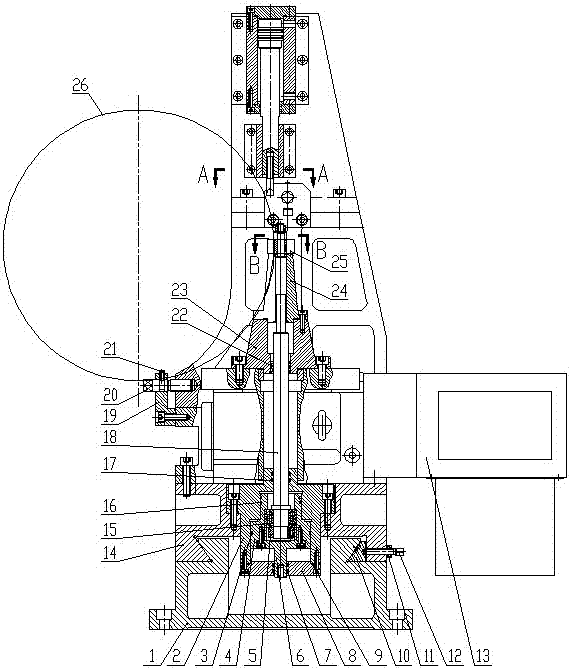

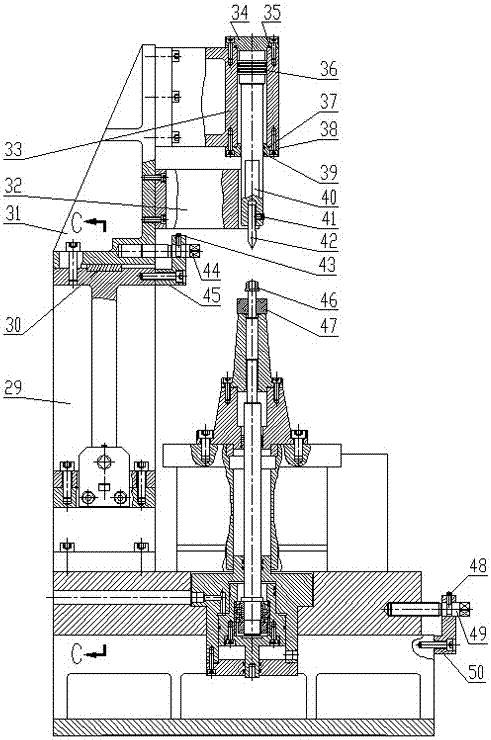

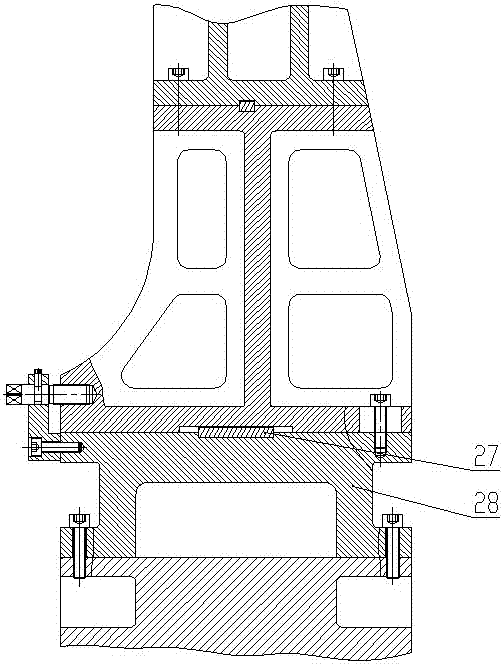

Rotor slot grinding fixture

A rotor slot and fixture technology, applied in the field of machinery, can solve the problems of low indexing, positioning and processing accuracy, low production efficiency, high labor intensity of workers, etc., so as to improve production efficiency, reduce labor intensity, and improve indexing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: Grinding the rotor slot fixture, installing the slide plate 14 on the base 1, installing the inclined iron 10, the matching clearance of the dovetail guide rail should be less than 0.02mm, and the installation should be tight Screw 12 and nut 11 are not locked temporarily; install the adjustment seat Ⅲ50 and the adjustment screw Ⅲ49, the screw Ⅳ48 is used to limit the axial movement of the adjustment screw Ⅲ49, the adjustment screw Ⅲ49 can only rotate, but cannot move axially; turn the adjustment screw Ⅲ49, Drive slide plate 14 to move, should be easy, uniform, without blocking phenomenon; Angular contact ball bearing 15 is contained on the pull rod 18, is pressed and fixed with locking nut 5, guarantees that angular contact ball bearing 15 rotates flexibly, and angular contact ball bearing 15 The axial runout is less than 0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com