Automatic oiling machine for torsional spring steel wire

An oiler and torsion spring technology, which is applied to coatings and devices that apply liquid to surfaces, can solve the problems of artificial oiling increasing labor costs, inability to accurately control the amount of oiling, and affecting product quality. Avoid uneven oiling, avoid inaccurate oiling position, and facilitate the effect of popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

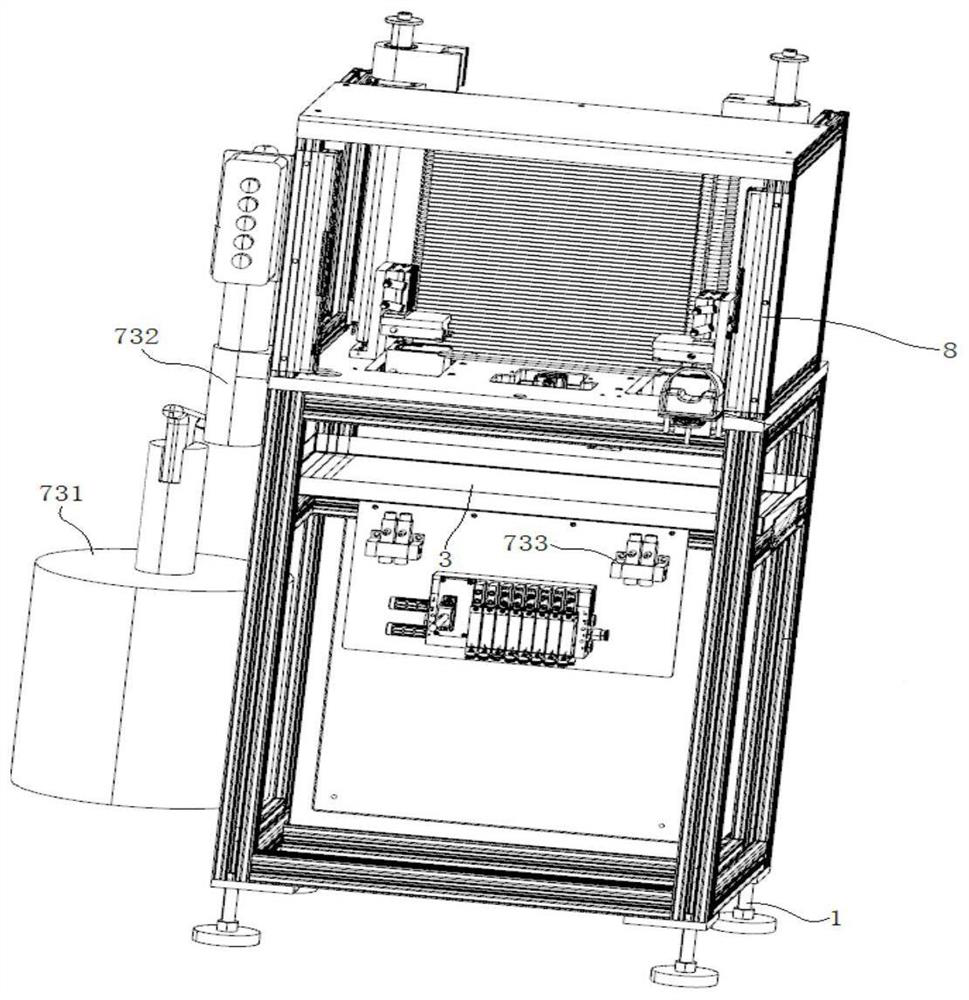

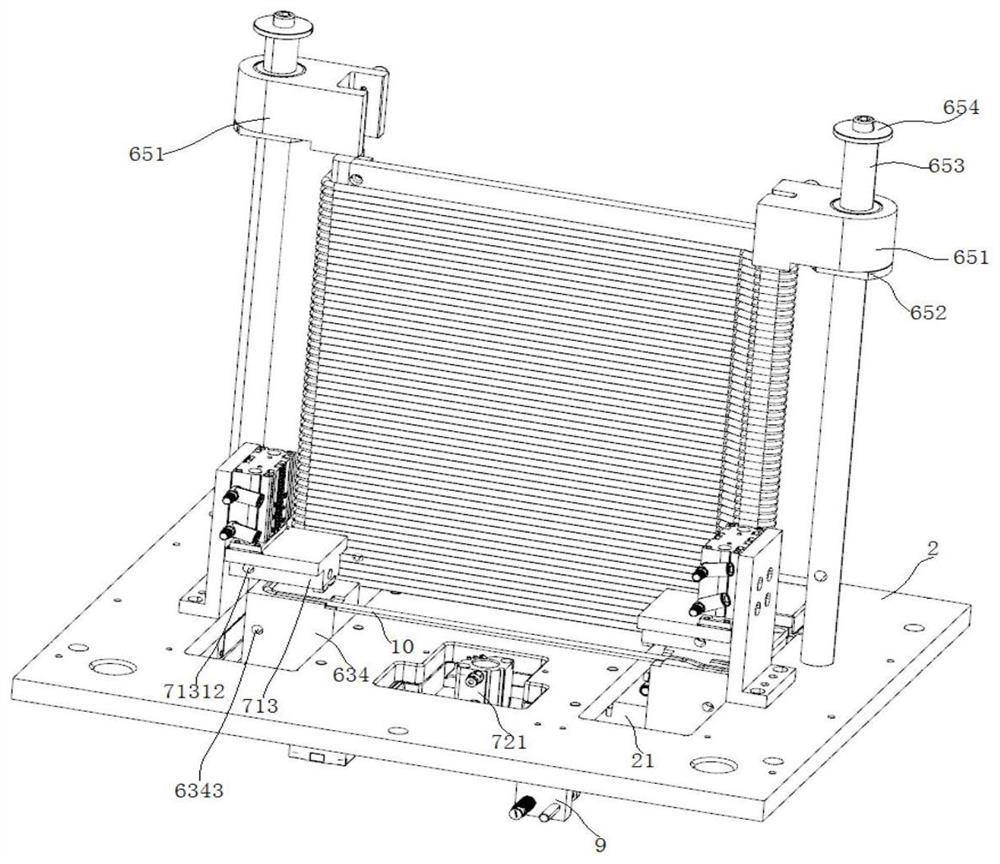

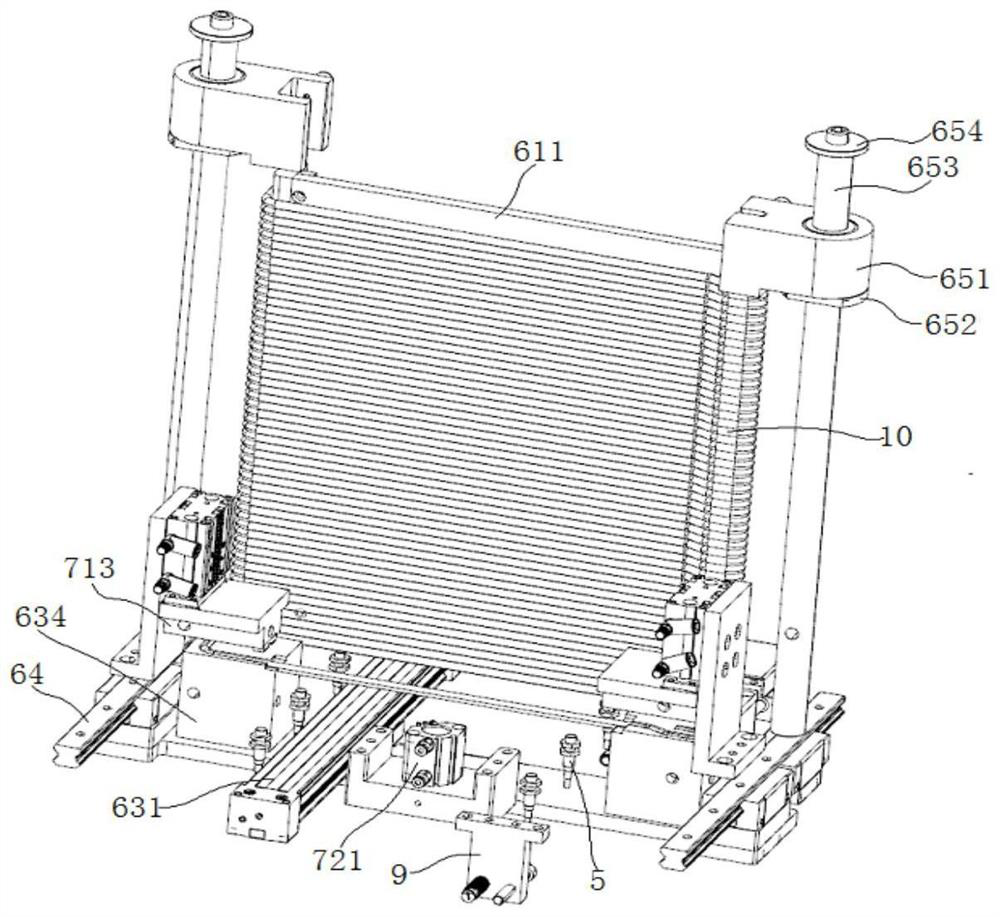

[0038] to combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , a kind of torsion spring steel wire automatic oiling machine of the present embodiment comprises base plate 2, and the lower end surface of base plate 2 is connected with rectangular frame through its four corners, and control cabinet is arranged in rectangular frame, and the lower end surface of this base plate 2 is fixed with two The guide rails 64 are parallel to each other. Between the two guide rails 64, a material distribution level, an oil application level and a material retrieving level are sequentially arranged along the length direction of the guide rail 64. Among them, the material distribution level is provided with a material storage part, and the material storage part is arranged along the height direction. A plurality of torsion springs 10 are arranged on the top, and the two ends of a torsion spring 10 located at the bottom are held up by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com