Method for preparing conductive polymer/carbon nanotube composite fiber thermoelectric material

A carbon nanotube composite and conductive polymer technology, applied in the direction of thermoelectric device node lead-out wire materials, etc., can solve the problems of fiber breakage, difficulty of continuous fiber materials, and inability to prepare continuous fibers, etc., to achieve compact structure, improve thermoelectric performance, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of spinning solution

[0034] Using commercial conductive polymer monomer solution, carbon nanotubes, polymerization agent, etc. as raw materials, according to the set ratio of polymer and carbon nanotubes, each reactant is weighed, and the polymer is prepared by in-situ doping and polymerization methods. / carbon nanotube mixed solution. Adjust the polymerization conditions to obtain conductive polymers with appropriate molecular weights. Adjust the polymer doping state and improve the solubility of the polymer. Select appropriate organic solvent to prepare spinning solution with appropriate concentration.

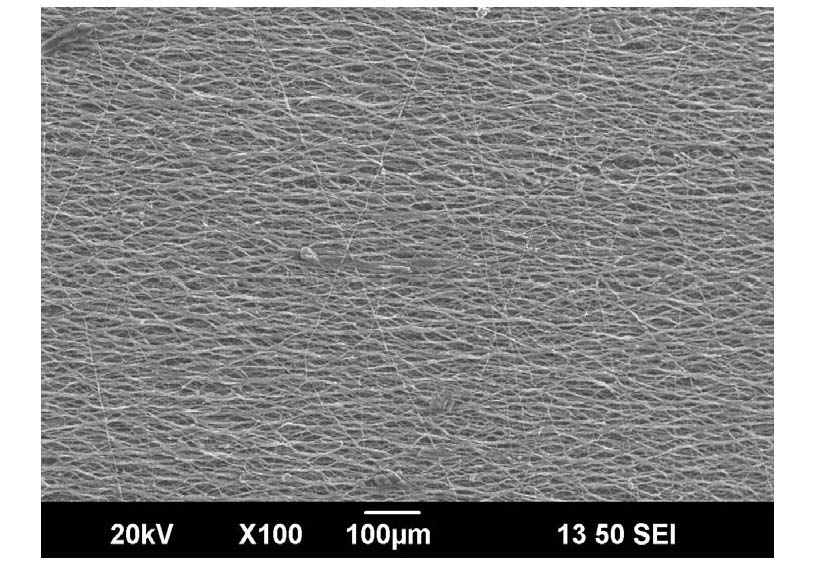

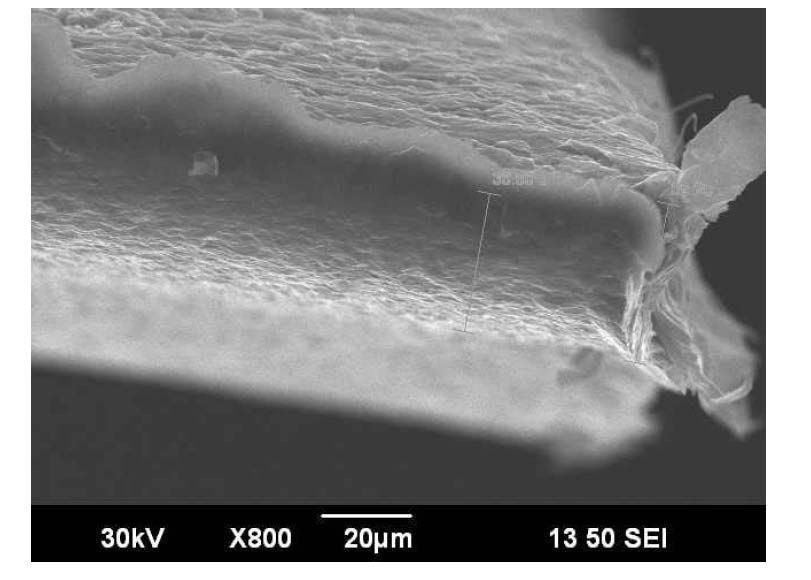

[0035] Preparation of spun film

[0036] The prepared conductive polymer / carbon nanotube spinning solution is added into a syringe with an appropriate needle diameter, the jet flow rate of the spinning solution is adjusted, and a certain high electric field intensity is applied to induce electrospinning. Use the roller with aluminum foil as the rece...

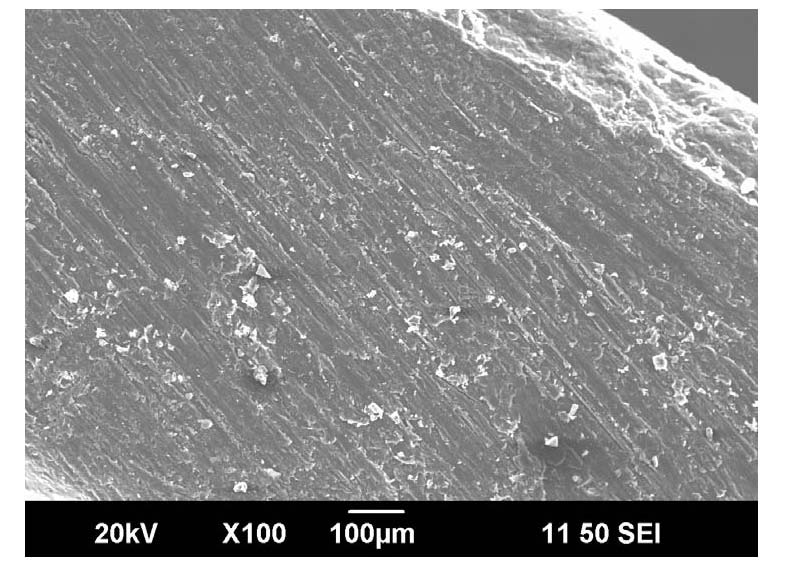

Embodiment 1

[0045] Preparation of polyaniline / carbon nanotube (wt40%) composite spinning solution: using commercial aniline solution, ammonium persulfate, hydrochloric acid, etc. as raw materials, first prepare 50ml, 1M hydrochloric acid, add 2.5ml aniline monomer solution and 1.67g carbon nano Tube, ultrasonically dispersed for 20 minutes. Prepare 5g of ammonium persulfate and 20ml of 1M hydrochloric acid solution, slowly add to the above reactants, and react in an ice bath for 6 hours to prepare a doped polyaniline / carbon nanotube composite solution. The filter cake was obtained by vacuum filtration, followed by vacuum drying at 60° C. for 48 hours. Then, the prepared powder is added into ammonia water for dedoping. After vacuum drying at 60 degrees for 48 hours, 912 mg of polyaniline / carbon nanotube composite in intrinsic state and 1140 mg of camphorsulfonic acid were added to 90 ml of dichloromethane or trichloromethane solution, and 12 mg of polyethylene oxide was added simultaneous...

Embodiment 2

[0049] Preparation of polyaniline / carbon nanotube (wt15%) composite fiber thermoelectric material: In this embodiment, the carbon nanotubes added in the preparation process of polyaniline spinning solution is 15% by weight. The preparation process of the spinning membrane is as follows: the prepared spinning solution is added to a syringe with a needle diameter of about 0.5mm, the injection flow rate of the spinning solution is adjusted to 2ml / h, and a high electric field of 10KV is applied to induce electrospinning. The spun film was deposited on a roller glued with aluminum foil as a receiving electrode, and the rotation speed of the roller was 1300 rpm. The preparation process parameters and process steps of the fiber blocks are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com