High-precision rotating dividing disc

A technology for indexing discs and rotary discs, applied in precision positioning equipment, metal processing machinery parts, metal processing equipment, etc., can solve problems such as large indexing errors and complex structures, and achieve high indexing accuracy, convenient operation, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

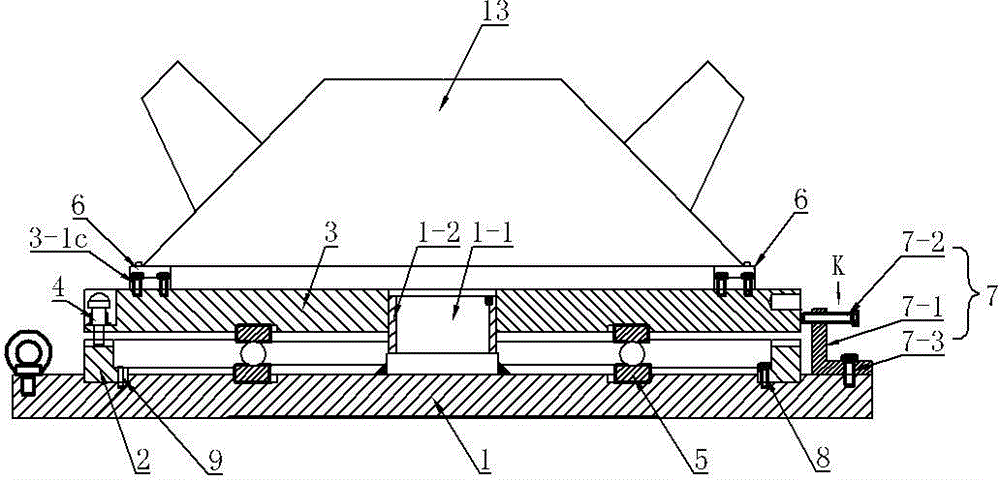

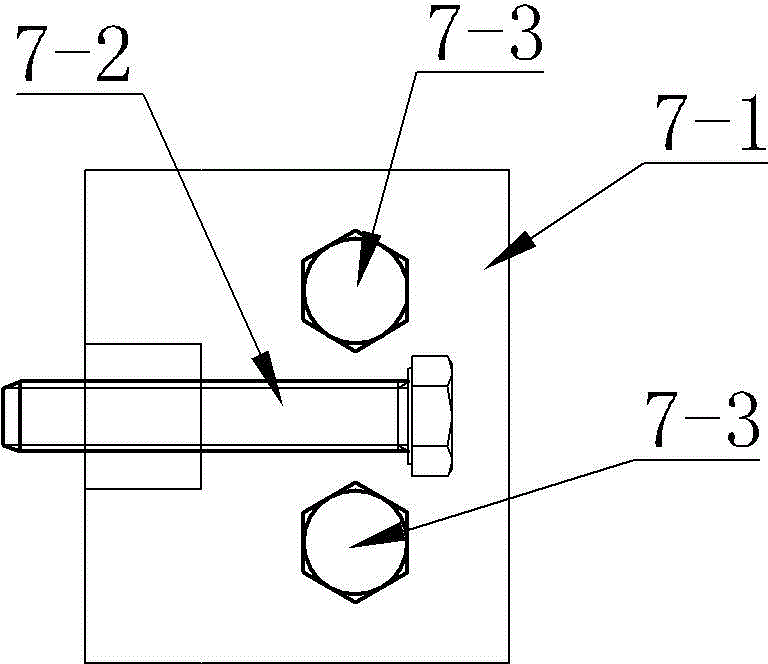

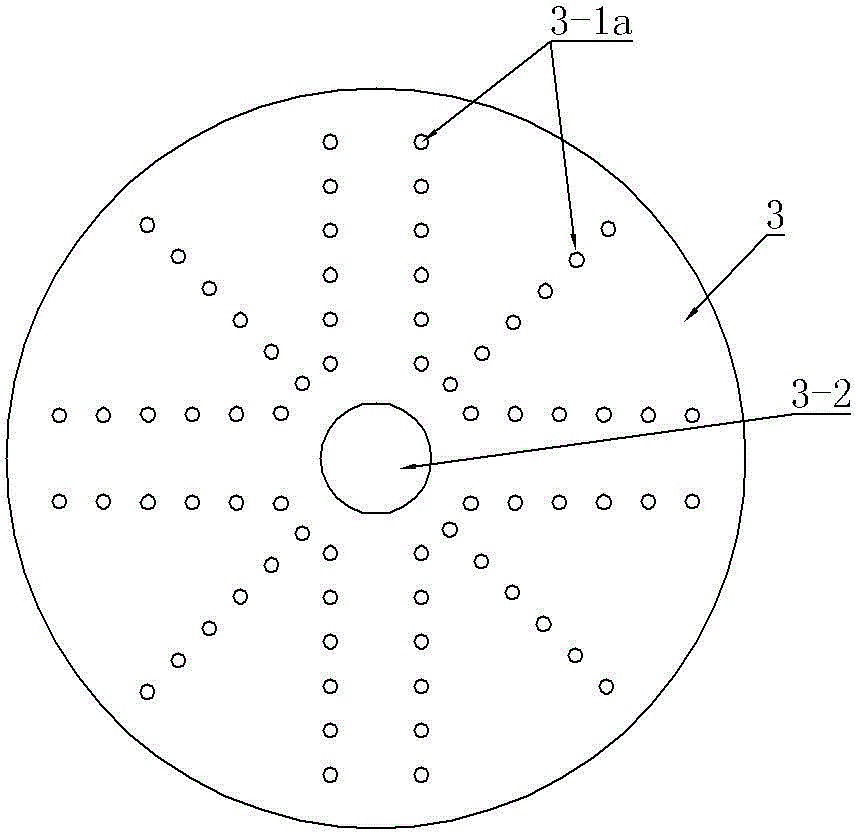

[0027] See figure 1 , the high-precision rotary indexing plate of the present invention includes a base 1, an indexing plate 2, a rotary plate 3 and an indexing pin 4, and the indexing plate 2 is in the shape of a ring disc, see Figure 6 and Figure 7 , the top surface of the indexing plate 2 is evenly distributed along the circumferential direction with a number of indexing grooves 10, the indexing plate 2 is provided with a ring-shaped step surface 11, and a number of positioning holes 12 are opened on the ring-shaped step surface 11, and positioning pins 9 , Bolts 8 fix the indexing plate 2 on the base 1 through any two positioning holes 12 respectively. Usually, in order to ensure the reliable installation and stability of the indexing plate 2 under certain circumstances, the circular ring located on the indexing plate 2 should be selected. Two positioning holes 12 on the same diameter of the step surface 11 are used to install positioning pins 9 and bolts 8 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com