Hanging type adaptive automatic drill pipe string discharge device

A discharge device and self-adaptive technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems such as inability to provide drilling and tripping operation methods, difficulty in adapting to the drill string gap, and complicated positioning control principles, etc., to achieve structural Compact, fast grabbing, accurate and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

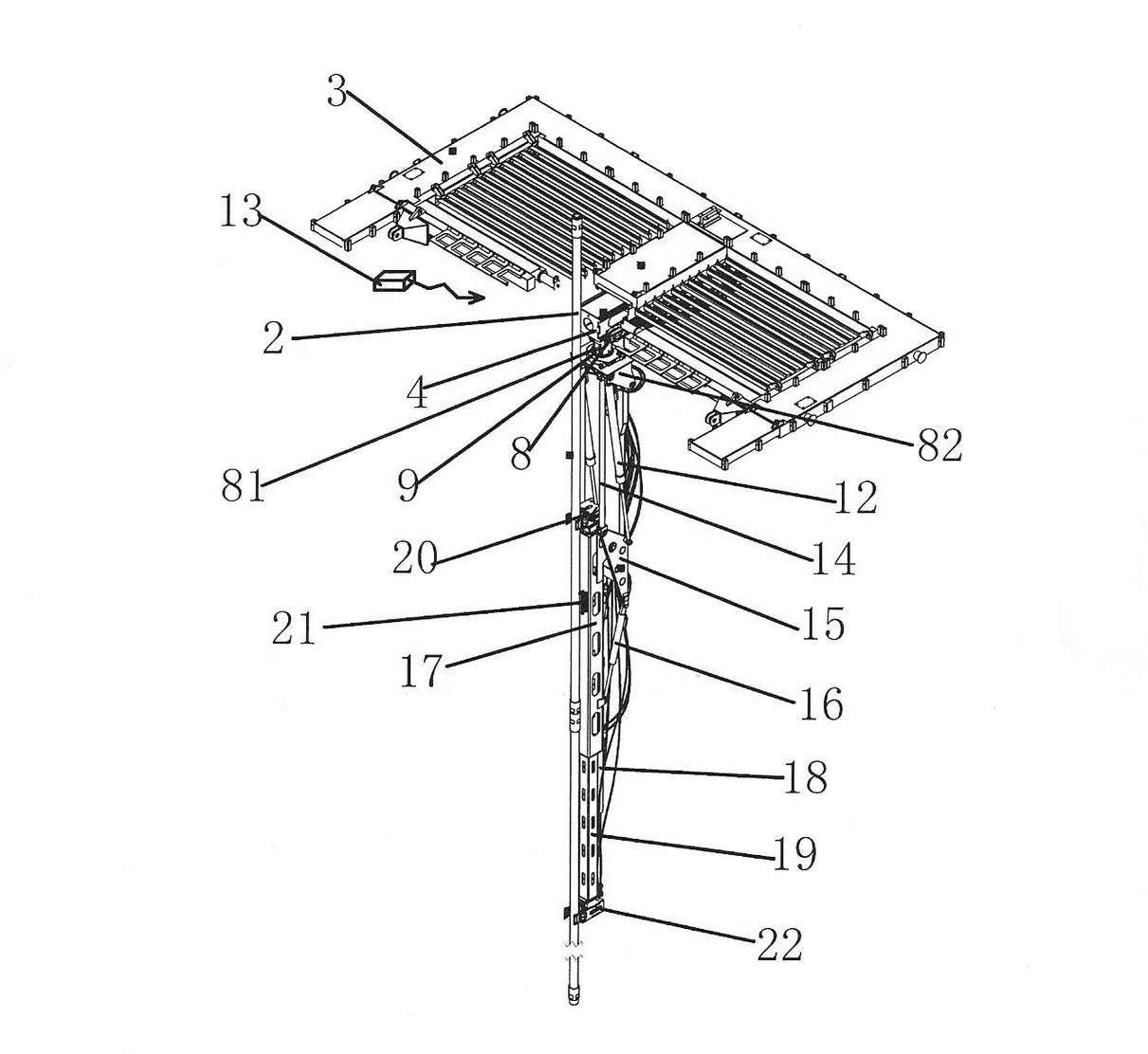

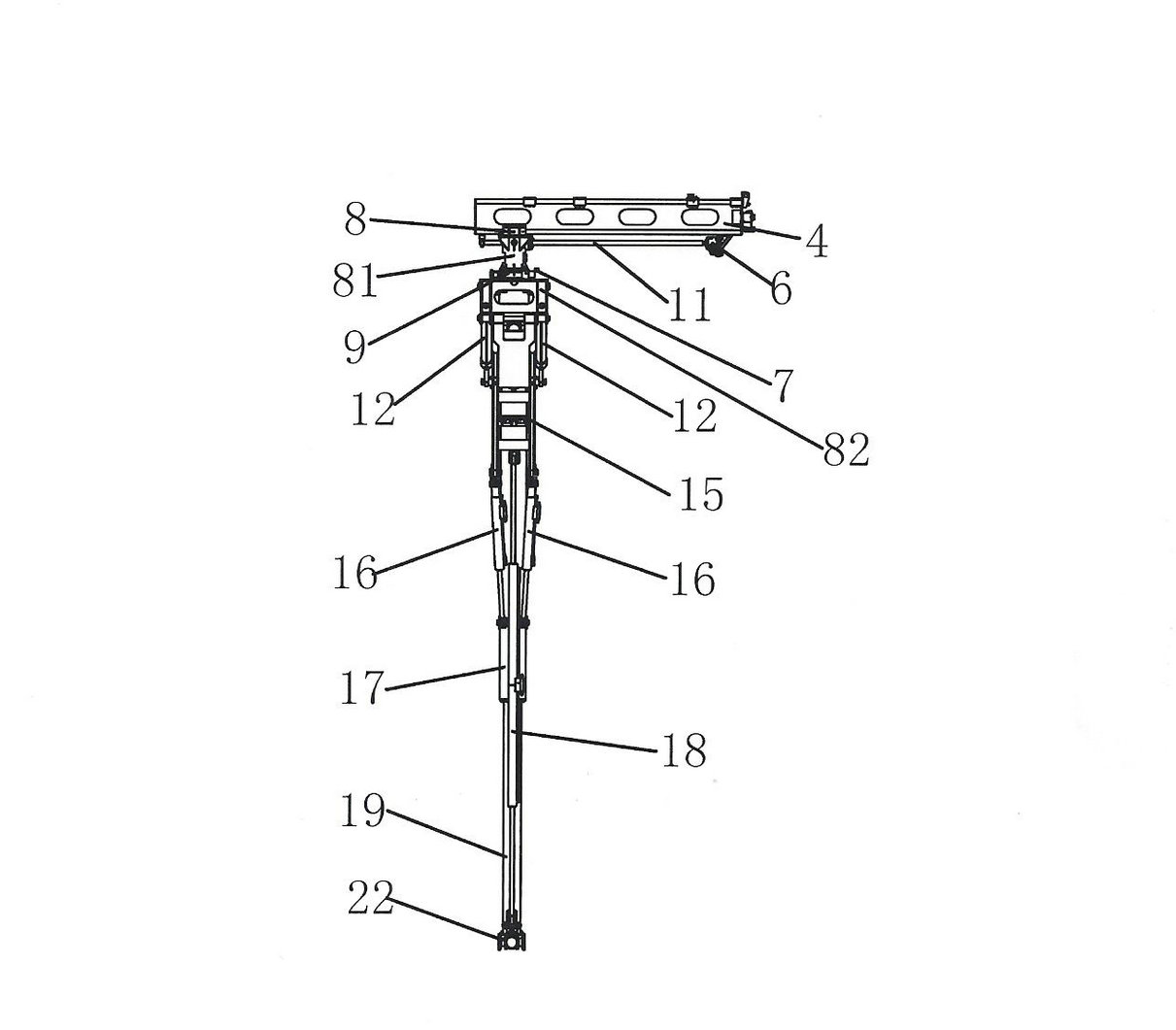

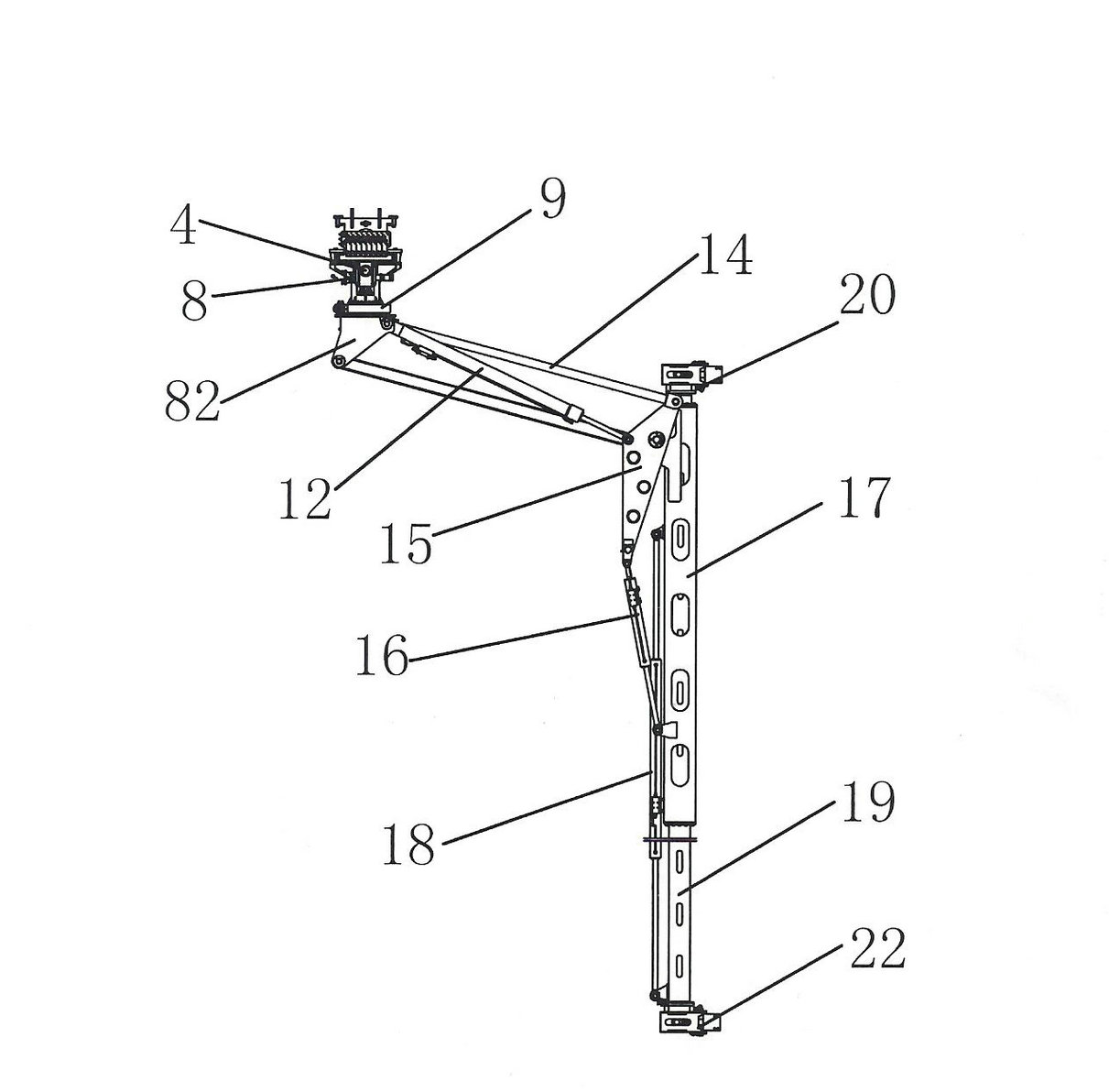

[0034] see figure 1 , figure 2 , image 3 with Figure 4As shown, the present embodiment is composed of a pipe racker guide rail 4, a hydraulic motor 6, a rotary encoder 7, a pulley 8, a worm gear rotary device 9, a screw pair 11, an extension hydraulic cylinder 12, a boom 14, a tripod 15, Composed of deviation correction hydraulic cylinder 16, mast 17, lifting hydraulic cylinder 18, mast inner guide rod 19, manipulator 20, 22, biaxial horizontal inclination sensor 21 and electro-hydraulic proportional control system 13 with PID adjustment function, pipe rower guide rail 4 is fixed At the bottom of the tongue platform 3 of the second-floor platform of the K-type derrick, the tackle 8 is suspended on the guide rail 4 of the pipe racker through the sliding guide block, and the screw pair 11 is arranged under the guide rail 4 of the pipe racker, and the screw pair 11 is connected with the tackle 8 , the hydraulic motor 6 is connected with the lead screw pair 11, the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com