Valve rod sealing structure and eccentric semi-ball valve

A sealing structure and valve stem technology, which is applied to the valve shell structure, shaft seal, valve details, etc., can solve the problems of valve stem wear, medium particles are isolated between the valve stem and the valve body, and achieve the effect of enhancing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

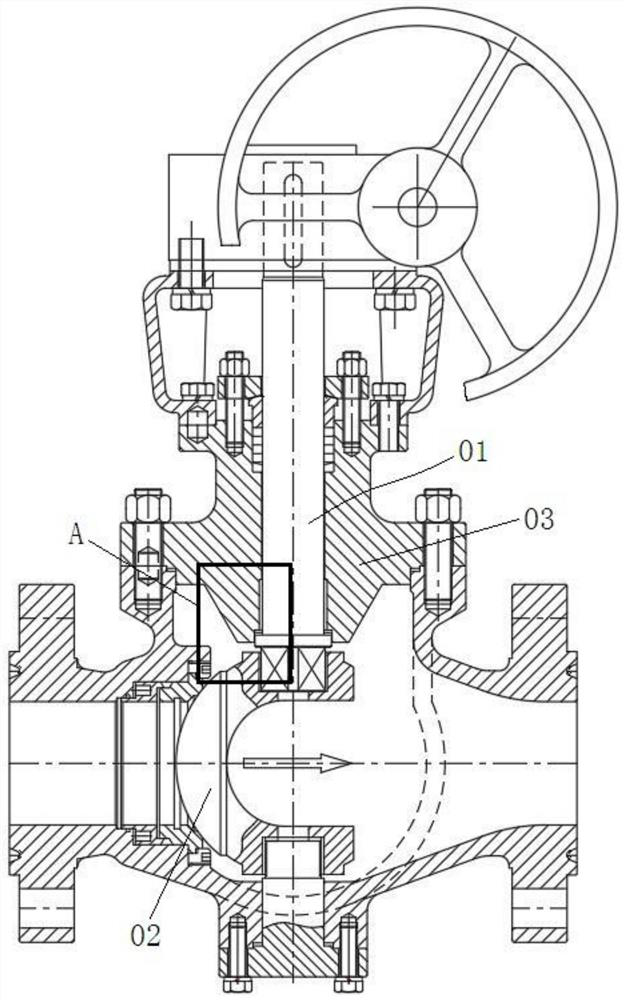

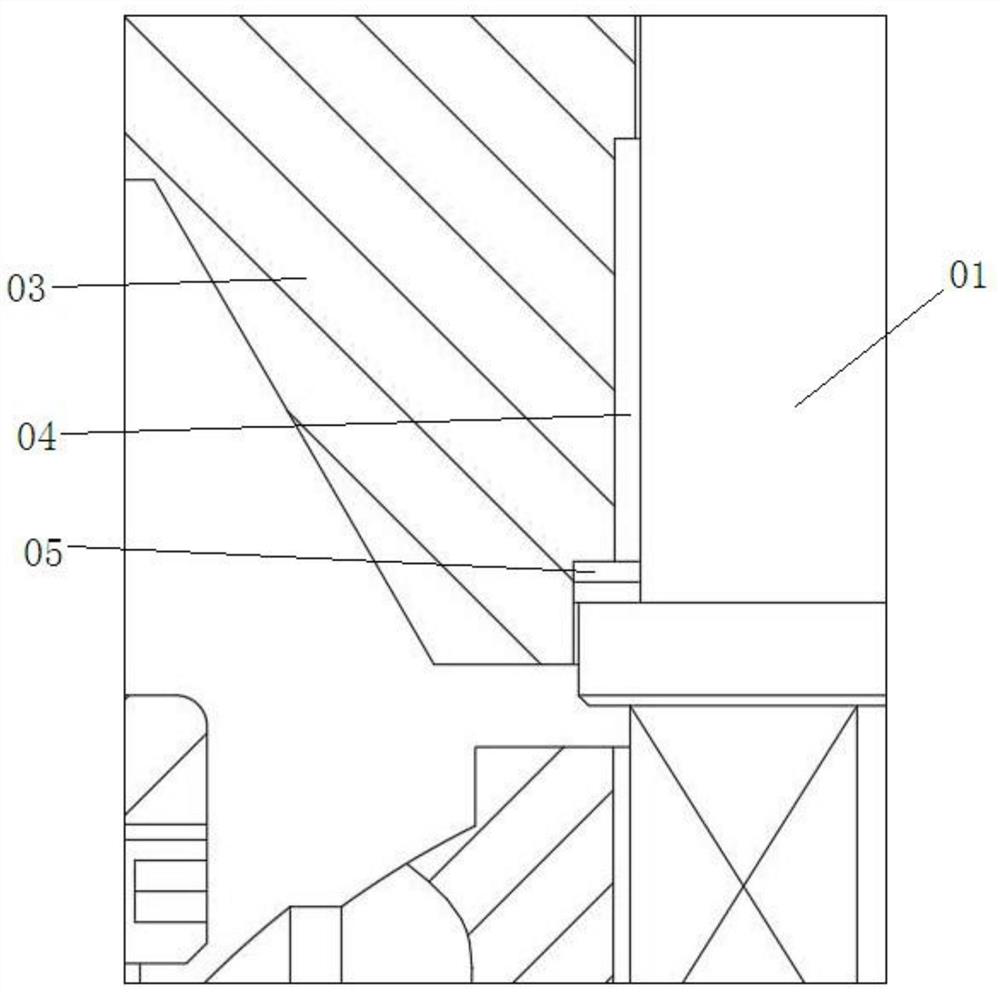

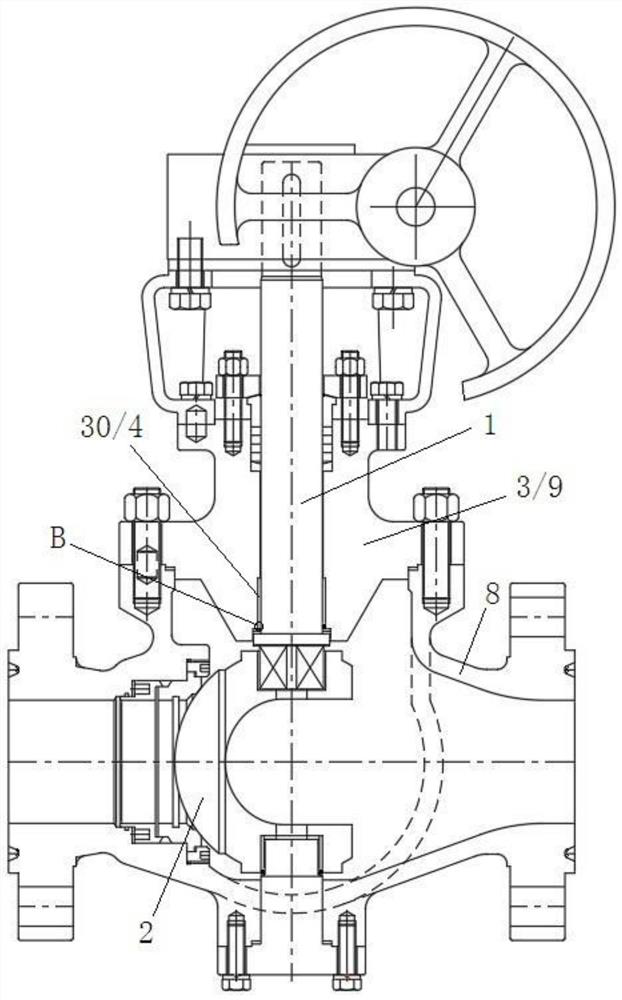

[0038] This embodiment provides a valve stem sealing structure, such as Figure 3-4 As shown, it includes: a lubricating bearing 4, an elastic seal 5, a pressing member 6 and a fixing member 7. The above-mentioned lubricating bearing 4, elastic sealing member 5, pressing member 6 and fixing member 7 are installed on the valve stem 1 close to the valve ball 2 The middle position between a section of one end and the support structure 3 on which the valve stem 1 is installed is used to prevent medium particles from entering between the valve stem 1 and the support structure 3 from this position, thereby preventing the medium particles from affecting the valve stem 1 and the support structure 3 Wear during rotation.

[0039] Specifically, the function of the lubricating bearing 4 is to reduce the rotational friction force, and the elastic sealing member 5 is sleeved on the valve stem 1 with an inverted U-shaped opening facing outward under the action of the fixing member 7 and the...

Embodiment 2

[0050] This embodiment provides an eccentric hemispherical valve, such as Figure 3-4 As shown, it includes: a valve body 8, a valve ball 2 installed inside the valve body 8, a valve stem 1 and a driving device; the valve stem 1 rotatably passes through the valve cover 9 and is fixedly connected to the valve ball 2; the valve ball 2 It is an eccentric hemisphere; it also includes a valve stem sealing structure installed on a section of the valve stem 1 close to the valve ball 2 and the middle part of the valve cover 9 for installing the section of valve stem 1; the valve stem sealing structure is an embodiment Stem seal structure described in 1.

[0051] Due to the adoption of the above-mentioned stem sealing structure, the ball valve of this embodiment naturally has all the advantages brought by the adoption of the above-mentioned structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com