Formation of a core structure of a wind turbine rotor blade by using a plurality of basic core components

A technology for wind turbines and rotor blades, applied in the field of basic core components, manufacturing such basic core components, and structural support components, can solve problems such as difficulty in manufacturing, and achieve easy and cheap manufacturing. "The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] It should be noted that in different figures, similar or identical elements have reference numerals with the same last two digits.

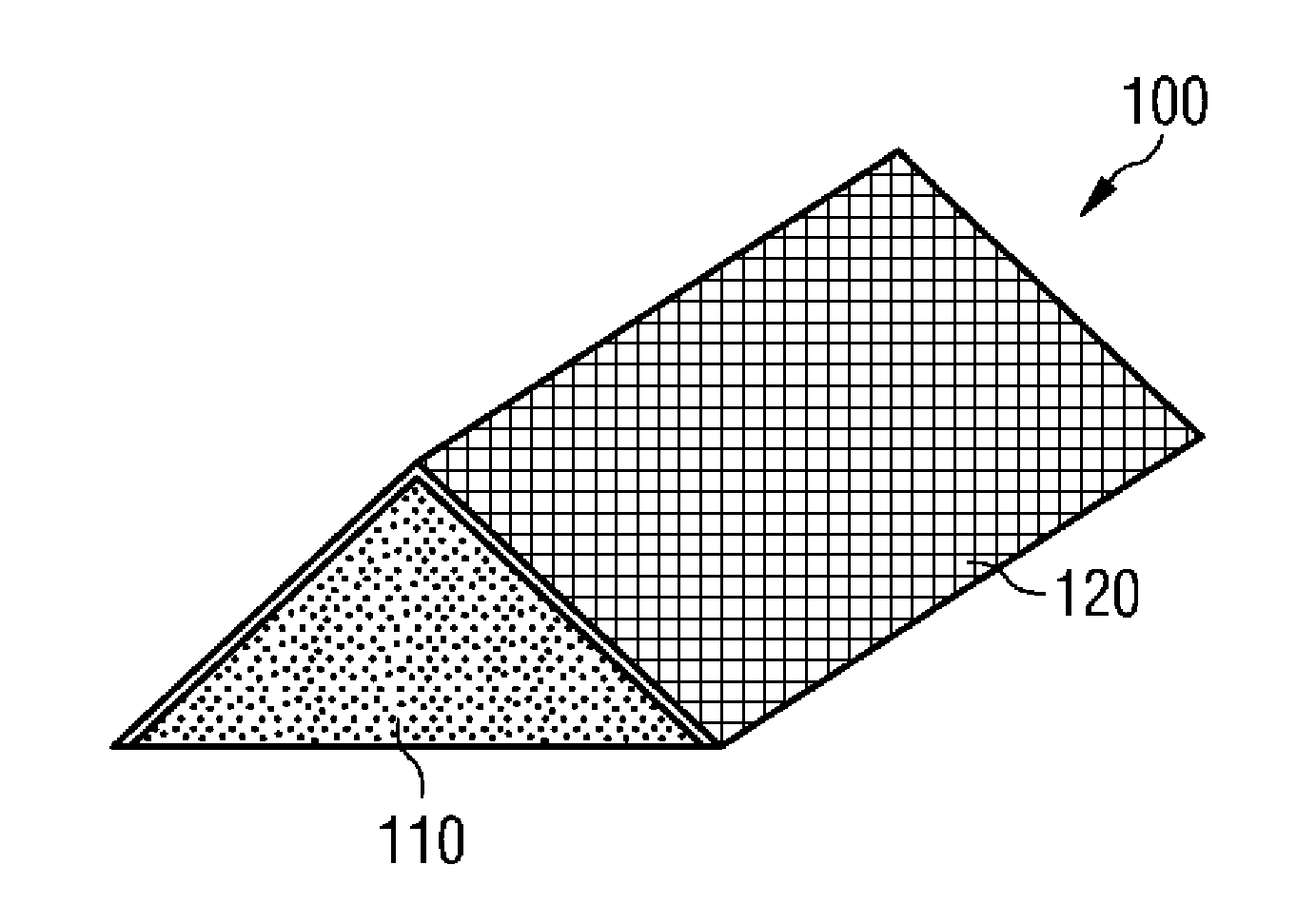

[0061] figure 1 A base core member 100 is shown having a triangular cross-sectional shape. According to the embodiments described here, a triangle has a right angle and two sides of the same length. It should be mentioned that the described invention is not limited to basic core members having such a triangular cross-sectional shape. Besides triangles, other forms can also be used.

[0062] The base core part 100 comprises a pre-cast base element 110 made of foam material. The precast base element is therefore also referred to as a foam profile 110 . The resin receiving layer 120 is adhered to the two surfaces associated with the two triangle sides having the same length. According to the embodiment described here, the resin receiving layer is a fiber layer 120, such as a glass fiber layer and / or a carbon fiber layer.

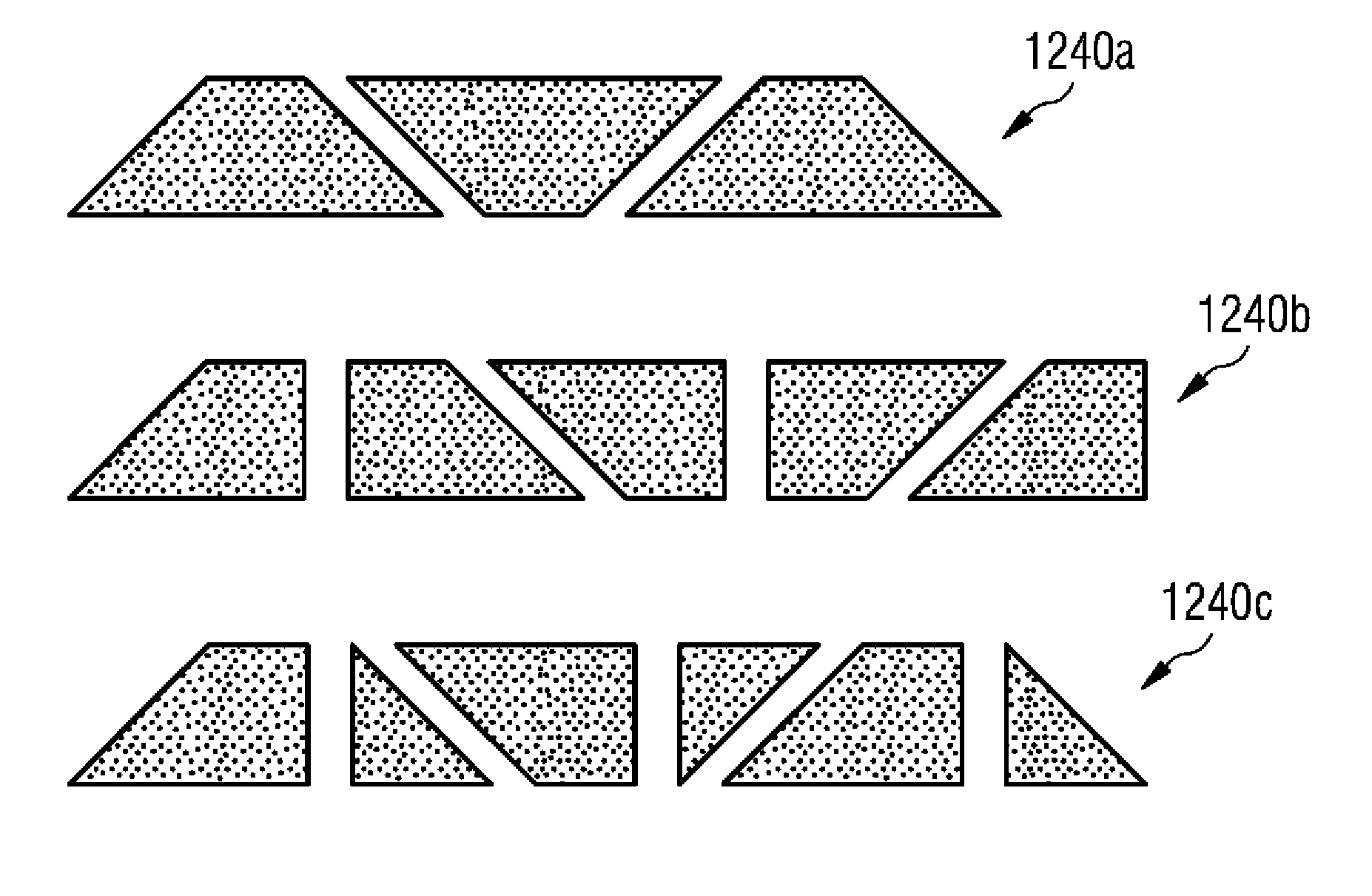

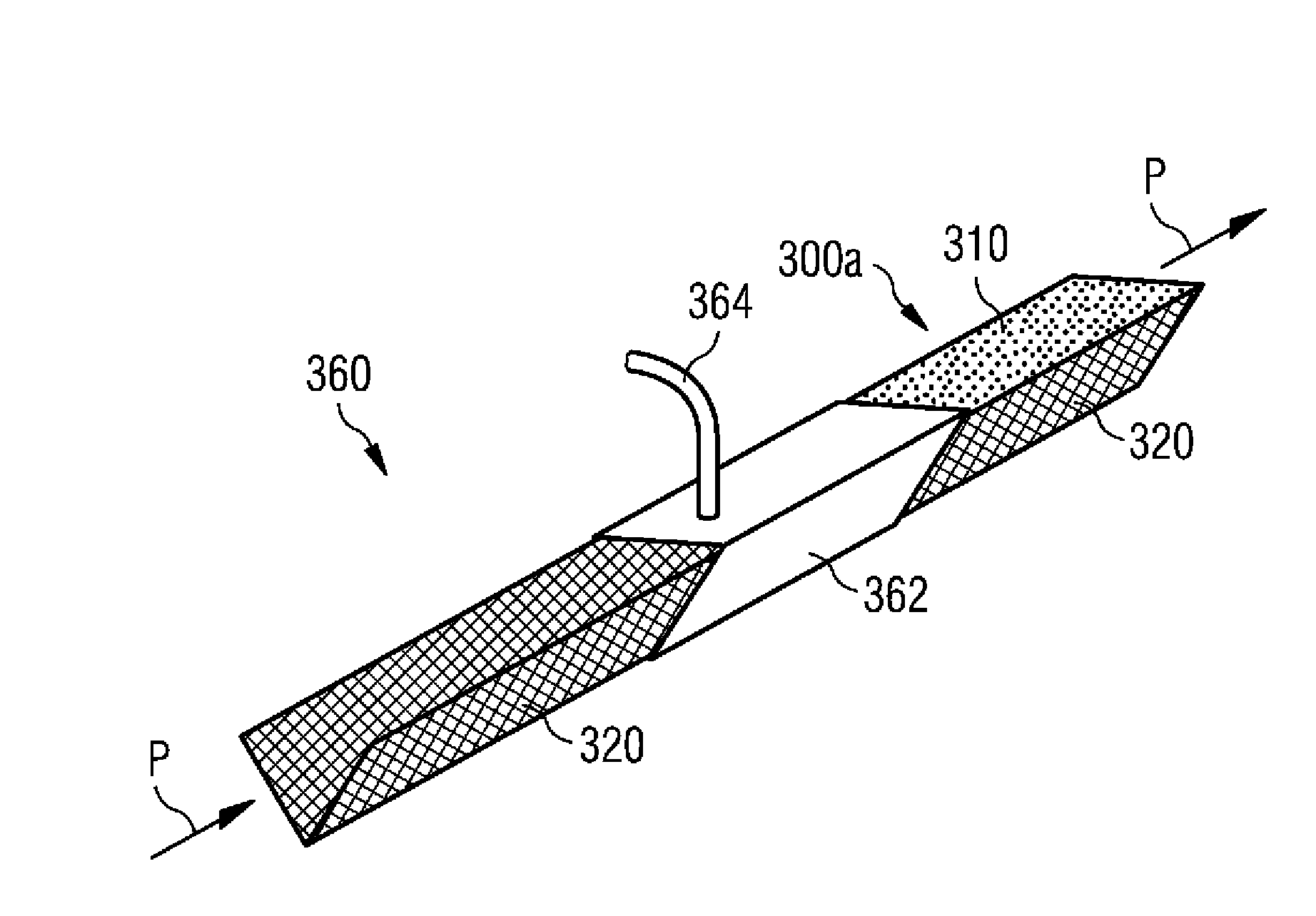

[0063] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com