Bidirectional synchronous automatic turning flapping-wing aircraft

A two-way synchronous, automatic flip technology, applied in the direction of helicopters, motor vehicles, aircraft, etc., can solve the problems of reducing drag, reducing drag, reducing the force-bearing area of wings, etc., to increase propulsion and lift, and increase the rotation angle. Large, the effect of improving flight efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

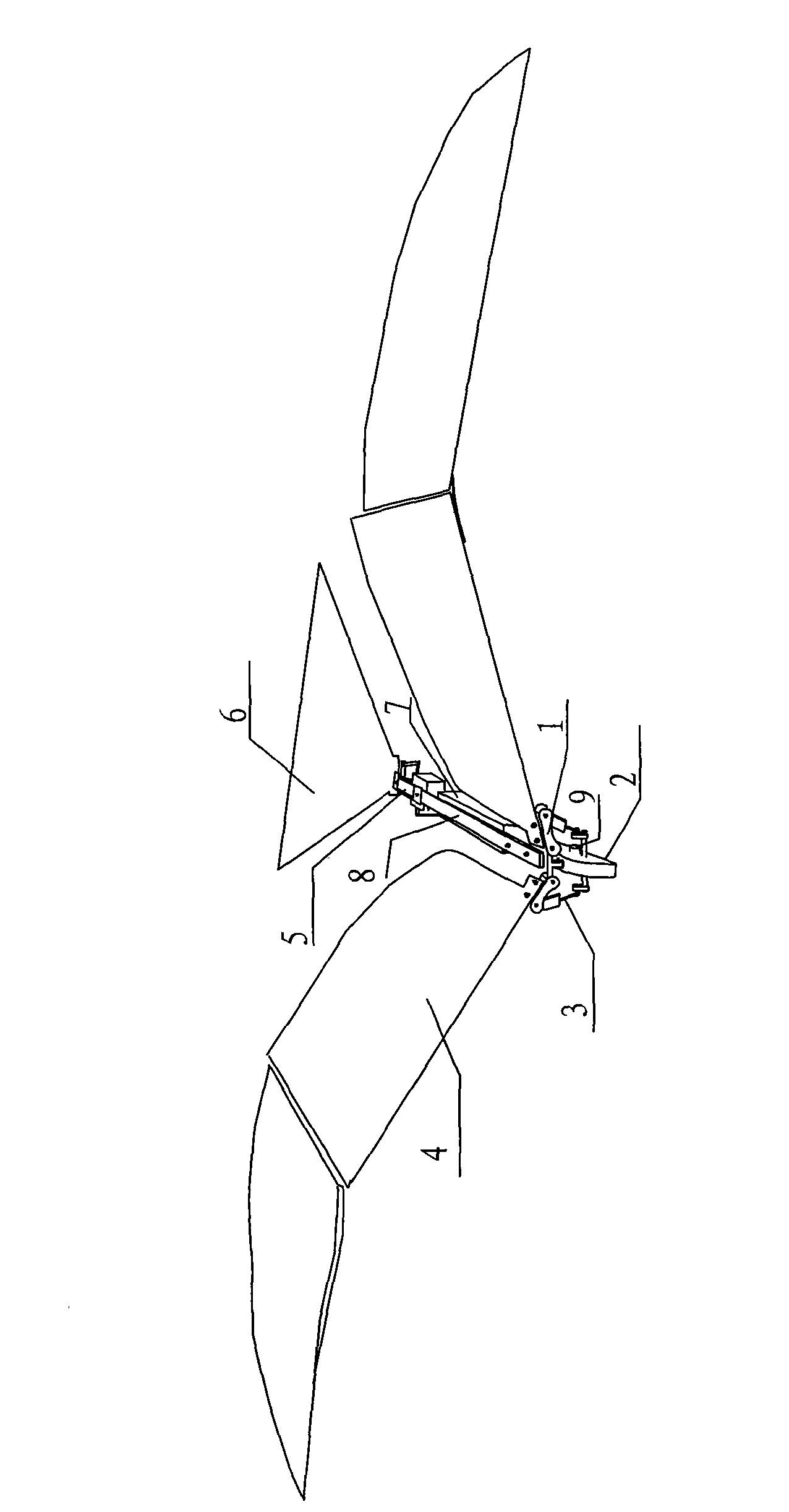

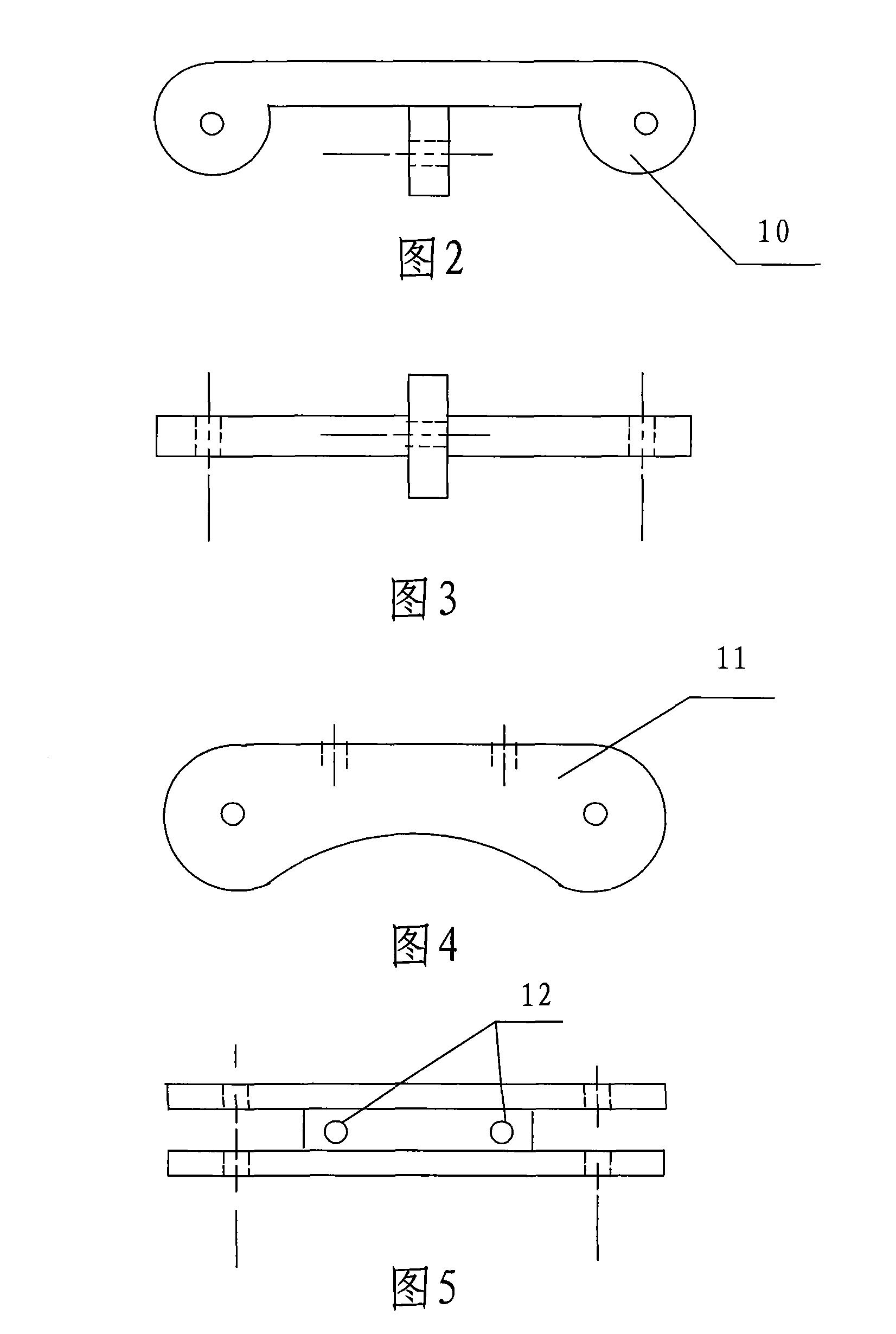

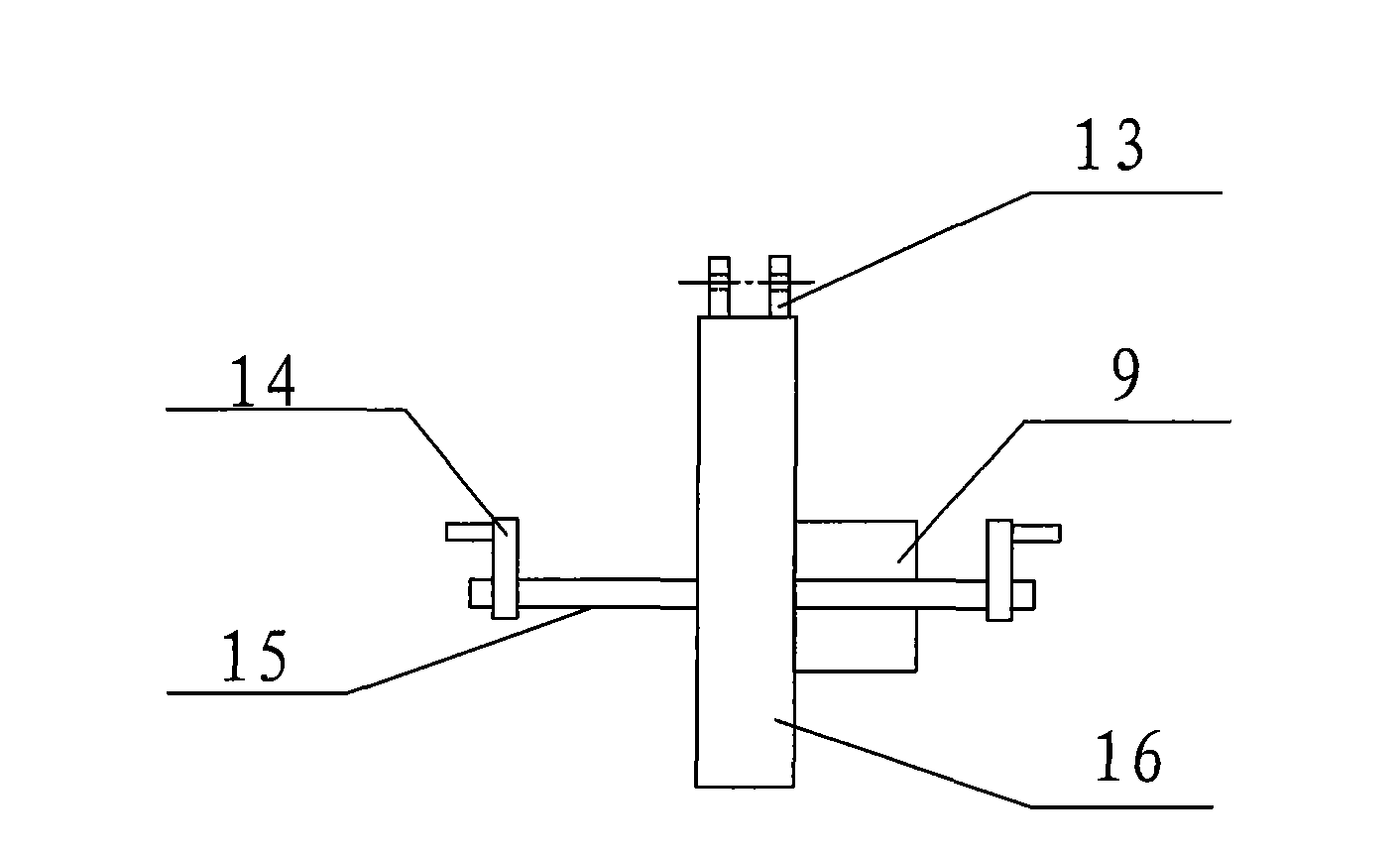

[0037] The two-way synchronous automatic flip flapping wing aircraft of the present invention comprises a flapping wing mechanism 1, a two-way synchronous output reduction mechanism 2, a connecting rod 3, a wing 4, an empennage control mechanism 5, an empennage 6, an equipment main box 7, a fuselage 8 and a motor 9 . After the motor 9 decelerates through the two-way synchronous output reduction mechanism 2, the flapping wing mechanism 1 is driven by the connecting rod 3 to drive the wing 4 to flutter up and down and automatically turn over. When the motor 9 rotated forward or reversed under the action of the control circuit, the wing 4 also fluttered and flipped forward or backward accordingly. Empennage control mechanism 5 controls empennage 6 to flutter up and down or turn left and right. Equipment such as battery, electronic governor and signal receiver are housed in the equipment general box 7. The fuselage 8 is used to connect various components, and there is an include...

Embodiment 2

[0054] Refer to attached Figure 18 :

[0055] The wing end 17 of the connecting rod is equipped with a joint bearing, which is connected with the outer end hole of the wing root 11 through a shaft. Two movable joint bearings are respectively installed on both sides of the joint bearing, which are connected to the connecting rod 3 through a spring; Joint bearing is arranged, is connected with crank 14. The 17 bearing holes at the wing end of the connecting rod are perpendicular to the center lines of the 18 bearing holes at the crank end of the connecting rod. This design enables the wing 4 to flip over at a greater angle during flight. Two movable joint bearings and springs are installed on the left and right to protect the joint bearing at the wing end 17 of the middle link from being damaged due to an excessive flip angle. .

[0056] attached Figure 17 It is the schematic diagram of the wing motion of embodiment 2. Refer to attached Figure 17 A brief description of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com