Method for obtaining high-performance polyaniline base thermoelectric materials

A polyaniline-based, thermoelectric material technology, applied in the direction of thermoelectric device junction lead-out material, etc., can solve the problems of difficult to achieve highly ordered arrangement of polyaniline molecules, limited thermoelectric performance, etc., to reduce the π-π conjugation effect. , low cost, and the effect of improving the degree of order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

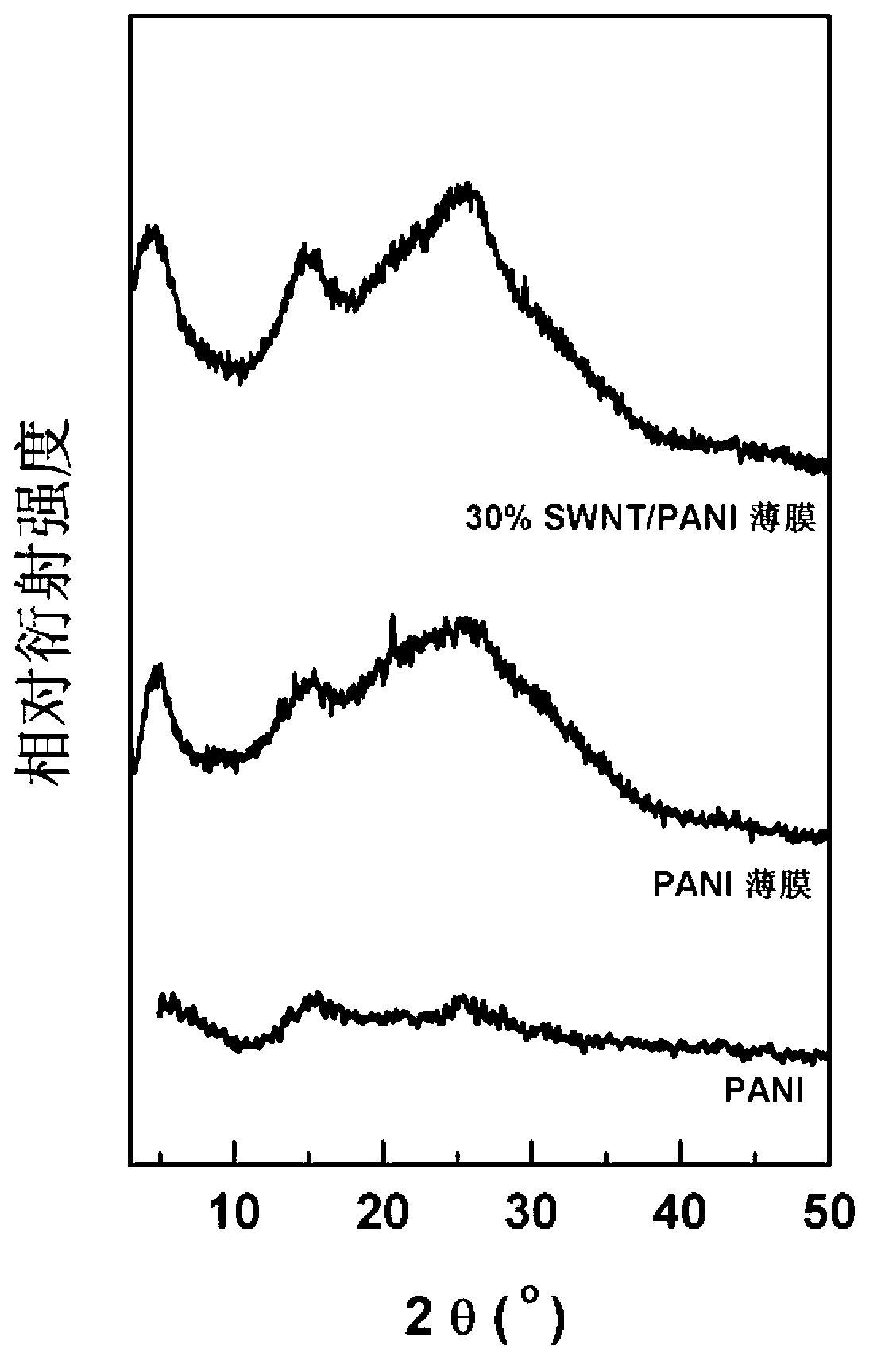

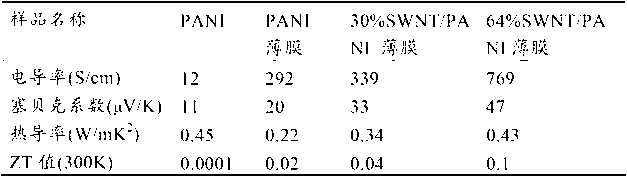

[0022] Preparation of polyaniline film (PANI film) thermoelectric material and single-walled carbon nanotube / polyaniline composite film (SWNT / PANI film) thermoelectric material from m-cresol solvent

[0023] The initial polyaniline powder (PANI) (0.86 g) prepared by in-situ oxidative polymerization was added to 250 mL of 1 mol / L ammonia solution, stirred for 24 hours, filtered, and vacuum-dried at 60°C to obtain the intrinsic polyaniline powder. Take 0.093g polyaniline powder in the intrinsic state, add an appropriate amount of camphorsulfonic acid according to the molar ratio of camphorsulfonic acid and polyaniline as 1:2, mix and fully grind for 2 hours to obtain polyaniline doped with camphorsulfonic acid powder.

[0024] Then, the polyaniline powder doped with camphorsulfonic acid was added into 6 mL of m-cresol, and stirred and reacted at room temperature for 8 hours to obtain a polyaniline solution. Draw about 0.03mL solution and pour it to an area of 20×20mm 2 On a ...

Embodiment 2

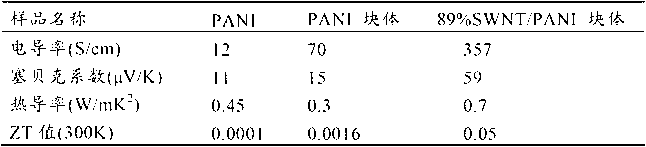

[0027] Preparation of polyaniline bulk (PANI bulk) thermoelectric materials and single-wall carbon nanotube / polyaniline composite bulk (SWNT / PANI bulk) thermoelectric materials from m-cresol solvent

[0028] The preceding steps of Example 1 were repeated to prepare polyaniline powder doped with camphorsulfonic acid. 0.21 g of camphorsulfonic acid-doped polyaniline powder was weighed and added into 3 mL of m-cresol solvent, and stirred at room temperature for 8 hours to obtain a concentrated solution of polyaniline. Take 1mL polyaniline concentrated solution, first dry naturally at room temperature in a fume hood to remove most of the solvent, and then put it in a vacuum drying oven at 60°C for 72 hours to obtain a polyaniline block treated with m-cresol solvent (PANI block).

[0029]Add single-walled carbon nanotubes with masses of 0.0465g, 0.372g, and 1.767g to the above-mentioned concentrated solution of polyaniline (the content of intrinsic polyaniline is 0.093g), and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com