Numerical control rack gear milling machine

A technology of gear milling machine and rack, which is applied in the field of CNC rack gear milling machine to achieve the effect of reducing cost, improving competitiveness and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

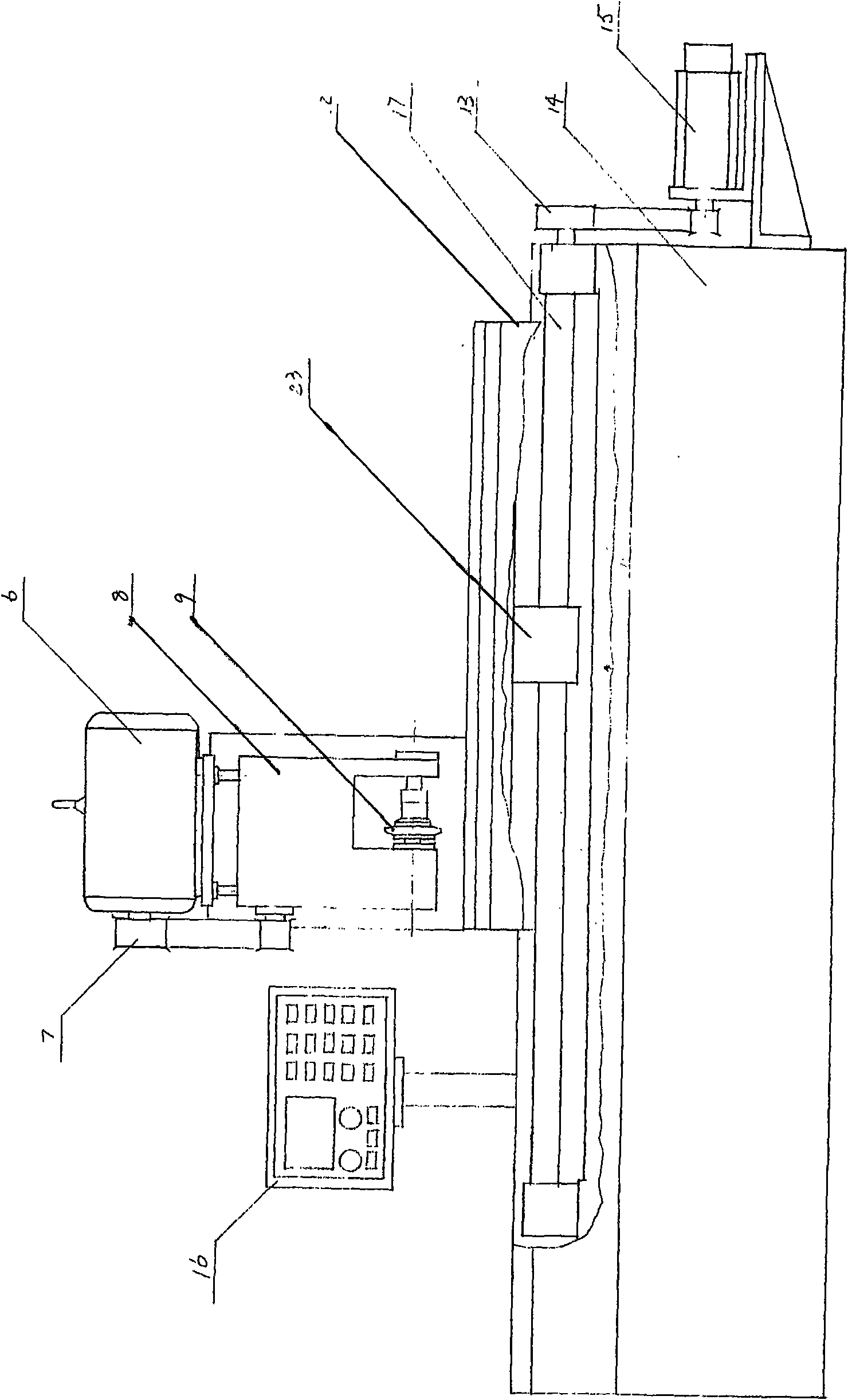

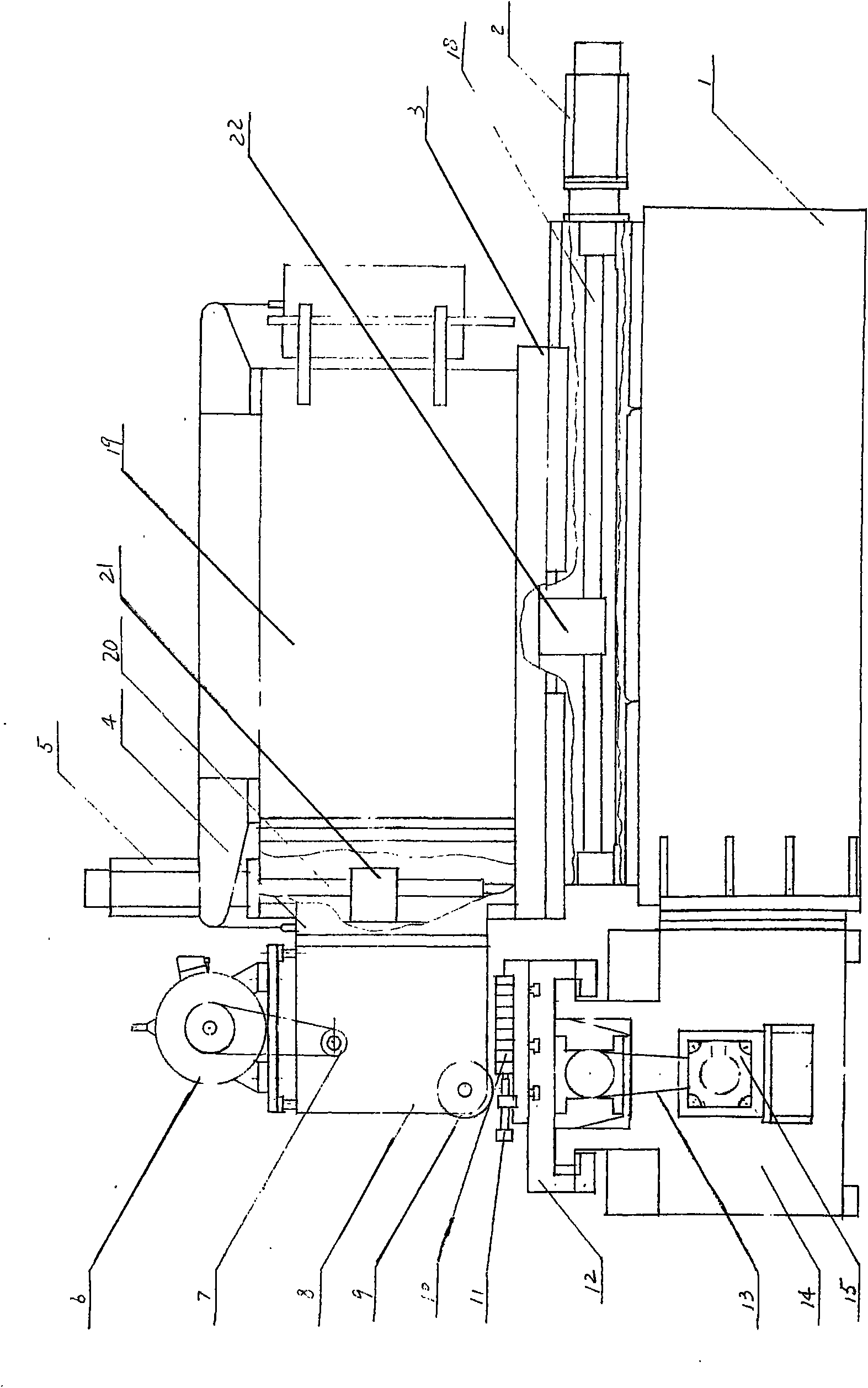

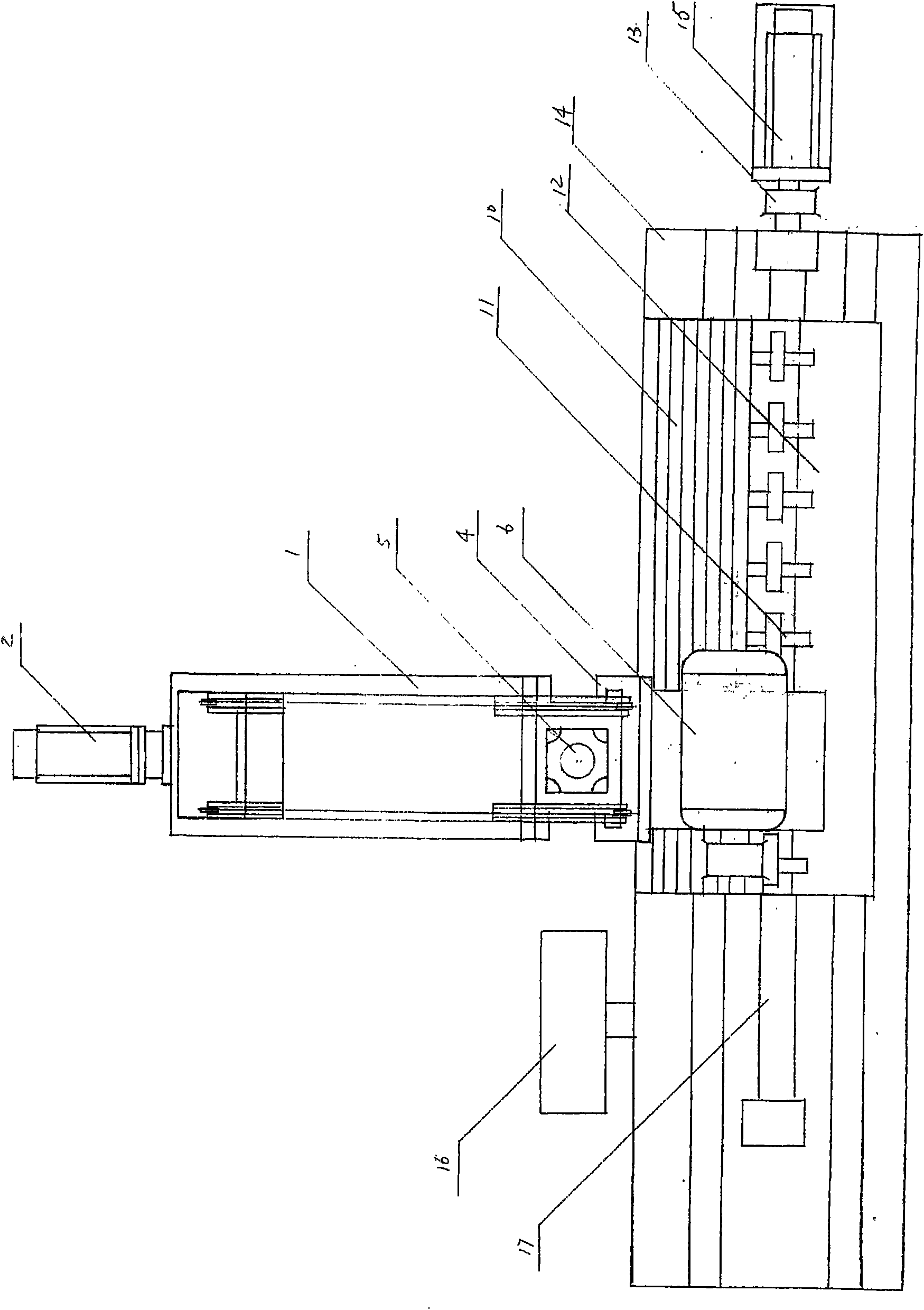

[0013] The present invention is described in conjunction with accompanying drawing.

[0014] A CNC rack gear milling machine, including a Z-direction bed 1, a Z-direction servo motor 2, a Z-direction carriage 3, a Y-direction small carriage 4, a Y-direction servo motor 5, a frequency conversion speed regulation motor 6, and a synchronous toothed belt Wheel 7, cutter shaft box 8, milling cutter 9, compression screw 11, X-direction large carriage 12, X-direction synchronous rack pulley 13, X-direction bed 14, X-direction servo motor 15, CNC system 16, X direction ball screw 17, Z direction ball screw 18, support 19, Y direction ball screw 20, Y direction ball screw nut 21, Y direction ball screw nut 22 and X direction ball screw nut 23 nuts.

[0015] The Z-direction bed 1 and the X-direction bed 14 are spliced into a T-shape, and the X-direction large carriage 12 is movably installed above the X-direction bed 14 (the X-direction large carriage 12 can be indexed and moved left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com