Bending device for terminal

A terminal block and bending device technology, which is applied in the manufacture of contact parts, etc., can solve the problems of poor bending effect, affecting the effect of wiring assembly, low efficiency of manual bending, etc., and achieves convenient and fast positioning installation and convenient positioning , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

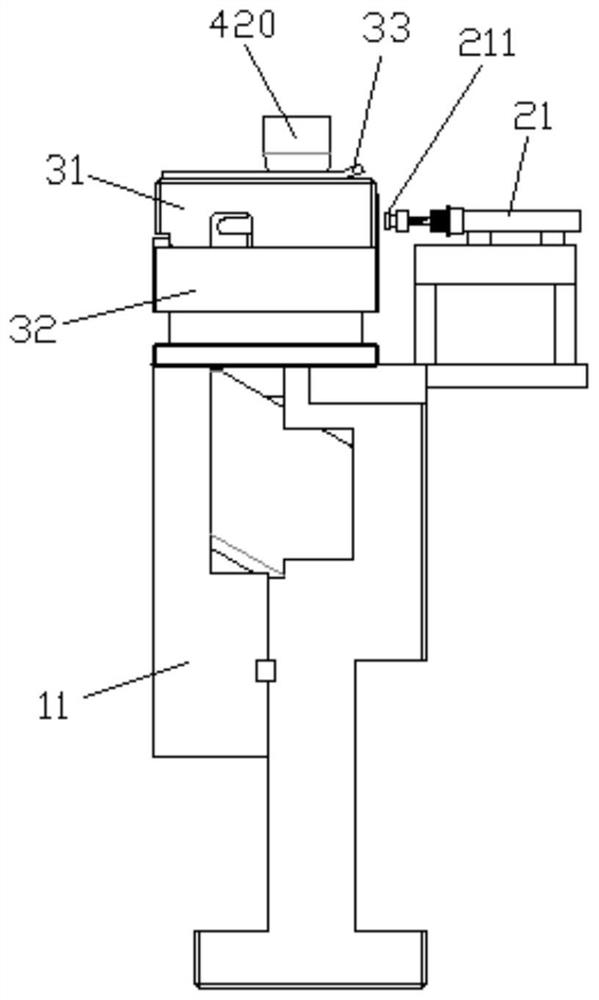

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

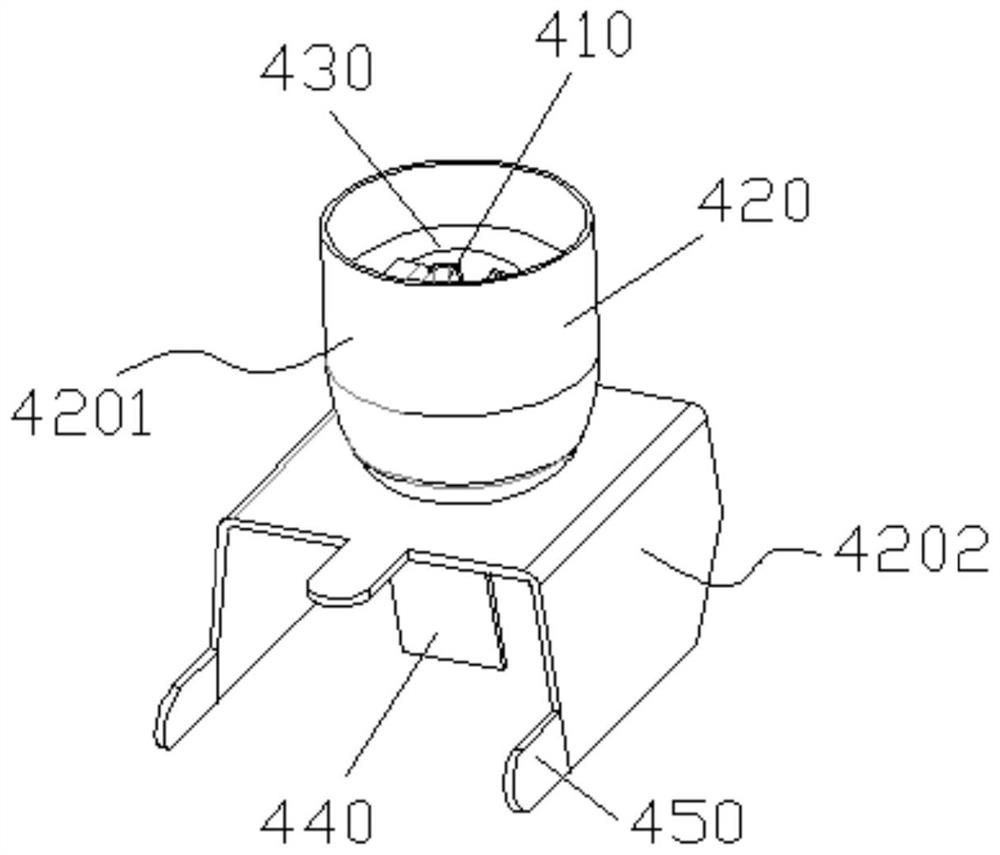

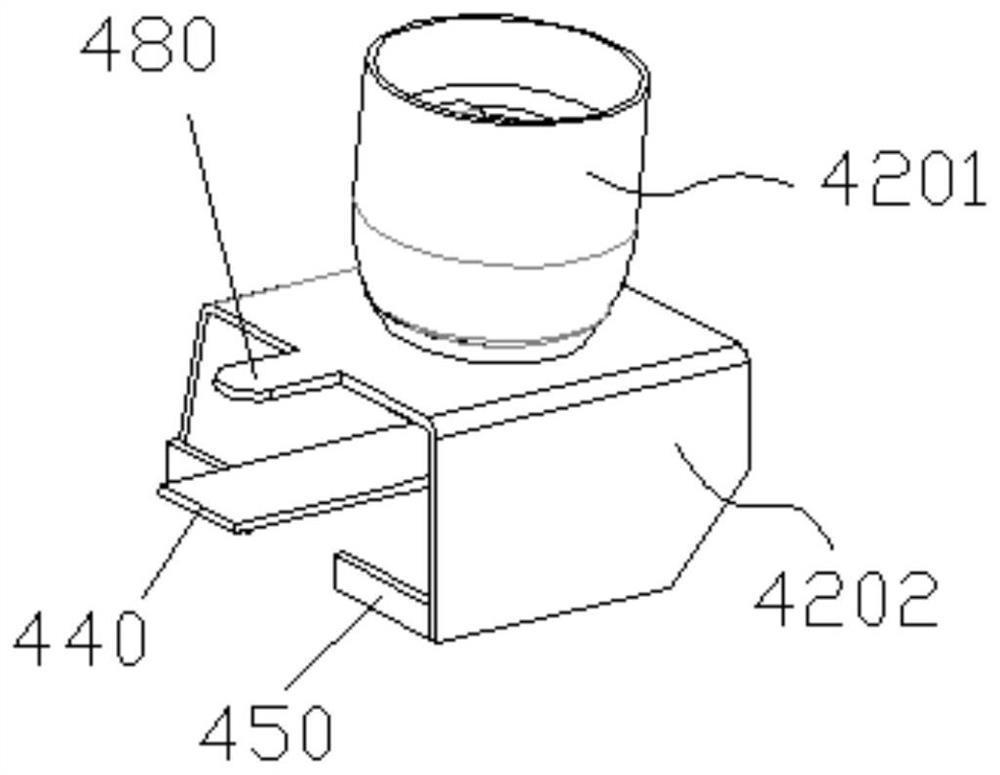

[0027] The present invention is a kind of bending device of connecting terminal, and the specific structure of connecting terminal involved in the present invention is as follows (as figure 1 and figure 2 ):

[0028] The terminal block includes an inner conductor 410, an outer conductor 420 and an intermediate insulating spacer 430. The outer conductor 420 includes a cylindrical sleeve 4201 and a U-shaped plate 4202. The U-shaped plate 4202 includes two sides and a bottom edge. The cylindrical sleeve 4201 The bottom end surface and the bottom edge of the U-shaped plate 4202 are welded and fixed together, and the two sides of the U-shaped plate 4202 are arranged along the axial direction of the cylindrical sleeve 4201 . On both sides of the U-shaped plate 4202, a first external insertion nose 450 is set, and a second external insertion nose 480 is arranged on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com