Glue mixing accelerator

An accelerator and glue mixing technology, applied in mixers, mixing methods, liquid and solid mixing, etc., can solve the problems of high glue supply pressure, easy blockage of glue guns, and small glue output, so as to improve flow rate and increase output. The effect of improving glue flow rate and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

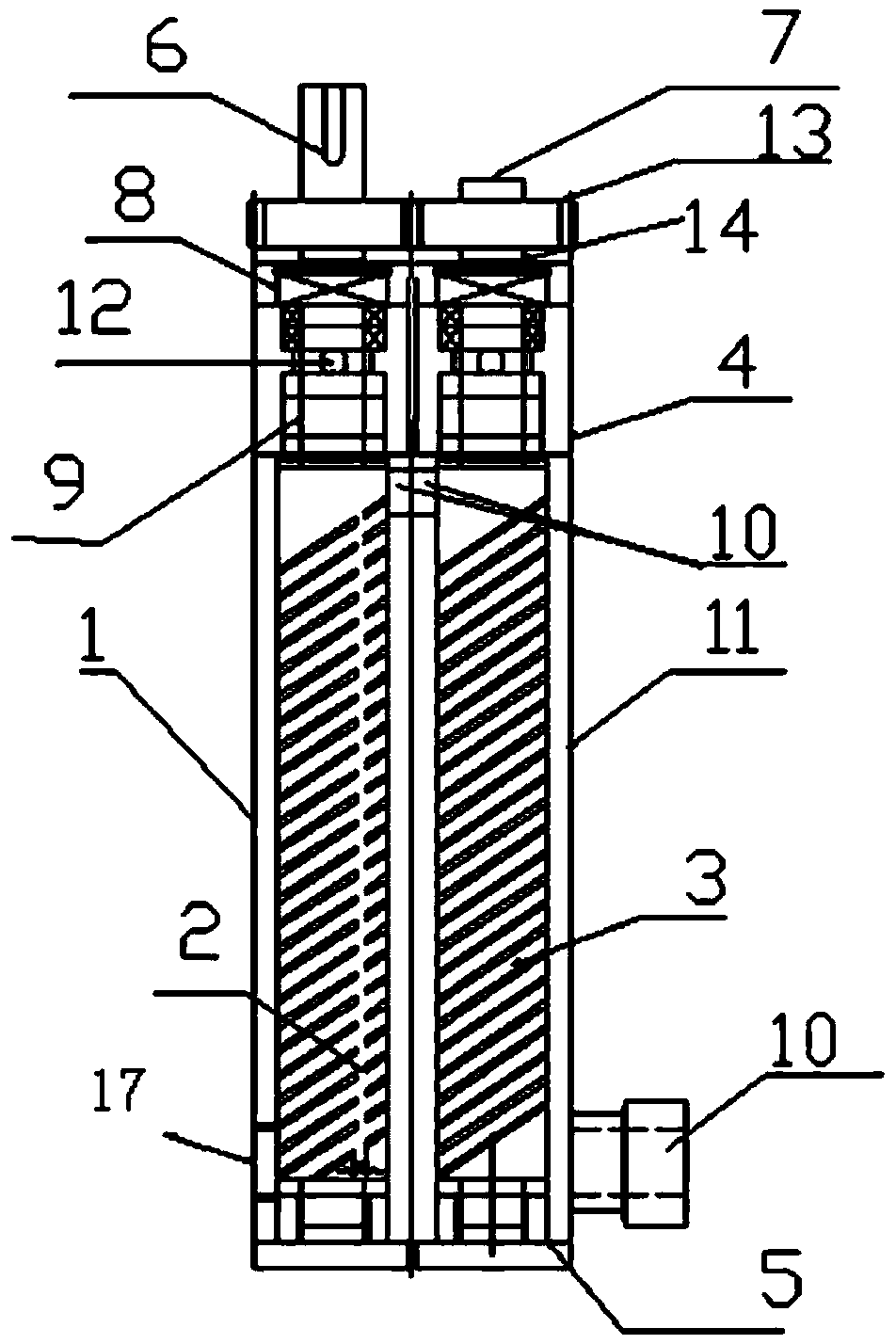

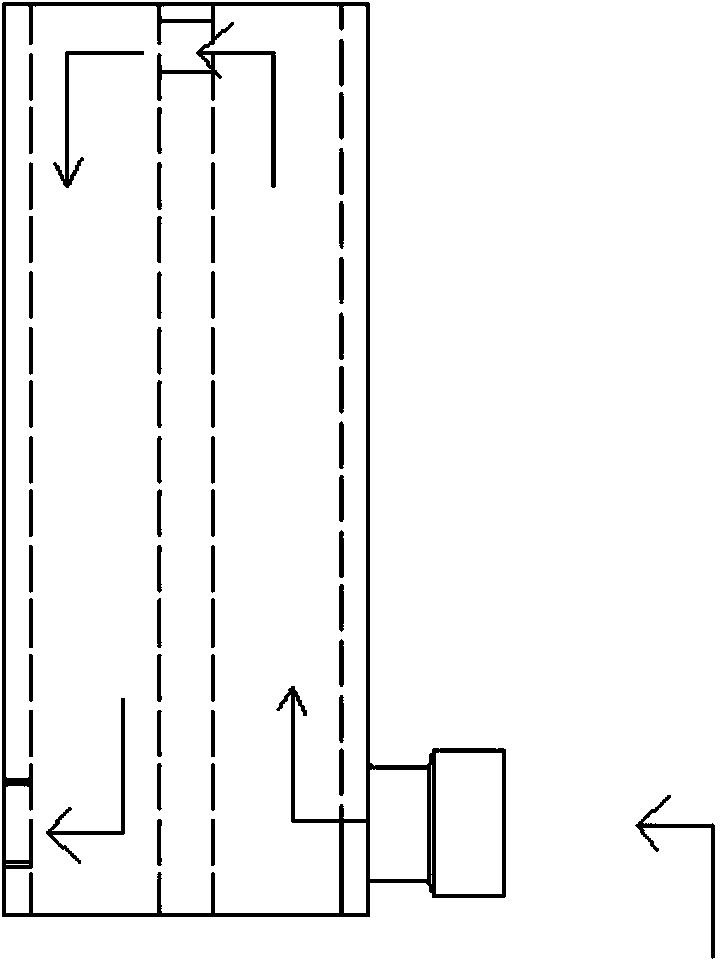

[0034] Such as Figures 1 to 3 As shown, the rubber mixing accelerator of the present invention includes two cavities arranged side by side, namely the first cavity 1 and the second cavity 11, and the upper and lower ends of the first cavity 1 and the second cavity 11 are respectively provided with upper and lower Cover 4 and base 5; the upper side of the first cavity 1 and the second cavity 11 are connected, the bottom side of the first cavity 1 is provided with an outlet 17, and the bottom side of the second cavity is provided with an inlet 10 , A, B component glue enters the second cavity 11 from the inlet at the same time according to the ratio, and then flows out from the outlet of the first cavity 1 to reach the working point;

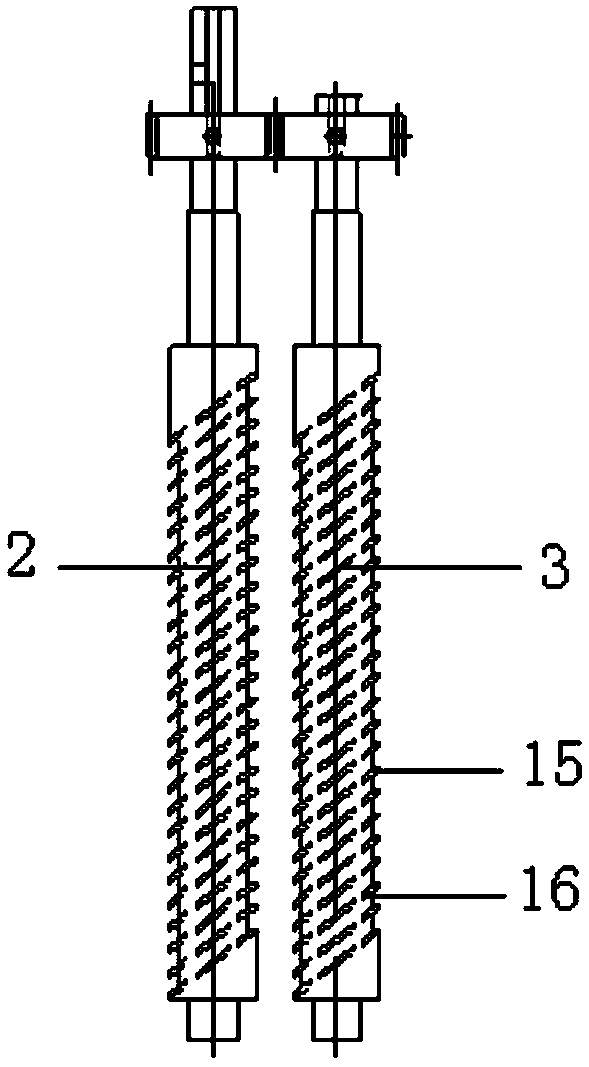

[0035] The first screw-type rubber mixing rod 2 and the second screw-type rubber mixing rod 3 are respectively installed in the first cavity 1 and the second cavity 11, the first screw-type rubber mixing rod 2 is driven by a driving device, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com