Multifunctional servo driven glass press with gears

A servo-driven, multi-functional technology, applied in glass pressing, glass forming, glass manufacturing equipment, etc., can solve the problem of non-adjustable indexing speed and number of rotating stations, heavy labor, inaccurate indexing of glass presses, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

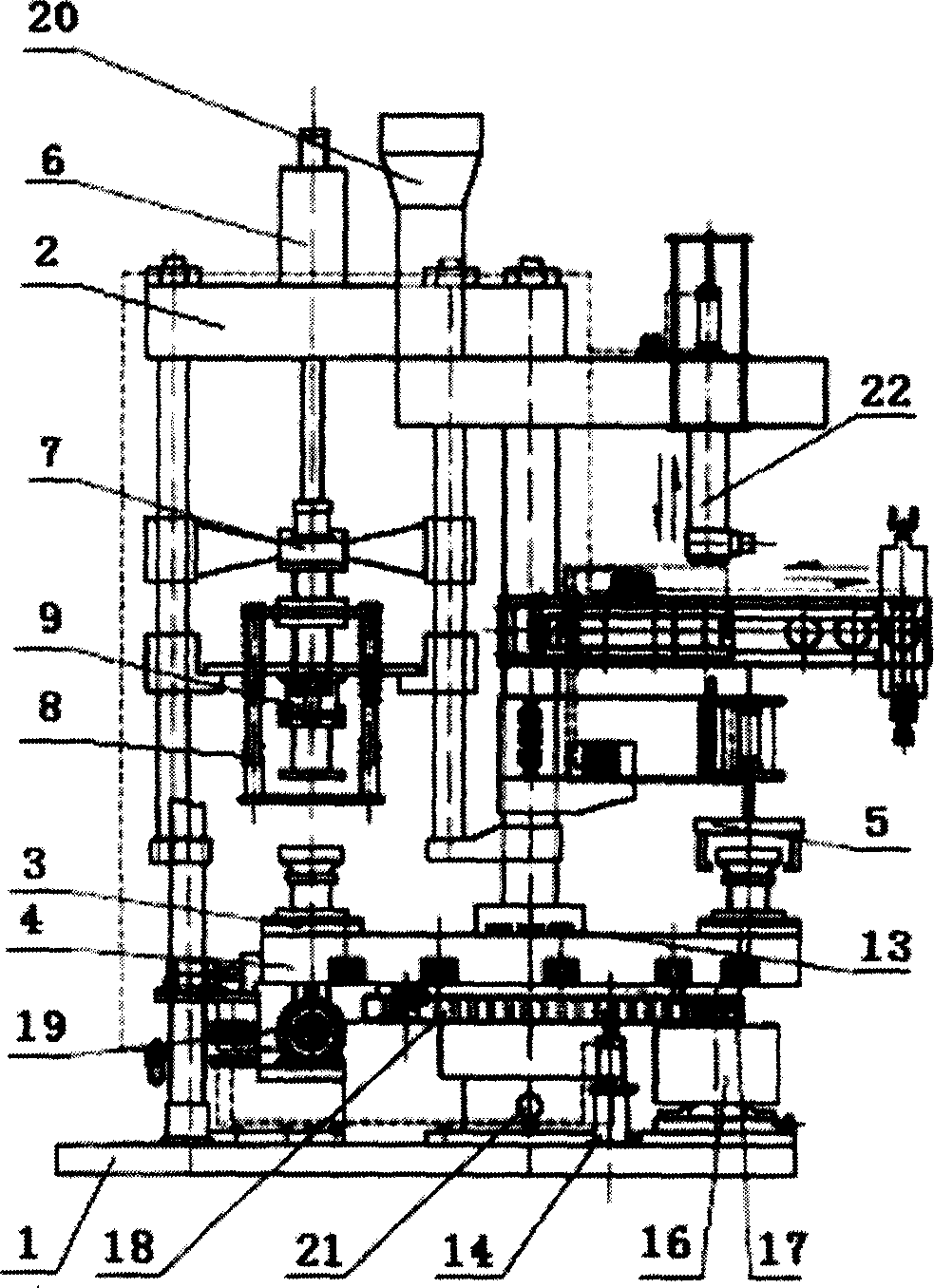

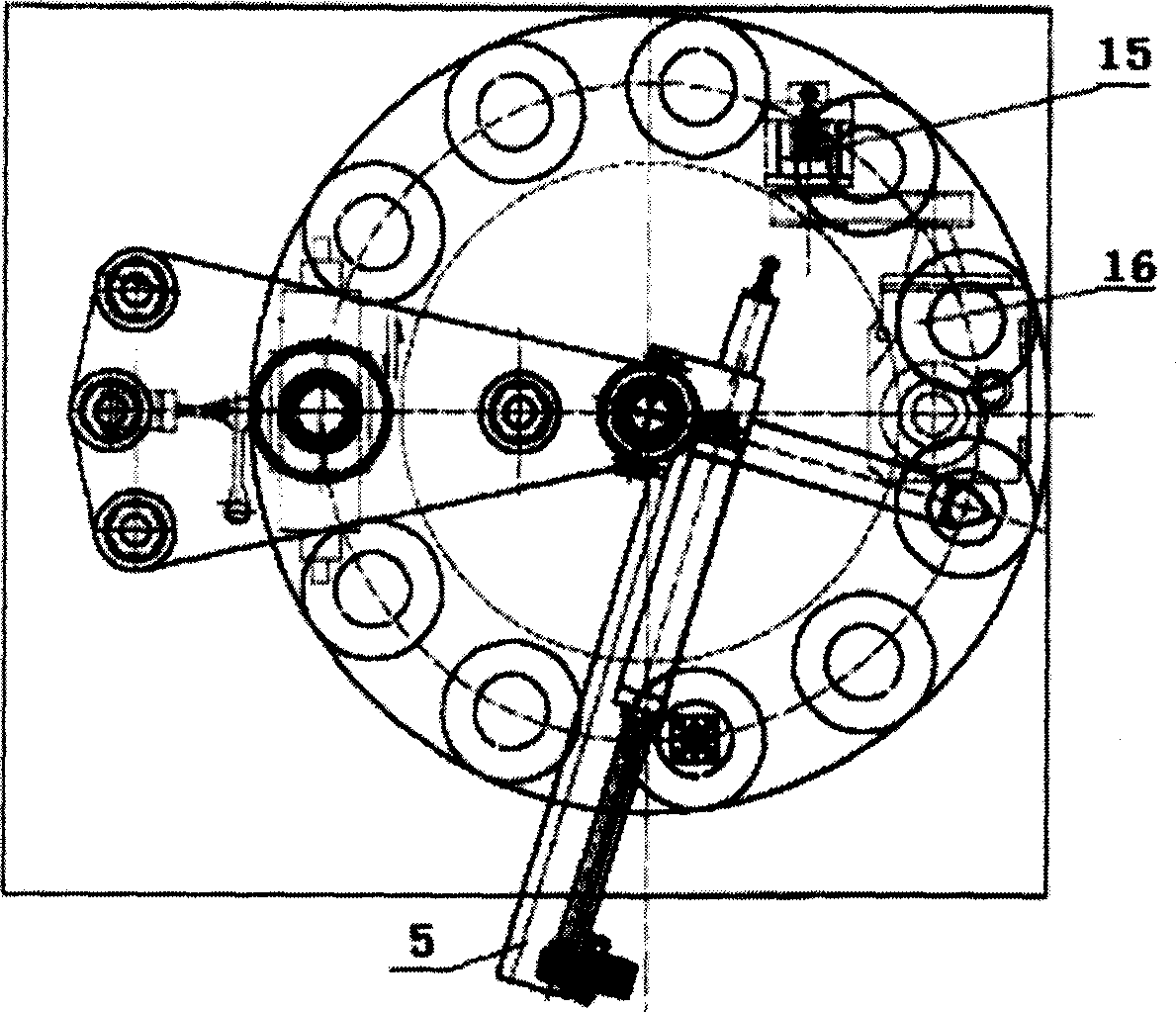

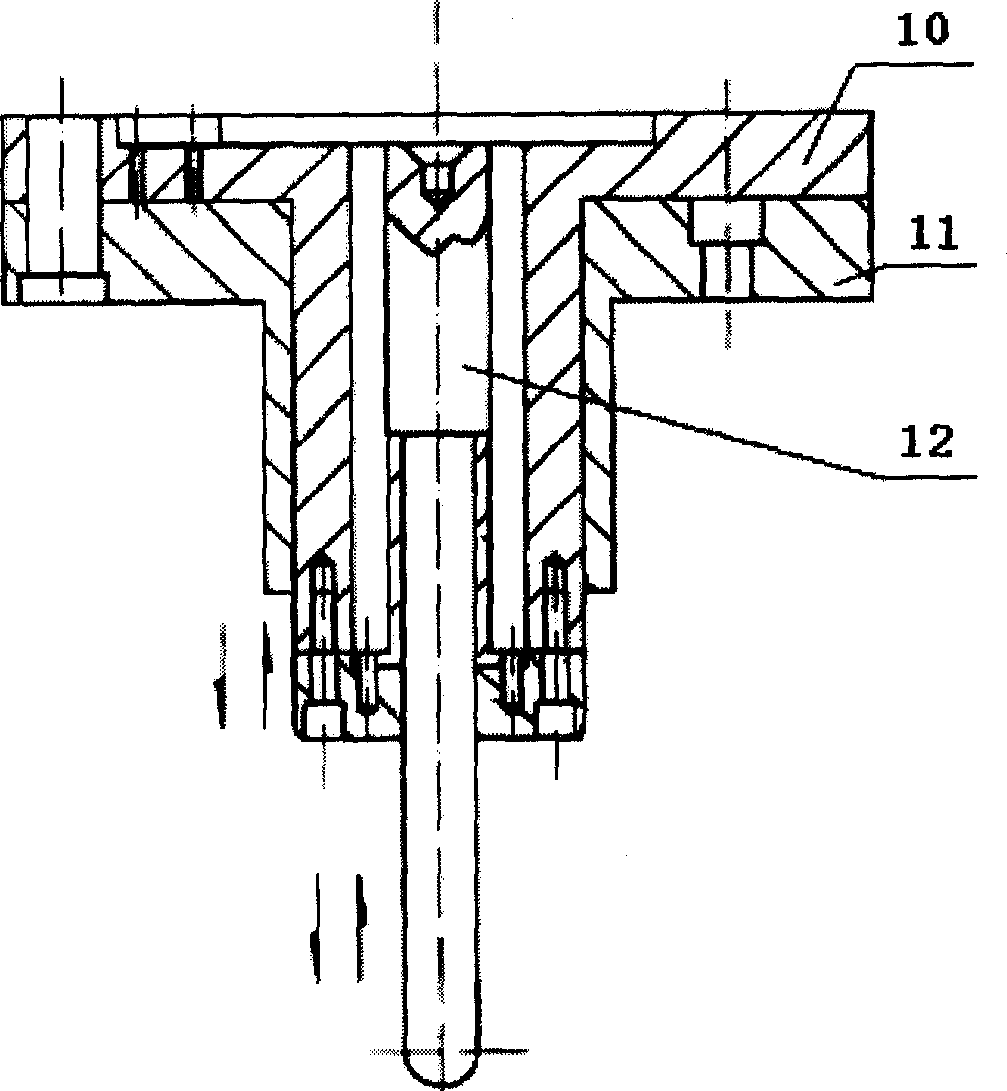

[0009] Such as figure 1 , figure 2 and image 3 As shown, a servo-driven gear multifunctional glass press of the present invention is composed of a base 1, an upper support frame 2, a stamping device, a mold base 3, a large plate 4, a mobile manipulator 5, a cooling device and a servo transmission device. The stamping device and the mobile manipulator 5 are arranged on the upper support frame 2, the mold base 3 is arranged on the large plate 4, the large plate 4 is arranged on the base 1, and the cooling device is arranged on the upper support frame 2 and the base 1, the stamping device is composed of a stamping cylinder 6, a stamping mechanism 7, a stamping head frame 8 and an automatic positioning device 9, the stamping cylinder 6 is arranged on the upper support frame 2, and the top of the stamping cylinder 6 The rod is connected with the stamping mechanism 7, a sliding column is arranged on both sides of the stamping mechanism 7, the stamping mechanism 7 is slidingly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com