Gripper jaws for transporting steel plate

A technology for clamping claws and steel plates, which is applied in the field of steel manufacturing and processing and steel transportation equipment, and can solve problems such as large costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

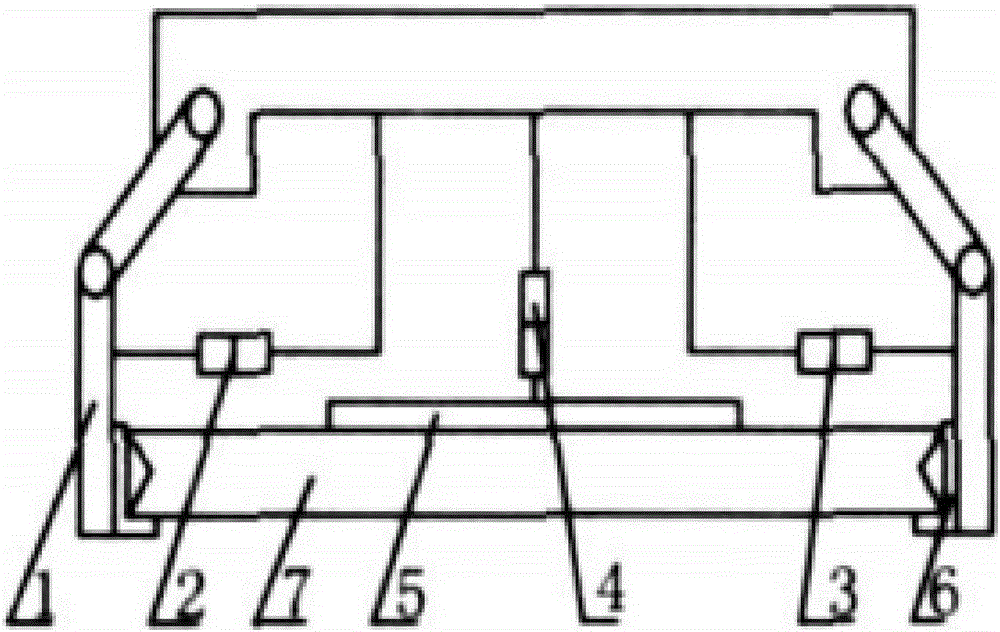

[0023] as attached figure 1 As shown, the clamping claws 1 are installed on both sides respectively, and are connected with respective connecting rods through hinges, and the connecting rods and the frame are also connected through hinges, so that the connecting rods can rotate relative to the clamping claws 1 and the frame. The tail end of the hydraulic telescopic cylinder 2 is fixed to the frame by bolts, and the other end is connected to the corresponding clamping claws 1 respectively, and the opening and closing of the clamping claws 1 are controlled by controlling the telescopic length of the hydraulic cylinder. The long side of the L-shaped plate 6 leans against the clamping claw 1, and the short side is on the same plane with the bottom end of the clamping claw 1. The L-shaped plate 6 is fixed on the clamping claw 1 with bolts, so that the bottom edge of the steel plate 7 Lean on the short sides of the L-shaped plate 6 respectively to prevent the steel plate 7 from slip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com