Intelligent transfer robot

An intelligent handling and robot technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems that the handling robot cannot classify products, and the handling robot is not reliable in grabbing workpieces, etc., and achieves simple structure, low cost, and increased friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

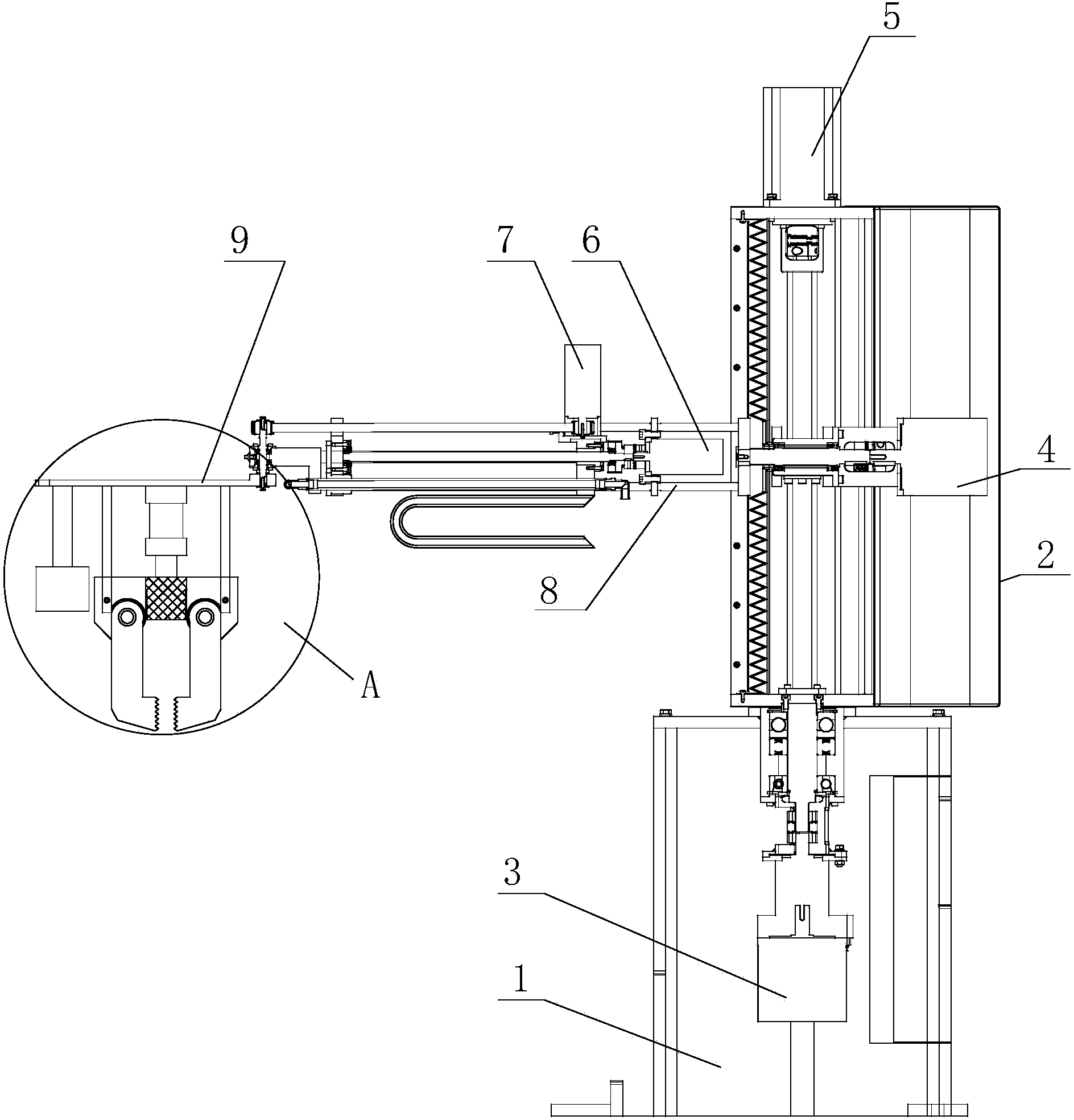

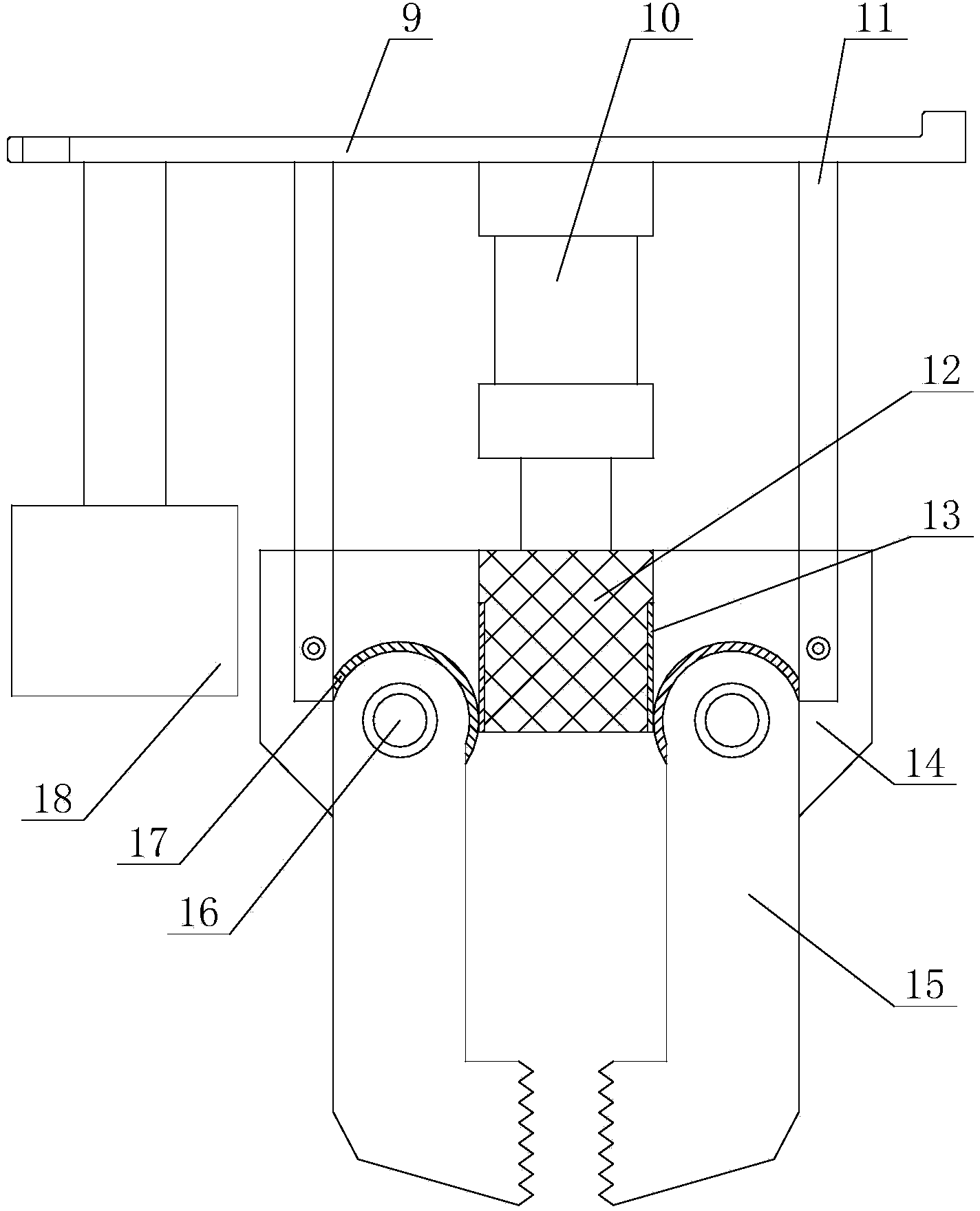

[0016] Please refer to figure 1 and figure 2 As shown, in this embodiment, an intelligent handling robot includes a base 1 and a rear cover 2 arranged above the base 1, a side of the rear cover 2 is horizontally provided with a mechanical arm 8, and the base 1 A swing arm movement mechanism driven by a swing arm servo motor 3 is arranged inside, and a turning movement mechanism driven by a turning servo motor 4 and a vertical movement mechanism driven by a vertical servo motor 5 are arranged inside the rear cover 2. The arm 8 is provided with a horizontal movement mechanism driven by a horizontal servo motor 6, the telescopic screw nut of the horizontal movement mechanism is fixedly connected with a rotary motion mechanism driven by a rotary servo motor 7, and the rotary motion mechanism is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com