Criss-crossed roller bearing with novel sealing structure

A technology of cross and sealing structure, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems that the cross rollers cannot be fully and effectively lubricated, and the oil leakage rate is high, so as to reduce the sealing pressure and ensure Sufficient lubrication and the effect of reducing oil leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

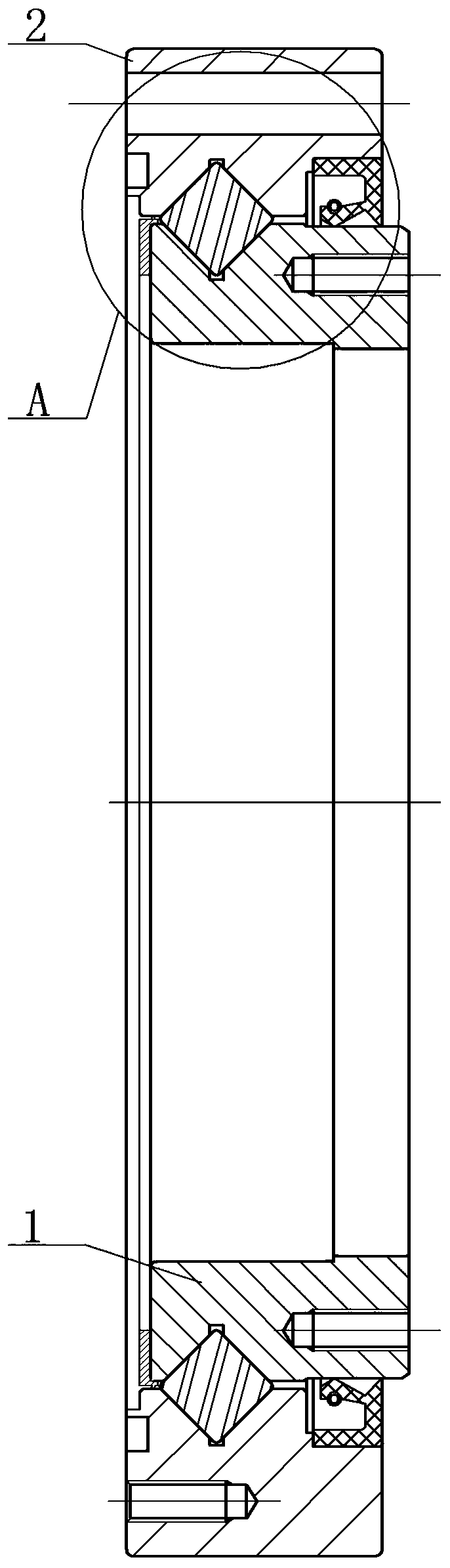

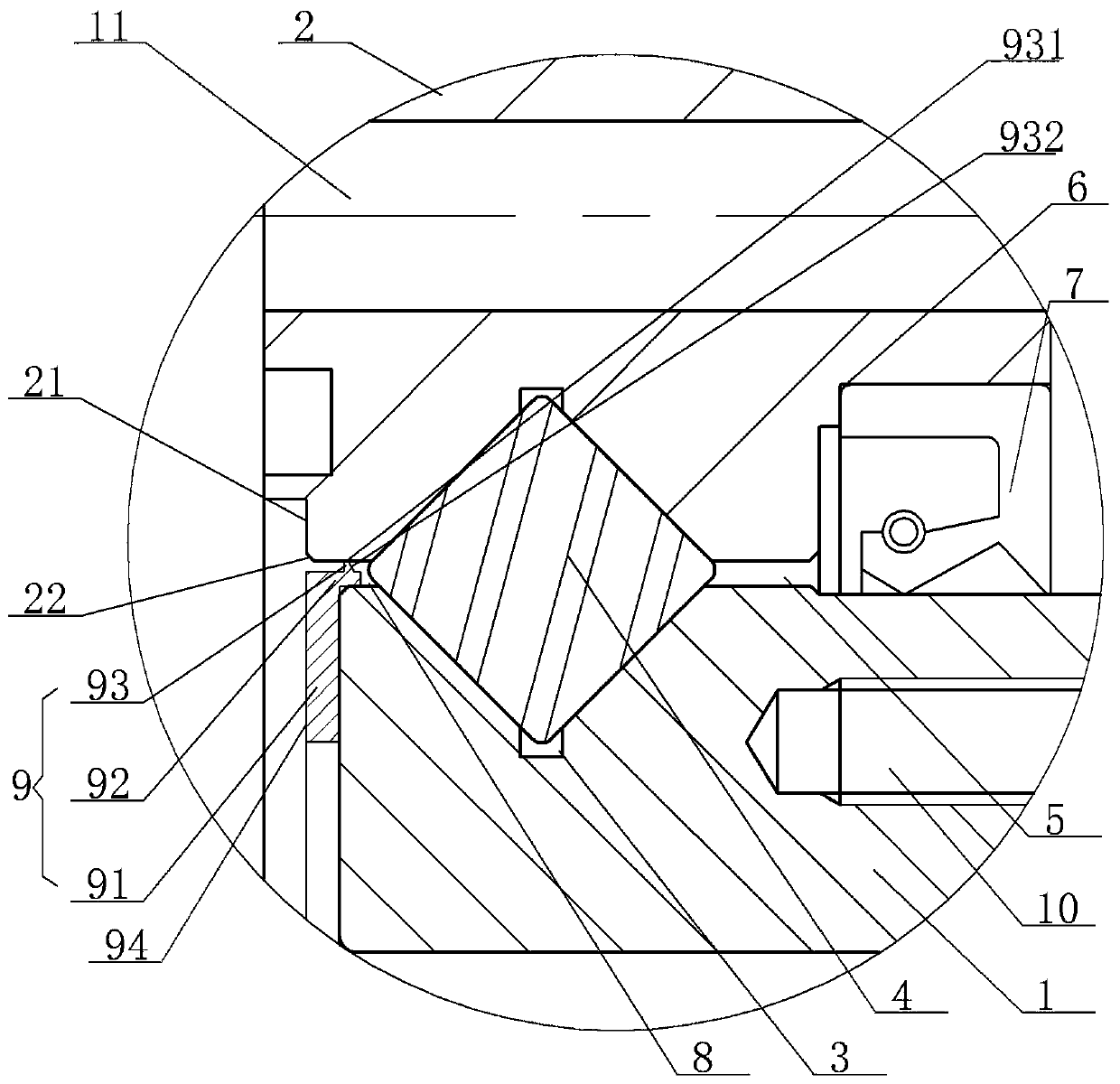

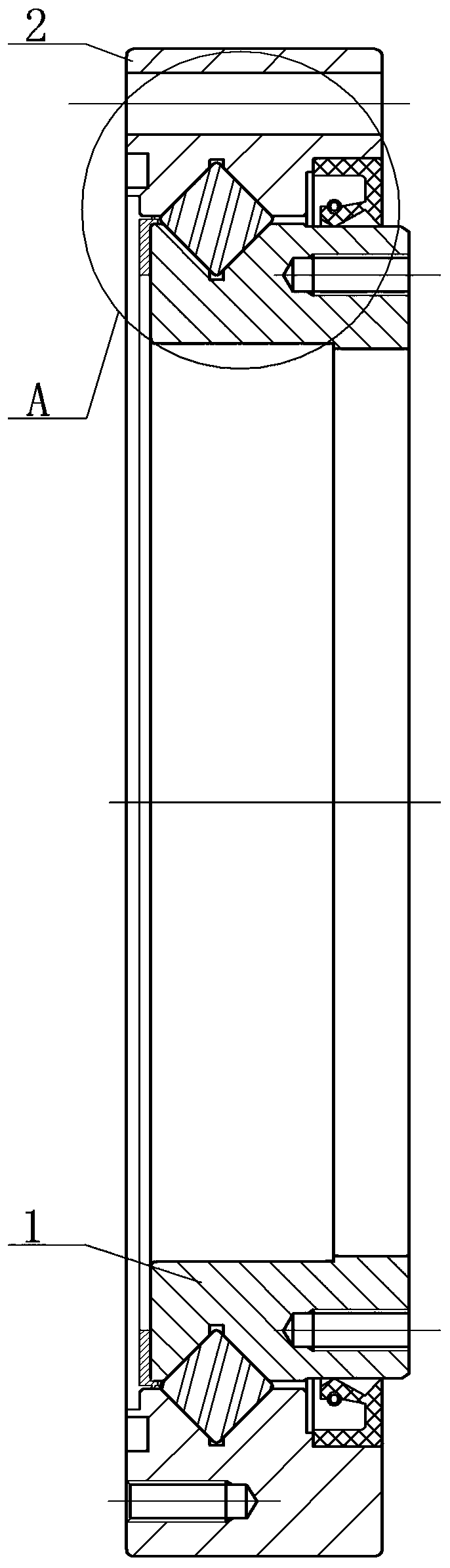

[0018] A new type of sealed structure crossed roller bearing, see figure 1 , figure 2 , which includes a bearing inner ring 1, a bearing outer ring 2, a roller installation ring groove 3 is provided at a corresponding thickness position between the outer ring surface of the bearing inner ring 1 and the inner ring surface of the bearing outer ring 2, and the corresponding roller 4 It is arranged in the corresponding roller groove of the roller installation ring groove 3 in the form of a cross, and the outer end of the bearing inner ring 1 and bearing outer ring 2 in the thickness direction is connected to the ring groove gap 5. The outer end is provided with a skeleton oil seal installation stop 6. The skeleton oil seal 7 is installed on the skeleton oil seal installation notch 6. The skeleton oil seal 7 seals the lubricating oil on the corresponding end face, and the inner end of the bearing inner ring 1 and bearing outer ring 2 in the thickness direction connects the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com