Method for machining equated holes of large-sized rotating member by gear hobbing machine

A technology of rotary parts and gear hobbing machines, which is applied in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., which can solve the problems of expensive machine tools and high processing costs of internal water rings, and achieve reduced manufacturing costs and high indexing accuracy , Guarantee the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

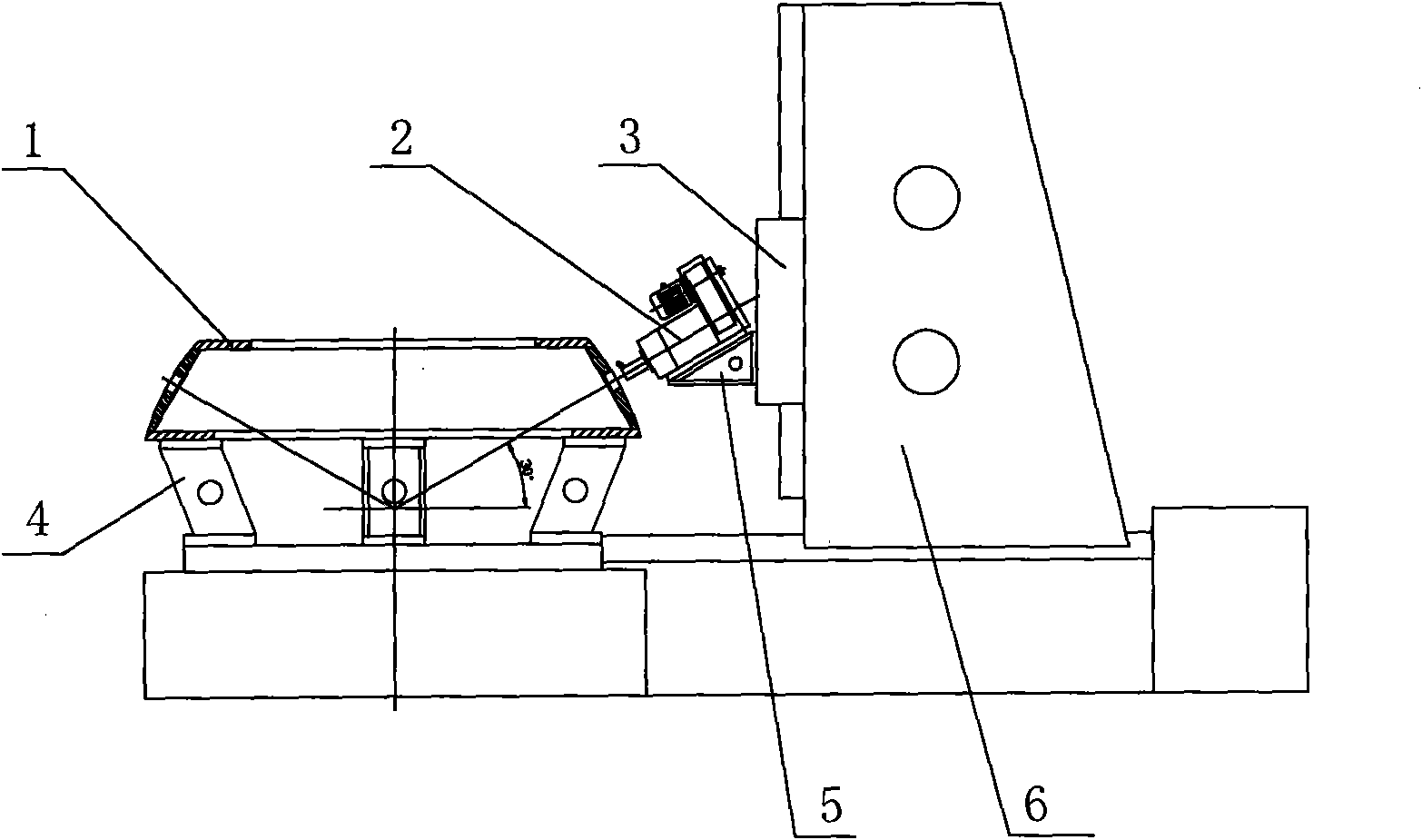

[0020] The method of the invention utilizes the performance of high indexing precision of the gear hobbing machine, and transforms the machine tool so that the upper guide vane shaft hole of the inner water distribution ring 1 is processed with high precision.

[0021] Taking the processing of 16 guide vane shaft holes with a size of Φ155H7 as an example, the specific steps of this method are described below:

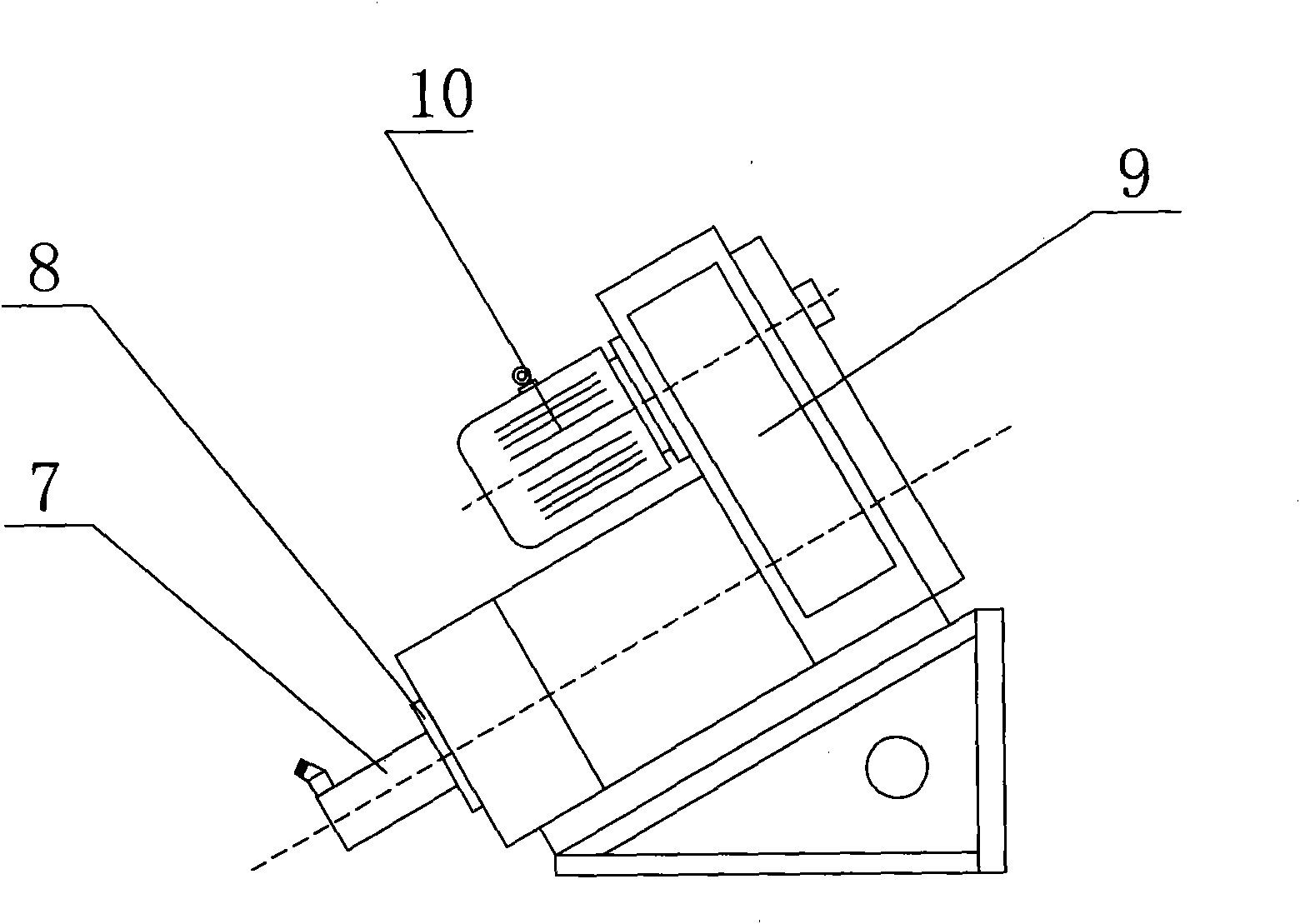

[0022] ①Remove the head of the hob on the gear hobbing machine, install the boring power head, install the boring power head 2 and the bracket 5 on the head of the hobbing machine, install the boring power head 2 on the bracket 5, and install the bracket 5 on the hobbing machine On the knife rest slide plate 3; the boring power head support 5 is a weldment, which is machined after eliminating the welding stress to ensure that the angle between the joint surface of the milling head and the hobbing machine column guide rail is 60 °. Wire cutting machine tools can be used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com