Pneumatic soft finger with tactile and shape perception function

A sensory and tactile technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of limited grasping and operation reliability, lack of external information perception ability, and inability to comprehensively provide reliable grasping of the grasper. The effect of reliable gripping and manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

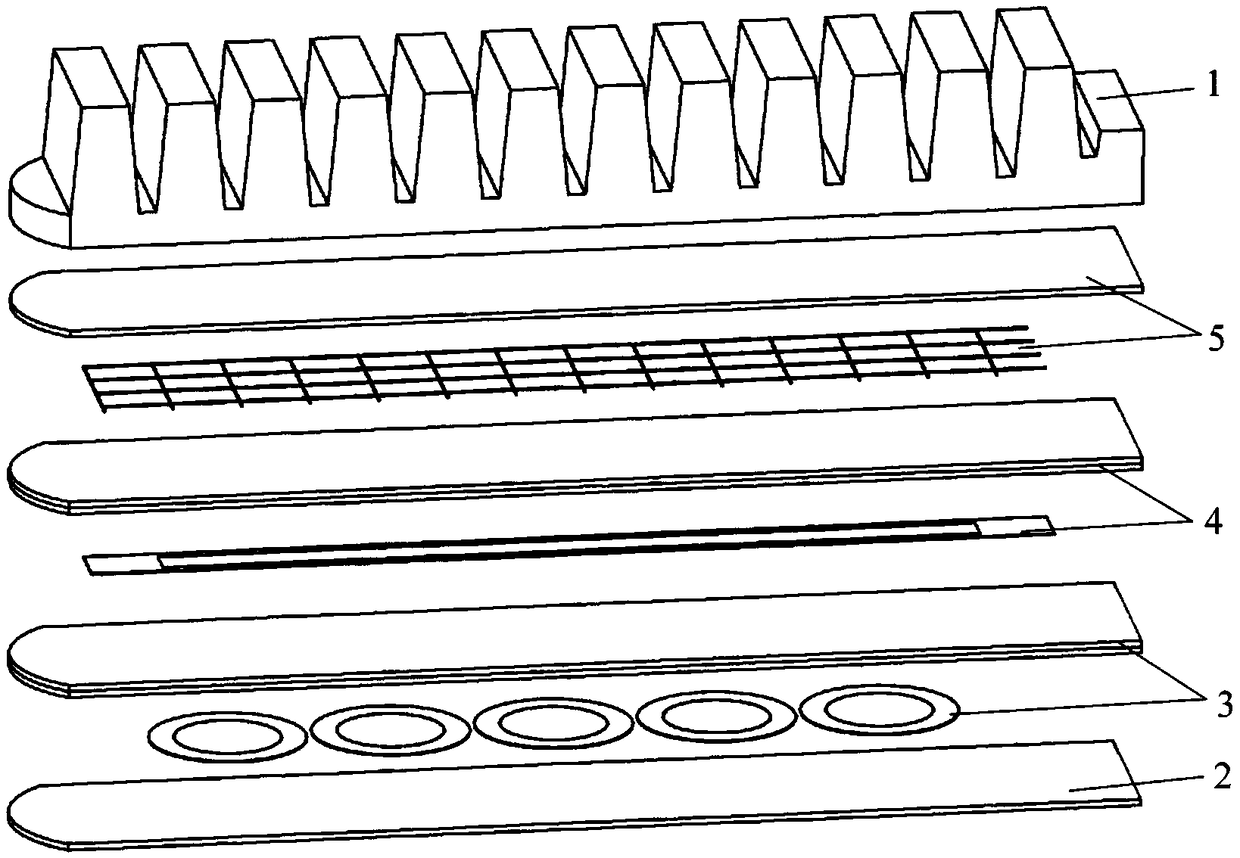

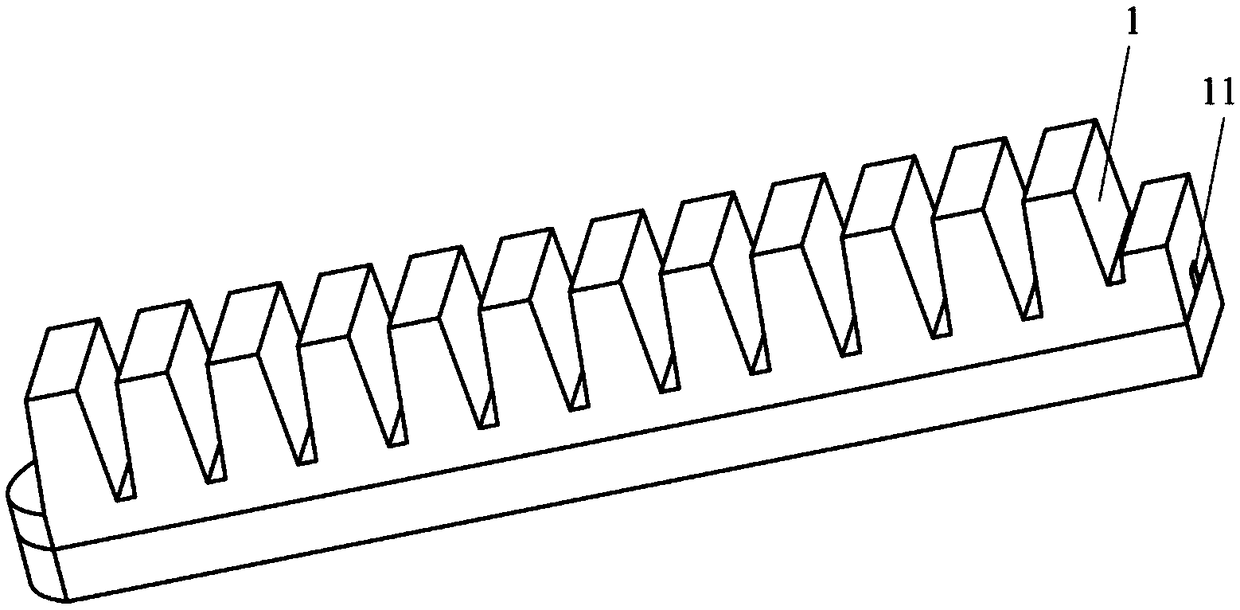

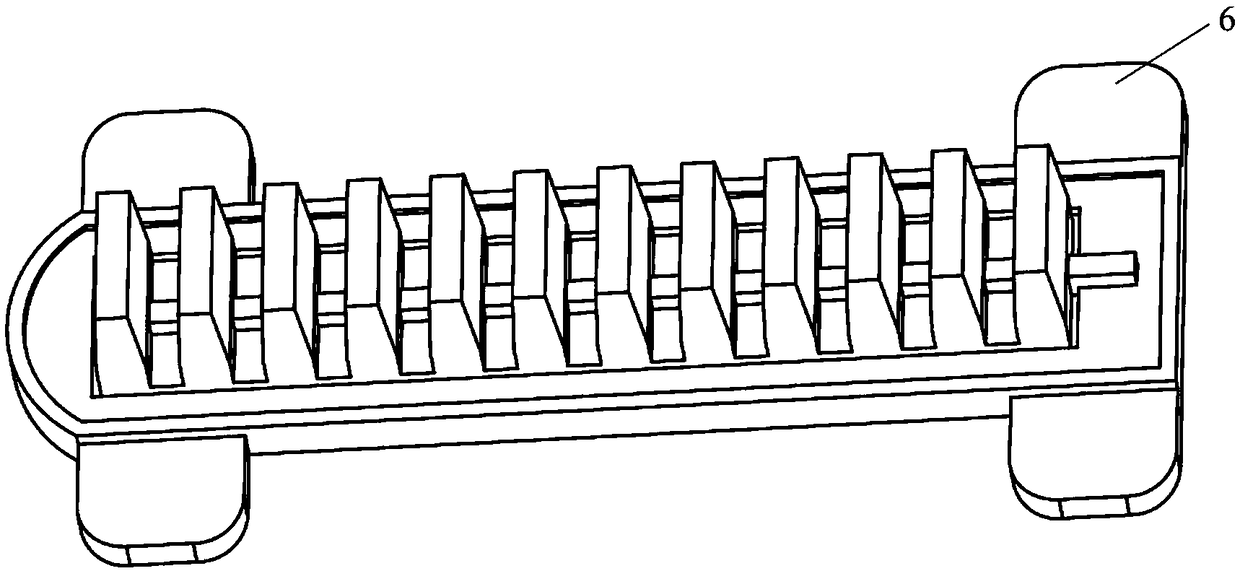

[0017] Such as figure 1 , figure 2 As shown, the pneumatic soft finger with tactile force and shape perception functions of the present invention consists of upper and lower parts. The upper part of the pneumatic soft finger is the driver 1, which is the driving structure of the pneumatic soft finger. The driver 1 is an integrated airbag formed by a plurality of stepped cavities connected in sequence on the left and right, and the bottoms of the plurality of stepped cavities are connected to each other. , the air bag is connected with the air pump.

[0018] As an embodiment of the present invention, the cavities communicate with each other through the channel 11 passing through the lower part of each cavity in the transverse direction, and the air pump communicates with the channel 11 . The external air pump controls the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com