Pneumatic serial-connection flexible hinge multi-finger paw of compliant mechanism

A technology of flexible hinges and compliant mechanisms, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of series flexible hinges that are difficult to bend, increase series flexible hinges, and small slope of the curve, etc., to reduce the minimum cross-sectional area, reduce the Minimum cross-sectional area, the effect of reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below is working principle and working process of the present invention:

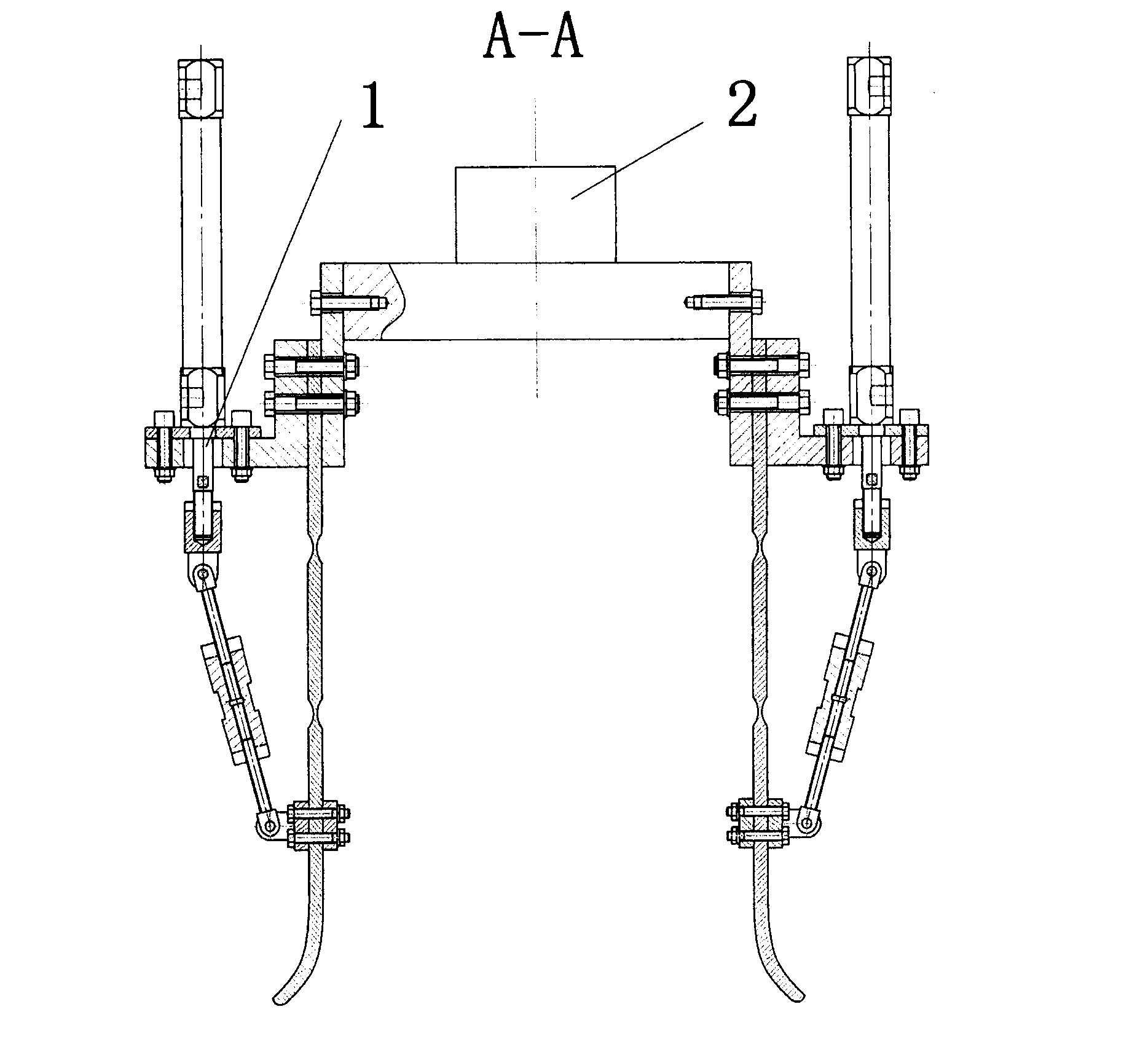

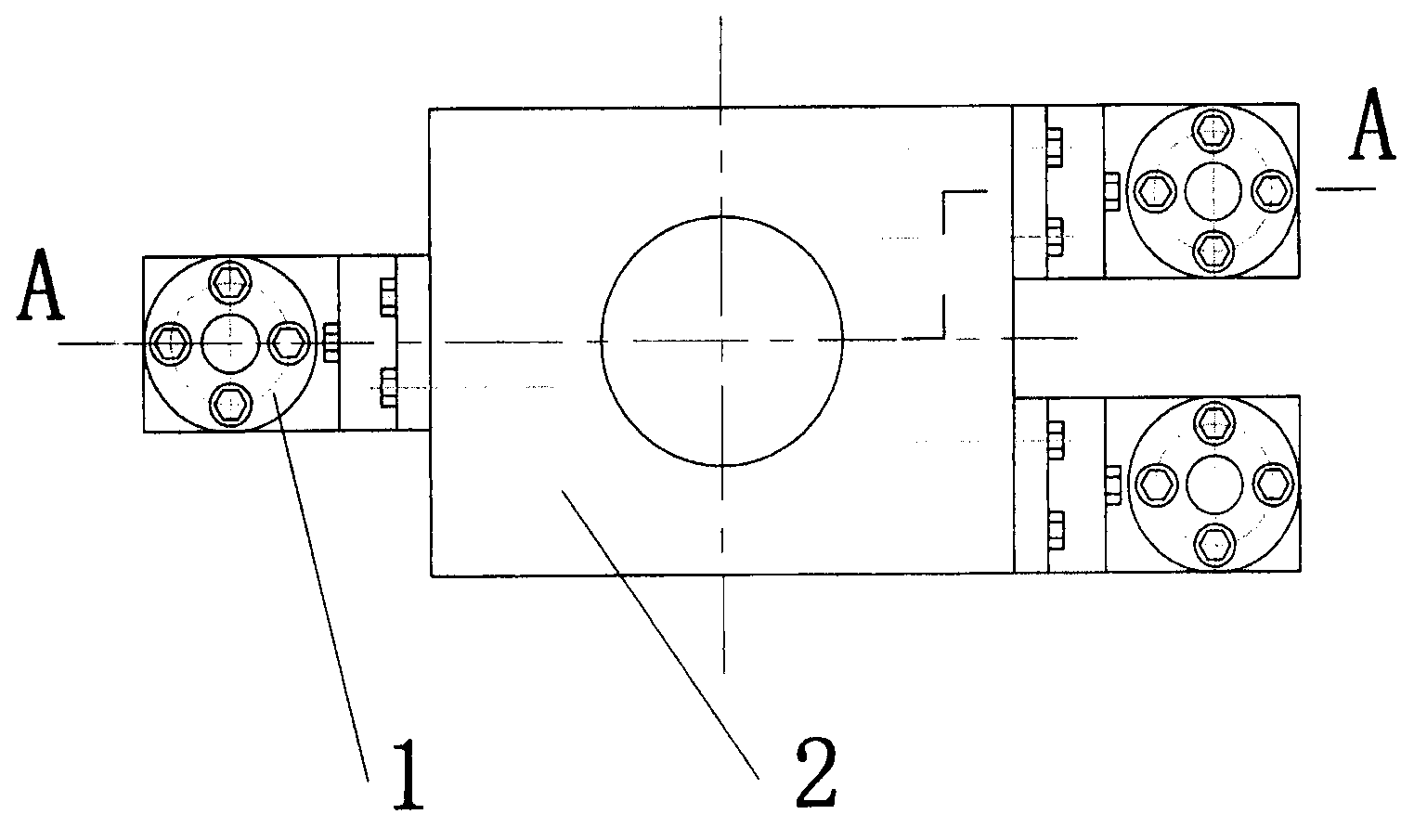

[0023] Such as figure 1 , 2 As shown, according to the long and rectangular complex objects, after experimental research and theoretical analysis, adjust the length of the two force rods (composed of the left threaded hinge rod 7a, the threaded sleeve 8a, and the right threaded hinge rod 8a), and then adjust the pressure plate 5a and the hinge The support 6a is fixed at the lower end of the series flexible hinge 4a. The series flexible hinge 4a is driven by the cylinder to produce large deformation. The bottom end of the series flexible hinge 4a clamped by the pressure plate 5a and the hinge support 6a is a curved surface segment, and the grasping of complex objects is on the curved surface segment of the series flexible hinge 4a.

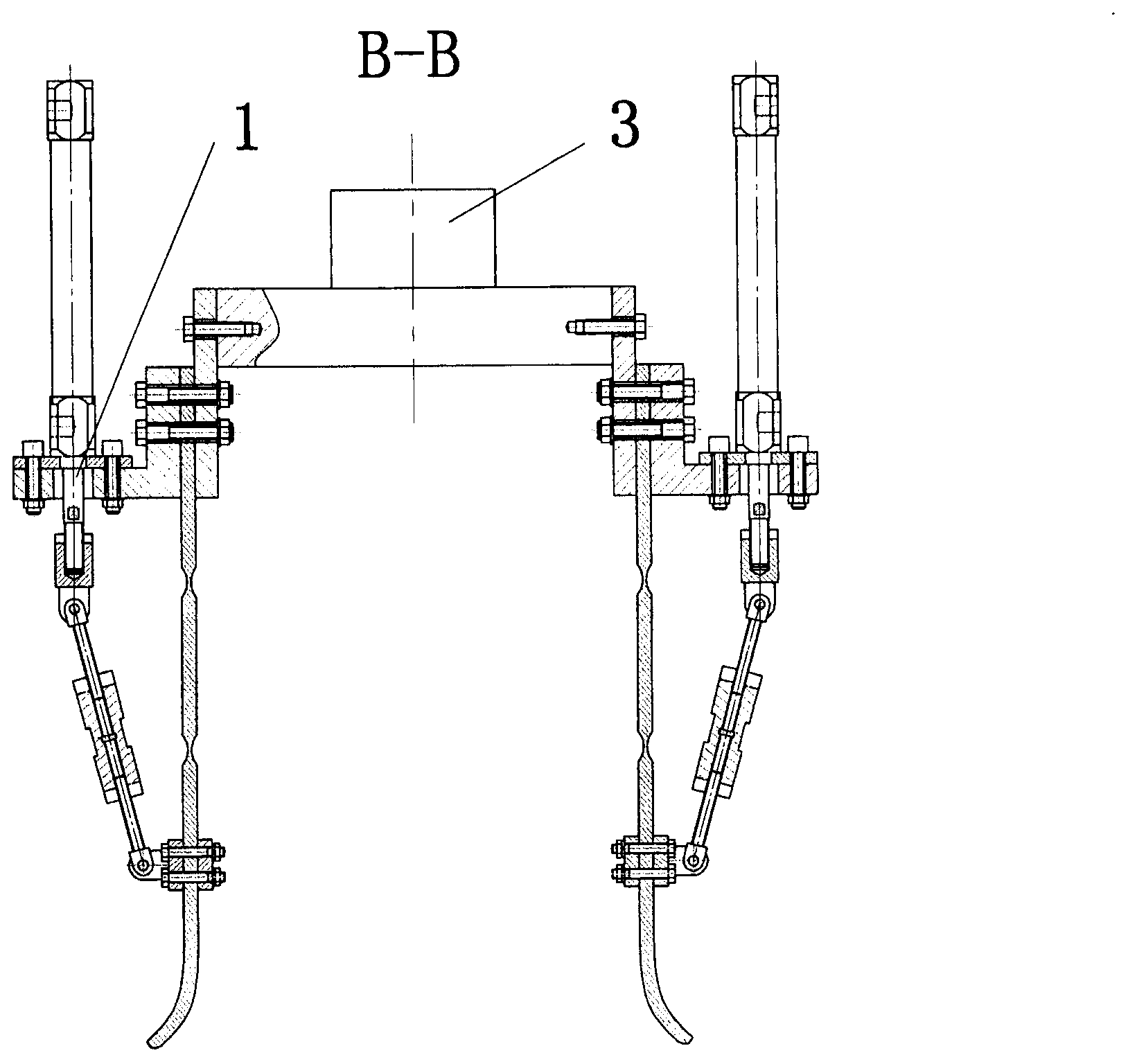

[0024] Such as image 3 , 4 As shown, the circular and short cylindrical complex objects are also regulated according to the above steps, after experimental resea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com