Waterproof plug

A waterproof plug and inner peripheral technology, applied in the direction of electrical equipment casing/cabinet/drawer, electrical components, base/housing, etc., can solve problems such as gaps and water resistance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] An embodiment of the present invention will hereinafter be described in detail with reference to the accompanying drawings.

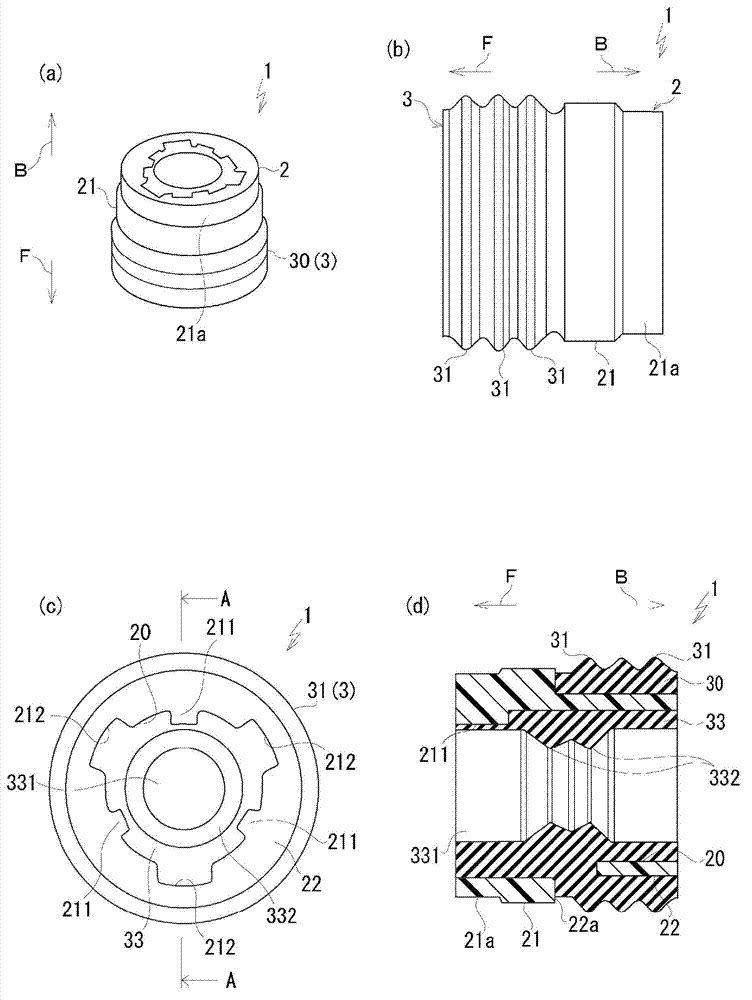

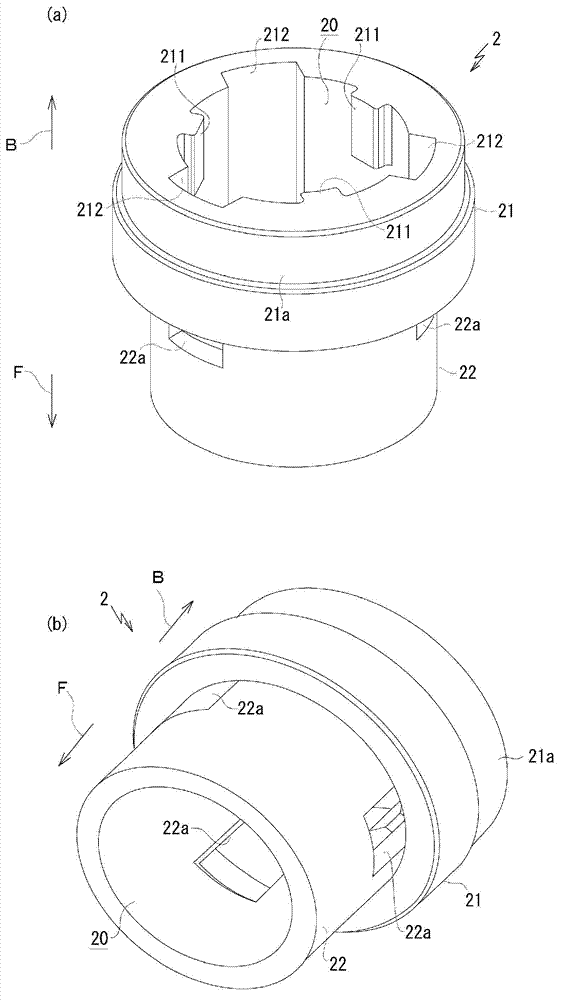

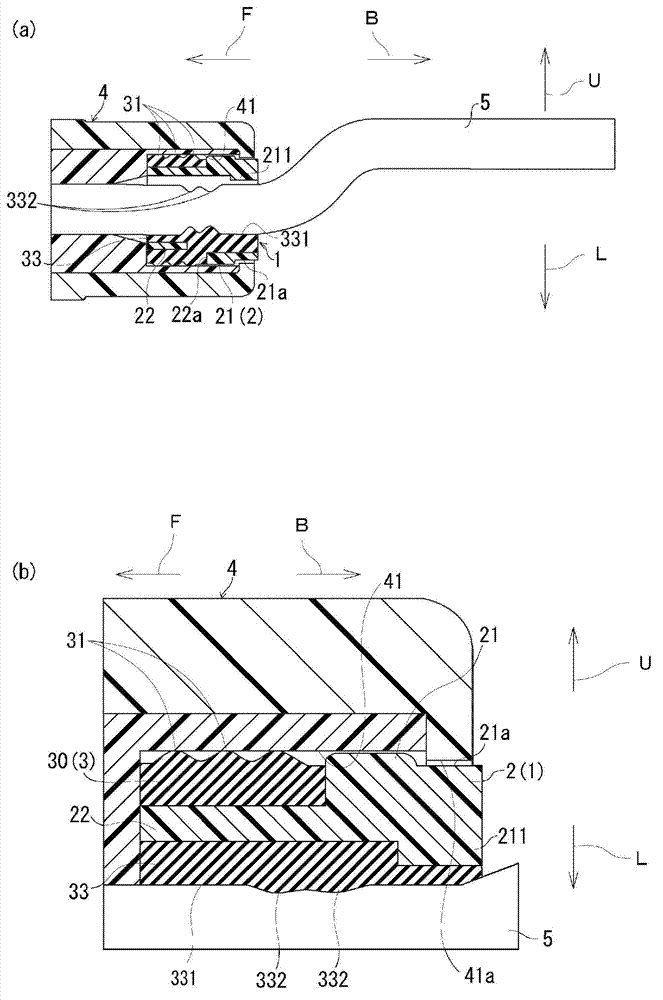

[0039] figure 1 (a) to 1(d) are views showing the waterproof plug 1 of the present embodiment. figure 2 (a) and 2(b) are perspective views showing the resin member 2 of the waterproof plug 1 . image 3 (a) and 3(b) are views showing a sealing structure using the cavity 41 of the waterproof plug 1 . Further, arrows F and B in the figure show the front and rear directions of the waterproof plug 1 . Further, arrows U and L in the figure show the upward and downward directions of the waterproof plug 1 .

[0040] figure 1 The waterproof plug 1 shown in (a) to 1(d) is a plug that is attached to a cavity 41 of a connector housing or the like (see image 3 (a) and image 3 (b)) and seal the gap between the cavity 41 and the electric wire 5 pulled out from the cavity 41 . The waterproof plug 1 includes a cylindrical resin member 2 and a sealing po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com