Method for preparing Bi-Sb-Te series thermoelectric material

A thermoelectric material, bi-sb-te technology, applied in the field of thermoelectric material preparation, can solve the problems of inability to return to the furnace for reuse, harsh single crystal growth conditions, poor machinability, etc., and achieves good industrial application prospects and short sintering time. , the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Mix the high-purity (≥99.9%) raw material powder according to the atomic ratio Bi:Sb:Te=0.4:1.6:3, mix it with balls, and then perform high-energy ball milling to obtain alloy powder, with a ball-to-material weight ratio of 15: 1. The ball milling speed is 400r / min, the ball milling time is 12h, and the ball milling is protected by high-purity argon gas. The ball milling is carried out in a steel ball milling tank. The selected balls can be stainless steel or hard alloy;

[0020] (2) Put the above-mentioned alloy powder into a graphite mold or a special powder metallurgy steel mold or a hard alloy mold, and sinter it in a plasma-activated sintering furnace. The heating rate is 40°C / min, and the sintering temperature is 410°C. Pressurization method, the pressure in the heating stage is 20MPa, the pressure in the holding stage is 40MPa, the holding time is 20min, and the whole sintering process is protected by argon atmosphere.

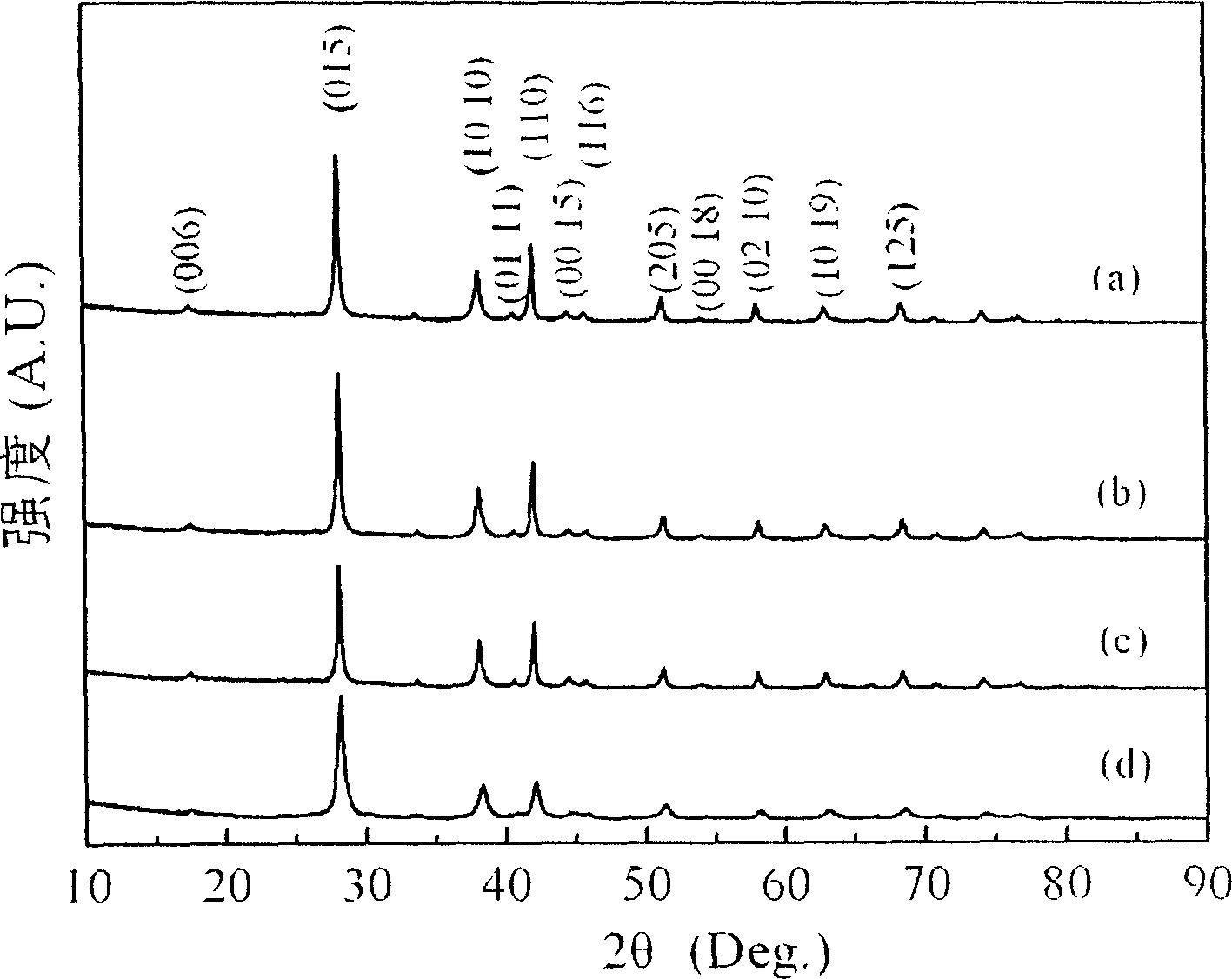

[0021] The X-ray diffraction patterns ...

Embodiment 2

[0023] (1) Mix the high-purity (≥99.9%) raw material powder according to the atomic ratio Bi:Sb:Te=0.2:1.8:3, mix it with balls, and then perform high-energy ball milling to obtain alloy powder, with a ball-to-material weight ratio of 20: 1. The ball milling speed is 380r / min, the ball milling time is 12h, and the ball milling is protected by high-purity argon;

[0024] (2) Put the above-mentioned alloy powder into a graphite mold, and sinter it in a plasma-activated sintering furnace. The heating rate is 40°C / min, and the sintering temperature is 410°C. Two-step pressurization method is adopted. The pressure in the heating stage is 20MPa, and the pressure in the holding stage is 40MPa. , The holding time is 20min, and the whole sintering process is protected by argon atmosphere.

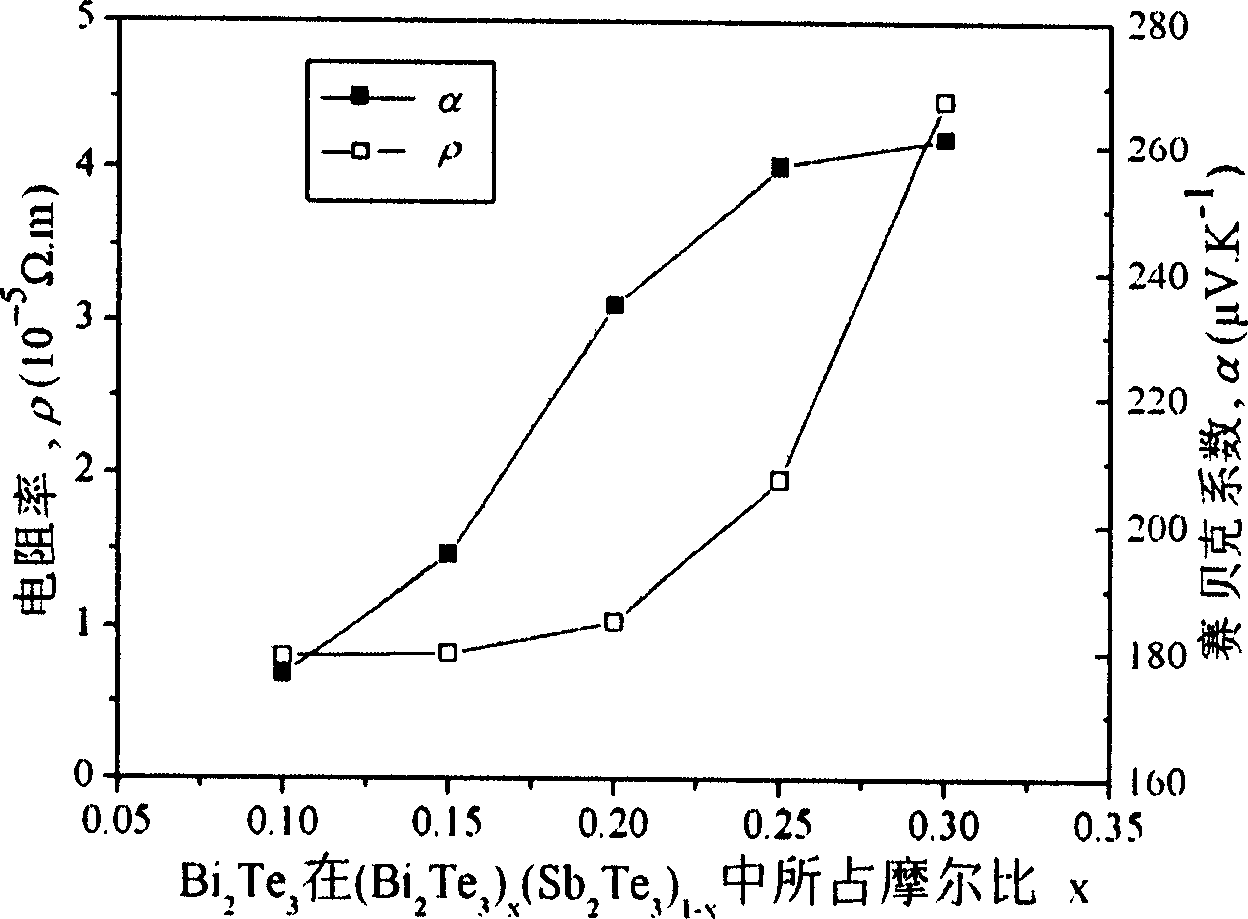

[0025] The thermoelectric performance was tested at 300K, and the resistivity ρ of the sintered sample was 0.801×10 -5 Ω.m, thermal conductivity κ is 1.210W / mK, Seebeck coefficient α is 176.36μV / K,...

Embodiment 3

[0027] (1) Mix the high-purity (≥99.9%) raw material powder according to the atomic ratio Bi:Sb:Te=0.6:1.4:3, mix it with balls, and then perform high-energy ball milling to obtain alloy powder, with a ball-to-material weight ratio of 10: 1. The ball milling speed is 350r / min, the ball milling time is 10h, and the ball milling is protected by high-purity argon;

[0028] (2) Put the above-mentioned alloy powder into a graphite mold, and sinter it in a plasma-activated sintering furnace. The heating rate is 60°C / min, and the sintering temperature is 410°C. Two-step pressurization method is adopted. The pressure in the heating stage is 20MPa, and the pressure in the holding stage is 40MPa. , The holding time is 10min, and the whole sintering process is protected by argon atmosphere.

[0029]The thermoelectric performance was tested at 300K, and the resistivity ρ of the sintered sample was 4.490×10 -5 Ω.m, thermal conductivity κ is 0.997W / mK, Seebeck coefficient α is 261.30μV / K, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com