High pressure self-compensation mechanism of water injection well pulse generator

A pulse generator and self-compensation technology, applied in the field of pressure compensation, can solve problems such as internal and external pressure imbalance, bearing impact, small space, etc., and achieve the effect of improving work reliability and reducing the pressure bearing of the sealing ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

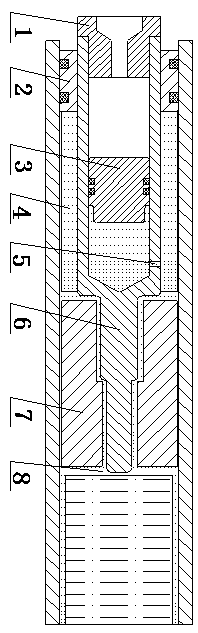

[0022] as attached figure 1 As shown, the high-pressure self-compensation mechanism of the pulse generator of the water injection well includes a cavity, an intermediate body, and a plugging body. The cavity is a sealed oil cavity 8, and the intermediate body is a hollow drive spindle 6. The plugging body It is a floating piston 3, the lower end of the hollow drive spindle 6 is immersed in the seal oil cavity, and a pressure self-compensating channel 5 is left in the radial direction to communicate with the seal oil cavity 8, and the cavity of the seal oil cavity 8 is sealed oil cavity, the center of the hollow drive spindle 6 is provided with a piston cavity, and a floating piston 3 is installed in the piston cavity, and the hollow drive spindle is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com