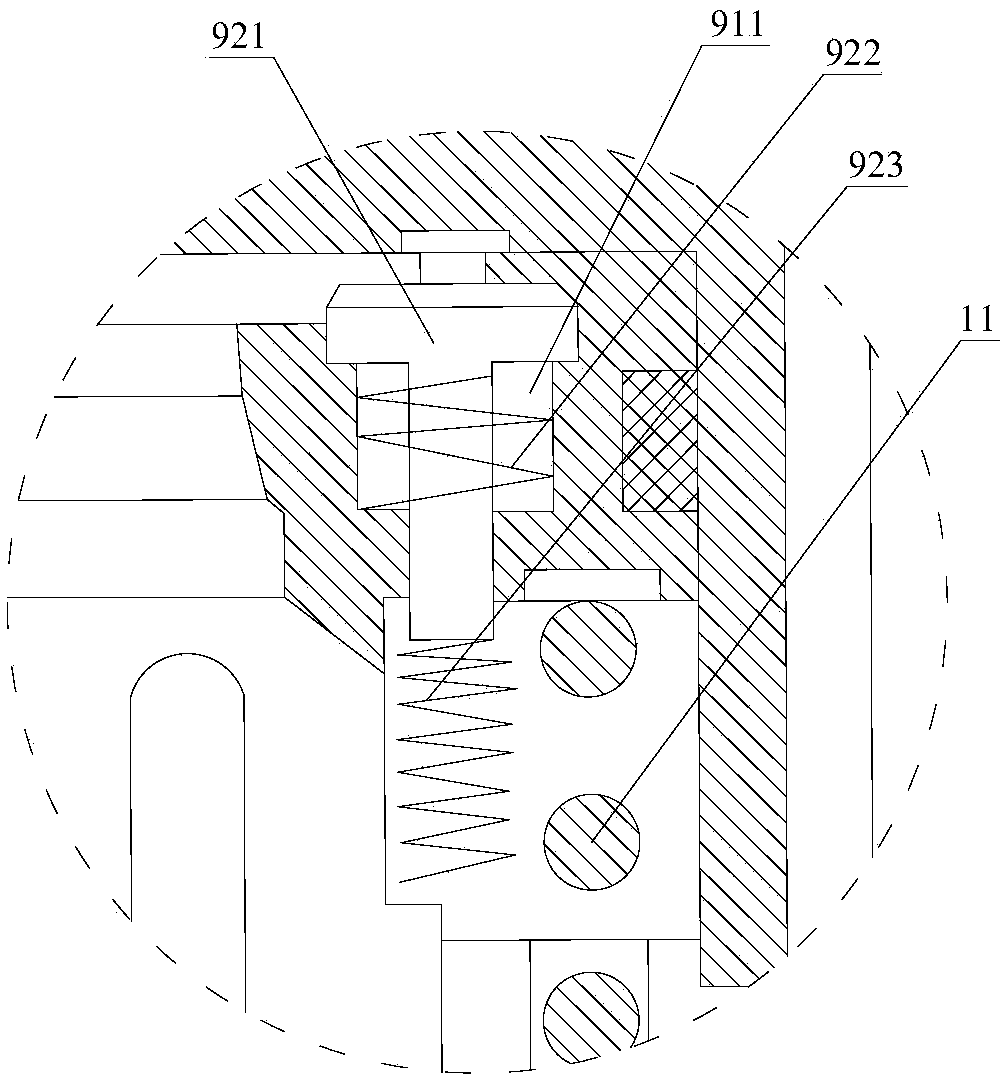

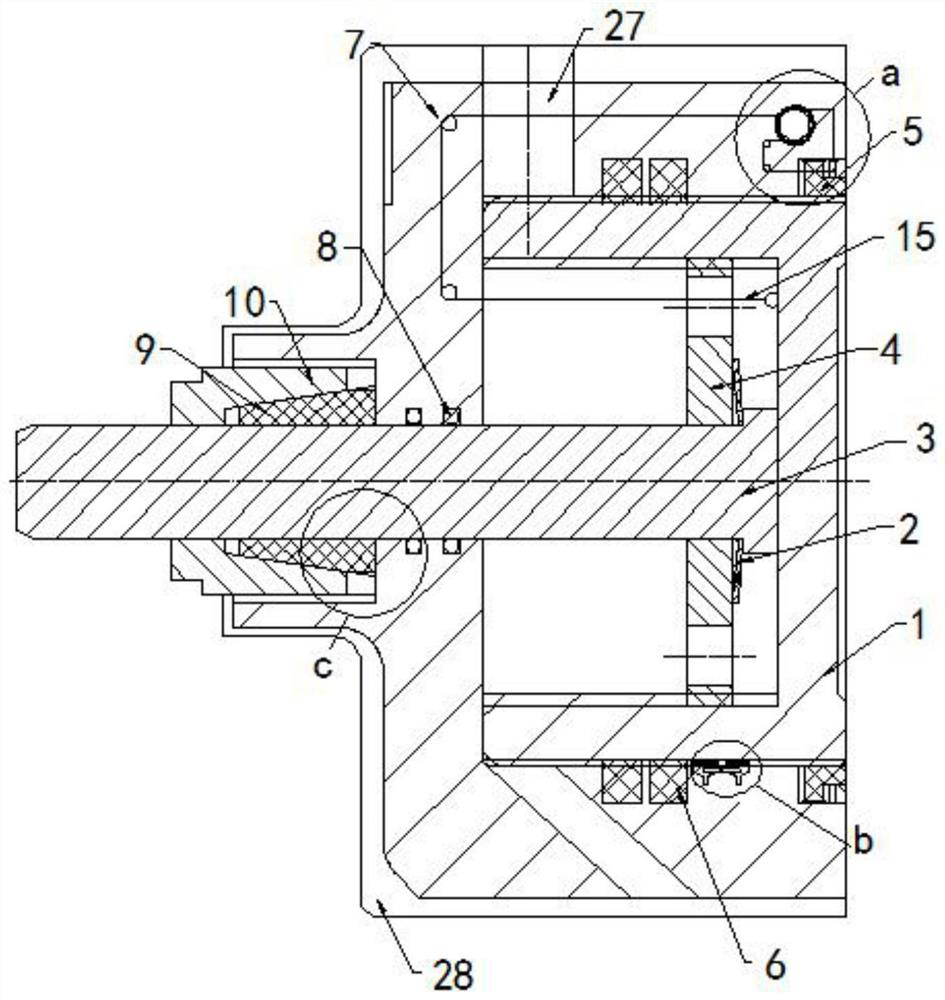

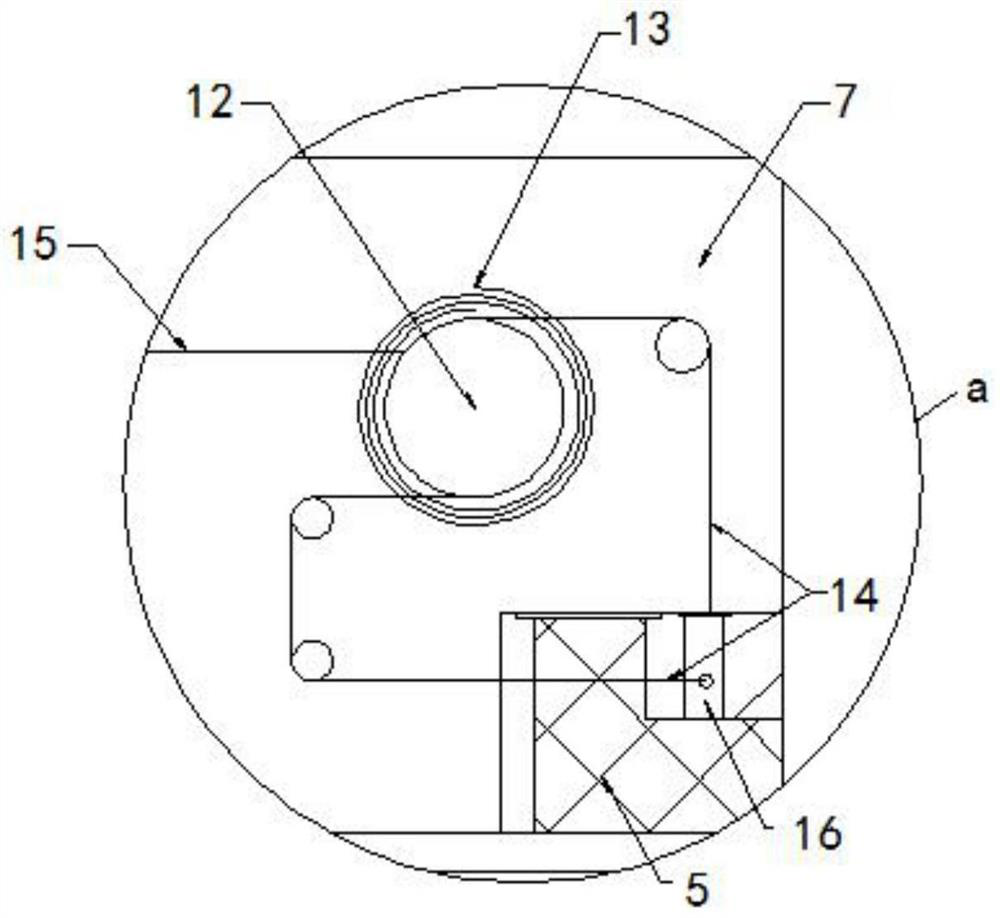

Supporting wheel and excavator with same

InactiveCN102774439AReduce the probability of oil spillsSimple structureEndless track vehiclesFriction weldingControl theory

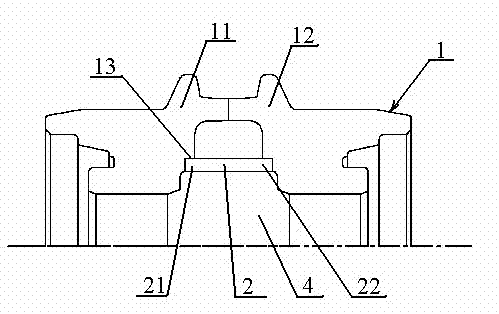

The invention provides a supporting wheel which comprises a wheel body (1) and a rotating shaft which are connected with each other, wherein the wheel body (1) comprises a left wheel body (11) and a right wheel body (12); the wheel body further comprises a sealing circular pipe (2); the left wheel body (11) and the right wheel body (12) are welded through friction welding; an annular working oil chamber is formed between the left wheel body (11) and the right wheel body (12); the sealing circular pipe (2) is arranged in the working oil chamber (3); the sealing circular pipe (2) is coaxial with the wheel body (1); one end of the sealing circular pipe (2) is seamlessly connected with the left wheel body (11); the other end of the sealing circular pipe (2) is hermetically connected with the right wheel body (12). An excavator comprises a chassis provided with the supporting wheel. The supporting wheel and the excavator have the advantages of simple structure, convenience, higher efficiency and economic efficiency and improvement in connecting strength of the wheel body, the harmful area is effectively isolated, and the standard cleanliness of lubricating oil is ensured.

Owner:CHANGSHU HUAWEI TRACK

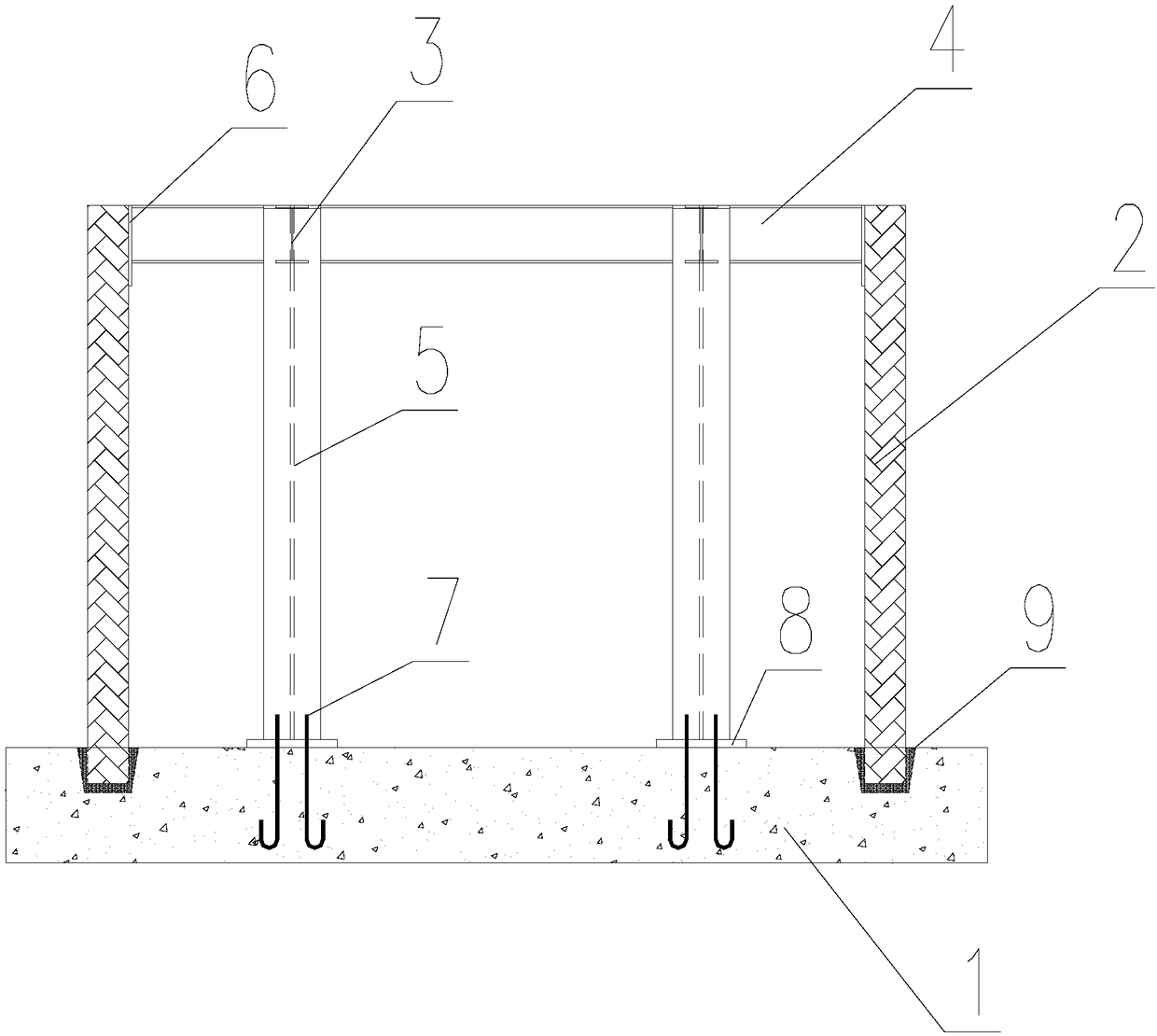

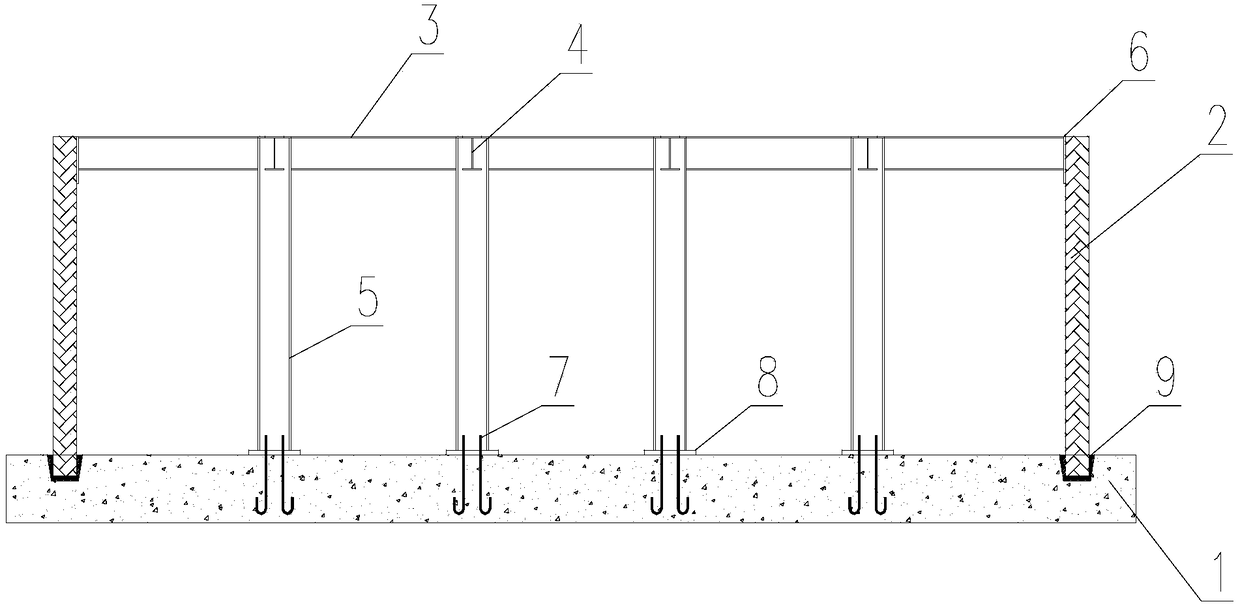

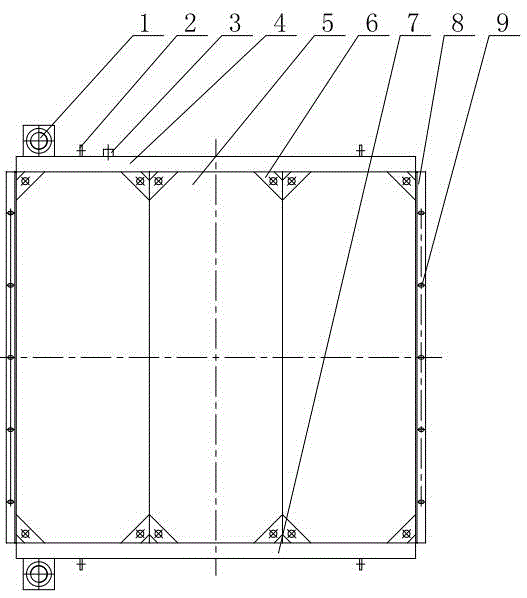

Overall-prefabricated main transformer foundation and oil pit structure used for indoor substation

PendingCN108316337AShorten the construction periodReduce the probability of oil spillsProtective foundationTransformerPre embedding

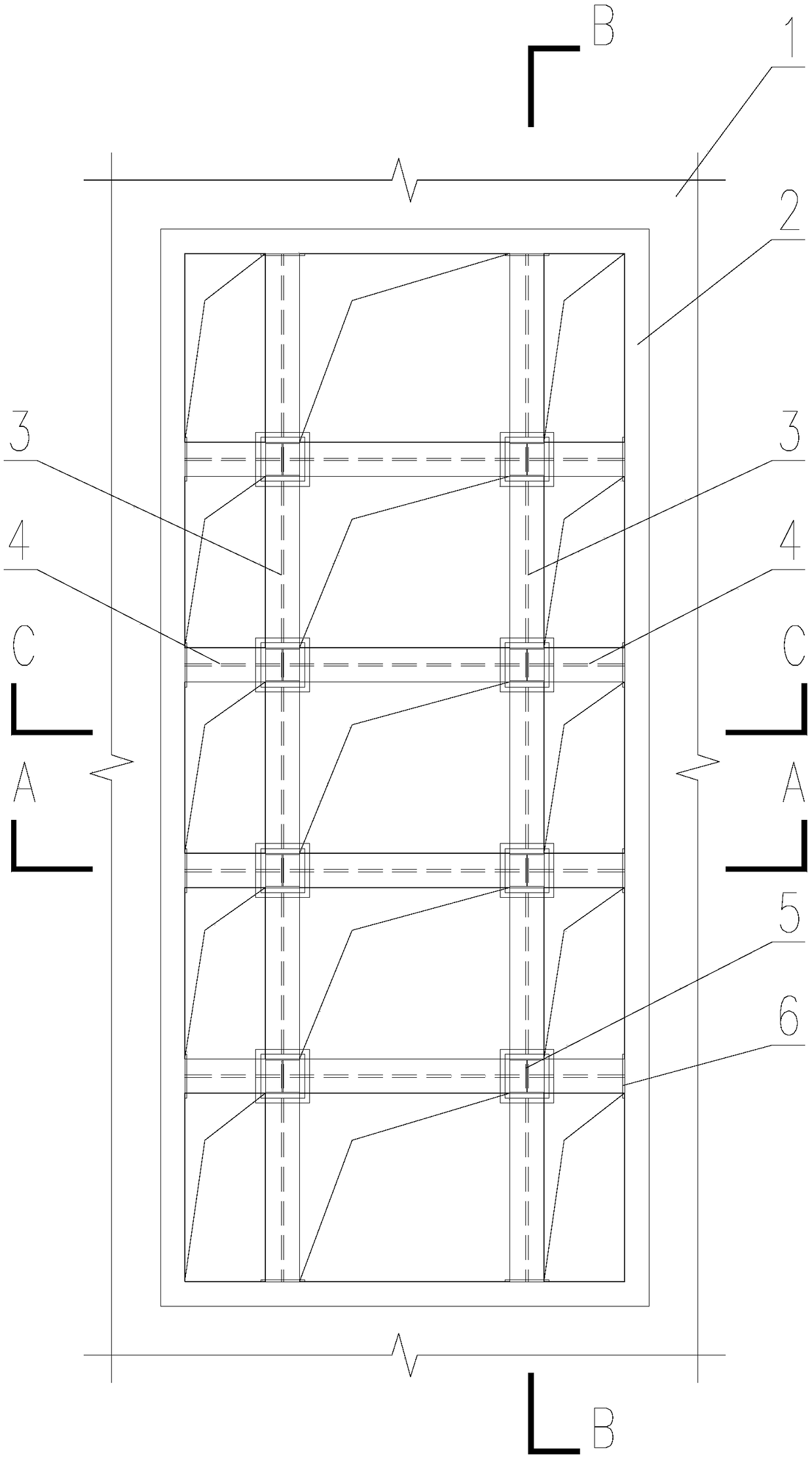

The invention relates to an overall-prefabricated main transformer foundation and oil pit structure used for an indoor substation. The overall-prefabricated main transformer foundation and oil pit structure comprises a cast building raft foundation. Matrix-arranged foundation bolts are pre-embedded in the position, where a main transformer is arranged, on the building raft foundation; foundation piles are arranged on the foundation bolts, and the tops of the foundation piles are connected with crossbeams; the column tops of the foundation piles are provided with rail beams in the length direction of the building raft foundation, and the rail beams and the crossbeams are perpendicularly arranged; oil pit wall clamping grooves are pre-formed in the position, around the main transformer, of the building raft foundation; and oil pit walls are placed in the clamping grooves, and the tops of the oil pit walls are connected with the crossbeams and the rail beams. An overall splicing technology of the main transformer foundation is adopted, and the defects of cast-in-place construction of a traditional main transformer foundation are overcome; the construction period of a main transformerfoundation item project can be shortened greatly, the construction efficiency is improved, and a frame system is good in structural stability and high in bearing capacity; and the oil pit oil-leakageprobability is decreased greatly by adopting a novel prefabricated wallboard splicing technology.

Owner:SHANGHAI ELECTRIC POWER DESIGN INST

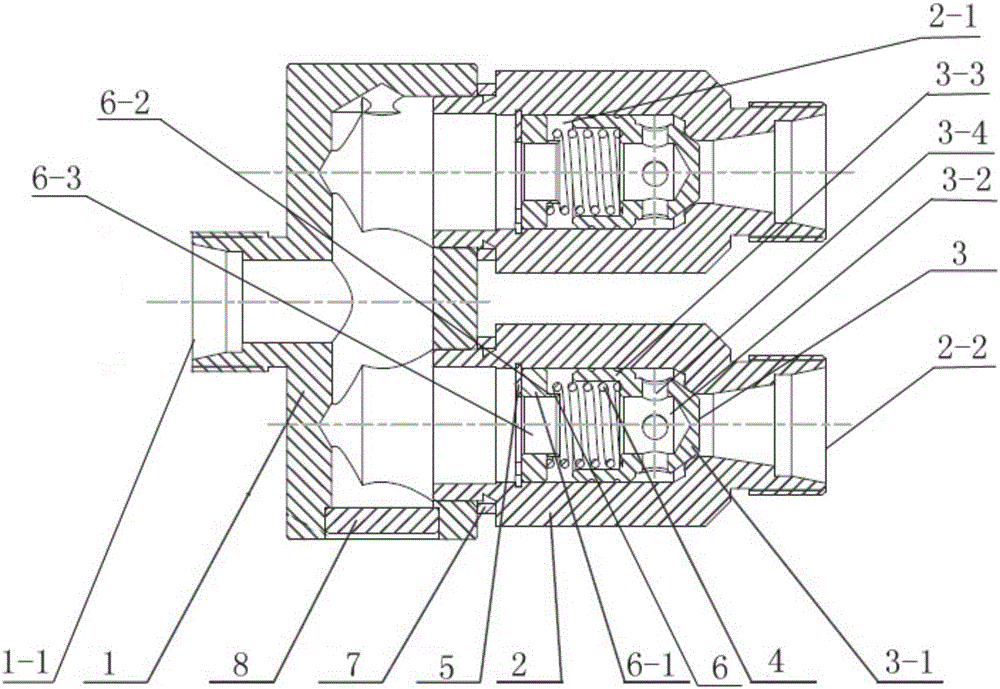

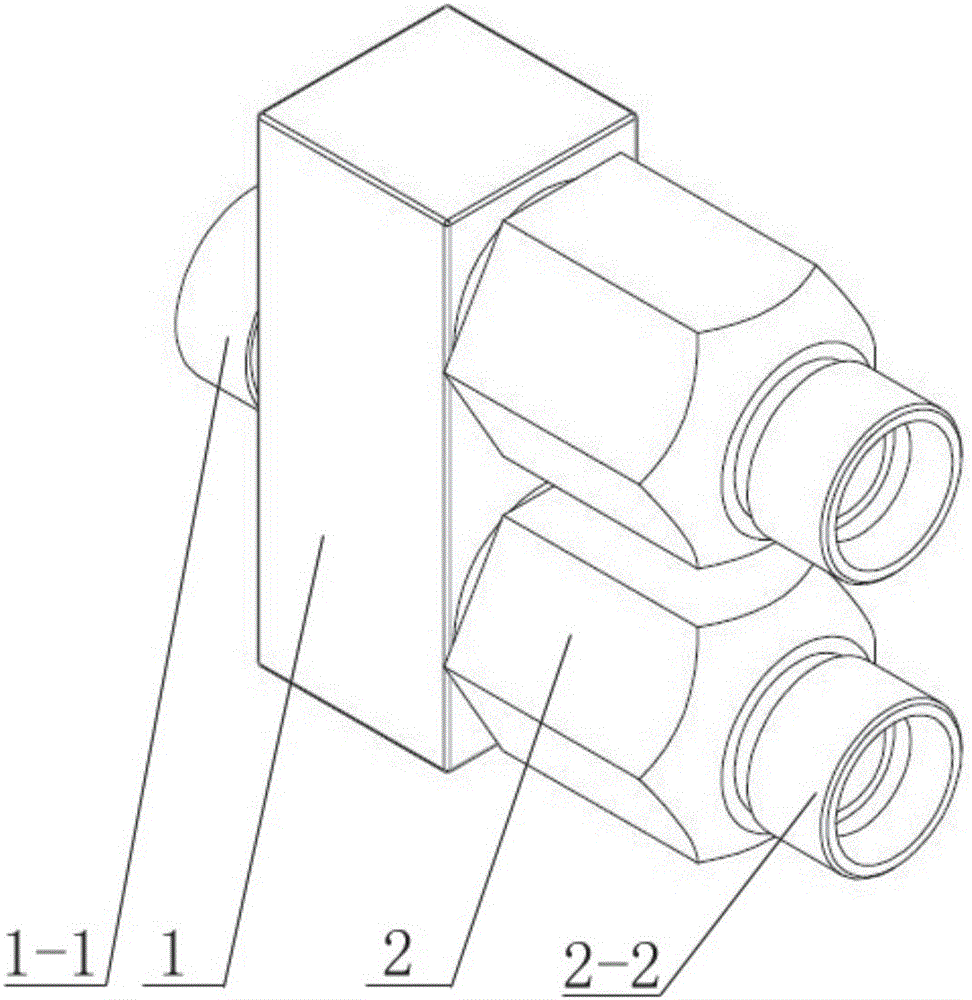

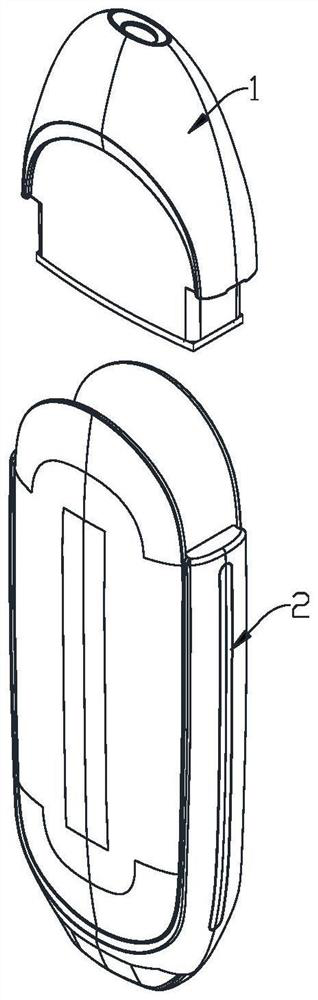

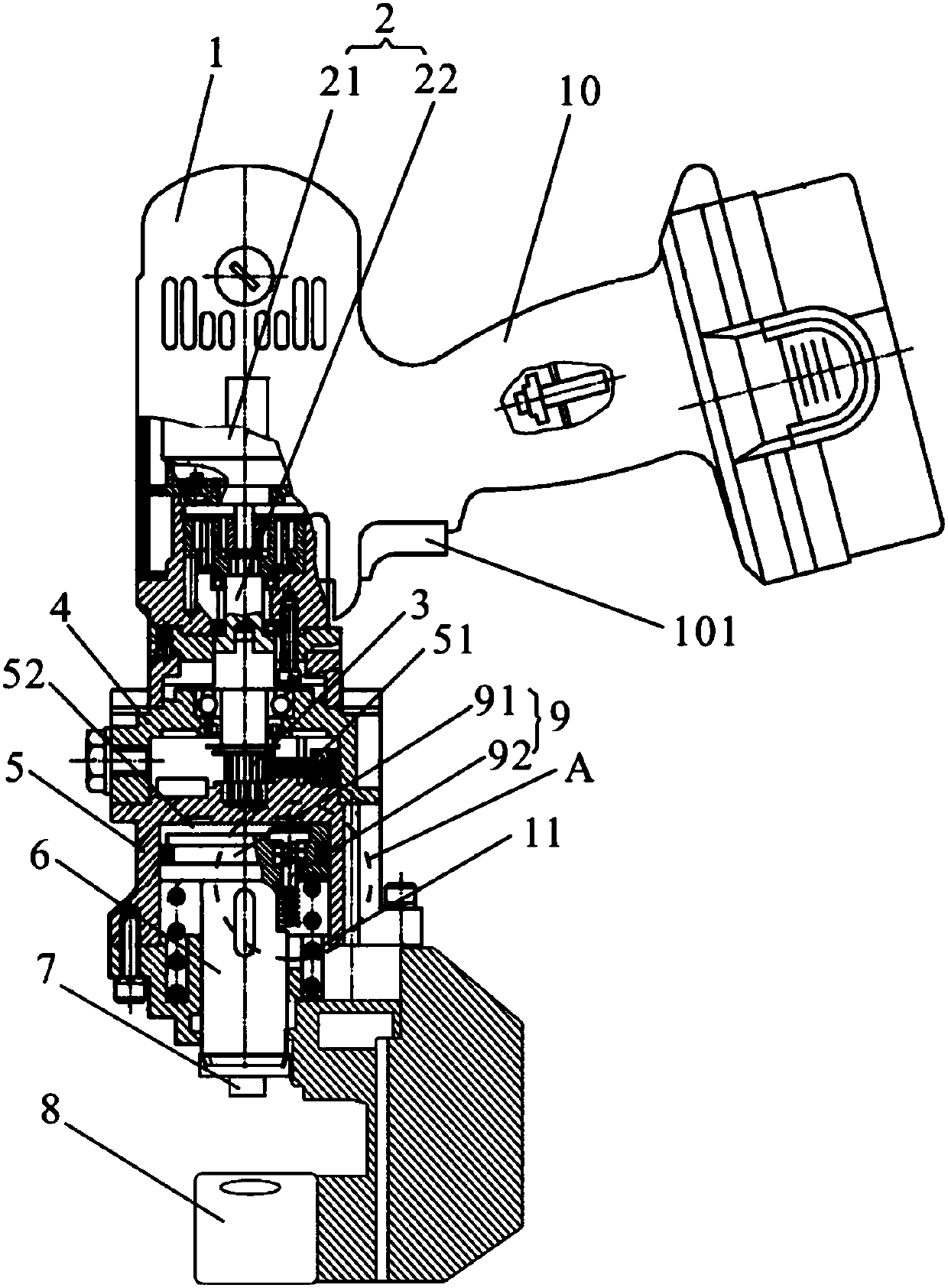

Hydraulic two-way check valve for steering system of new-energy bus

InactiveCN105730505ACompact structureImprove reliabilityCheck valvesMultiple way valvesNew energyEngineering

The invention discloses a hydraulic two-way check valve for a steering system of a new-energy bus. The hydraulic two-way check valve comprises a three-way body (1) and two valve bodies (2) arranged at two inlets of the three-way body (1), wherein the two valve bodies (2) are arranged in parallel; an outlet of the three-way body (1) is an oil outlet (1-1); each valve body (2) comprises a valve cavity (2-1) and an oil inlet (2-2), one end of the valve cavity (2-1) is communicated with the corresponding oil inlet (2-2) while the other end of the valve cavity (2-1) is communicated with three-way body (1), and a valve element component for controlling connection or disconnection between the valve cavities (2-1) and the corresponding oil inlets (2-2) is arranged in the valve cavity (2-1) and comprises a valve element (3), a spring (4) and a retaining ring (5), which are sequentially arranged in the oil inlet direction; the retaining rings (5) are fixed on inner walls of the corresponding valve cavities (2-1); one end of each spring (4) is fixed to the corresponding valve element (3), and the other ends of the springs (4) are fixed to the corresponding retaining rings (5). The hydraulic two-way check valve, provided by the invention, for the steering system of the new-energy bus, has the advantages of compact structure, small assembly space and good safety.

Owner:HIGER

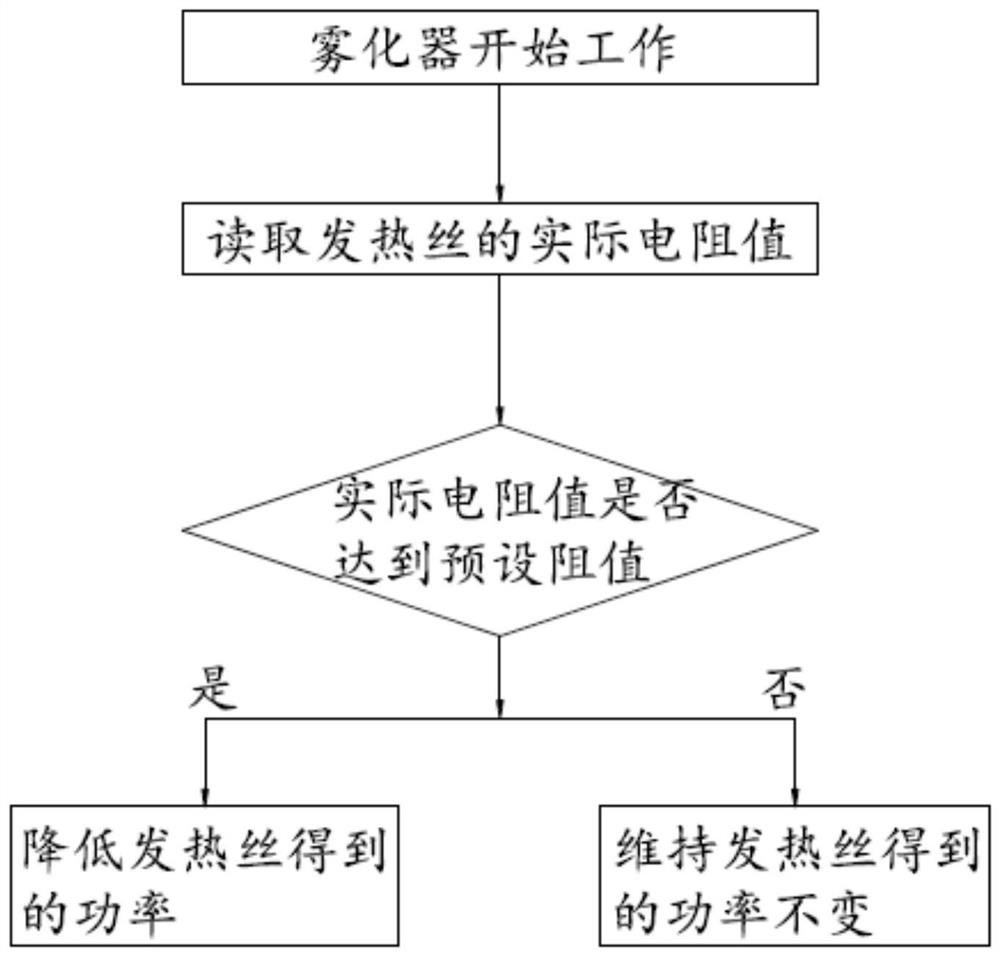

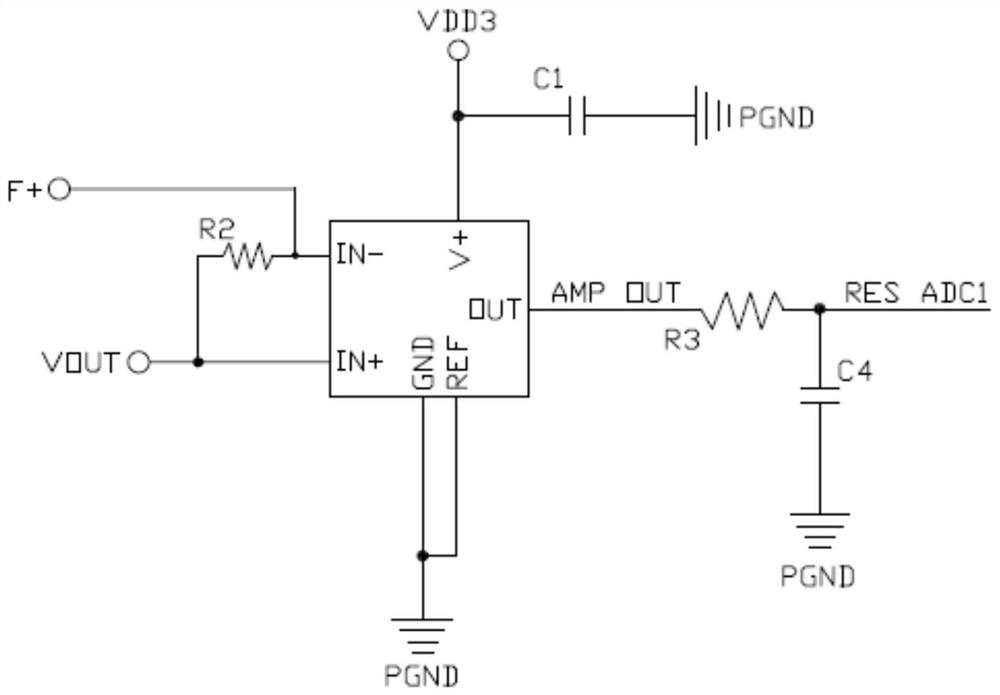

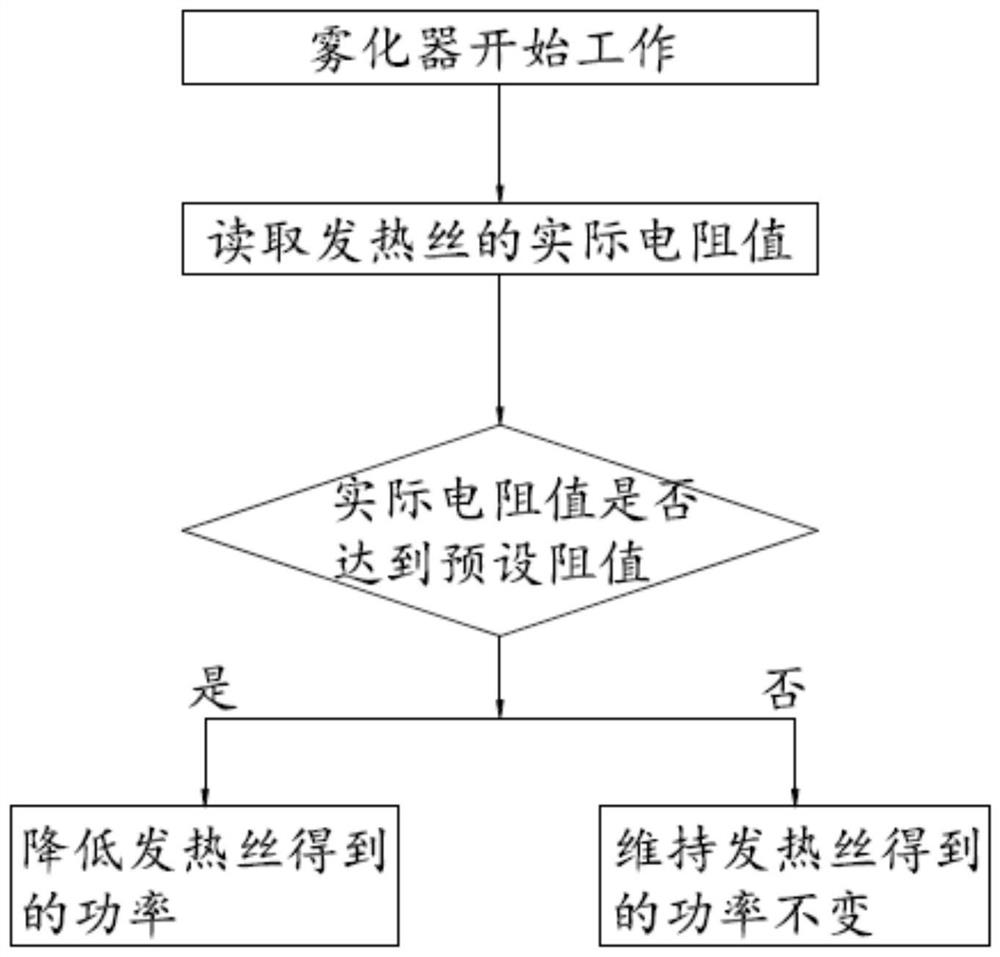

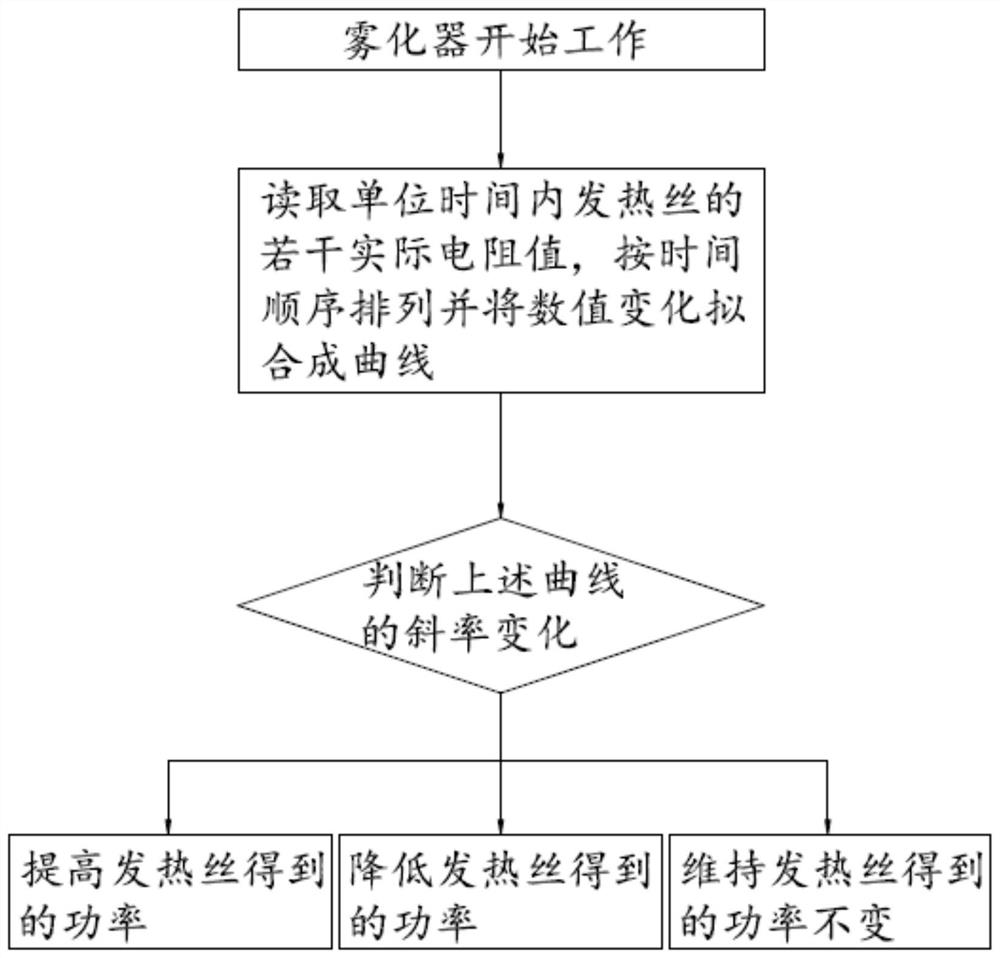

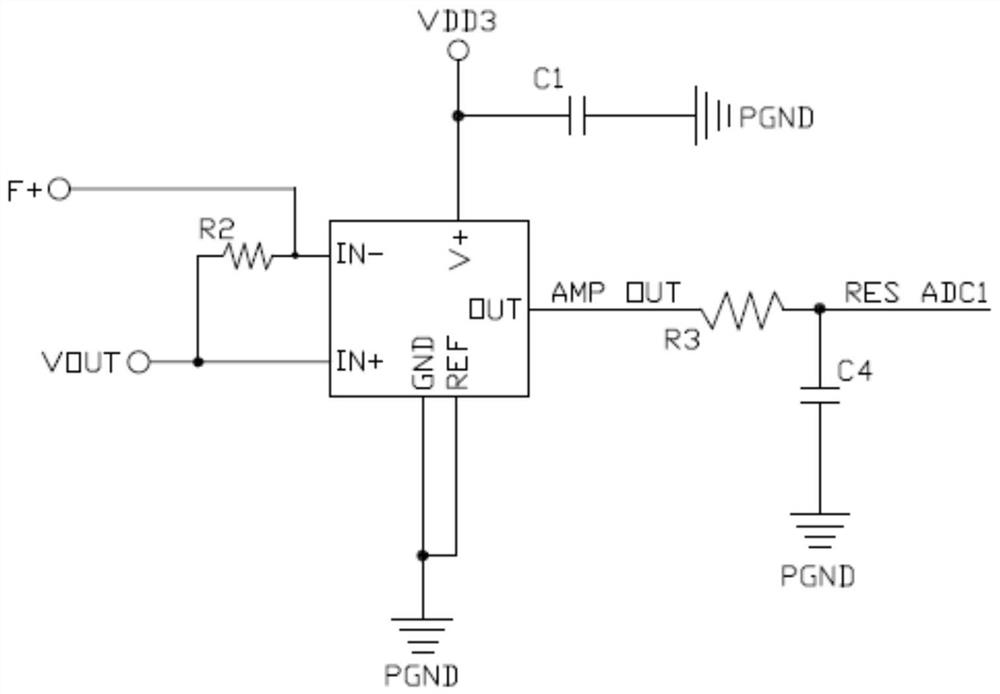

Heating control method of electronic cigarette and electronic cigarette

PendingCN112535325AGet accurate resistanceAccurate adjustmentTobaccoProcess engineeringElectronic cigarette

The invention relates to the field of electronic cigarettes, and particularly discloses a heating control method of an electronic cigarette and the electronic cigarette. A heating wire with a temperature coefficient is selected to manufacture an atomizer. Before the electronic cigarette is started, various parameters of the heating wire are obtained, and the parameters comprise a normal-temperature resistance value of the heating wire converted through a formula. After the electronic cigarette is started, the actual resistance value of the heating wire is obtained, the actual temperature of the heating wire is calculated based on the actual resistance value of the heating wire, if the actual temperature is higher than the set temperature, the actual power of the heating wire is reduced, and otherwise, the actual power of the heating wire is not reduced. Compared with a method of directly detecting the temperature, a new temperature sensor does not need to be introduced, the structure of the electronic cigarette is simplified, the resistance can be converted into the temperature, resistance detection equipment only needs one circuit board, even the circuit can be integrated into anexisting control circuit board, and miniaturization of the electronic cigarette is achieved.

Owner:SHENZHEN JIYOU TECH CO LTD

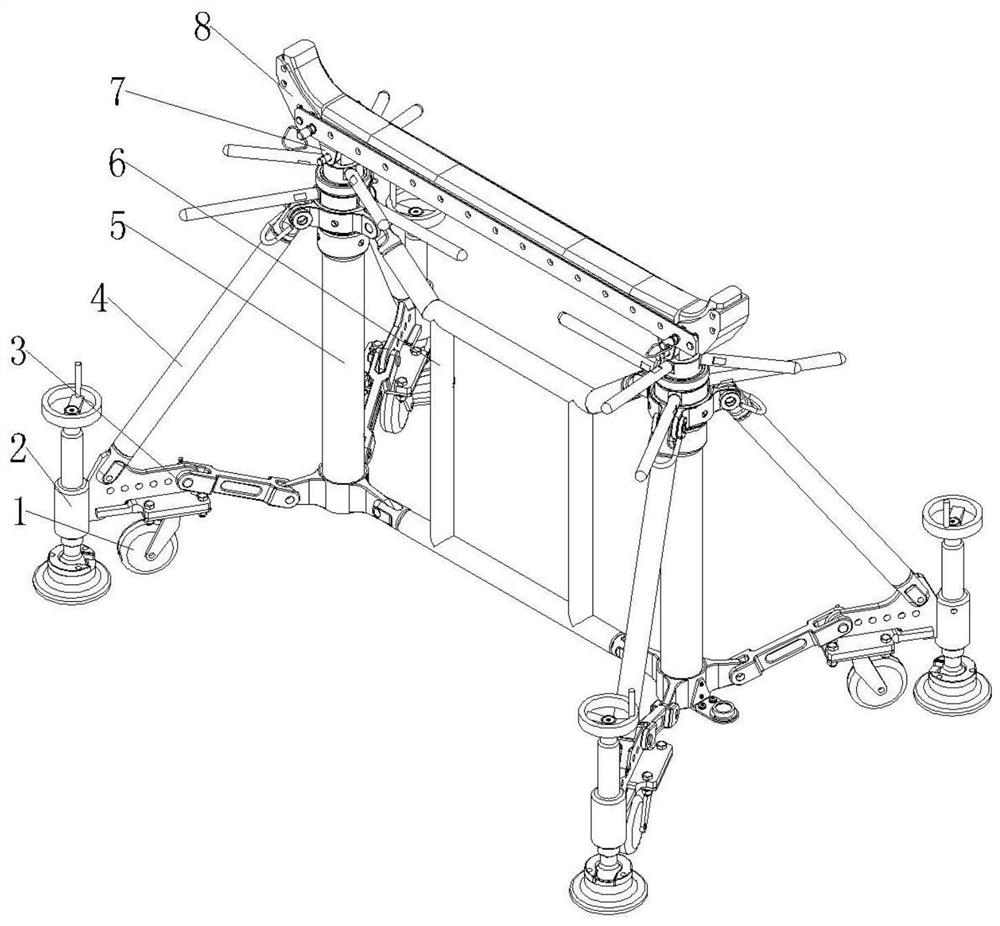

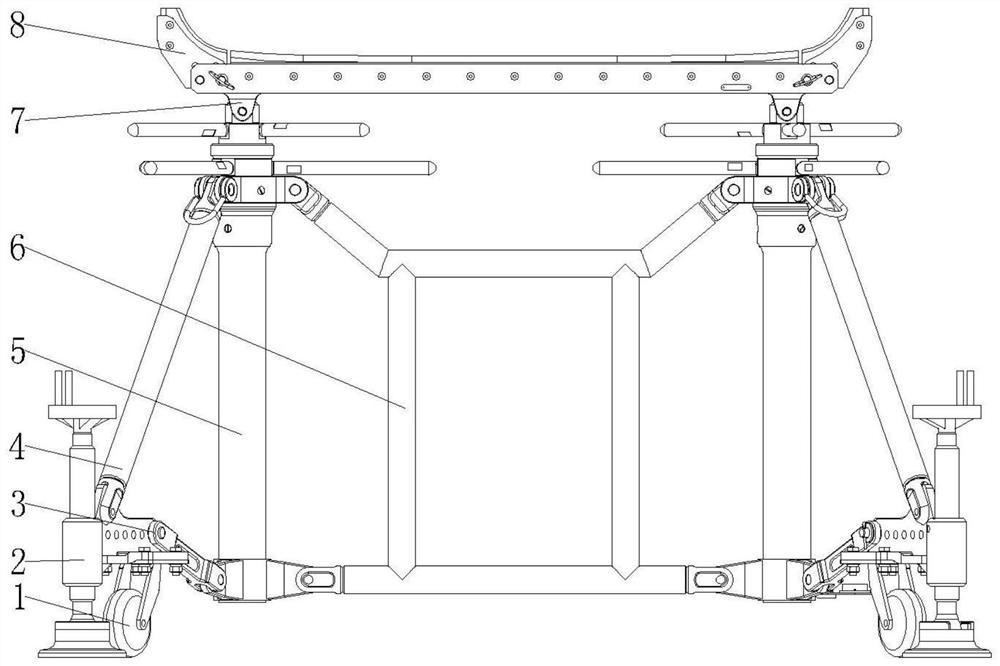

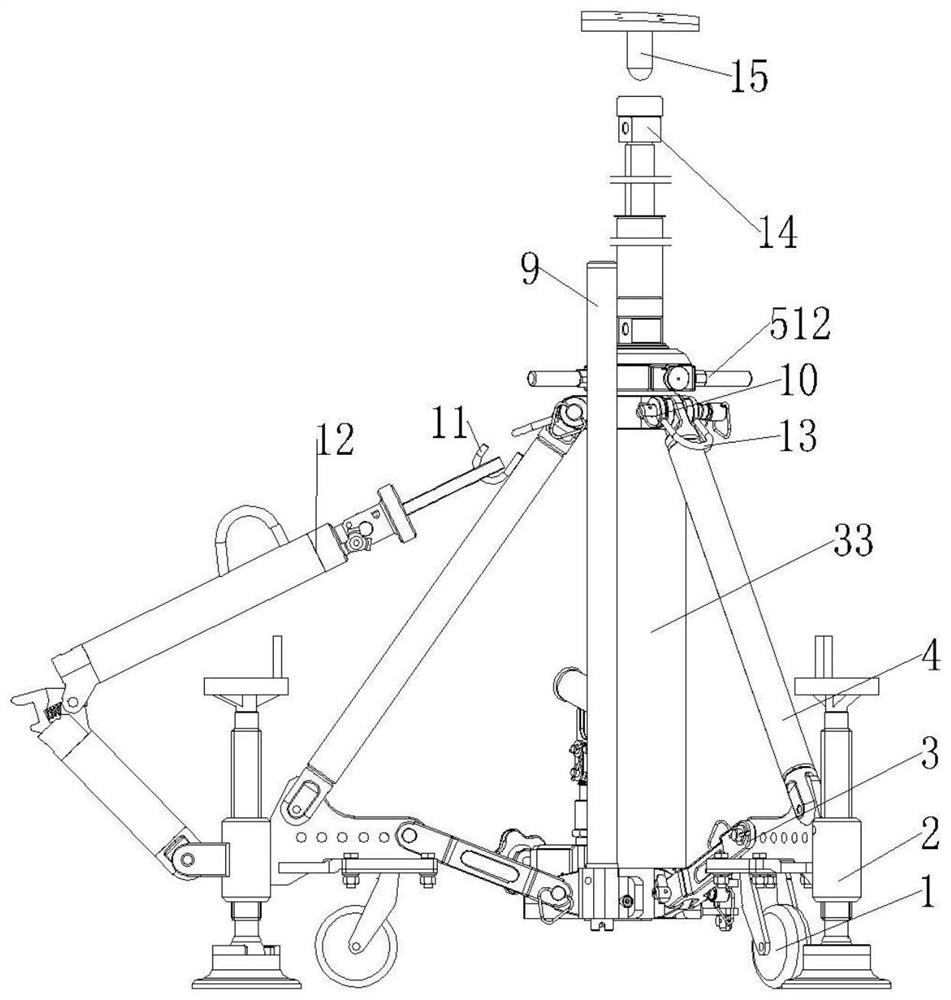

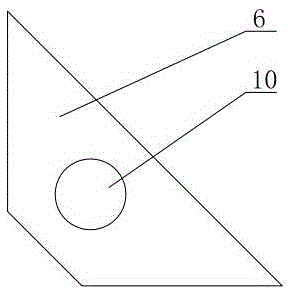

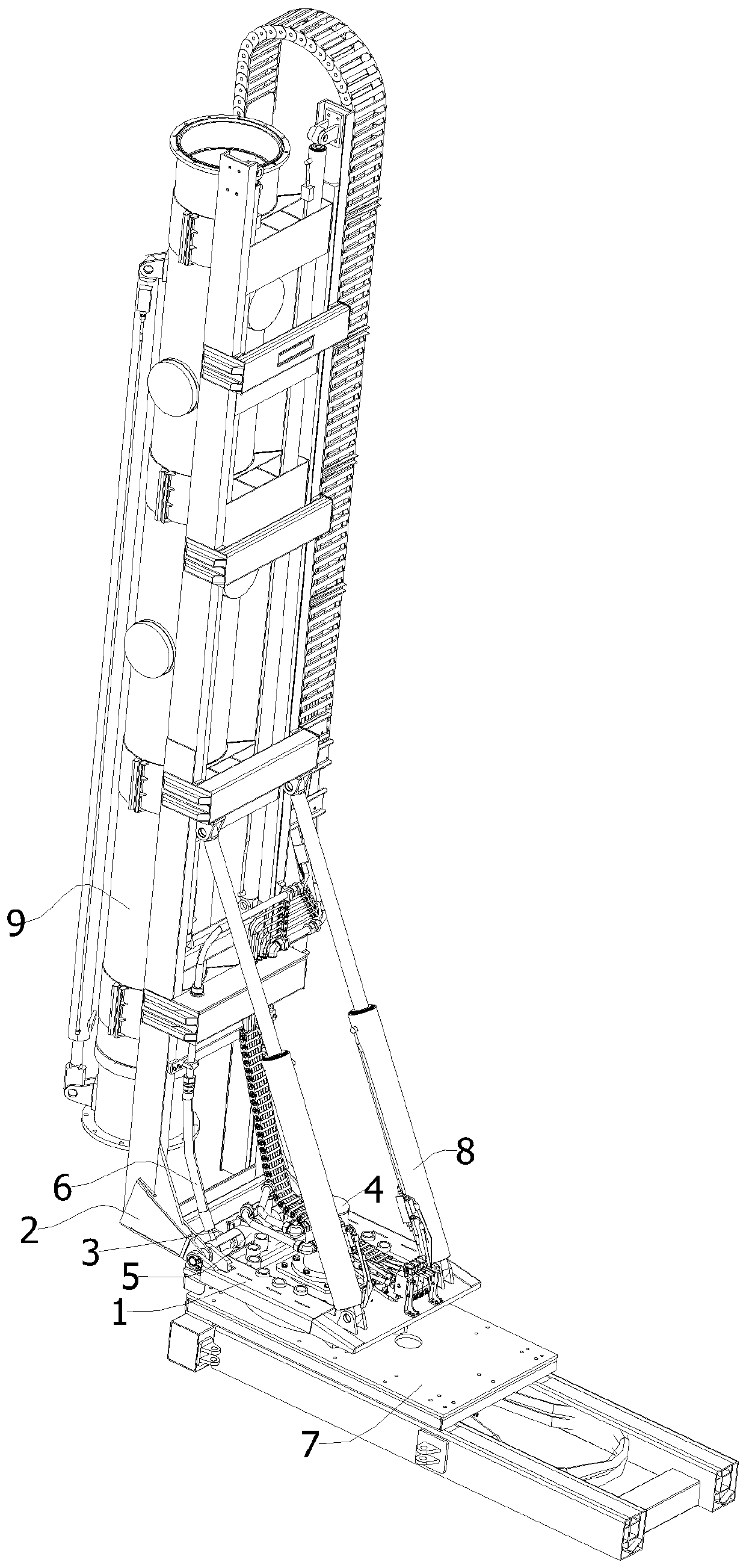

Supporting equipment suite for airplane

PendingCN112875572ASimple structureIncrease work slackLifting framesAircraft maintainanceJackscrewMachine

The invention discloses a supporting equipment suite for an airplane, and relates to the technical field of equipment maintenance. The supporting equipment suite comprises a base, the base is movably connected with one ends of a plurality of pull rods, and the other ends of the plurality of pull rods are movably connected with supporting legs. According to the supporting equipment suite for the airplane, the load of a tripod composed of mechanical jacking assemblies, the base, pull rods and supporting frames is calculated according to the maximum load, and therefore it is guaranteed that the requirement for the structural strength meets the standard during exchange; and when two structures are formed during specific exchange, only a first supporting plate assembly, a second supporting plate assembly or a third supporting plate assembly of a bracket, connecting frames and inclined supporting columns need to be disassembled, then the needed structure is formed through reassembly, and therefore the problems that due to the fact that a jack structure and a bracket structure belong to jacking and supporting type equipment at present, do not interfere with each other and are independently developed and produced, a jack and a machine body bracket component do not have interchangeability, and then certain troubles are brought to workers.

Owner:上海航空机械有限公司

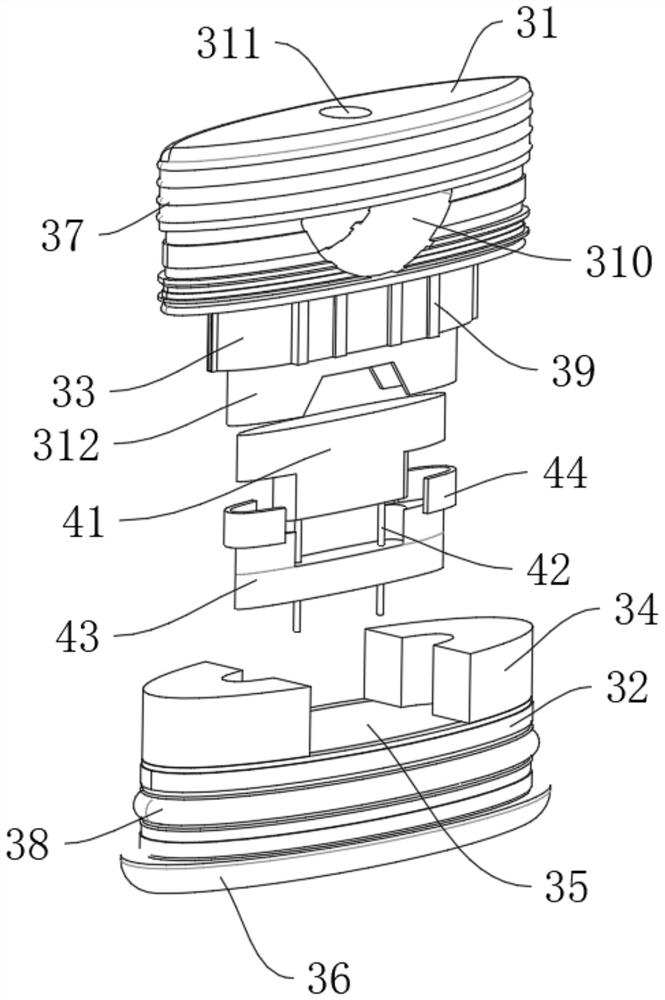

A bolt-free double-flange vertical vibration motor

ActiveCN106208509BEasy to installImprove the protective effectMechanical energy handlingSupports/enclosures/casingsVertical vibrationEngineering

The invention discloses a double-flange vertical vibration motor free from bolt fixing and relates to the vibration motor. The double-flange vertical vibration motor comprises a motor base, end covers which are arranged at two sides of the motor base and are equipped with built-in bearing chambers, a stator arranged in the motor base, a rotor which matches the stator and is equipped with a rotation shaft, bearings arranged in the bearing chambers of the end covers, and eccentric blocks located on the rotation shaft at two sides of the motor base. The rotor is rotationally connected with the end covers through the bearings externally sleeved on the rotation shaft. The motor is characterized in that one end of each end cover is a motor base connection end matching the motor base. Each motor base connection end projects towards a periphery to form a connection flange. Each connection flange is used for being connected and fixed with an external device. The peripheral surface of each connection flange is a conical surface. One end of each connection flange is a connection end matching the motor base. The diameter of each connection end of the connection flange is greater than that of the other end, so that the motor is compressed and fixed by the external device with an inner conical surface matching the conical surface. According to the technical scheme of the double-flange vertical vibration motor, the processing and fixing are convenient, the location accuracy is high, the product life can be prolonged, the protection level can be improved, and the maintenance is convenient.

Owner:WOLONG ELECTRIC GRP CO LTD +1

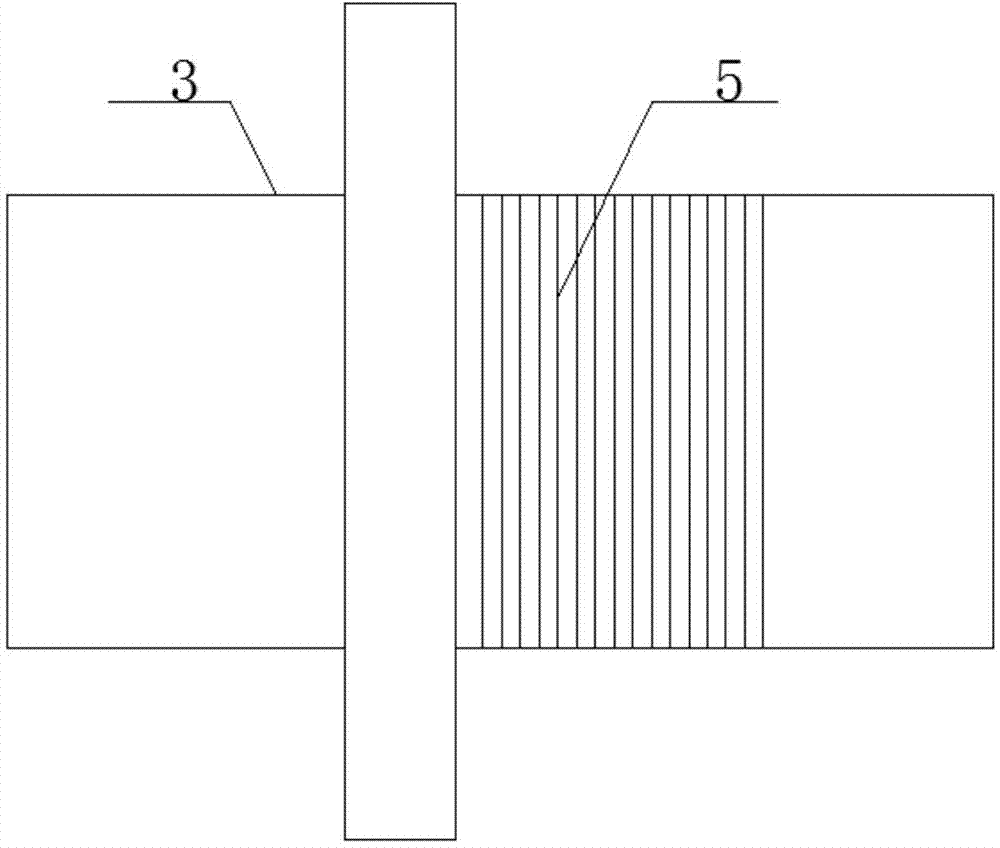

Mold guide structure

InactiveCN110696230ASolve the problem of easily flowing and polluting the moldAvoid runningStructural engineeringMechanical engineering

The invention provides a mold guiding structure. The structure involves an annular groove, an oil leakage port, a cover plate, a rubber plug, an oil outlet and a groove, wherein the annular groove isformed in the upper end face of a base and is arranged on the outer side of a guide column, the groove is formed in the left end face of the base, the cover plate is installed on the inner left end face of the groove through an inner hexagonal bolt, the oil leakage port is formed in the lower end face inside the annular groove and communicates with the groove, the oil outlet is formed in the lowerside of the left end face of the cover plate, and the rubber plug is installed in the oil outlet. According to the structure, oil flowing down from the guide column is collected through the annular groove, so that the purpose of collecting the residual oil is achieved, and the influence of residual oil on the surface of a mold is reduced. The structure has a residual oil collecting function, is convenient to install and good in stability.

Owner:方金兰

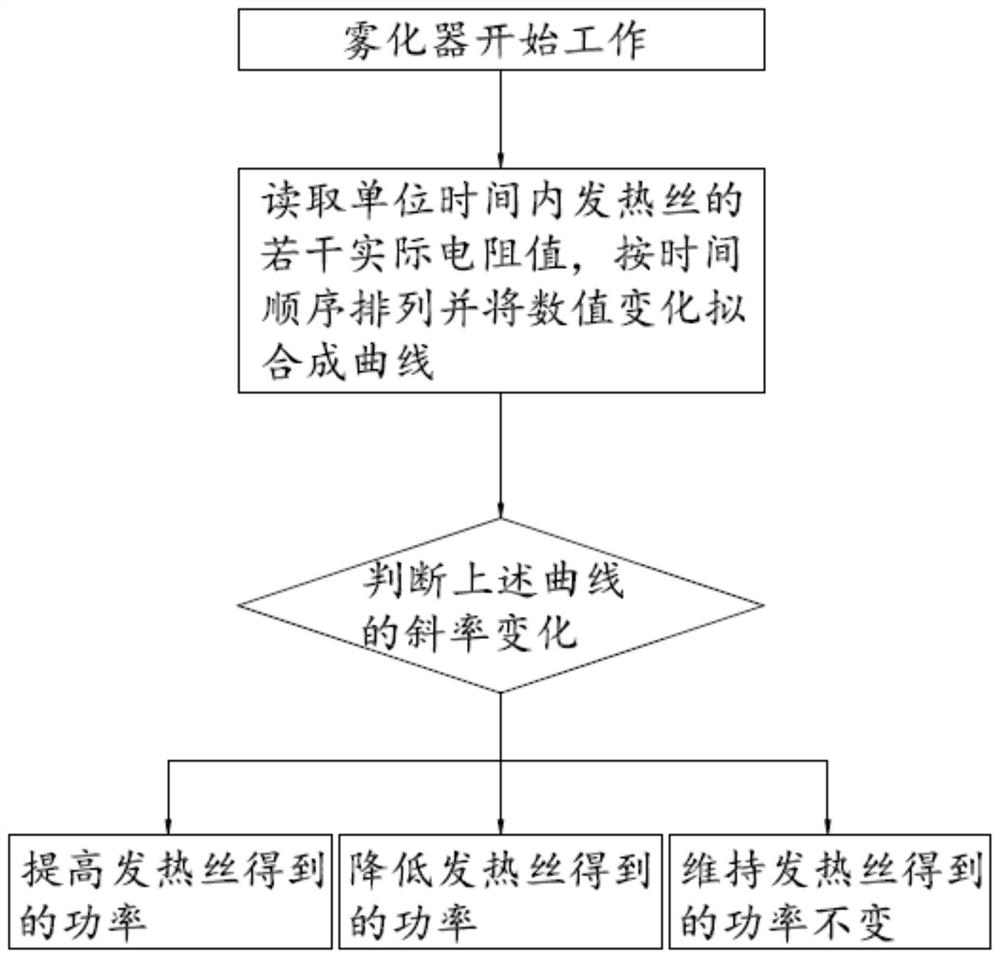

Heating monitoring method of electronic cigarette and electronic cigarette

PendingCN112535324AGet accurate resistanceAccurate adjustmentTobaccoPhysicsElectrical and Electronics engineering

The invention relates to the field of electronic cigarettes, and particularly discloses a heating monitoring method of an electronic cigarette and the electronic cigarette. A heating wire with a temperature coefficient is selected for manufacturing an atomizer, the normal-temperature resistance value and the normal-temperature temperature of the heating wire are initialized, the set resistance value and the set temperature of the electronic cigarette are initialized, there is a contact resistance value and an expansion coefficient between the heating wire and an elastic needle, there are mapping relations between the normal-temperature resistance value and the normal-temperature temperature and between the set resistance value and the set temperature, and the mapping relations additionallyinclude the contact resistance value of the heating wire and the elastic needle. The actual resistance value of the heating wire is obtained after the electronic cigarette is started, the actual temperature of the heating wire is calculated based on the actual resistance value of the heating wire, the actual temperature is compared with the set temperature, if the actual temperature is higher than the set temperature, the actual power of the heating wire is reduced, and otherwise, the actual power of the heating wire is not reduced. The precision of the detected resistance is improved, so that the precision of the corresponding temperature is improved, and an accurate basis is provided for regulation and control.

Owner:SHENZHEN JIYOU TECH CO LTD

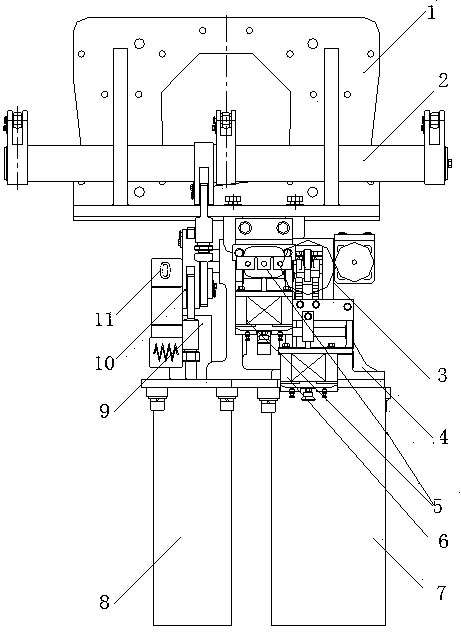

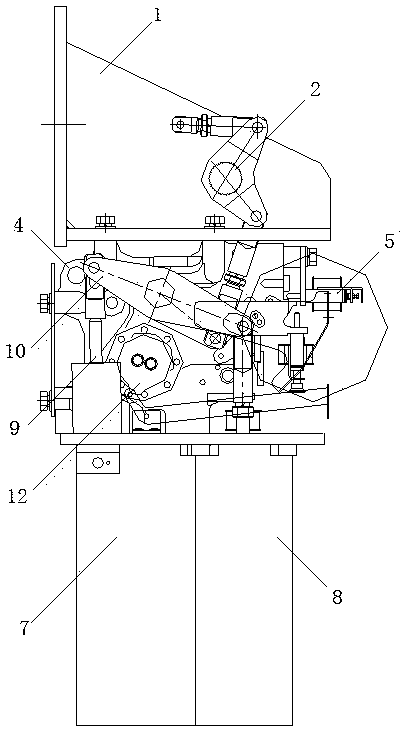

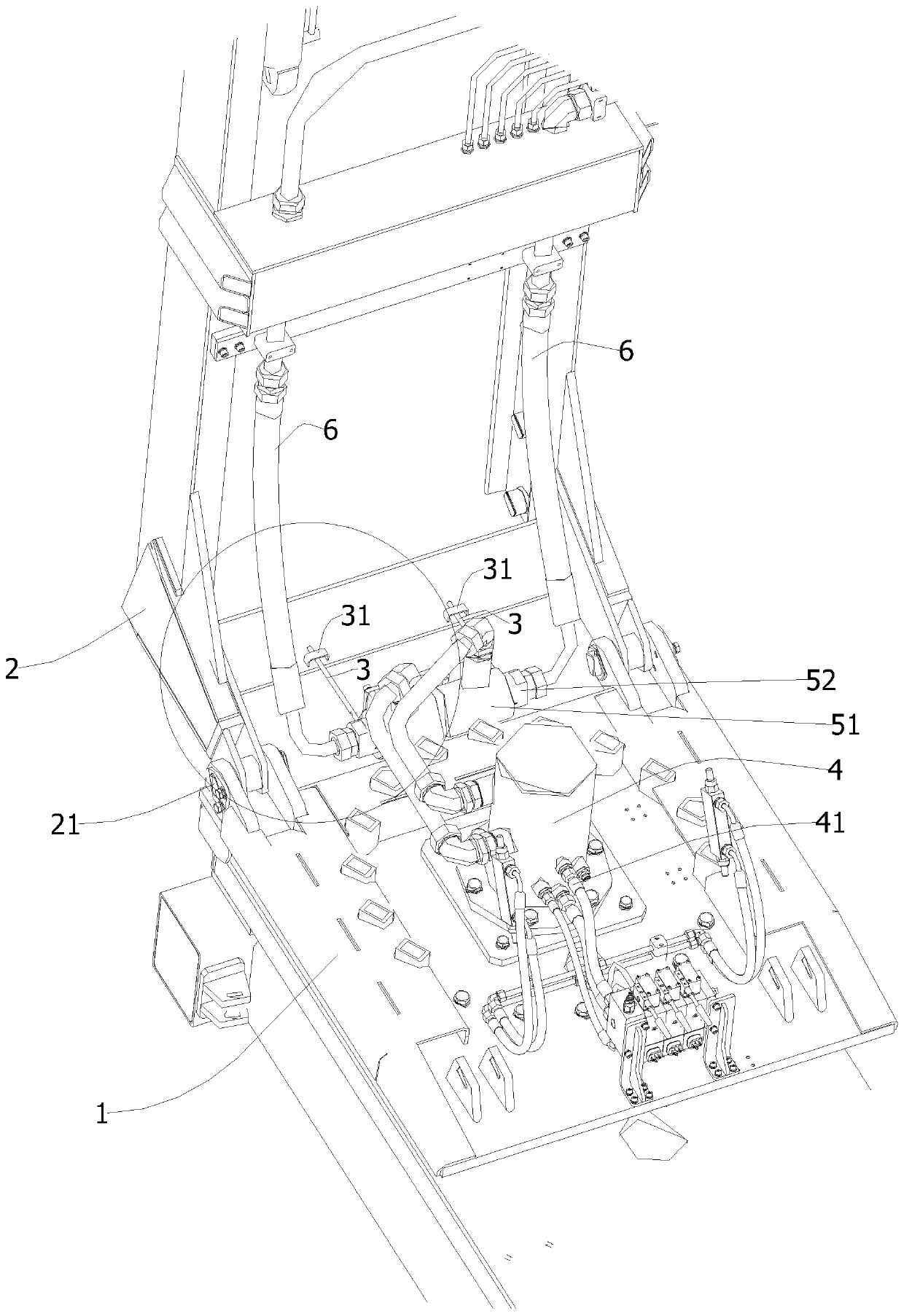

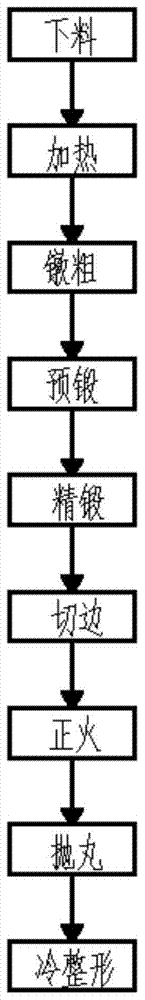

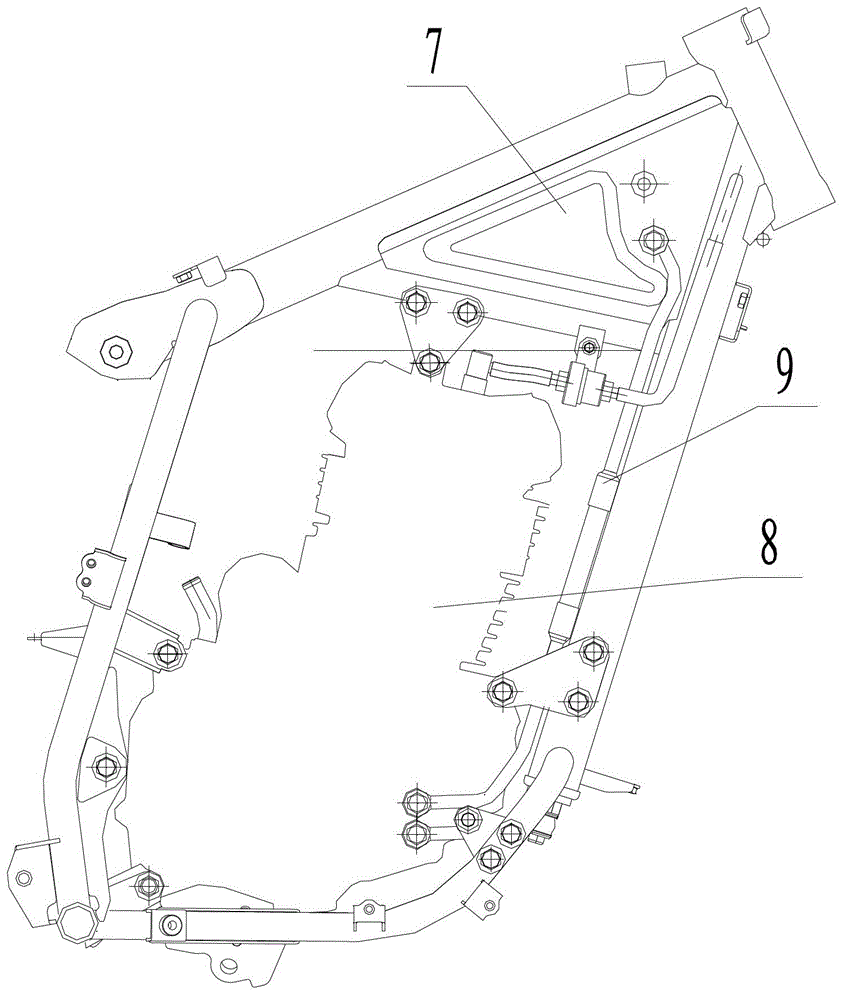

High-voltage breaker spring operating mechanism and transmission device

PendingCN109786141ASimple structureSmall safe runSwitch power arrangementsSwitching device condition indicationEngineeringEnergy storage

The invention provides a high-voltage breaker spring operating mechanism and a transmission device. The mechanism comprises a mechanism support, a transmission component, an energy conversion component, an opening control component, an energy storage component, a closing spring component, a closing control component, an opening spring component and a buffer, wherein the transmission component, theenergy conversion component, the opening control component, the energy storage component, the closing spring component, the closing control component, the opening spring component and the buffer arearranged on the mechanism support; the closing spring component is driven to store energy during action of the energy storage component; the energy conversion component comprises an output shaft and an output crank; the transmission component comprises a main shaft, a middle crank and driving cranks arranged at the two ends of the main shaft, wherein the driving cranks are connected with a breakerthrough driving rods; one end of the output crank is connected with the opening spring component and the middle crank, and the other end of the output crank is connected with the buffer; during closing operation, the closing spring component releases energy, the output crank drives the transmission component to drive the beaker to be closed; and during opening operation, the opening spring component releases energy, and the output crank drives the transmission component to drive the breaker to be open. The mechanism is reasonable in design, compact in assembling, convenient to observe and maintain, high in reliability and worth of popularization.

Owner:山东泰开电器机构有限公司

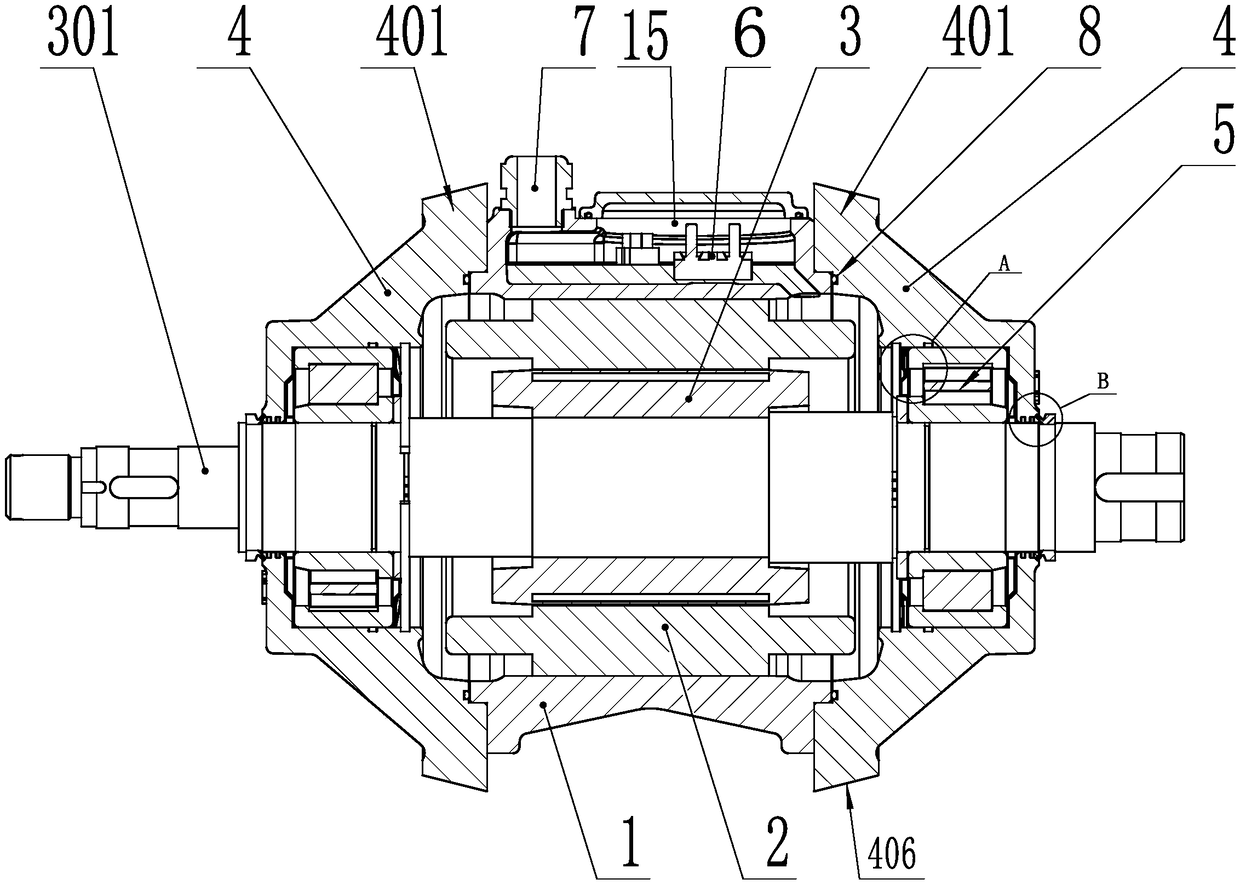

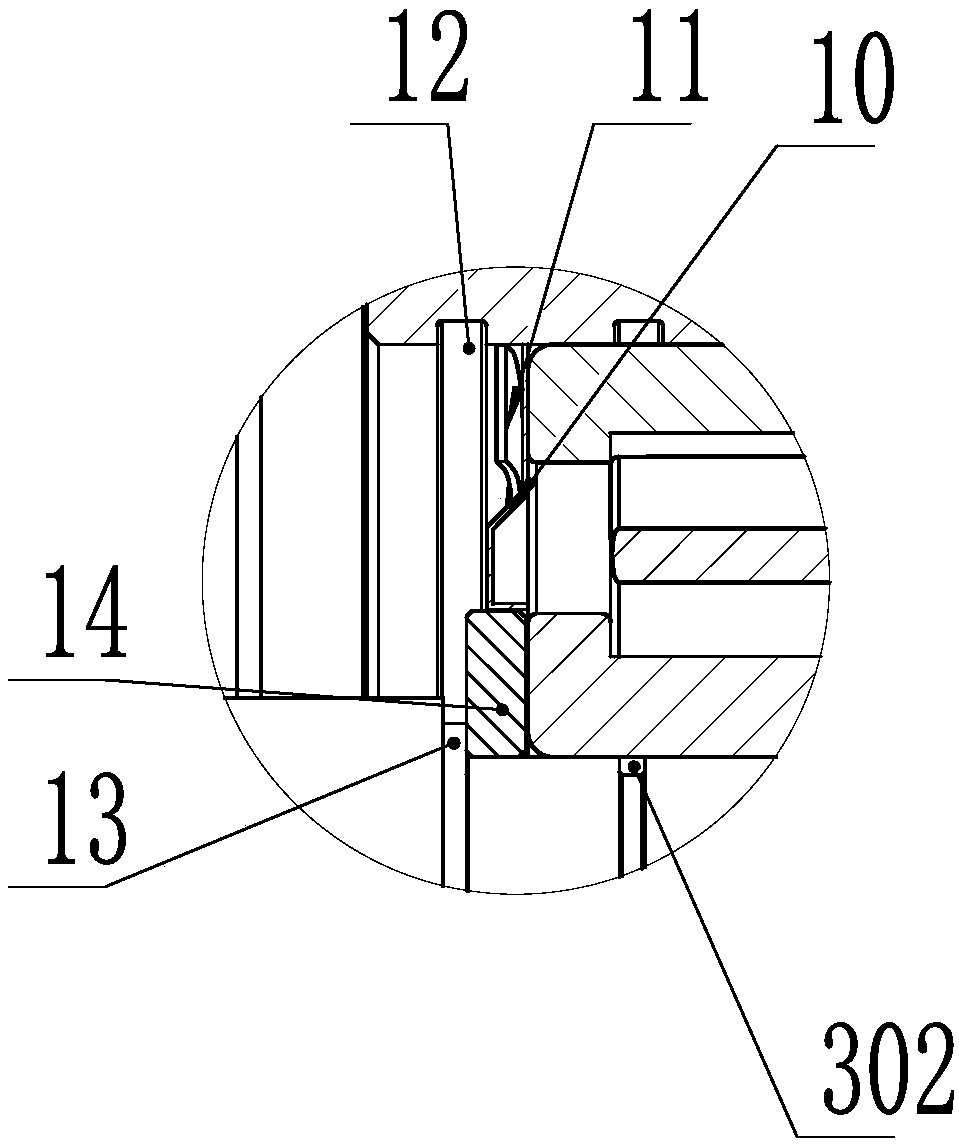

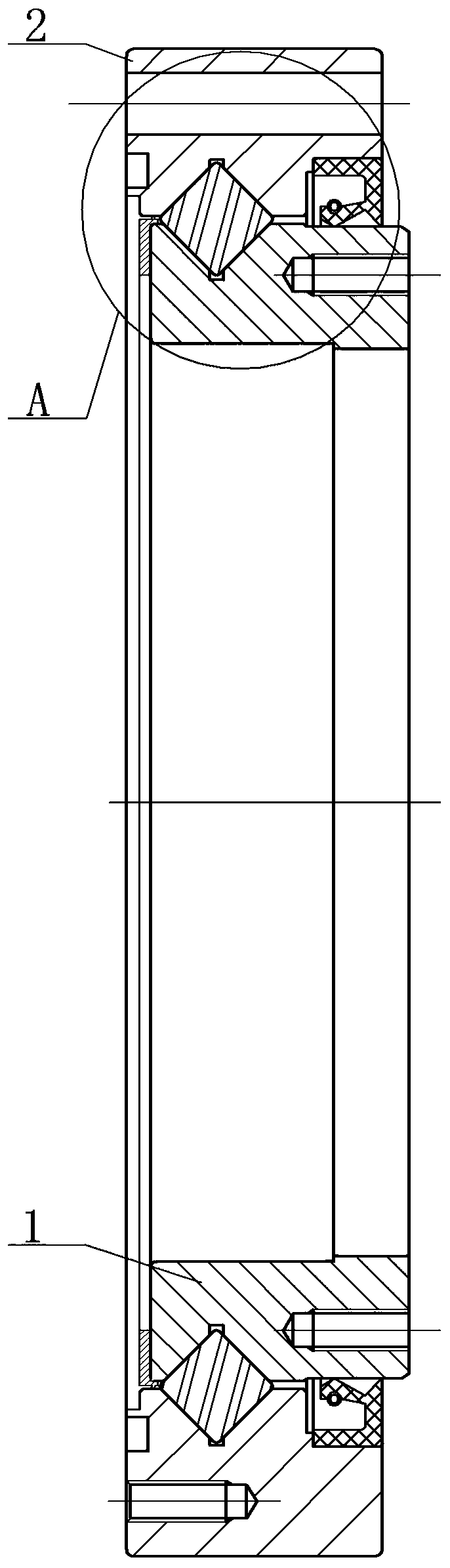

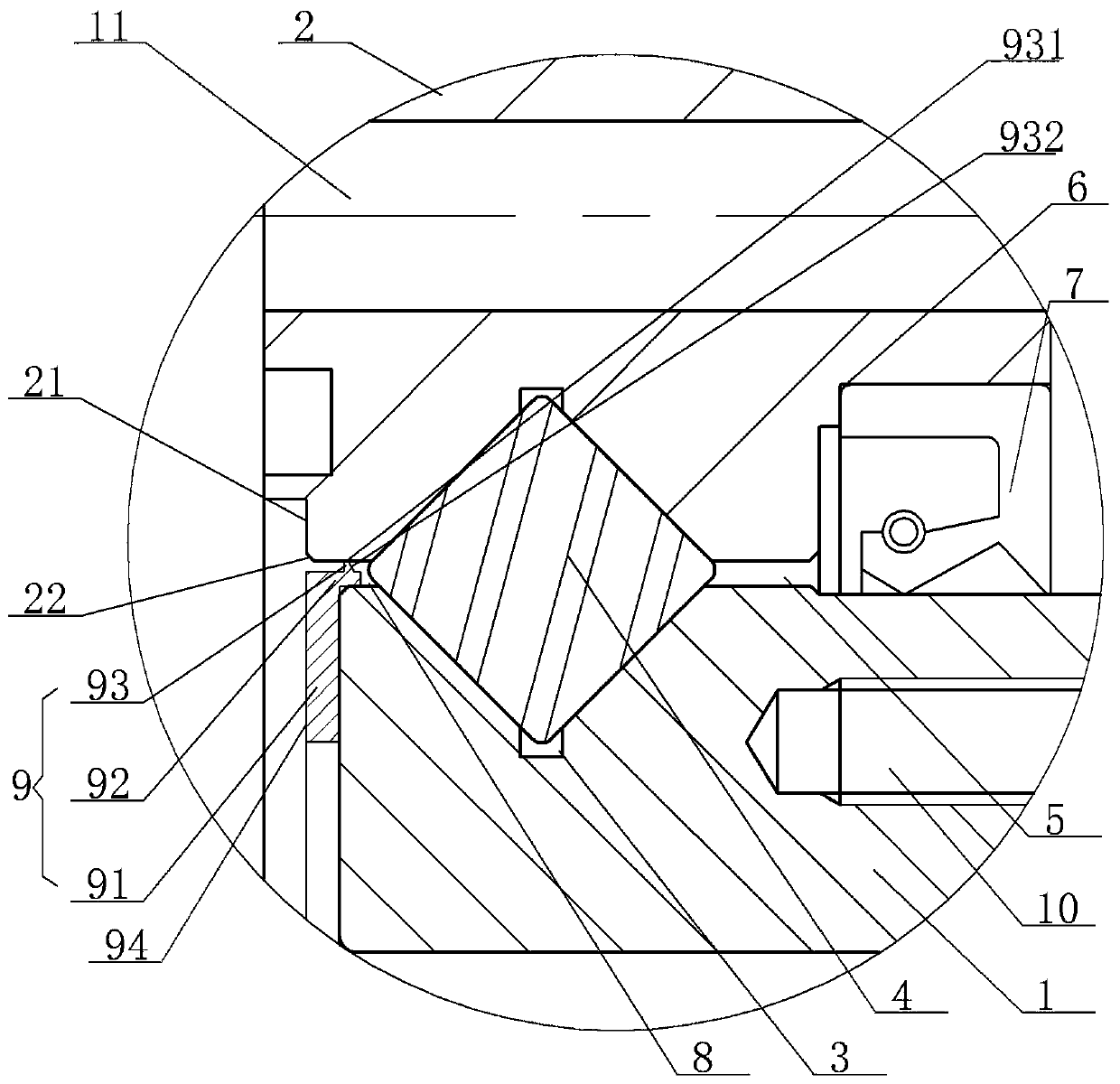

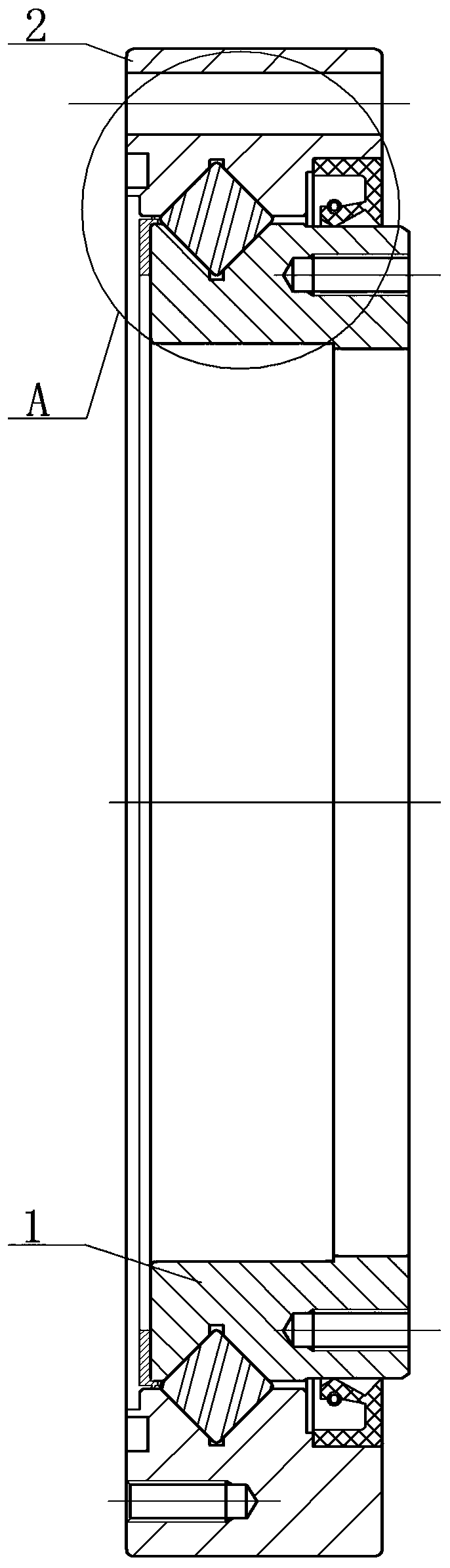

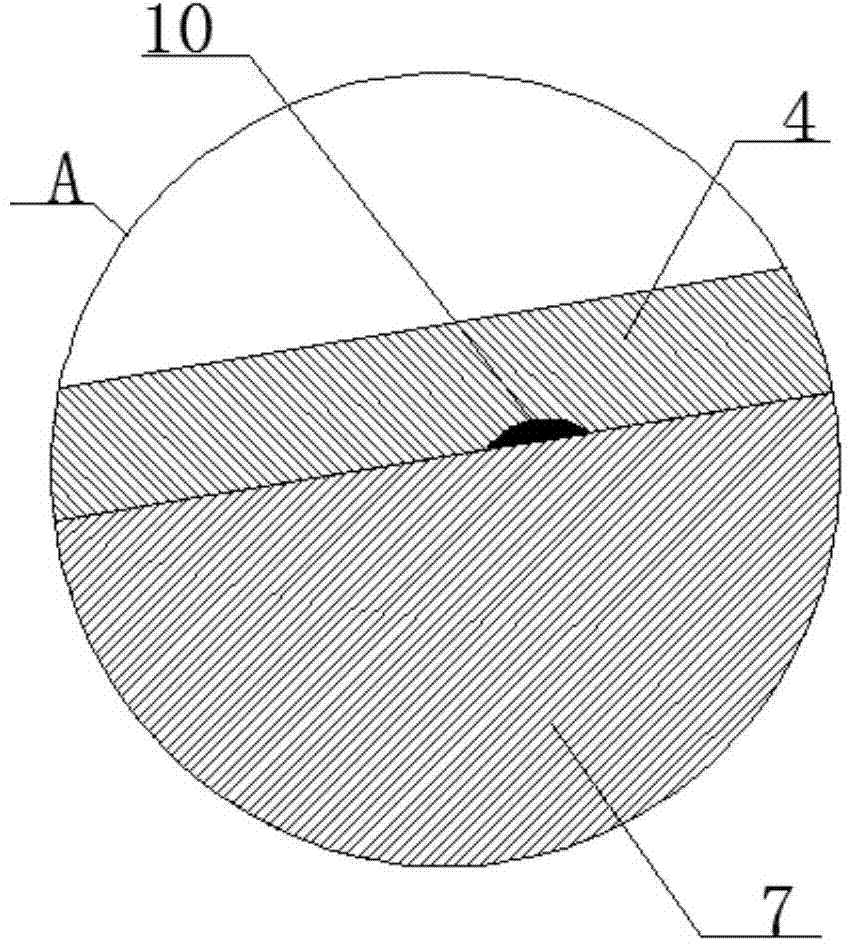

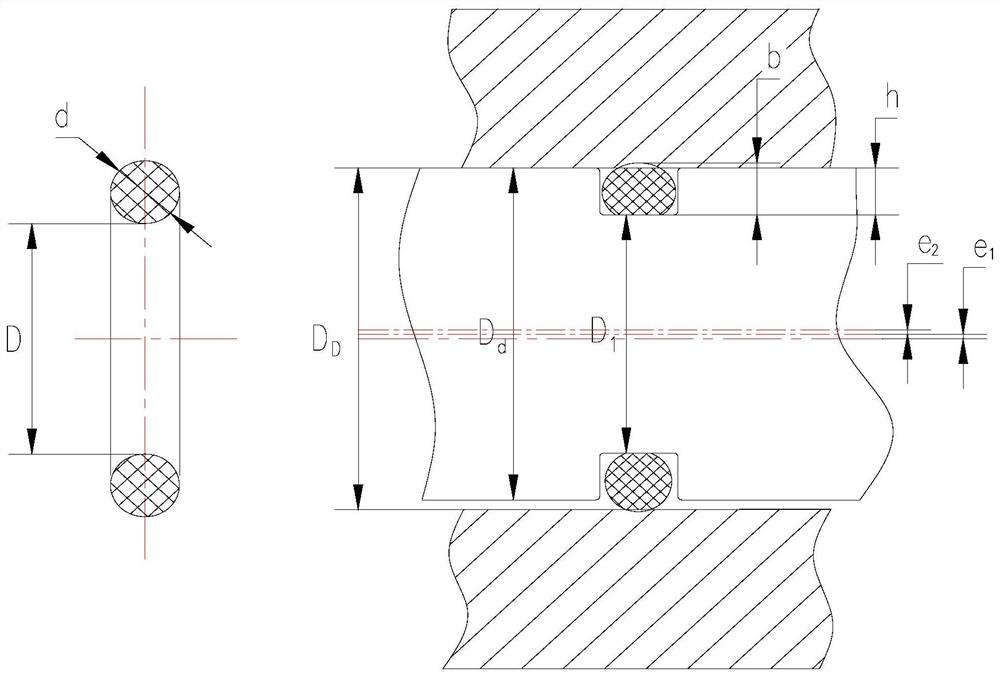

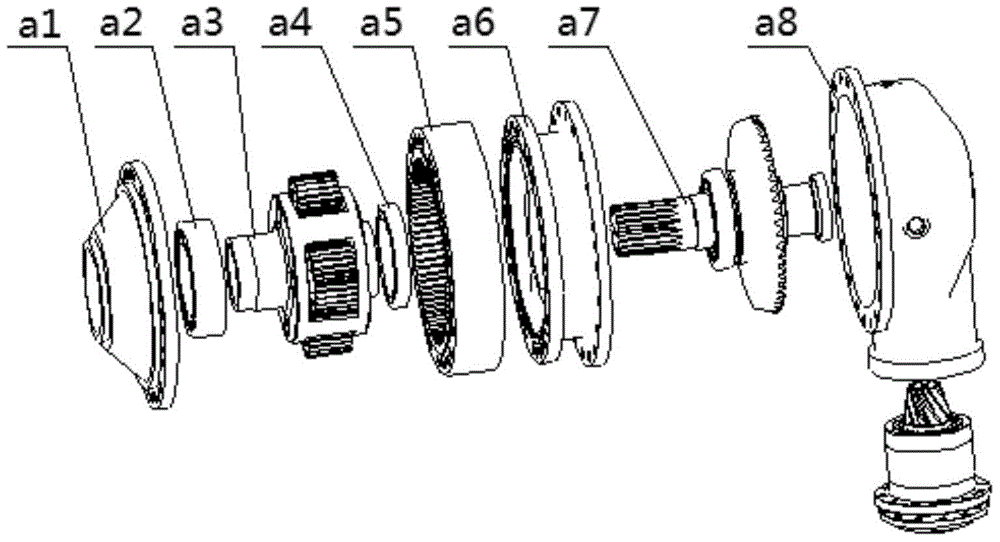

Criss-crossed roller bearing with novel sealing structure

PendingCN110030279AReduce the probability of oil spillsReduce sealing pressureBearing componentsEngineeringMechanical engineering

The invention provides a criss-crossed roller bearing with a novel sealing structure. The sealing pressure of a framework oil seal is reduced, the oil leakage rate of the bearing is reduced, and criss-crossed rollers are ensured to be lubricated sufficiently. The criss-crossed roller bearing with the novel sealing structure comprises a bearing inner ring and a bearing outer ring, wherein roller installation ring slots are formed in the corresponding thickness positions between an outer ring surface of the bearing inner ring and an inner ring surface of the bearing outer ring; the correspondingrollers are arranged in corresponding roller slots of the roller installation ring slots through a criss-crossed form; a framework oil seal installation seam allowance is arranged at the outer end ofan outer-end connecting ring slot gap in the thickness direction after the bearing inner ring and the bearing outer ring are assembled; a framework oil seal is arranged on the framework oil seal installation seam allowance and blocks lubricating oil at the corresponding end surface; a sealing element blocks the tail end of an inner-end connecting ring slot gap in the thickness direction of the bearing inner ring and the bearing outer ring, and concretely comprises a connecting ring, a transition flanging ring and an outer convex seal ring; and the first end surface of the connecting ring andthe inner end surface of the bearing inner ring are fixedly arranged in a fitting way.

Owner:SUZHOU LEADERDRIVE HARMONIC WAVE TRANSMISSION TECH CO LTD

A production process for improving oil leakage of soft capsules

ActiveCN104705772BImprove oil leakageImprove the nature of oil spillsCapsule deliveryFood shapingPropolisFish oil

The invention relates to a production technology for improving oil leakage of soft capsules. The technology effectively solves the problem of easy oil leakage of soft capsules by adjusting the drying mode, a ratio of gelatin to glycerin to water, and the rubber thickness. The quality of soft capsules obtained through the technology disclosed in the invention is stable. The technology can be widely used to prepare liquid calcium, soybean lecithin, fish oil, propolis, squalene, natural vitamin E and other soft capsules.

Owner:BY HEALTH CO LTD

Radiator device capable of reducing oil leakage rate

InactiveCN105486110AExtended service lifeCompact structureSafety devices for heat exchange apparatusStationary conduit assembliesEngineeringMechanical engineering

The invention relates to a radiator device capable of reducing an oil leakage rate. The radiator comprises a second core body, and further comprises a first three-way joint and a second three-way joint, wherein the two ends of the second core body are respectively provided with end sockets; the bottom of the second core body is provided with a first core body; the two ends of the first core body are respectively provided with end sockets; a radiator inlet and a radiator outlet are respectively formed in the end sockets at the two ends of each of the first core body and the second core body; two branches of the first three-way joint are respectively connected to radiator inlets of two radiators; the another branch of the first three-way joint is a header outlet; and two branches of the second three-way joint are respectively connected to radiator outlets of the two radiators, and another branch of the second three-way joint is a header outlet. The radiator device is compact and reasonable in structure, and is convenient to operate; the two core bodies are combined to obtain a large radiator; and at the two ends of each heat exchanger, the same connector is used for charging oil and discharging oil by virtue of the corresponding three-way joint, so that the oil leakage rate is greatly reduced, and the service lives of the heat exchangers are prolonged.

Owner:WUXI POWER HEAT EXCHANGER MFG

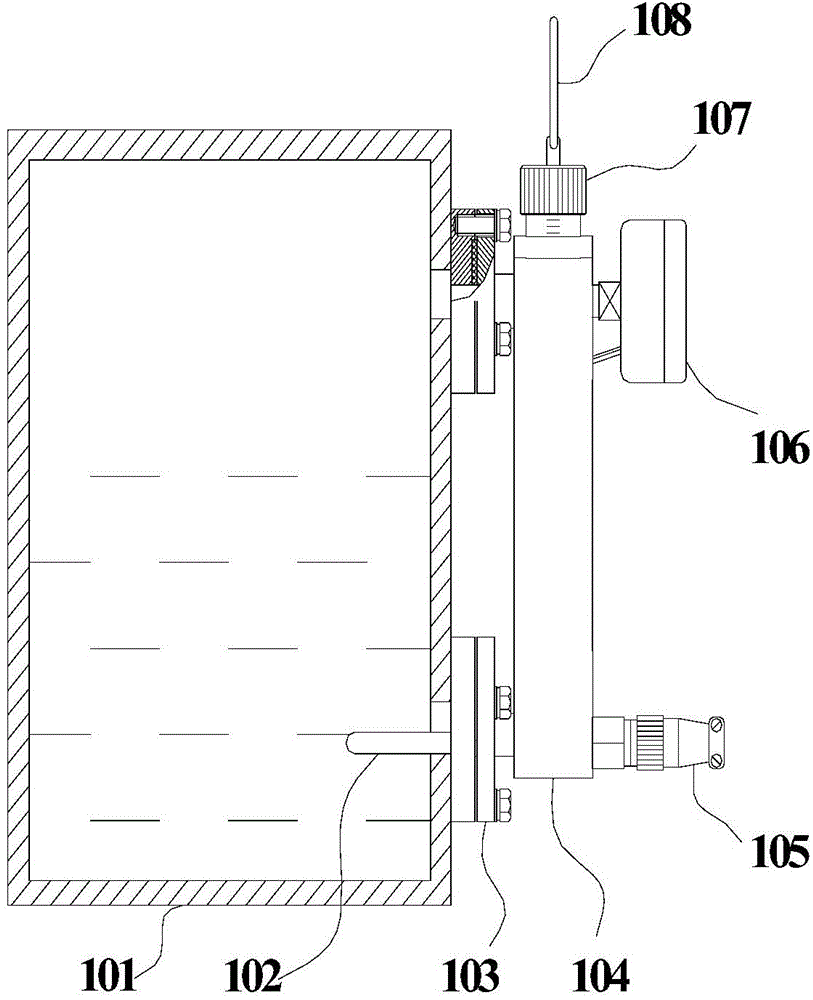

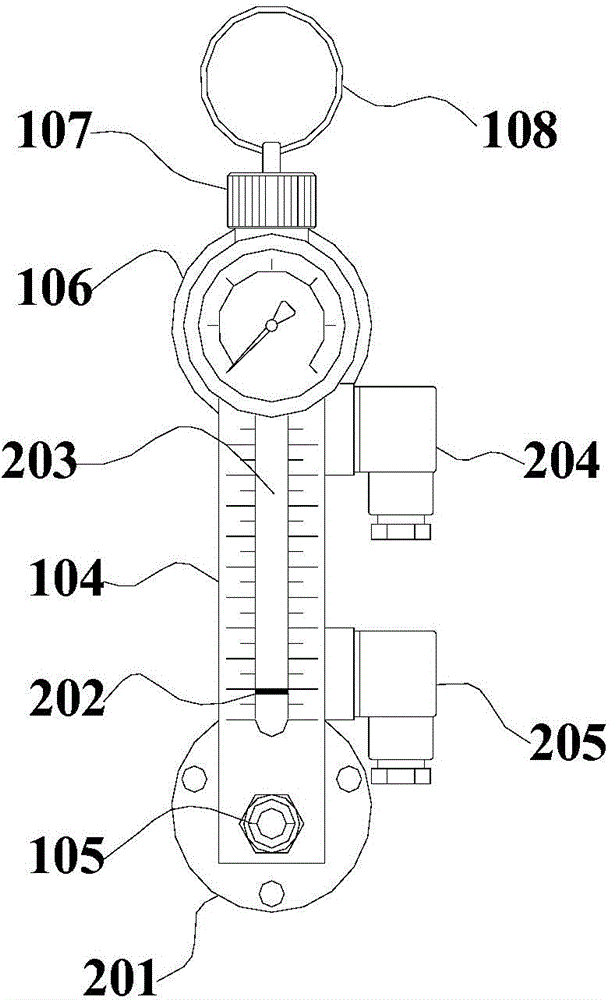

Transformer comprehensive protection device and its system

InactiveCN103559980BReduce in quantityReduce the probability of oil spillsThermometer detailsFluid pressure measurementTransformerControl theory

The invention relates to the field of transformers, in particular to a transformer comprehensive protection device and a system thereof. The transformer comprehensive protection device includes a main body, a temperature sensing element, a transparent liquid level connecting pipe and a pressure measuring element; the main body is provided with an upper through hole and a lower through hole; the protective tube of the temperature sensing element passes through The lower through hole protrudes out of the main body; the liquid level communication pipe is located in the main body and one end of the liquid level communication pipe communicates with the upper through hole, and the other end communicates with the lower through hole ; The load cell communicates with the upper through hole. In the transformer comprehensive protection system, the upper through hole communicates with the first hole through a flange; the lower through hole communicates with the second hole through a flange. The transformer comprehensive protection device and system provided by the present invention, compared with the high probability of oil leakage when multiple monitoring devices are used in the prior art, reduces the number of holes opened on the oil tank, thereby reducing the probability of oil leakage.

Owner:宋红庆

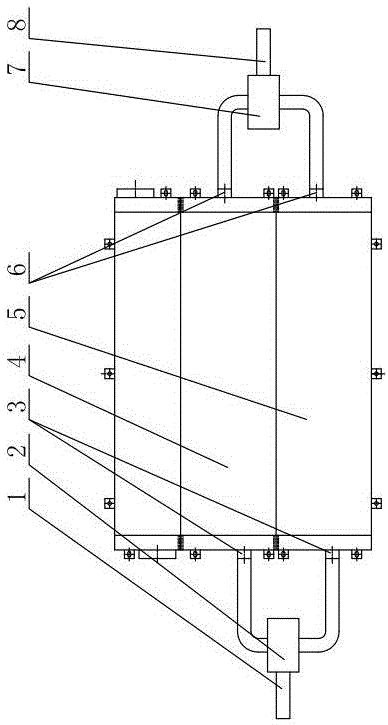

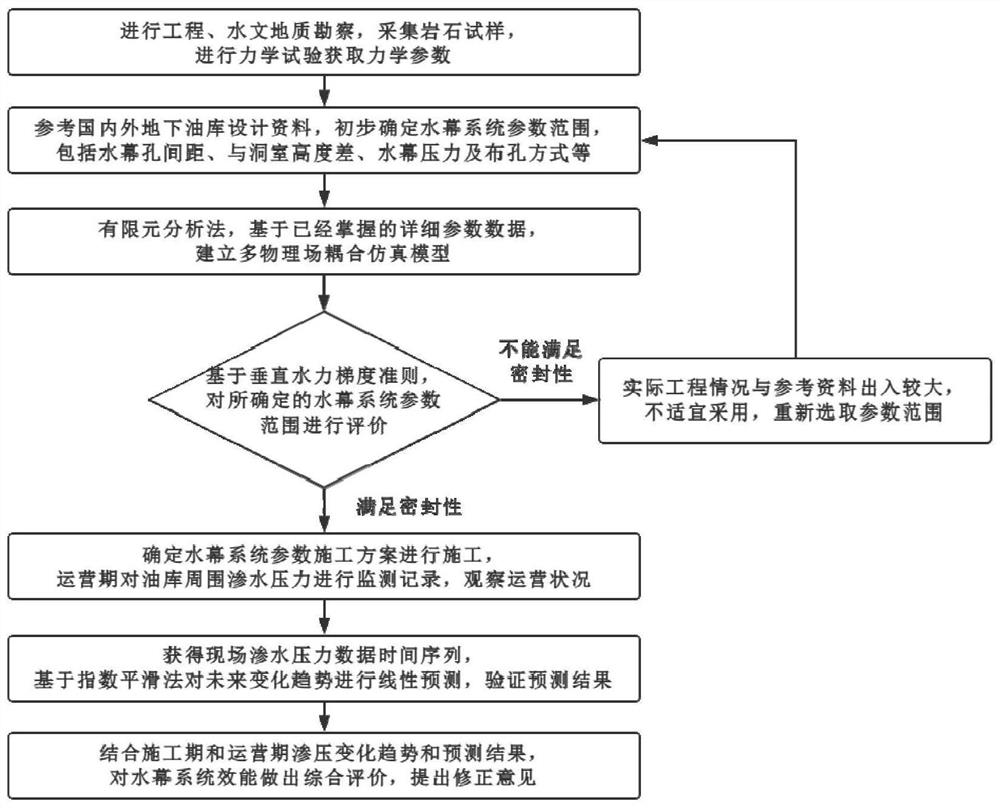

Analysis system and method for design and correction of water curtain system in underground water-sealed oil storage depot

ActiveCN111157346BNarrow down the parameter selection areaHigh feasibilitySurveyMaterial strength using tensile/compressive forcesElement analysisLaboratory test

This disclosure provides an analysis system and method for the design and correction of the water curtain system of an underground water-sealed oil storage depot. Study the case and obtain the relevant parameter data required for the scheme in the laboratory test. Through the finite element analysis method, the selection range of the specific parameters of the water curtain system can be quickly and accurately narrowed, and the final design and construction plan can be determined accurately, time-saving, highly feasible, and low oil leakage rate.

Owner:SHANDONG UNIV

Heat radiator capable of enhancing core strength and lowering oil leakage rate

InactiveCN105486107ACompact structureReasonable structureSafety devices for heat exchange apparatusStationary conduit assembliesHigh intensityUltimate tensile strength

The invention relates to a heat radiator capable of enhancing core strength and lowering the oil leakage rate. The heat radiator comprises a large core formed by combining a plurality of core bodies. An upper seal head is arranged at the top of the large core. A lower seal head is arranged at the bottom of the large core. Input connectors are arranged at the left end of the upper seal head and the left end of the lower seal head respectively. Lifting lugs are arranged at the two ends of the upper seal head and the two ends of the lower seal head respectively. An output connector is arranged at the top of the position, between the two corresponding lifting lugs, of the upper seal head. The left end and the right end of the large core are each provided with angle aluminum, and long round holes are formed in the angle aluminum at intervals. Rib plates are welded to the four corners of each core body respectively. The heat radiator is compact and reasonable in structure and convenient to manufacture and mount; aluminum plate reinforcing ribs are welded to the four corners of each core body respectively, so that deformation is avoided, and the vibration resisting strength is enhanced; and after the core strength is enhanced, in high-strength vibration, the oil leakage rate can be effectively lowered, and use reliability is improved.

Owner:WUXI POWER HEAT EXCHANGER MFG

Operation platform of drainage vehicle

InactiveCN111572434AAvoid distortionAvoid wear and tearAdjustable jointsItem transportation vehiclesControl engineeringControl theory

The invention relates to an operation platform of a drainage vehicle. The operation platform comprises a swing mechanism, a turnover mechanism, a swing joint, a linkage rod and a linkage plate. One end of the turnover mechanism is hinged with the swing mechanism; the swing joint is arranged on the swing mechanism, and the swing joint is connected with an oil pipe on the turnover mechanism; and oneend of the linkage rod is connected with the turnover mechanism through the linkage plate, and the other end of the linkage rod is connected with the swing joint. The invention discloses the operation platform of the drainage vehicle and the drainage vehicle. The turnover mechanism is driven by a driving mechanism to turn over; and when the turnover mechanism overturns, the linkage rod is drivento overturn, the linkage rod overturns to drive the swing joint to overturn, and the oil pipe overturns together with the swing joint and the turnover mechanism so that the two ends of the oil pipe are relatively not twisted, the oil pipe is prevented from being twisted and abraded, an oil leakage probability caused by oil pipe breakage is greatly reduced, and an overall structure is simpler.

Owner:FUJIAN QIAOLONG EMERGENCY EQUIP CO LTD

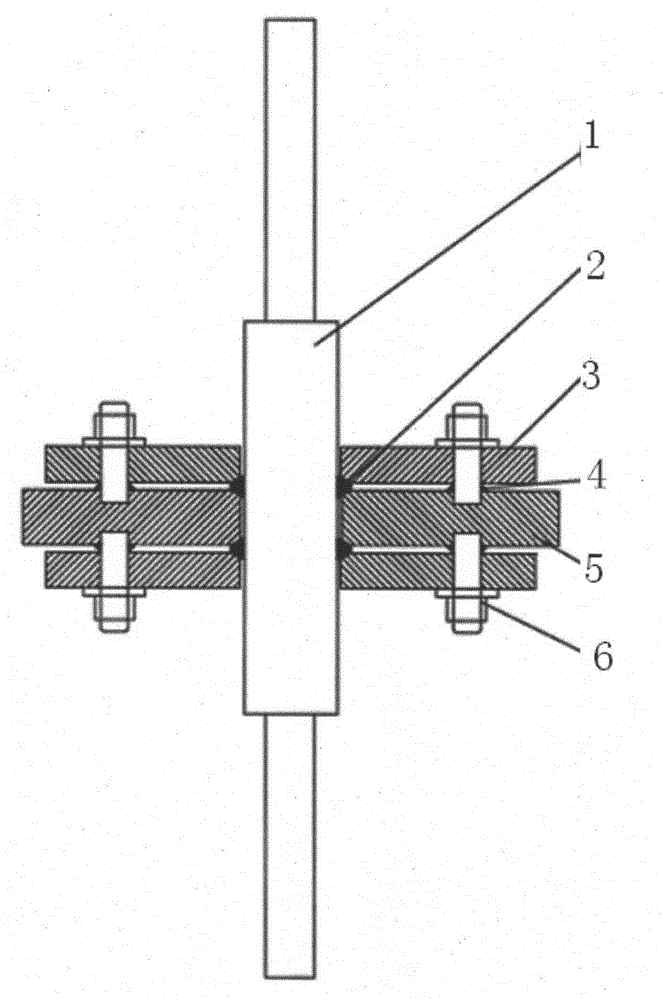

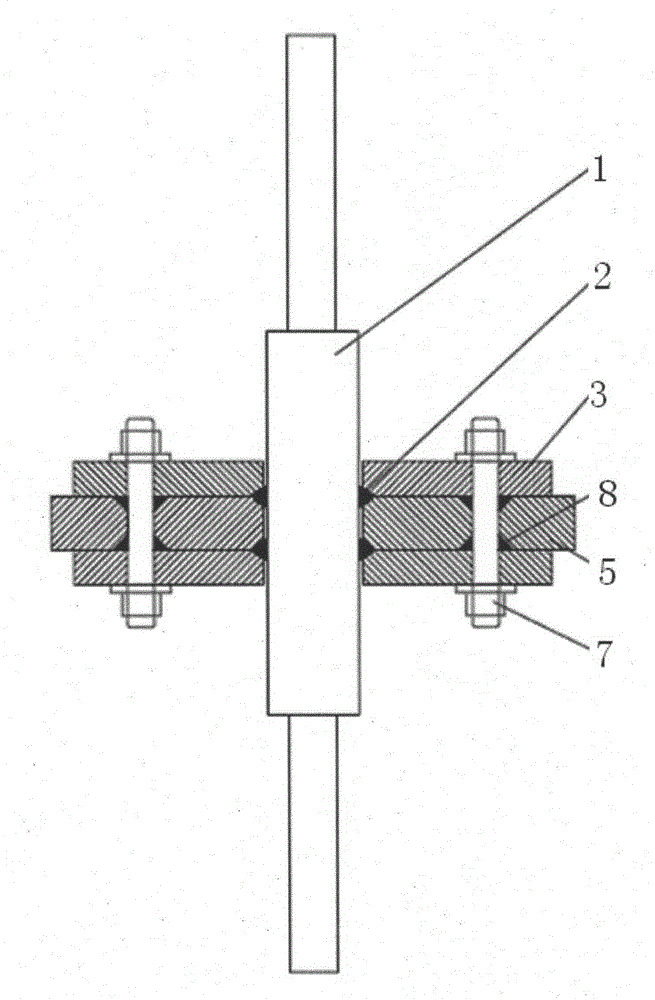

Low-voltage high-current conducting bar fixing mode of electric furnace transformer

ActiveCN103606439AReduce the probability of oil spillsAvoid feverTransformers/inductances coils/windings/connectionsLow voltageTransformer

The invention relates to a low-voltage high-current conducting bar fixing mode of an electric furnace transformer, and provides a coil head outgoing method for reducing partial discharge of the transformer. The mode is characterized by including the steps that (1) a conducting bar is fixed to a non-magnetic steel plate, (2) the left end and the right end of the non-magnetic steel plate are respectively provided with a through hole, and the upper end and the lower end of each through hole are respectively provided with a beveling groove in a chamfering mode, (3) two non-magnetic screw rods penetrate through the two through holes respectively, the upper end and the lower end of each non-magnetic screw rod are exposed out of the upper face and the lower face of the non-magnetic steel plate respectively, the non-magnetic screw rods and the non-magnetic steel plate are welded and fixed with the beveling grooves as welding seams, and after welding, smoothness of the upper face and the lower face of the non-magnetic steel plate is guaranteed; (4) the upper face and the lower face of the non-magnetic steel plate are respectively provided with a sealing pad, and the sealing pads are pressed with a pressing element. The low-voltage high-current conducting bar fixing mode has the advantages of reducing the oil leaking probability of the conductive bar after installation and preventing the fixing screw rods of the conducting bar from being exceedingly heated.

Owner:CHINT ELECTRIC

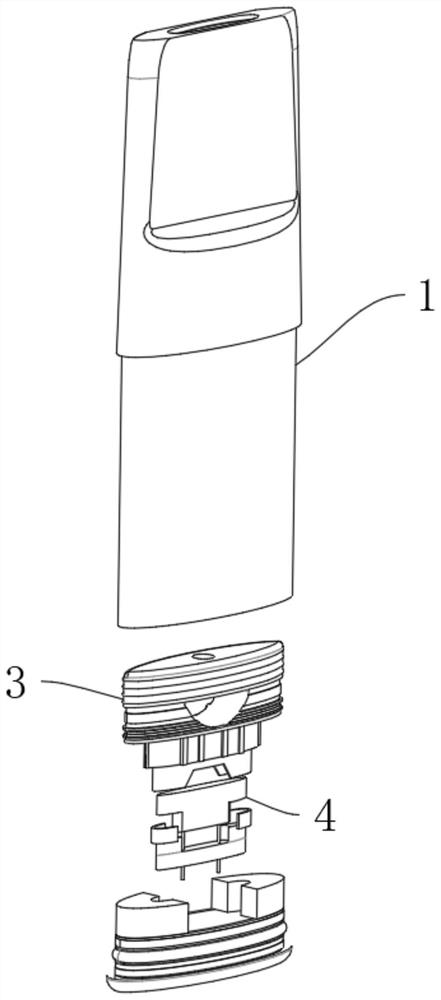

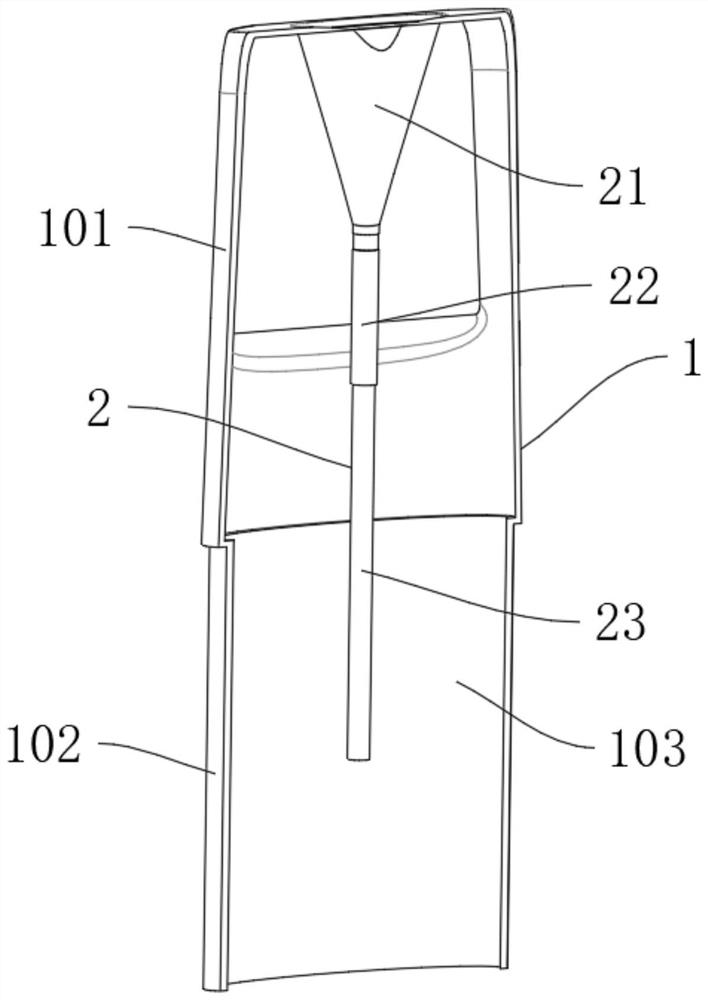

Electronic cigarette cartridge with sealing structure

InactiveCN114747802AReduce the probability of oil spillsReduce the probability of generating condensate-type oilTobaccoRubber ringAerosolize

The invention discloses an electronic cigarette cartridge with a sealing structure, and particularly relates to the field of electronic cigarettes, the electronic cigarette cartridge comprises an oil cup structure used for storing oil, the top of an inner cavity of the oil cup structure is connected with a mist guide mechanism used for sucking smoke, and a sealing assembly is inserted into the bottom of the inner cavity of the oil cup structure; an atomizing core assembly used for atomizing tobacco tar is installed in the sealing assembly, the sealing assembly comprises a limiting type sealing upper support, a limiting type sealing lower support with the consistent section is placed at the bottom of the limiting type sealing upper support, and a limiting bearing base is installed at the bottom of the limiting type sealing upper support. The assembled atomizing core and the limiting bearing seat are close to one plane, the plane upwards forms an atomizing area, the plane downwards forms an oil storage bin, the atomizing area does not make contact with the tobacco tar part, after the atomizing core is heated, mist overflows from the top of the atomizing core, the first sealing rubber ring and the second sealing rubber ring achieve the oil sealing effect, and the probability of oil leakage is reduced.

Owner:刘志琪

Novel anti-corrosion ship steel casting piece stop valve

The invention discloses a novel anti-corrosion ship steel casting piece stop valve and relates to the technical field of ship supporting equipment. The novel anti-corrosion ship steel casting piece stop valve comprises a valve body, a valve body inlet and valve body outlets, wherein the valve body inlet and the valve body outlets are arranged on the two sides of the valve body, the number of the valve body outlets is two to three, each valve body outlet comprises a straight pipe and a cone-shaped pipe, the straight pipe is fixedly connected with the valve body, the cone-shaped pipe is fixedly connected with the straight pipe, the straight pipe is provided with a section of external thread, the thread on the straight pipe is connected to a linear type sleeve, the sleeve is connected to a cone-shaped locking pipe, the locking pipe and the cone-shaped pipe have the same slant angles, in addition, the smallest diameter of the locking pipe is smaller than the largest diameter of the cone-shaped pipe, and the valve body inlet and the straight pipe are provided with a large ball valve and small ball valves respectively. The novel anti-corrosion ship steel casting piece stop valve has the advantages that the lock sealing of a fuel hose is achieved, the security coefficient is high, the stability is high, the operation is convenient, oil leakage can not occur, the large ball valve and the small ball valves are arranged on the valve body inlet and the straight pipe, the safety of the valve body is improved, and the probability of oil leakage is lowered.

Owner:泰州市成成铸铜有限公司

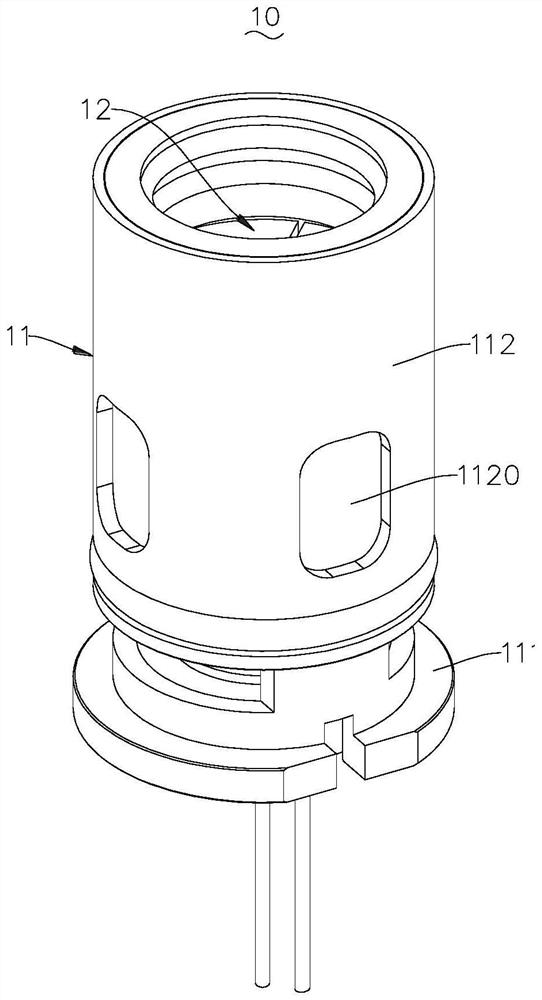

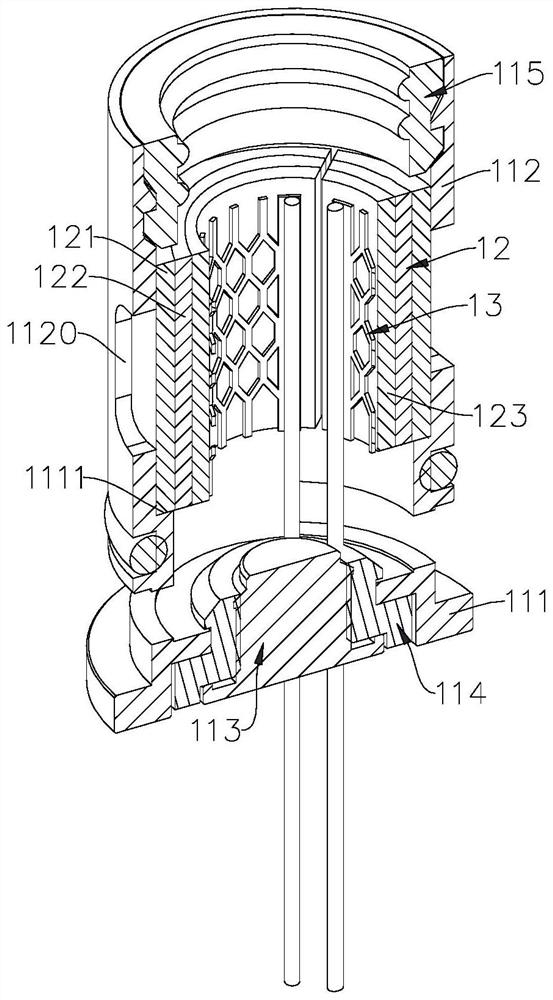

Electronic atomization device and atomizer, atomization assembly and liquid guide device thereof

InactiveCN114732164AGood liquid locking effectReduce the probability of oil spillTobaccoPhysicsEngineering

The invention relates to an electronic atomization device and an atomizer thereof, an atomization assembly and a liquid guide device, and the liquid guide device is used for the electronic atomization device and comprises third liquid guide cotton; the third liquid guide cotton is located at the liquid guide rear end, and the water retention rate of the third liquid guide cotton is 65%-80%. The liquid guiding device has the beneficial effects that the liquid locking effect is good, and the oil leakage probability can be greatly reduced.

Owner:HAINAN MOORE BROTHERS TECH CO LTD

Hydraulic valve bonnet manufacturing process

The invention relates to a hydraulic valve cover manufacturing process. The process includes the following steps of a, discharging, wherein the required raw material is prepared according to weight and size, b, heating, wherein heating is conducted on the raw material in a heating furnace, c, upsetting, wherein the heated raw material is placed in an upsetting die, unsetting is conducted on the raw material to form a workblank, and the oxide skin on the surface of the workblank is removed; d, dummying, wherein performing is conducted on the workblank generated after the oxide skin is removed to form a pre-forging piece, e, precision forging, wherein fine machining is conducted on the preformed workblank to form a precision forging piece, f, burr cutting, wherein burrs of the precision forging piece are cut on a punching machine, g, normalizing, wherein the precision forging piece generated after burr cutting is conducted is placed in a furnace, and normalizing is conducted on the precision forging piece, h, shot blasting, wherein the oxide skin on the surface of the precision forging piece generated after normalizing is conducted is removed and i, cold sizing, wherein local cold sizing is conducted on the precision forging piece on a cold forging machine. According to the hydraulic valve cover manufacturing process, the workblank is formed through hot forging, then cold-extrusion is conducted on a key face, the plane degree and parallel degree are guaranteed, traditional machinery machining is replaced, the production cost is saved, and the forged piece is high in mechanical strength and stable in size accuracy.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

punching machine

The invention provides a punching machine which comprises a shell, a drive assembly, an eccentric shaft, an oil cylinder, a hydraulic pump, a push shaft, an upper punch die, a lower punch die and an oil return assembly. The drive assembly is arranged in the shell. The eccentric shaft is connected with the drive assembly. The oil cylinder is arranged in the shell. The hydraulic pump comprises multiple piston assemblies arranged in the circumferential direction of the eccentric shaft. Each piston assembly is provided with multiple oil holes communicating with the oil cylinder. The eccentric shaft rotates to drive the multiple piston assemblies to move in the direction perpendicular to the axis of the eccentric shaft, and oil in the oil cylinder is extruded into an oil cavity of the hydraulic pump. The push shaft is arranged in the shell and connected with the oil cavity of the hydraulic pump. After the oil enters the oil cavity, the push shaft moves in the direction where the lower punch die is located. The upper punch die is connected with the push shaft. The lower punch die and the upper punch die are oppositely arranged on the shell. The oil return assembly is connected with the push shaft, the oil cavity and the oil cylinder. After the push shaft moves to the limited position in the direction where the lower punch die is located, the oil return assembly is started, and the oil in the oil cavity flows back into the oil cylinder through the oil return assembly.

Owner:HANGZHOU OUDUN ELECTROMECHANICAL

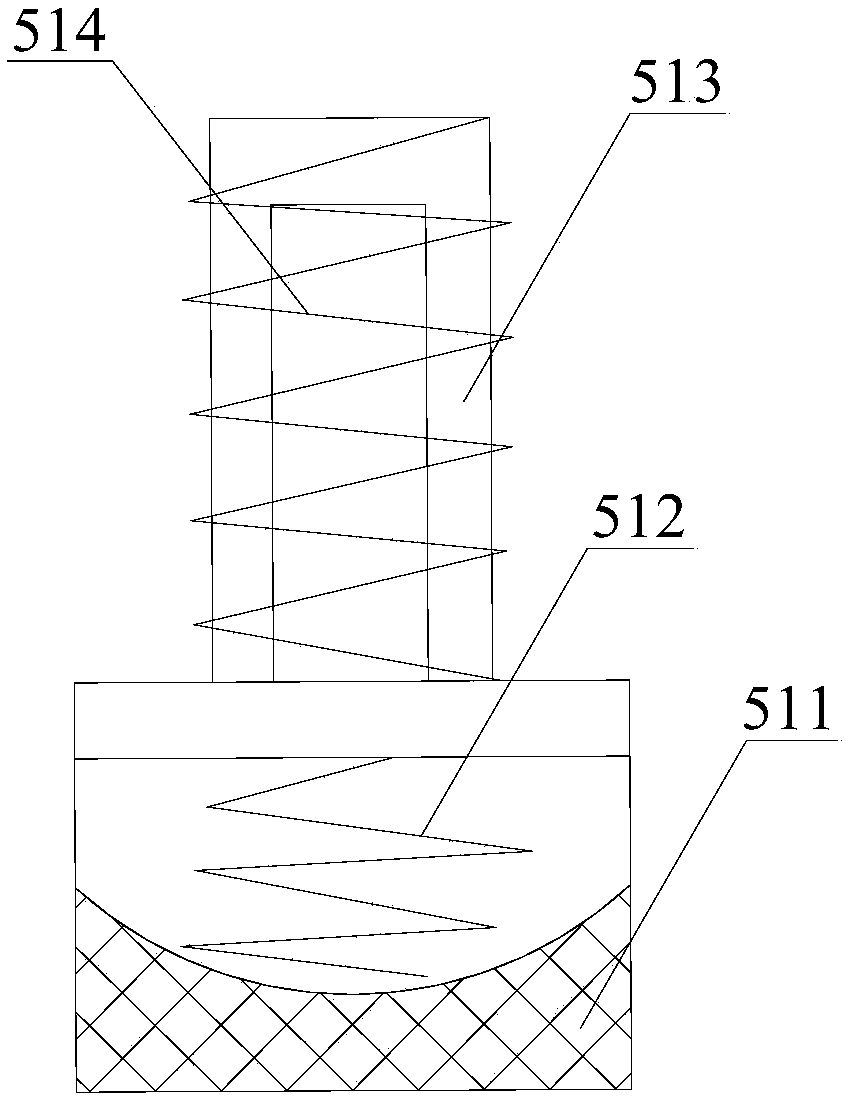

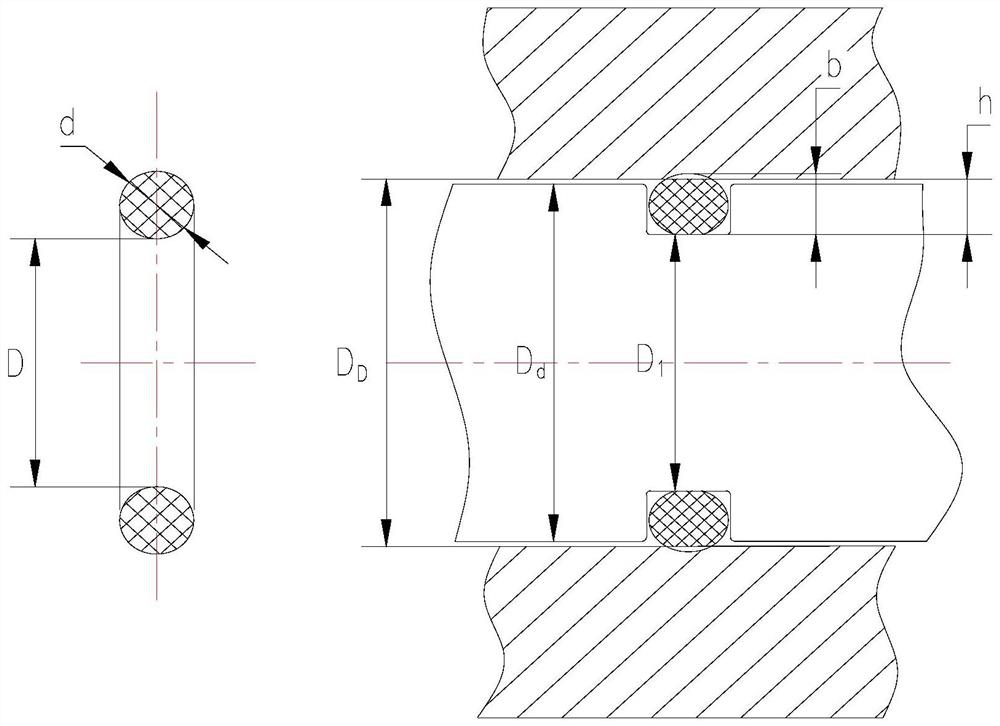

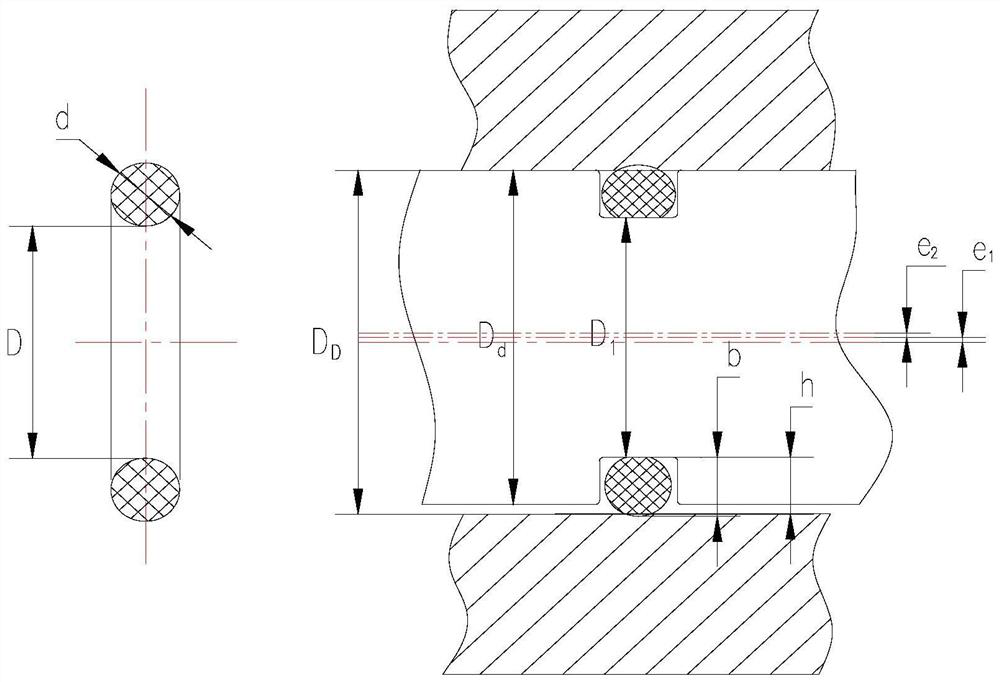

Method for calculating compression ratio of shaft sealing ring

PendingCN114780900AReduce compressionSmall h valueEngine sealsComplex mathematical operationsEngineeringMechanical engineering

The invention belongs to a shaft sealing technology, and particularly relates to a method for calculating the compression ratio of a shaft groove sealing ring. According to the method for calculating the compression ratio of the shaft groove sealing ring, the assembling eccentricity and the machining eccentricity are obtained, the depth parameter of the radial groove formed after assembling is calculated, when the compression ratio of the sealing ring is calculated, the assembling eccentricity and the machining eccentricity are added into the depth parameter of the radial groove, and the actual depth of the radial groove is obtained; and calculating the compression ratio of the sealing ring by using the actual depth of the radial groove and the radial size of the section of the sealing ring. According to the method provided by the invention, the limit condition of assembly can be better reflected, the calculated minimum compression ratio is more accurate, an important reference basis can be provided for the design of a sealing structure, and the oil leakage rate is reduced.

Owner:HARBIN DONGAN ENGINE GRP

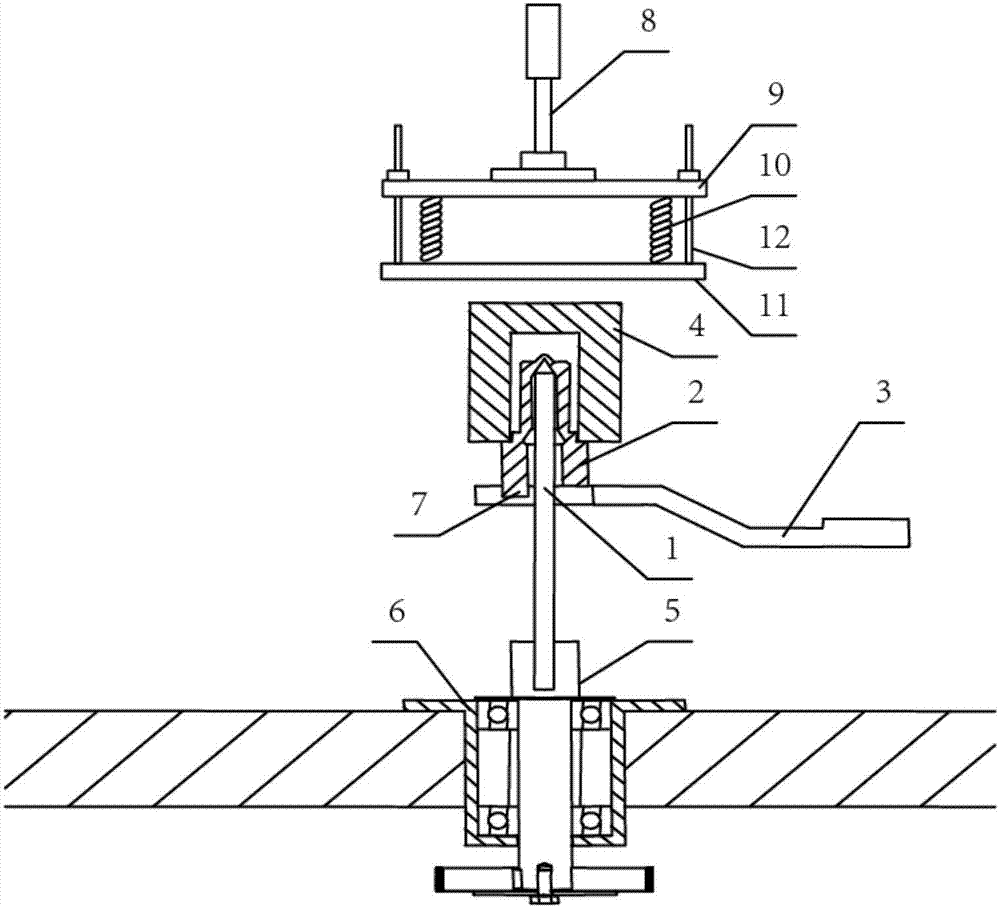

Base surface grinding machine

InactiveCN107042468AReduce the probability of oil spillsGood effectSeat surface grinding machinesLapping machinesSuperfinishingEngineering

The invention belongs to the field of seat surface grinders, and in particular relates to a seat surface grinder. The seat surface grinder comprises: a grinding rod, a support plate for placing a valve body, and a counterweight placed on the valve body, The top of the grinding rod passes through the support plate, the bottom is clamped on the rotating shaft, the rotating shaft is fixed by the bearing, the valve body is provided with a protrusion, and the support plate is provided with a protrusion matched with the protrusion. groove. The invention can provide a seat surface grinder which can solve the problem of super-finishing of the seat surface, can improve the smoothness of the seat surface and improve the oil sealing effect.

Owner:天津市天油油泵油嘴制造有限公司

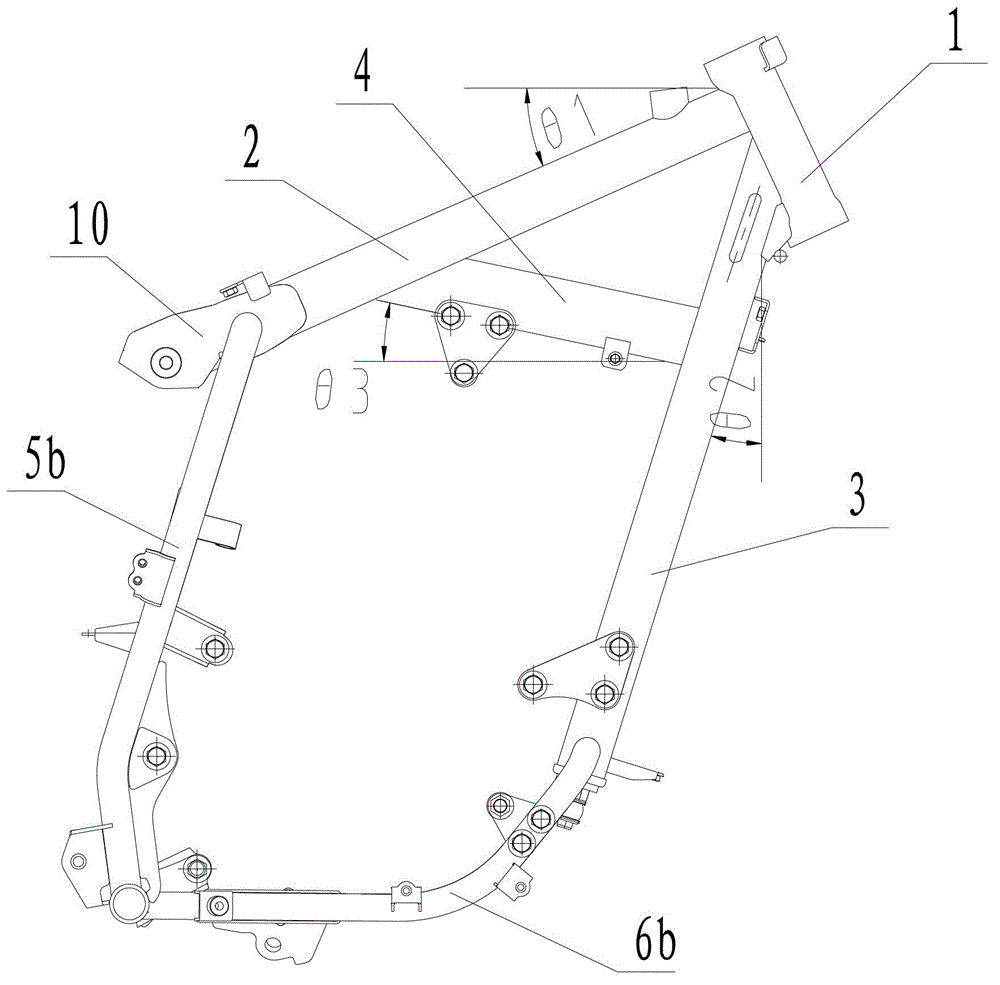

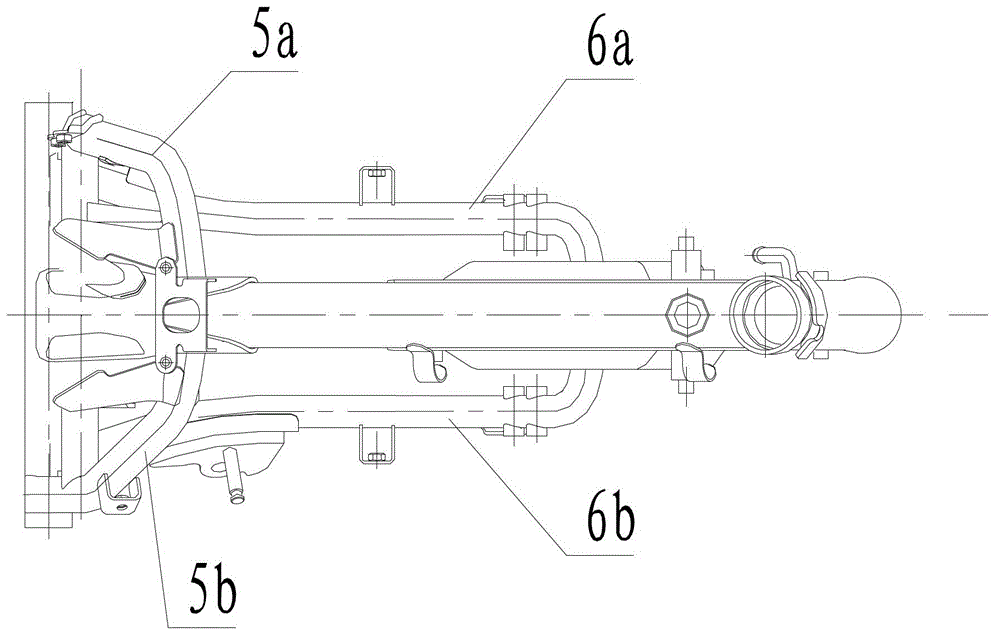

Motorcycle frame front body assembly convenient for welding oil pool

InactiveCN102975805AReduce welding difficultyReduce the probability of oil spillsMotorcyclesVehicle frameStraight tube

The invention discloses a motorcycle frame front body assembly convenient for welding an oil pool, and the motorcycle frame front body assembly comprises a head tube, wherein a front main tube and a front oblique tube are arranged on the same side of the head tube; a front supporting tube is arranged between the front main tube and the front oblique tube; the head tube, the front main tube, the front oblique tube and the front supporting tube are respectively of a straight tubes; the lower part of the front main tube is provided with a left main tube and a right main tube; the lower part of the front oblique tube is provided with a left lower main tube and a right lower main tube; an angle formed between the front main tube and the horizontal line is 24DEG; an angle formed between the front oblique tube and the plumb line is 17DEG; and an angle formed between the supporting tube and the horizontal line is 12DEG. By optimizing the angle of the tubes surrounding the oil cooling oil pool, the welding difficulty of the oil pool is greatly alleviated, the production working hours of a frame can be reduced, the service life of the frame can be prolonged, and the oil leakage probability of a frame oil cooling system can be reduced.

Owner:力帆科技(集团)股份有限公司

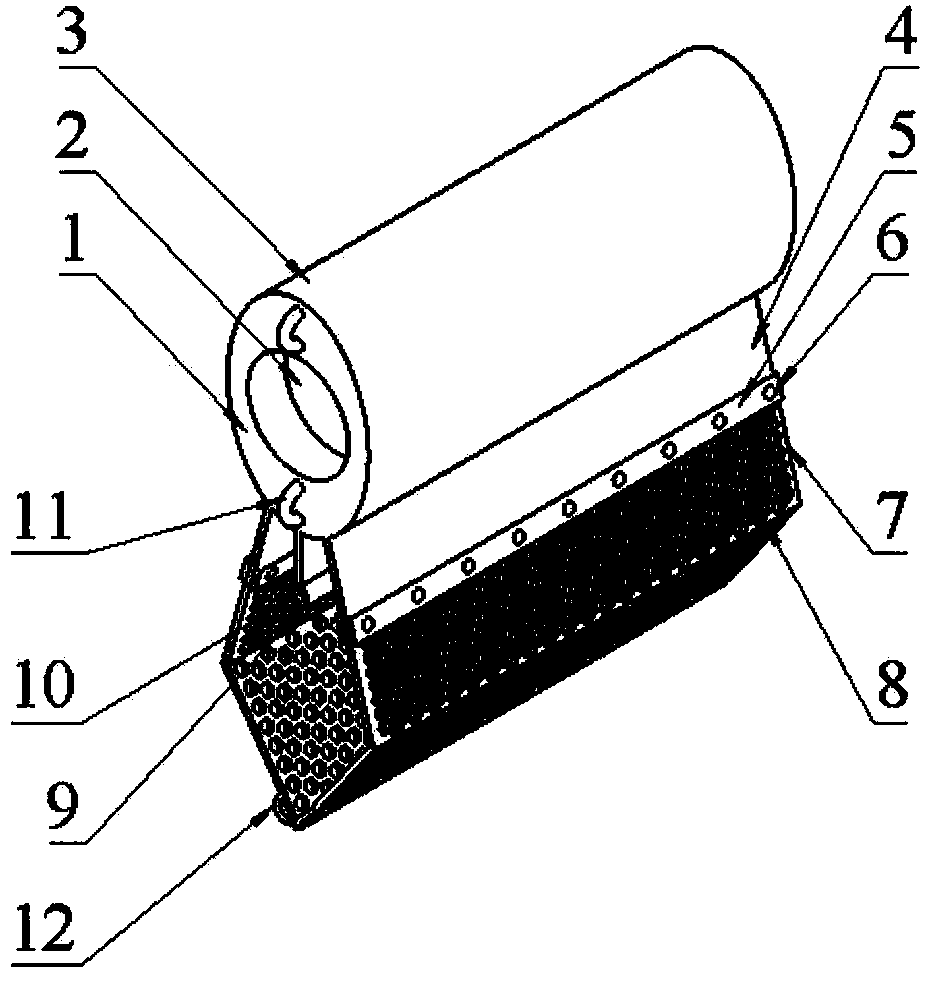

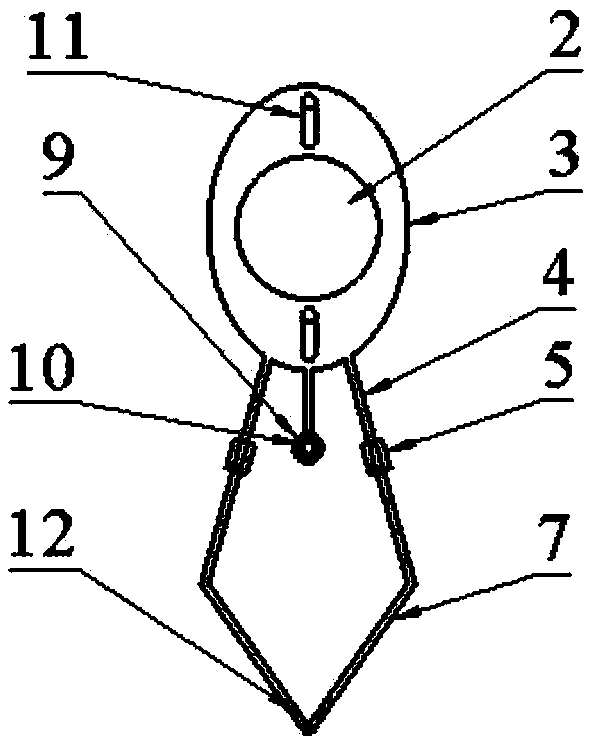

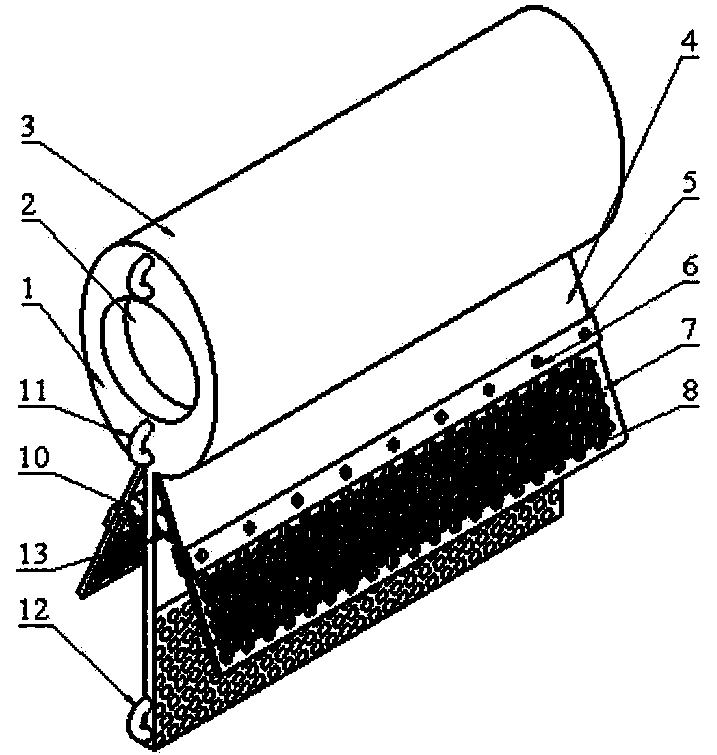

Folding mesh oil containment boom for coping with torrent rivers and laying method of folding mesh oil containment boom

PendingCN111411615AWith innovative benefit effectImprove the stress environment of rapidsWater cleaningGeneral water supply conservationFiberStructural engineering

The invention particularly provides a folding mesh oil containment boom for coping with torrent rivers and a laying method of the folding mesh oil containment boom, and belongs to the field of oil containment booms. The folding mesh oil containment boom aims at solving the problem that under current torrent type water area working condition, a common structure in the oil containment boom application technology fails. The folding mesh oil containment boom comprises components such as floating bodies, floaters, outer wrapping cloth, skirt body connecting cloth, connecting pieces, aluminum alloymesh plates, expansion bags, SAP water-absorbent resin fibers, floating body fixing anchor seats and mesh fixing anchor seats, the skirt body structure of a traditional oil containment boom is partially replaced with the aluminum alloy mesh plates, the water circulation amount is increased, the near-body flow speed of the oil containment boom is reduced, and stress of the oil containment boom is reduced, and therefore, the steady state of the oil containment boom is maintained; the aluminum alloy mesh is automatically expanded through expansion of a water absorption material to form double meshes, so that the spilled oil interception efficiency is improved; an oil absorption felt wrapped by the aluminum alloy mesh can further reduce failure loss caused by spilled oil entrainment. In the background of rapid development of the current petroleum transportation industry, the folding mesh oil containment boom has capacity of coping with the torrent river spilled oil interception, and has high market competitiveness.

Owner:SOUTHWEST PETROLEUM UNIV

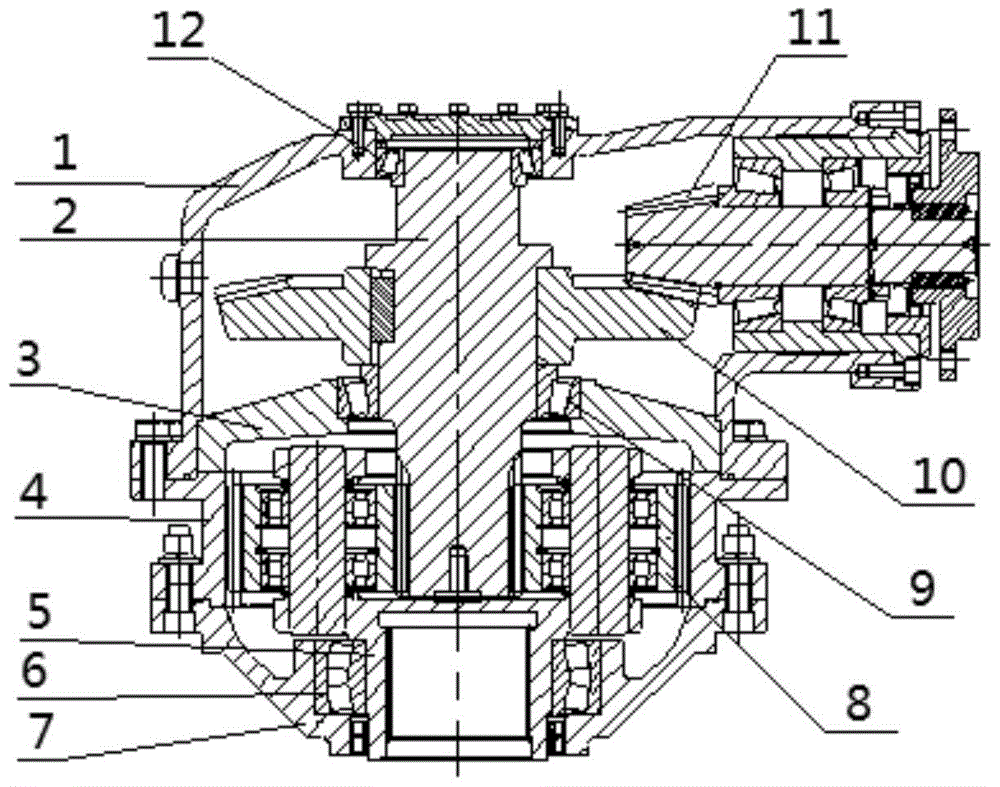

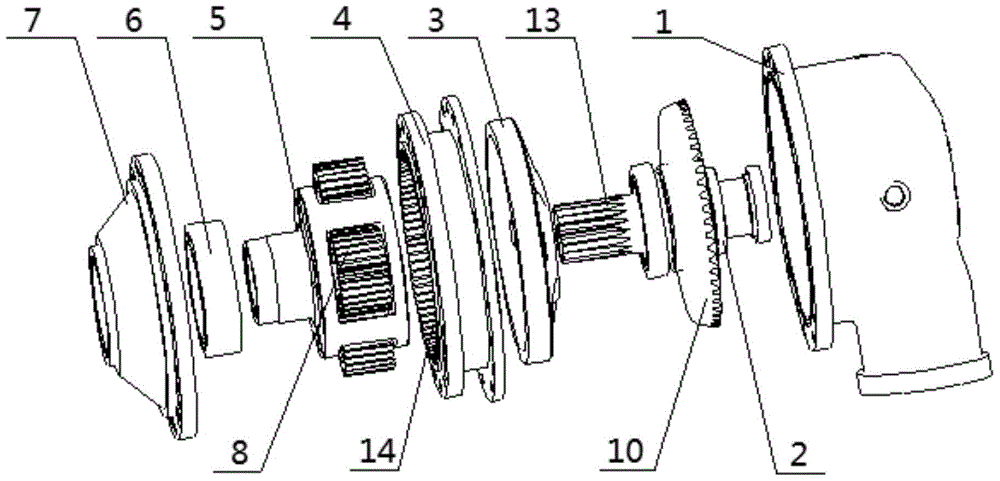

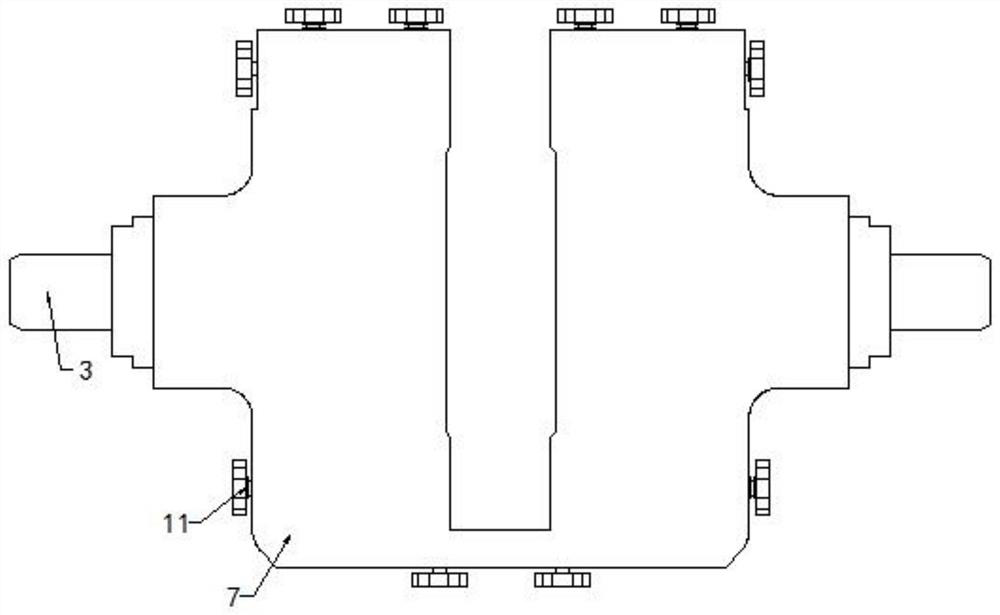

Reducer for concrete mixer

ActiveCN103591222BUniform loadReduce in quantityGear vibration/noise dampingToothed gearingsRadial stressReducer

The invention relates to a speed reducer for a concrete mixing main machine. The speed reducer comprises an upper casing, a lower casing, a planet carrier assembly, an inner gear and a gear shaft, wherein teeth are arranged at one end of the gear shaft in the peripheral direction, the gear shaft extends into the planet carrier assembly and meshed with all planet gears in the planet carrier assembly, the planet gears of the planet carrier assembly are meshed with the inner gear, the planet carrier assembly is arranged between the upper casing and the lower casing, and the planet carrier assembly is of a single-end floating type supporting structure to achieve transmission. Due to the facts that the planet carrier assembly is of the single-end floating type supporting structure to achieve transmission and the two ends are not supported by a bearing, the coaxiality requirements for bearing holes needn't to be taken into consideration. Thus, the processing efficiency is improved. Meanwhile, the single-end floating type supporting structure can balance load between all planet gears in the planet carrier assembly, the gear side gap between the planet gears and the inner gear can be adjusted by self according to radial stress on the planet gears, the rotation noise is reduced, and the stability and the reliability of transmission are improved.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

Brake return piston device with automatic compensation function

PendingCN114776740APrevent agingRealize processingBrake actuating mechanismsSlack adjustersRubber materialBrake

The invention discloses a brake return piston device with an automatic compensation function. The brake return piston device comprises a piston body, an inlet, a guide rod and a brake caliper body, the piston body is clamped in the brake caliper body in a sliding mode, and an inlet allowing brake fluid to enter is formed in the brake caliper body; the guide rod is clamped on the left side of the interior of the brake caliper body in a sliding manner; the disc spring part is arranged in the brake caliper body, the disc spring part is located between the disc spring adjusting nut and the piston body, and the disc spring adjusting nut is clamped in the brake caliper body in a sliding mode. According to the brake return piston device with the automatic compensation function, the phenomenon that internal parts made of rubber materials are aged is avoided, the effects of automatic clearance compensation and braking are achieved through the arrangement of a disc spring adjusting nut and a disc spring piece, and the brake return piston device with the automatic compensation function can be applied to brakes of different specifications through the arrangement of a rubber taper sleeve. And the internal leakage condition is monitored through the sound box.

Owner:山东云宇制动器股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com