Bag breaking mechanism and automatic object and bag separation system

An automatic separation and bag breaking technology, which is applied in the field of bag breaking mechanism and bag separation system, can solve the problems of poor universality, inapplicability of garbage bags, failure to achieve the result of separation of garbage and plastic bags, etc., to ensure reliability and Thoroughness, avoiding the effect of stretching too long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

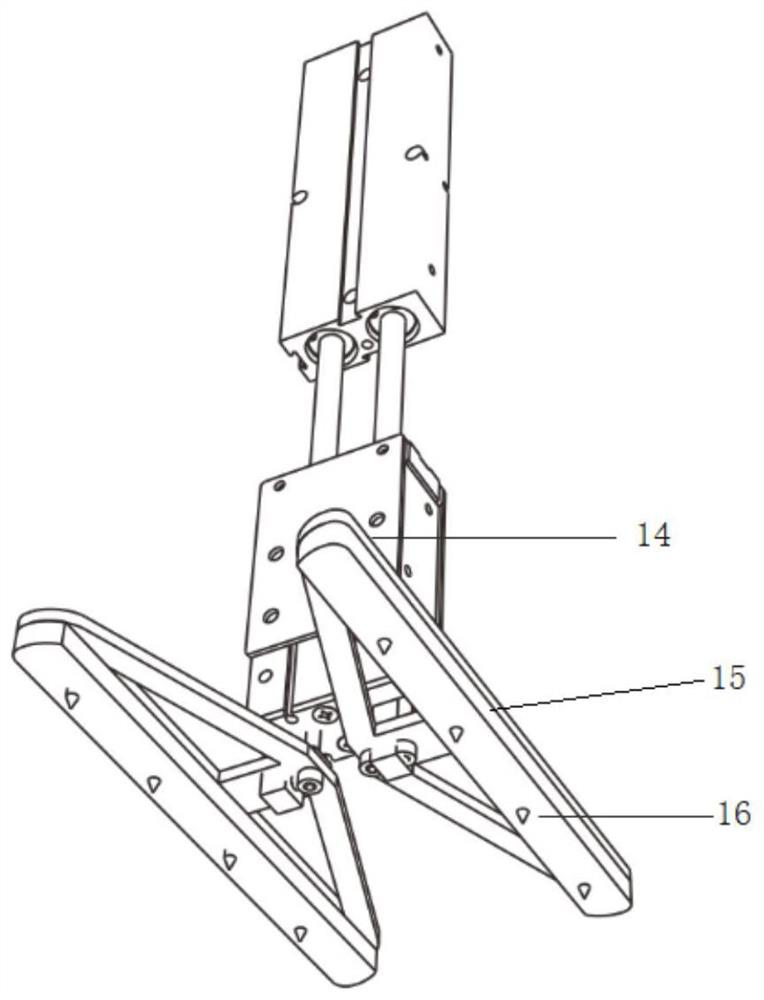

[0075] This embodiment provides a bag breaking mechanism. The bag breaking mechanism 3 is used to tear the garbage bag after the robot unit 1 grabs the garbage bag, so that the garbage in the garbage bag falls.

[0076] Such as Figure 4-Figure 6As shown, the bag breaking mechanism 3 is a left-right symmetrical structure, including: an outer frame 17, an upturning auxiliary plate 18, a vertical tooth bag breaking plate 19, a synchronous frame 20, a rotating shaft A21, a rotating shaft B, a bearing 22, a bag breaking driver 23, a convex Table gear 24 and spur rack 26. Its connection relationship is: the groove-shaped structure formed by the outer frame 17, two upward-turning auxiliary plates 18 and two vertical tooth bag-breaking plates 19 has a certain slope (the slope and size can be adjusted according to actual needs), ensuring that the plastics of the containing items When the bag is thrown in, it can finally fall on the two vertical tooth bag breaking plates 19 only by th...

Embodiment 2

[0082] This embodiment provides an automatic bag separation system for garbage and garbage bag separation, which can realize reliable separation of garbage and garbage bags without changing the habits and methods of residents' garbage disposal. It is applicable to many scenarios, easy to use, and highly automated.

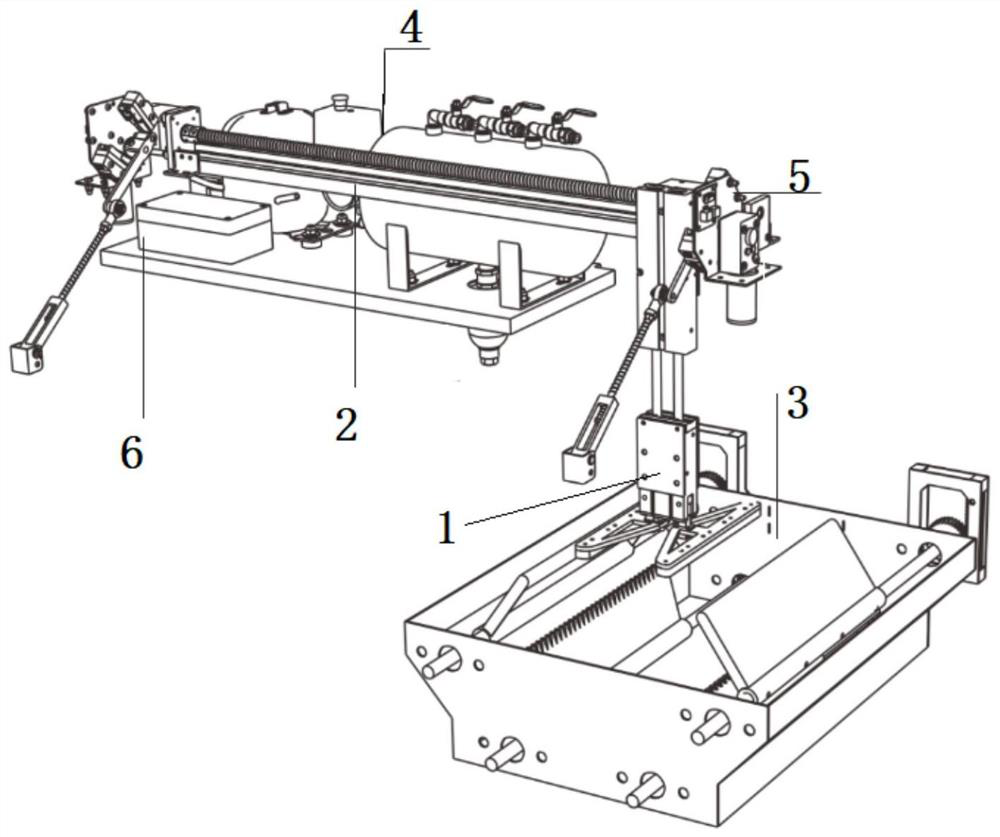

[0083] Such as figure 1 and figure 2 As shown, the bag automatic separation system includes: a manipulator unit 1, a horizontal movement unit 2, a bag breaking mechanism 3, a power unit 4 and a control unit 6; wherein the bag breaking mechanism 3 adopts the bag breaking mechanism described in the above-mentioned embodiment 1, It is used to tear the garbage bag after the manipulator unit 1 grabs the garbage bag, so that the garbage in the garbage bag falls.

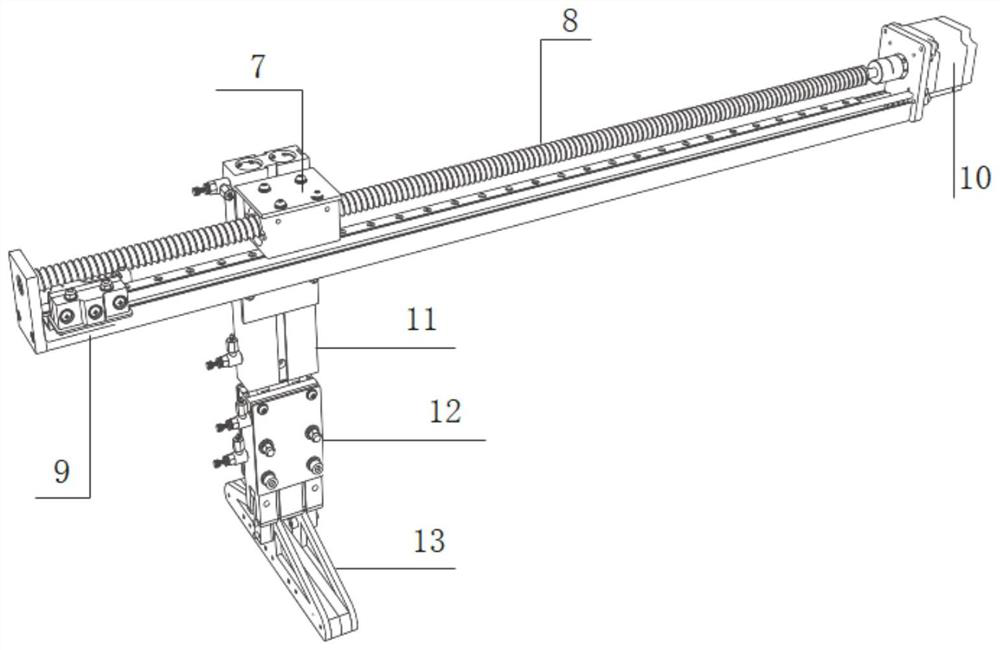

[0084] The manipulator unit 1 is connected with the sliding table 7 in the horizontal moving unit 2 through fixing screws, so that when the sliding table 7 slides horizontally, it can drive the manipulator un...

Embodiment 3

[0101] On the basis of the above-mentioned embodiment 2, in order to ensure the safety of the personnel when the bag automatic separation system is in operation, an automatic door opening unit 5 is further provided. The unit 6 is connected; the automatic door opening unit 5 can open or close the bung of the garbage can A33 and the garbage can B34 under the control of the control unit 6, and when putting in the garbage bag, the control unit 6 controls the automatic door opening unit 5 to open the bucket of the garbage can A33 Cover, plastic garbage bags are thrown in the bag breaking mechanism 3, and then the control unit 6 controls the automatic door opening unit 5 to close, and controls the manipulator unit 1, the horizontal movement unit 2 and the bag breaking mechanism 3 to start working to complete the separation of garbage and garbage bags.

[0102] The automatic door opening unit 5 can be selected from a connecting rod type, a push rod type, a pulley type, an electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com