Smoke discharge pipe assembly for gas-fired equipment

A smoke exhaust pipe and component technology, which is applied in the field of household gas equipment, can solve the problems of not providing the connection method of the smoke exhaust pipe, and achieve the effects of reducing displacement, stabilizing the mechanical connection, and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

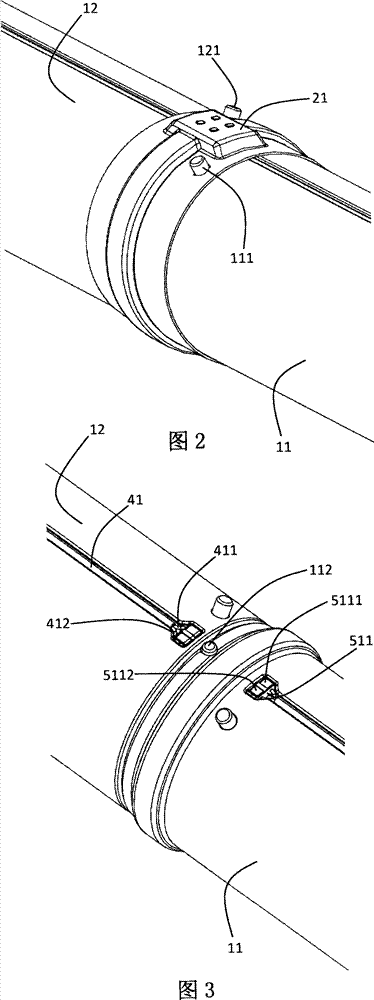

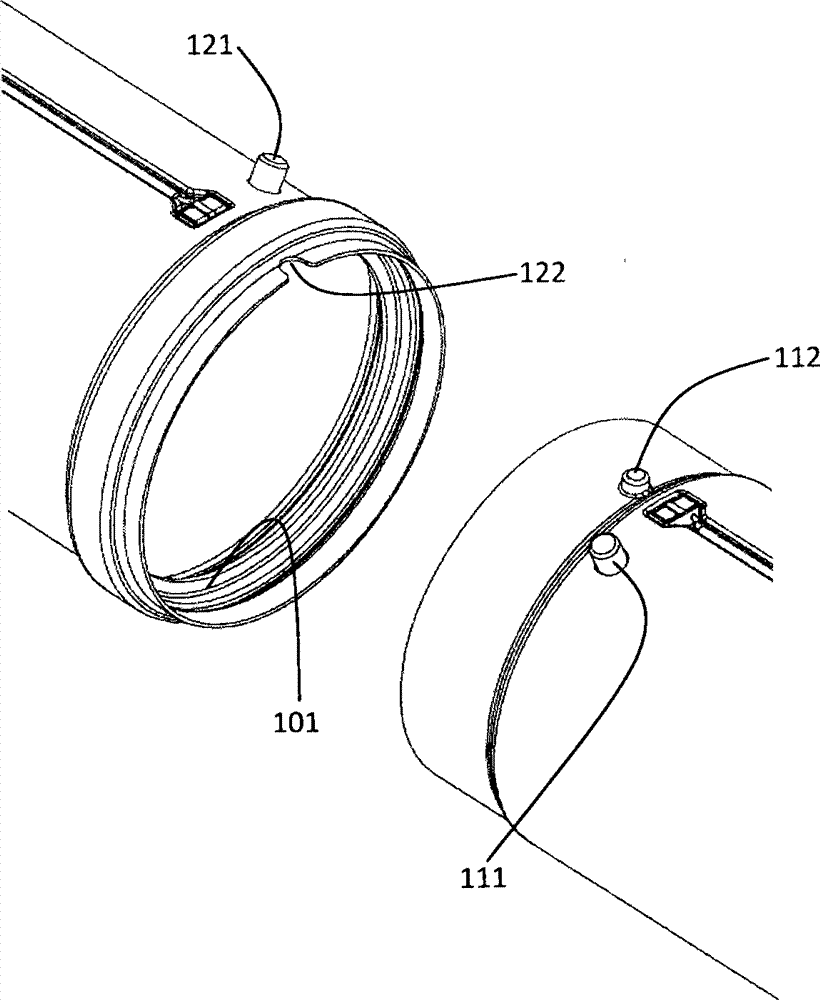

[0034] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0035] Gas equipment uses combustible gas as fuel, such as natural gas, city gas, liquefied petroleum gas, biogas, etc., and provides heat by burning combustible gas to meet the needs of users. For example, gas water heaters that provide domestic hot water can also provide domestic Gas boilers for hot water and heating needs, and gas cookers, etc. Next, the smoke exhaust pipe assembly of the present invention will be described by taking a gas water heater as an example.

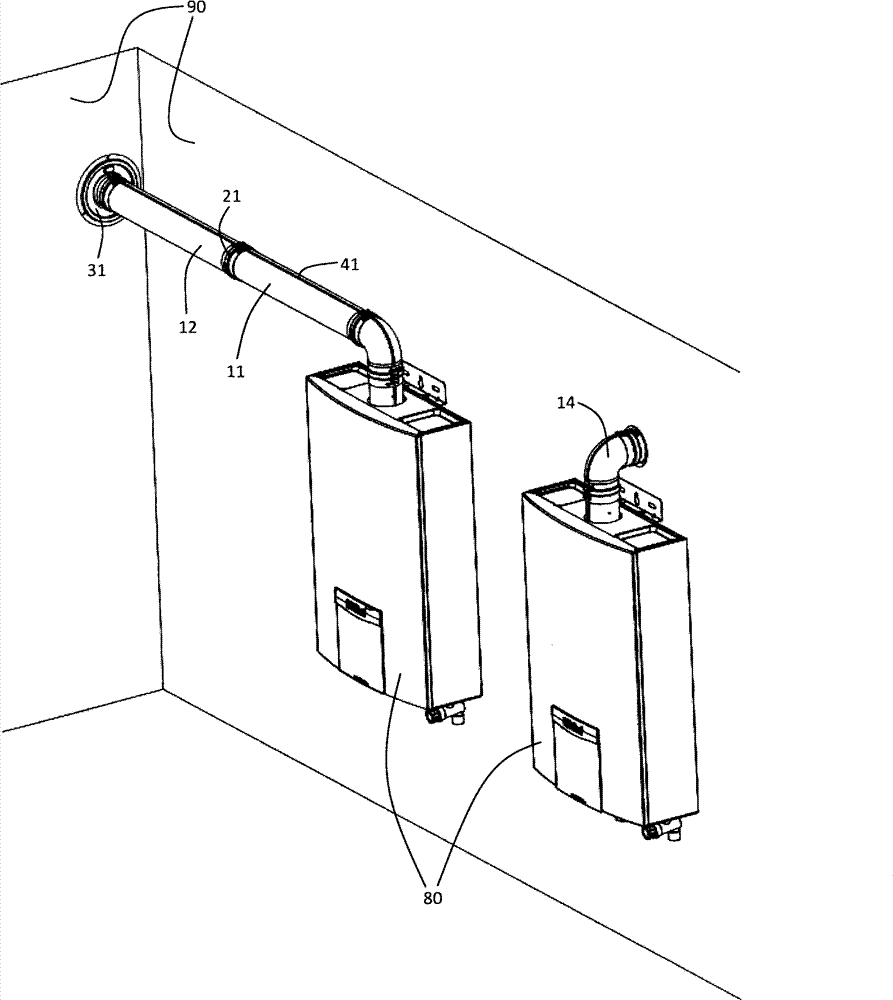

[0036] Such as figure 1 As shown, the gas water heater 80 can be exhausted through the smoke exhaust pipeline formed by the connection of variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com