Manipulator used for griping high-temperature workpieces

A technology of manipulators and workpieces, which is applied in the field of manipulators, can solve the problems of restricting the automation of hot forging industry, unstable feeding, jamming or loosening of manipulators, etc., achieves good heat insulation and versatility, improves automation, and is not easy to jam or loosen. loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

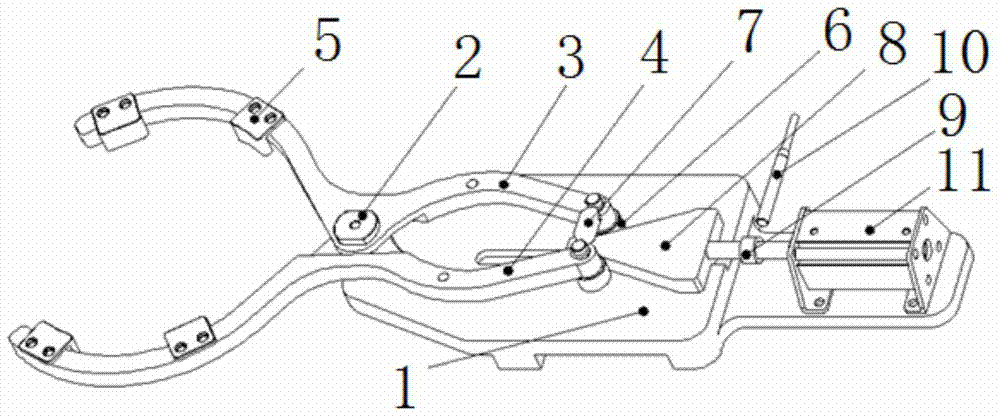

[0019] Such as figure 1 As shown, the manipulator for grabbing high-temperature workpieces includes a manipulator mounting plate 1, a power cylinder, gripper I3, and gripper II4, wherein gripper I3 and gripper II4 are set correspondingly, and gripper I3 and gripper II4 They are hinged by a revolving pin 2, and the revolving pin 2 is fixed on one end of the manipulator mounting plate 1, and the two jaws can rotate relative to each other.

[0020] One end of the two jaws is the end for clamping the workpiece, and the other end of the two jaws is the driving end. The relative movement of the two jaws through the driving end drives the relative movement of one end of the two jaws to realize the work of clamping the workpiece. The manipulator has only one hinge point and has a simple structure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com