Numerical control rotary table

A technology of rotary workbench and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low reliability and low precision, achieve reliable work, high precision, and improve indexing precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

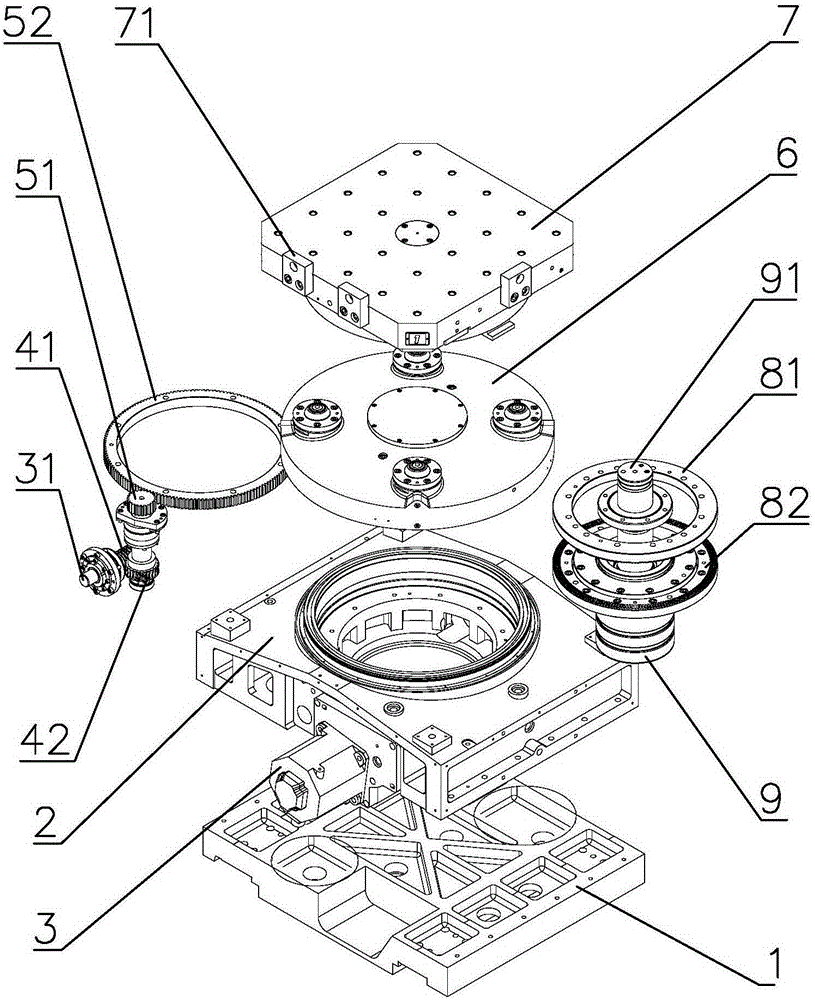

[0021] Such as figure 1 As shown, a numerically controlled rotary workbench includes a connection plate 1 placed on the guide rail of the machine tool, a gearbox 2 is fixed on the connection plate 1, a motor 3 is provided on one side of the gearbox 2, and the output shaft 31 of the motor is in a horizontal direction. The output shaft 31 passes through the side wall of the gearbox 2, enters the inner cavity of the gearbox and is connected to the worm gear; the output shaft 31 drives the worm 41 to rotate, and the worm gear 42 drives a reduction gear set to rotate, and the reduction gear set includes a driving gear 51 and a driven gear 52 , the axis of the driven gear 52 is perpendicular to the horizontal plane, the upper end of the driven gear 52 is fixed with a workbench support body 6, and a workbench is fixed above the workbench support body 6; a locking mechanism is installed in the middle of the driven gear, and the locking mechanism includes a fixed On the upper ratchet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com