Steel ball roller indexing apparatus

An indexing device and steel ball technology, which is applied in metal processing equipment, precision positioning equipment, metal processing machinery parts, etc., can solve problems such as unstable inherent characteristics and affecting the application of steel ball indexing discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

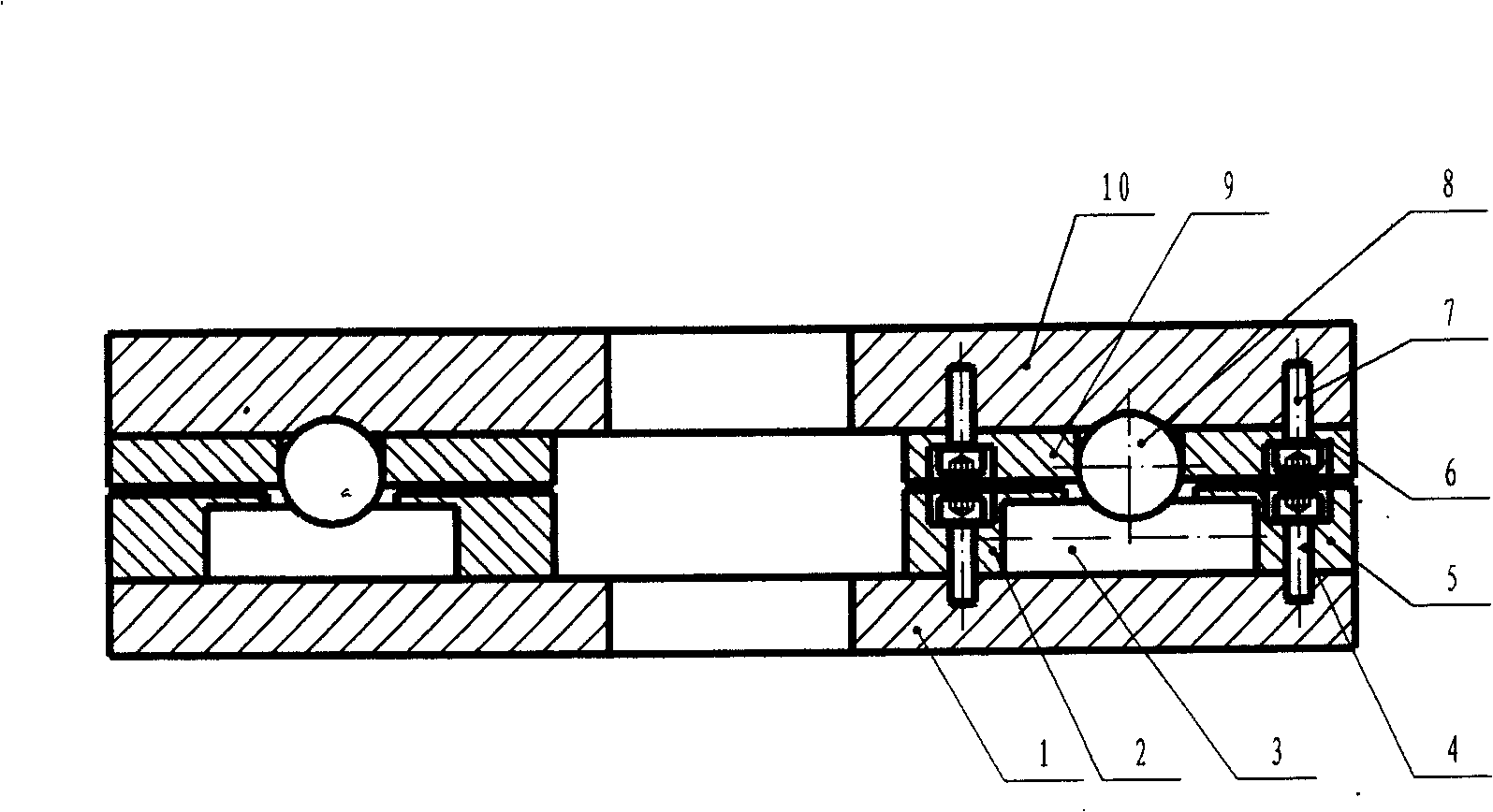

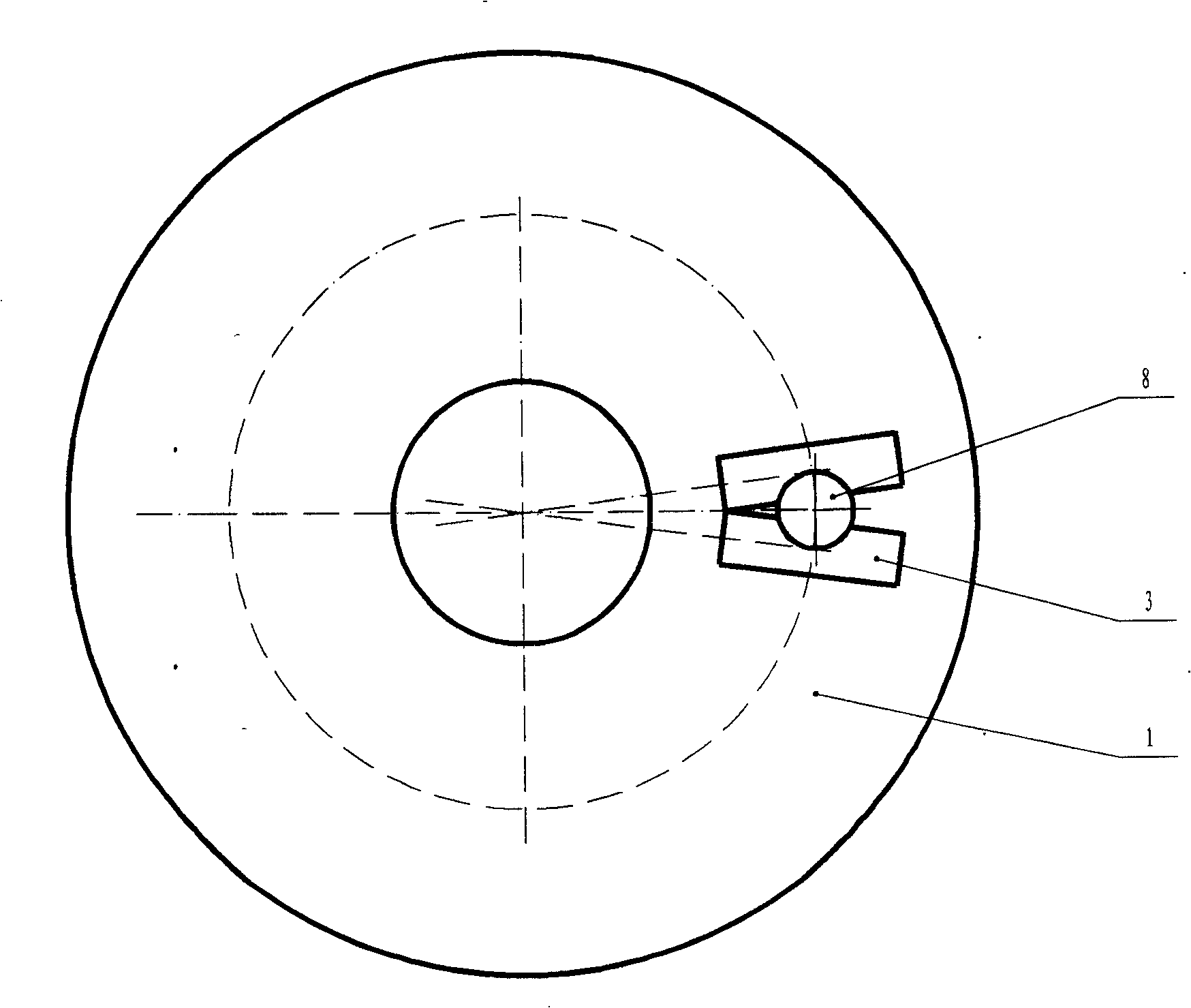

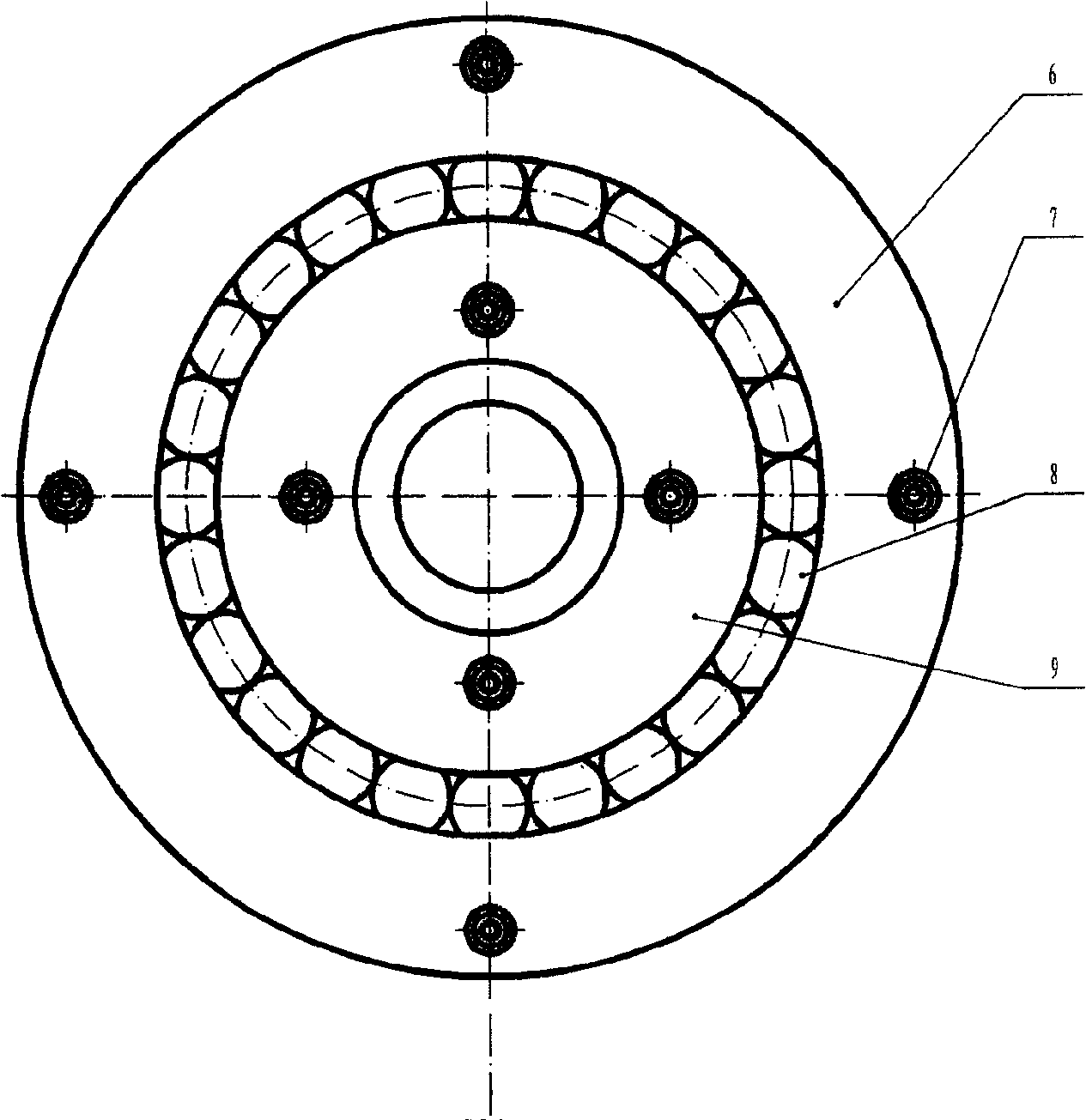

[0016] figure 1 , figure 2 , image 3 and Figure 4 In the shown structure, the upper disc body 10 has a ring-shaped groove, on which a group of steel balls 8 with the same diameter are arranged, and are fixed in the ring-shaped groove by the steel ball outer fixing ring 9 and the steel ball inner fixing ring 6. In the group of steel balls, the position of one steel ball is fixed on the disc and cannot move on the annular groove, while the rest of the steel balls are allowed to move slightly on the annular groove. A group of cylindrical rollers 3 arranged circularly and radially around the lower plate body 1 are fixed on the lower plate by roller outer fixing rings 5 and roller inner fixing rings 2. Among the group of cylindrical rollers are The position of one cylindrical roller is fixed on the disc and cannot be moved, while the remaining cylindrical rollers are allowed to move slightly. A steel ball on the upper plate is in contact with two cylindrical rollers on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com