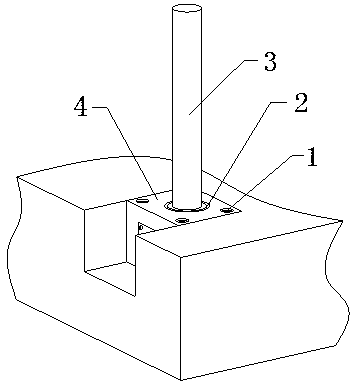

Mold guide structure

A mold guide and guide column technology, applied in the mold field, can solve the problems of polluting the mold, lack of residual oil collection function, etc., and achieve the effect of improving the sealing effect, avoiding random flow, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

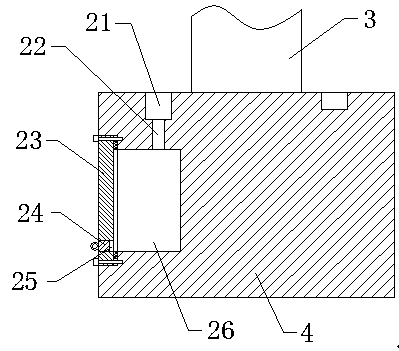

[0019] Specific implementation: when in use, insert hexagon socket bolts in the four sets of countersunk holes 1, and use the socket bolts to connect the base 4 with the mold. When it is necessary to lubricate the guide column 3, apply lubricating oil on the On the guide post 3, when there is more lubricating oil on the guide post 3, the lubricating oil flows down along the guide post 3 under its own gravity, and then flows into the annular groove 21, because the inner lower end surface of the annular groove 21 is high on the right and low on the left. The inclined surface, so the lubricating oil flowing into the annular groove 21 is collected on the left side of the annular groove 21, and then the lubricating oil flows into the groove 26 through the oil leakage port 22, because a cover plate 23 is installed on the left side of the groove 26, and the cover plate A sealing ring is installed on the right end of 23, so the lubricating oil will not flow out from the gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com