Synchronous control mechanical arm

A synchronous control and manipulator technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of large occupied space, large component size, complex control, etc., to prolong the service life, reduce the size of components, and simplify the motor circuit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

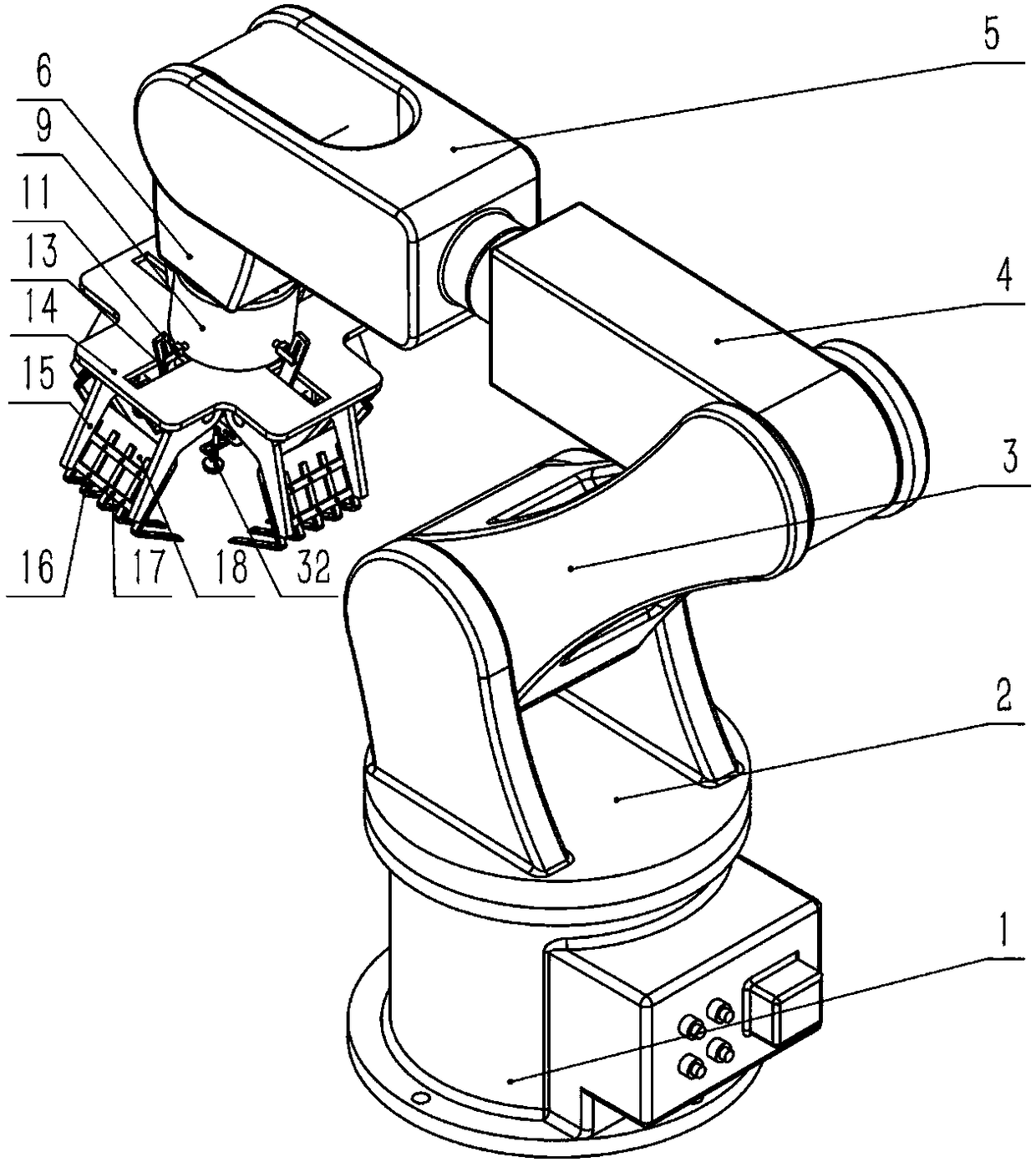

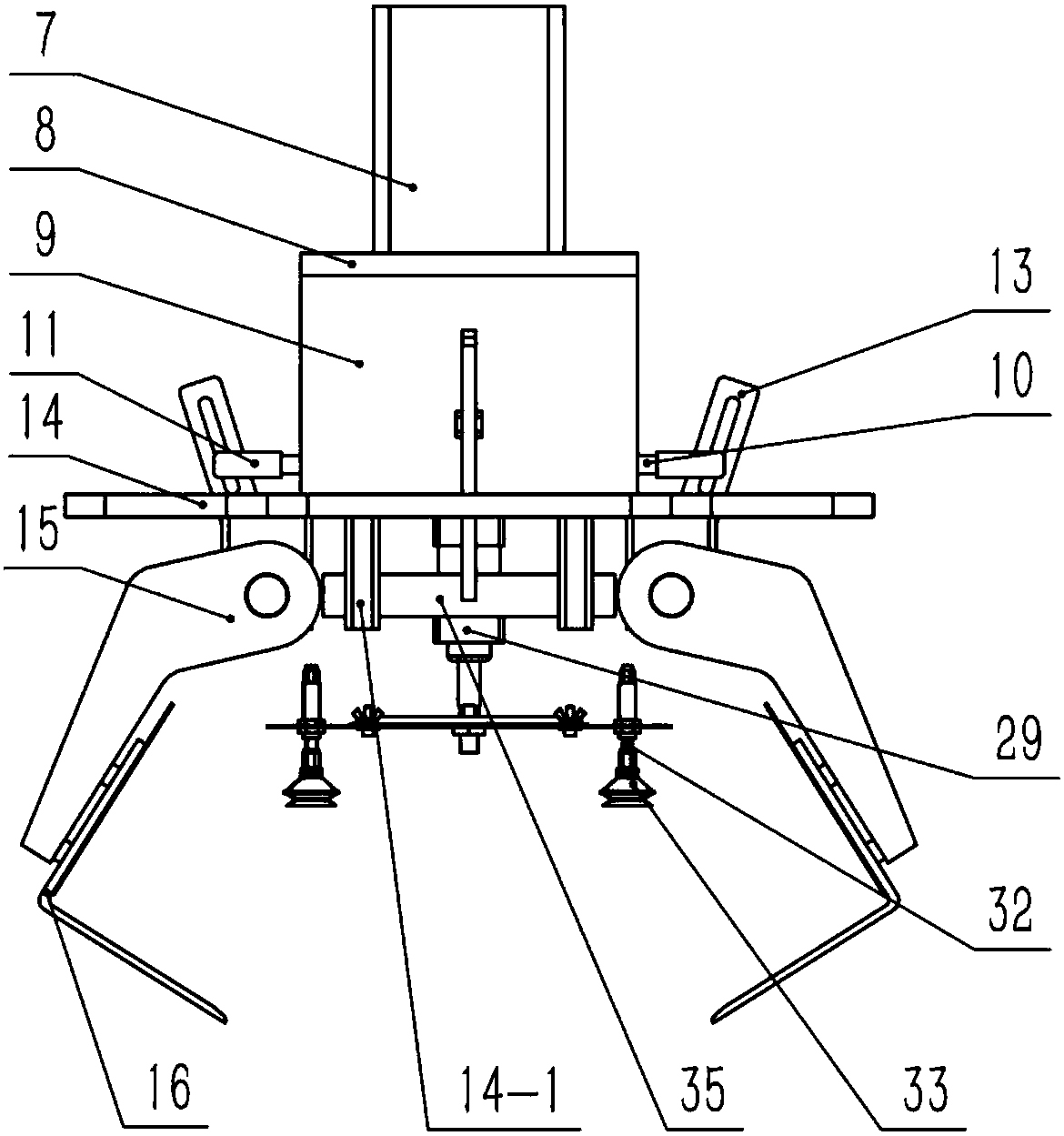

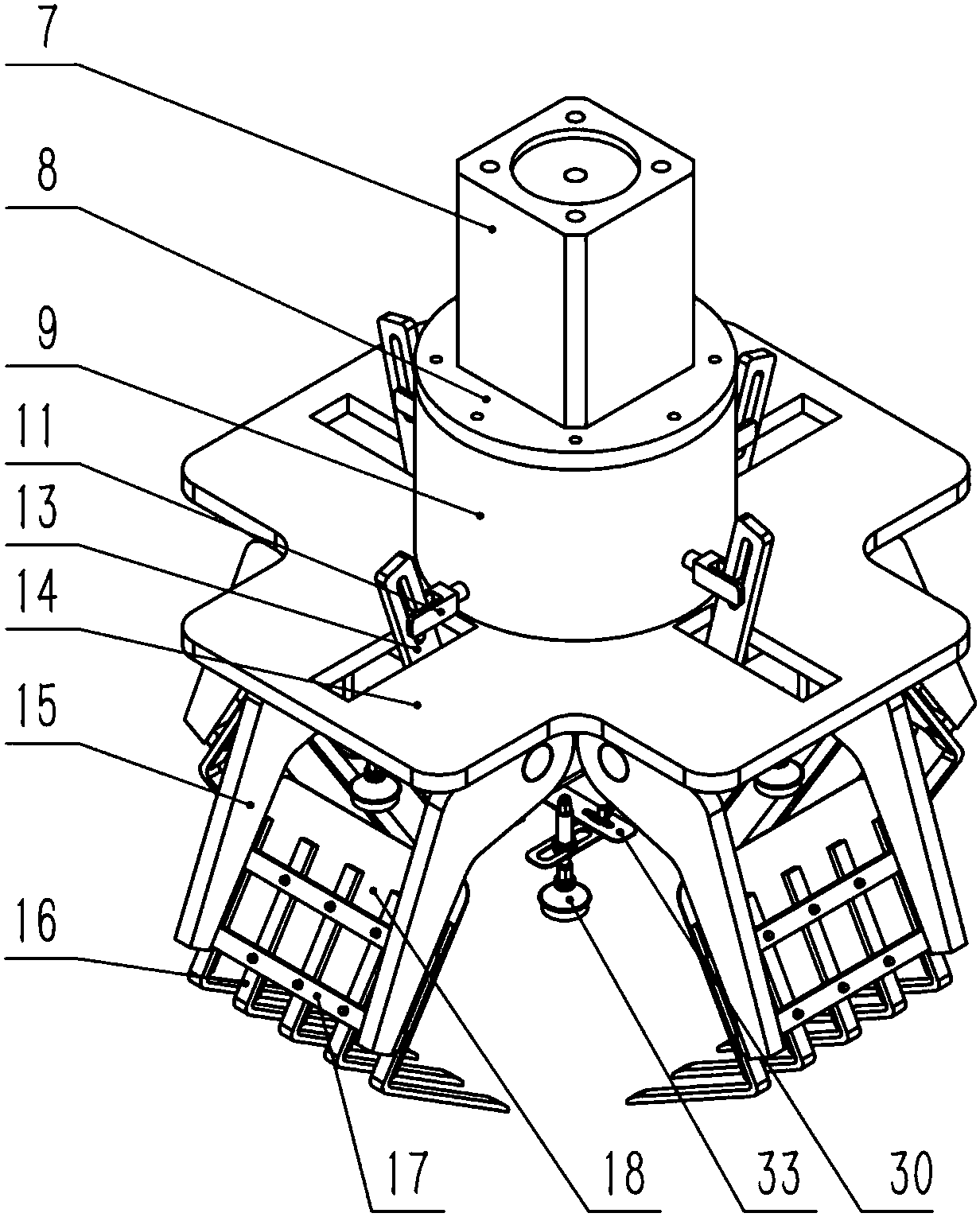

[0027] combine figure 1 , figure 2 and Figure 9 , a kind of synchronous control manipulator of the present invention, comprises base 1, rotating table 2, big arm 3, first small arm 4, second small arm 5, wrist 6, mechanical grasping device; Said mechanical grasping device passes screw fixed at the lower end of the wrist 6;

[0028] The mechanical grabbing device includes a drive mechanism, a linkage mechanism, and a mechanical claw; the drive mechanism is fixed on the lower end of the wrist 6; the drive mechanism is fixed on the upper end of the connecting platform 14 through a support frame 9; the drive mechanism and the linkage mechanism Connected, used to drive the swing of the linkage mechanism; the upper end of the connecting platform 14 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com