Indexable insert and cutting tool having indexable insert

a cutting tool and indexable technology, applied in the direction of turning machine accessories, manufacturing tools, shaping cutters, etc., can solve the problems of poor cutting chip discharge properties, high cost, and time-consuming for cutting type chips to be replaced, so as to prevent vibration and facilitate the attachment to the holder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

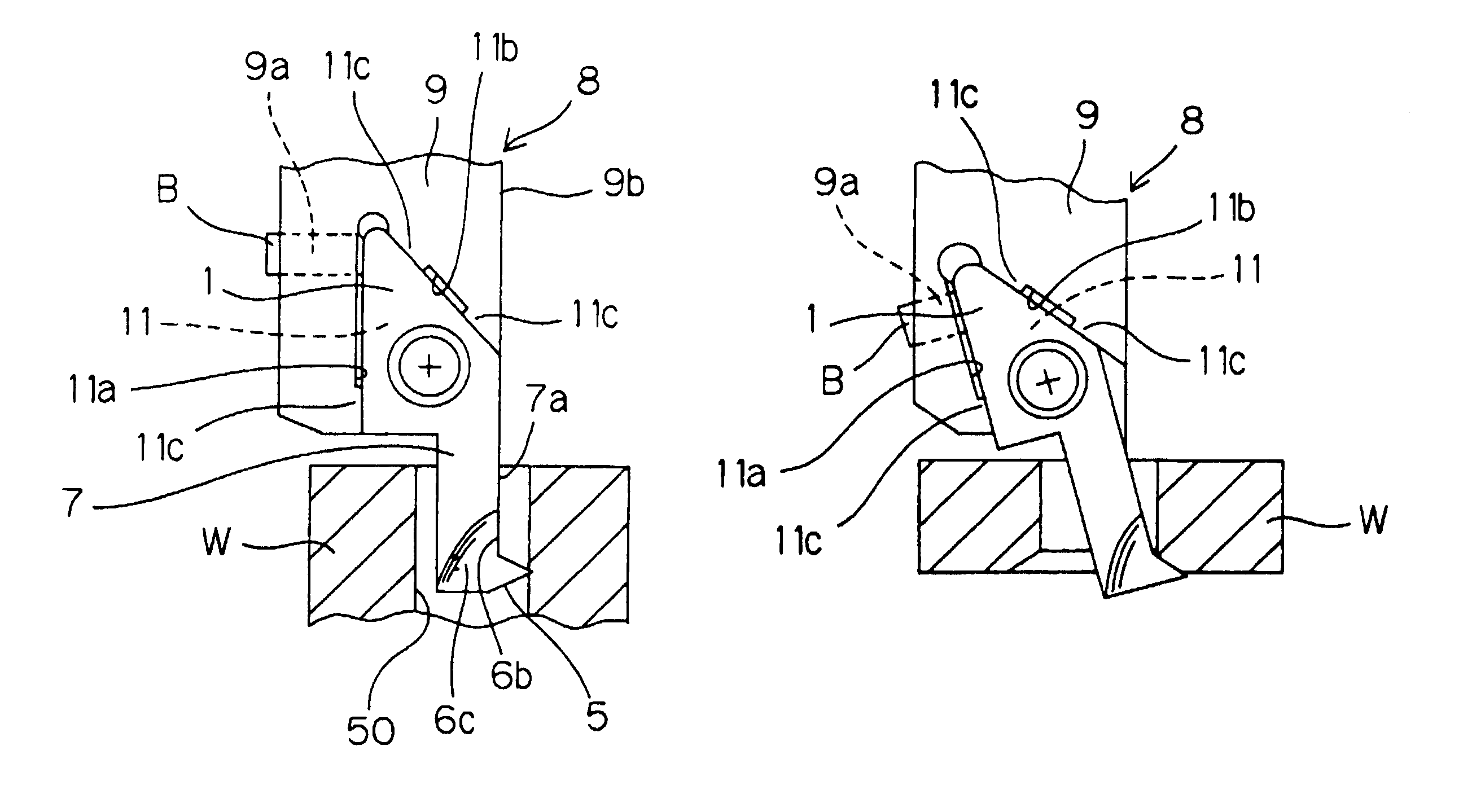

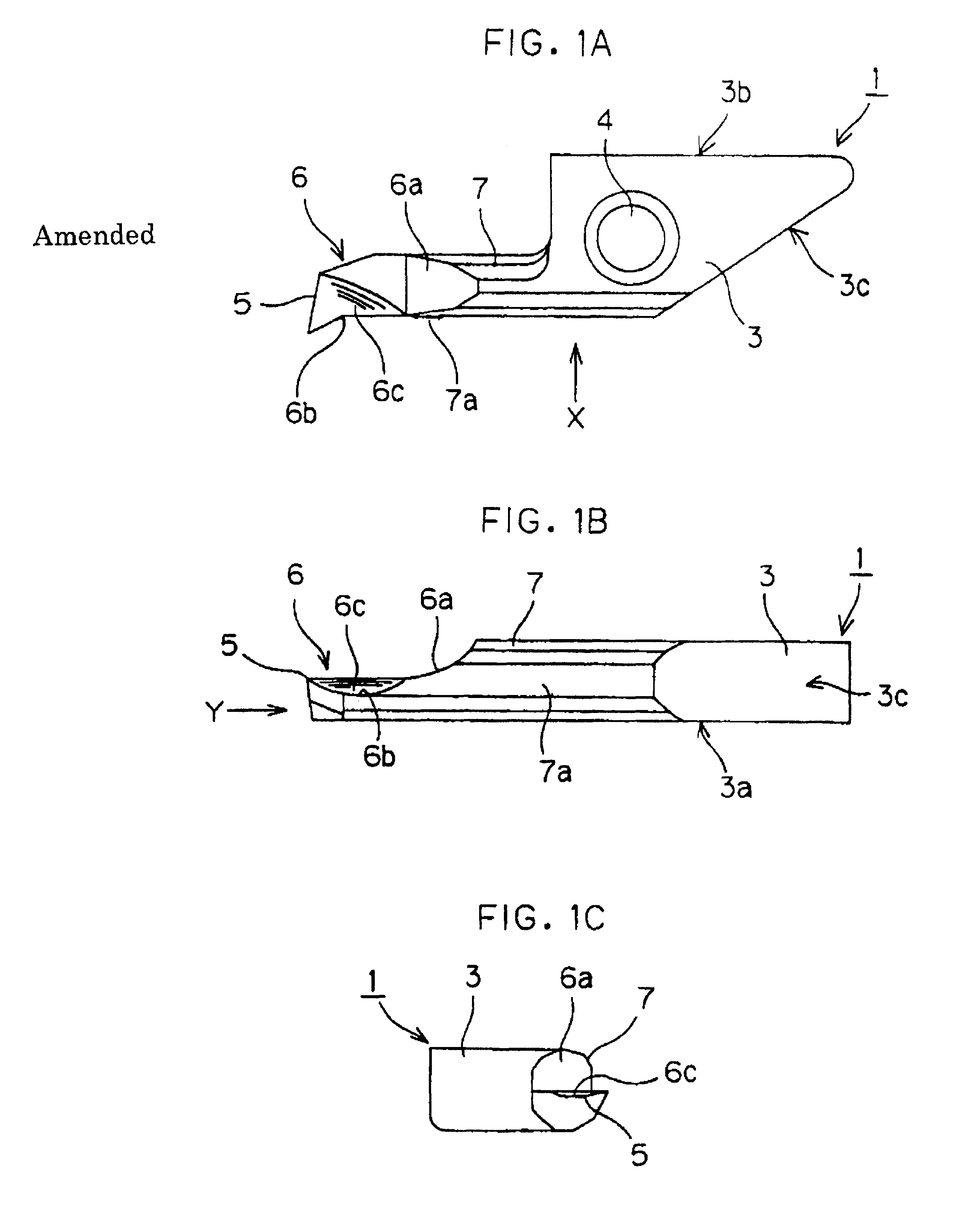

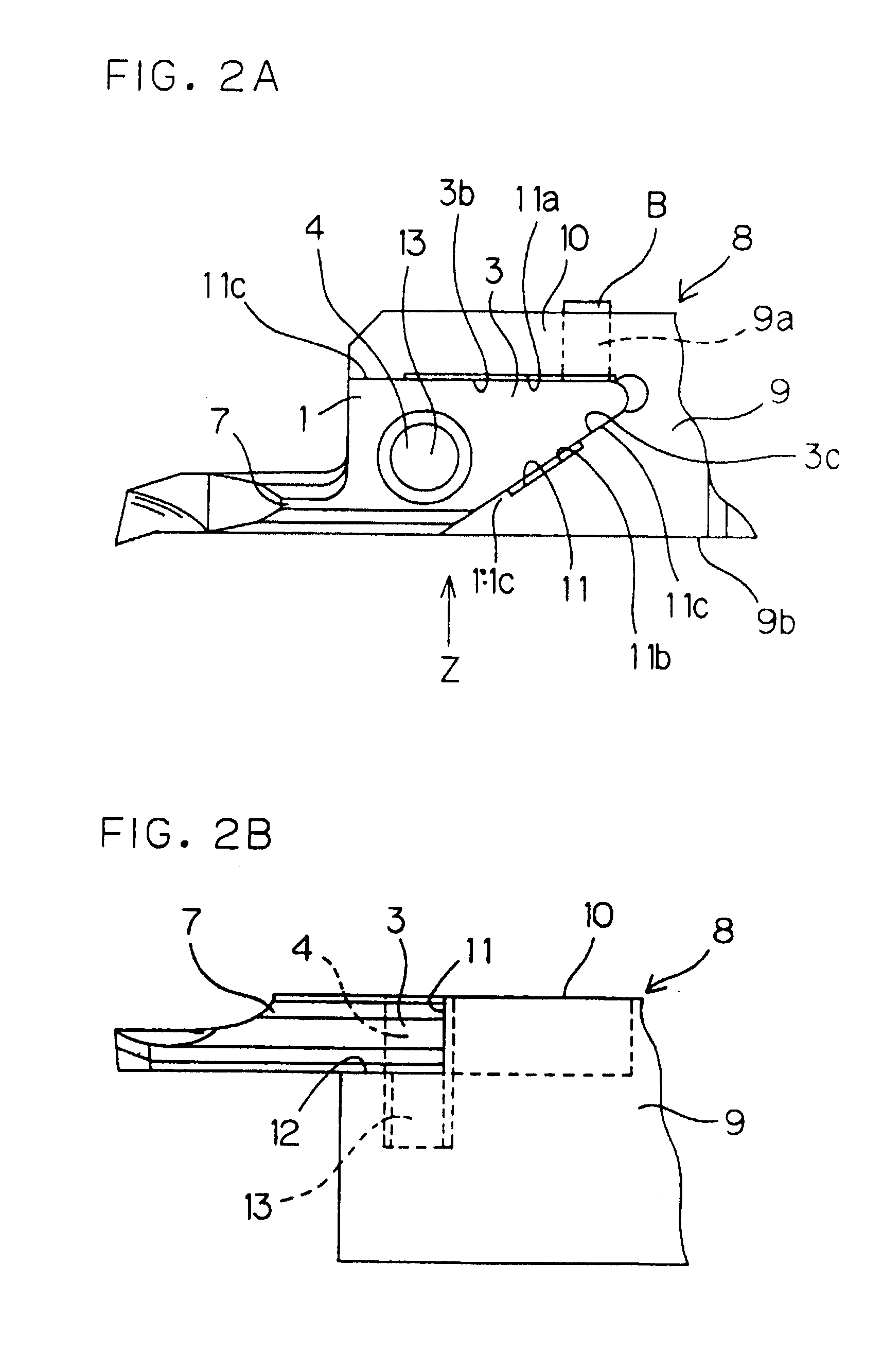

[0029]FIG. 1A is a top plan view of an indexable insert 1 according to one embodiment of the present invention, FIG. 1B is a perspective view taken along a line X shown in FIG. 1A (a front view of the indexable insert 1), and FIG. 1C is a perspective view taken along a line Y shown in FIG. 1B (a left side view of the indexable insert 1).

[0030]Referring to FIGS. 1A to 1C, the indexable insert 1 has a flat plate-shaped base 3 at its rear (on the right side of FIGS. 1A and 1B). The base 3 comprises a bottom surface 3a which is abutted, when it is attached to a holder, described later, against the holder, and a first side surface 3b and a second side surface 3c. The first side surface 3b and the second side surface 3c extend so as to cross each other in an acute-angled manner at the rear. Near the center of the base 3, a bolt hole 4 through which a bolt is to be passed is formed along the thickness of the base 3.

[0031]A stick-shaped portion 7 extends toward a front end of the indexable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acute-angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com