High-mechanical-strength potassium-sodium niobate based lead-free piezoelectric ceramic material, preparation method of material and application of material

A potassium sodium niobate-based, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of low bending strength and achieve good electrical properties, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention provides a method for preparing the potassium sodium niobate-based lead-free piezoelectric ceramic material described in the above technical solution, comprising the following steps:

[0061] (1) According to the type and molar ratio of each metal element in the potassium sodium niobate-based lead-free piezoelectric ceramic material, weigh the corresponding amount of Li 2 CO 3 、K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Ta 2 o 5 , MnO 2 , Fe 2 o 3 、Ni 2 o 3 , CuO, Cr 2 o 3 、Co 2 o 3 , CeO 2 、Nd 2 o 3 and Yb 2 o 3 , as a raw material;

[0062] (2) crushing the raw materials to obtain a mixture;

[0063] (3) Pre-burning the mixture to obtain a pre-fired material;

[0064] (4) crushing the calcined material to obtain a fine powder;

[0065] (5) After mixing the fine powder and the binder, press molding to obtain a molding material;

[0066] (6) Sintering the molding material to obtain a ceramic material;

[0067] (7) Putt...

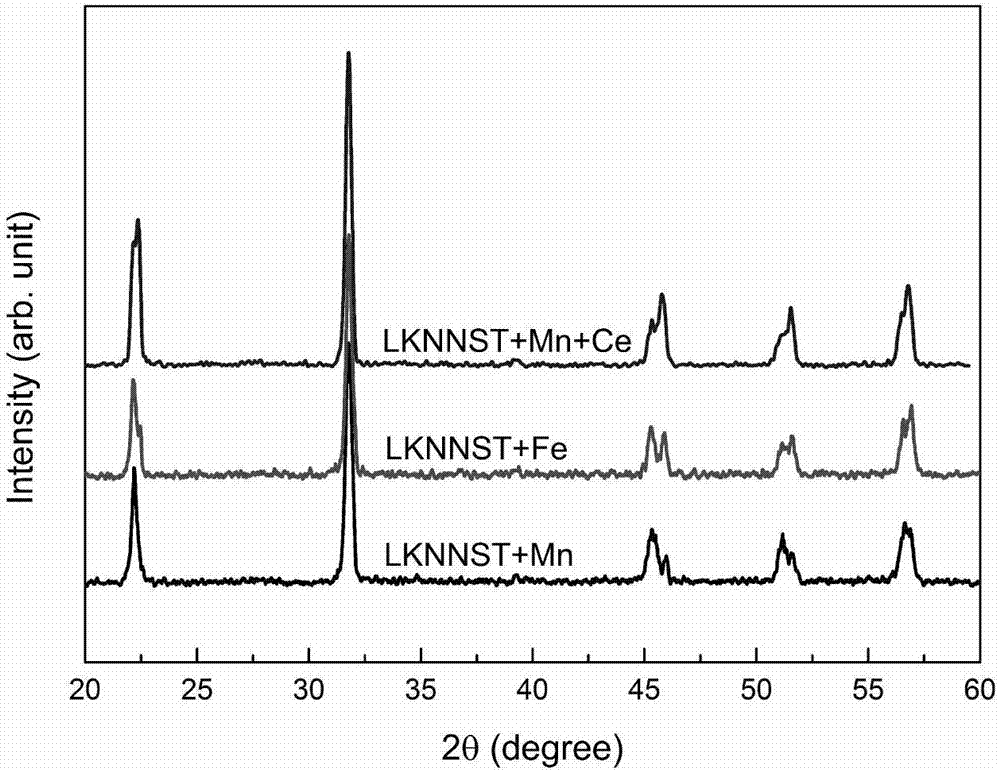

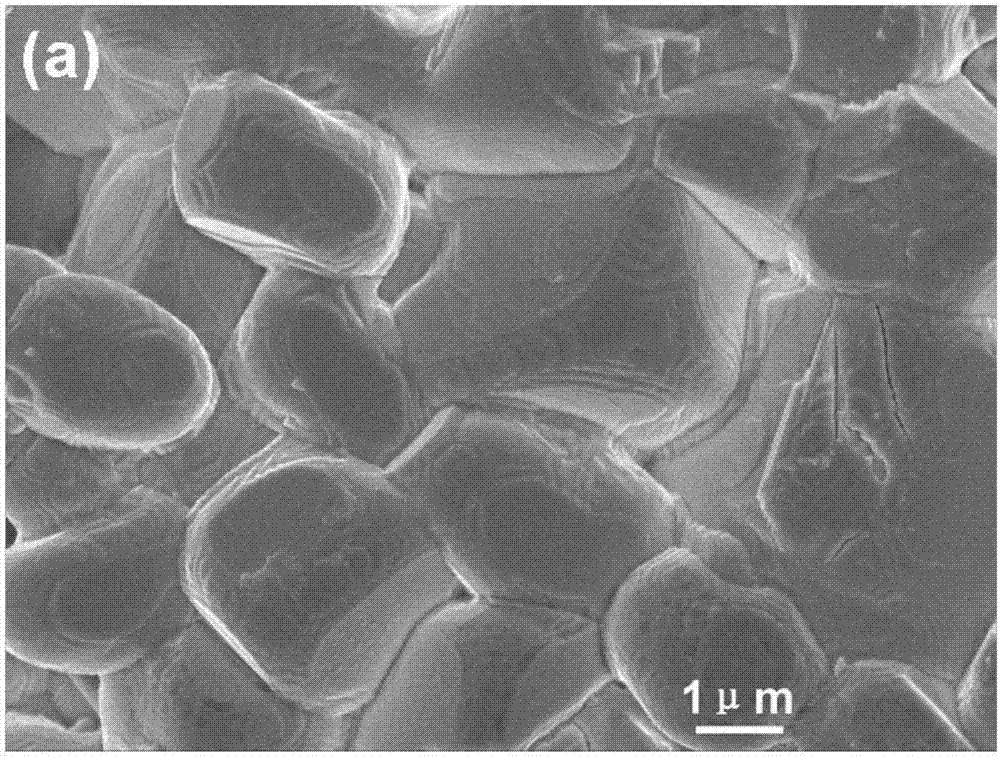

Embodiment 1

[0088] (1), purchase chemically pure Li from the market 2 CO 3 、K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Ta 2 o 5 , MnO 2 As raw material, according to the chemical formula [Li of potassium niobate base lead-free piezoelectric ceramic material of the present invention 0.06 (K 0.47-x Na 0.47+x )][(Nb 0.893 Sb 0.057 Ta 0.05 ]O 3 +y MnO 2, wherein x=0, y=0.0008 take the raw material; put the weighed raw material into the ball mill jar, add the dehydrated alcohol accounting for 80% of the total weight of the above raw material, and mix it on the planetary ball mill at a speed of 150r / min And grind for 2h;

[0089] (2), put the mixed material after ball milling in the crucible after drying at 80°C, pre-burn at 900°C, and keep it for 3.5h; After water ethanol, grind at a speed of 150r / min for 4h;

[0090] (3), dry the finely ground pre-fired synthetic powder at 80°C, add an appropriate amount of binder, place it in a mold, and press it into the required ceram...

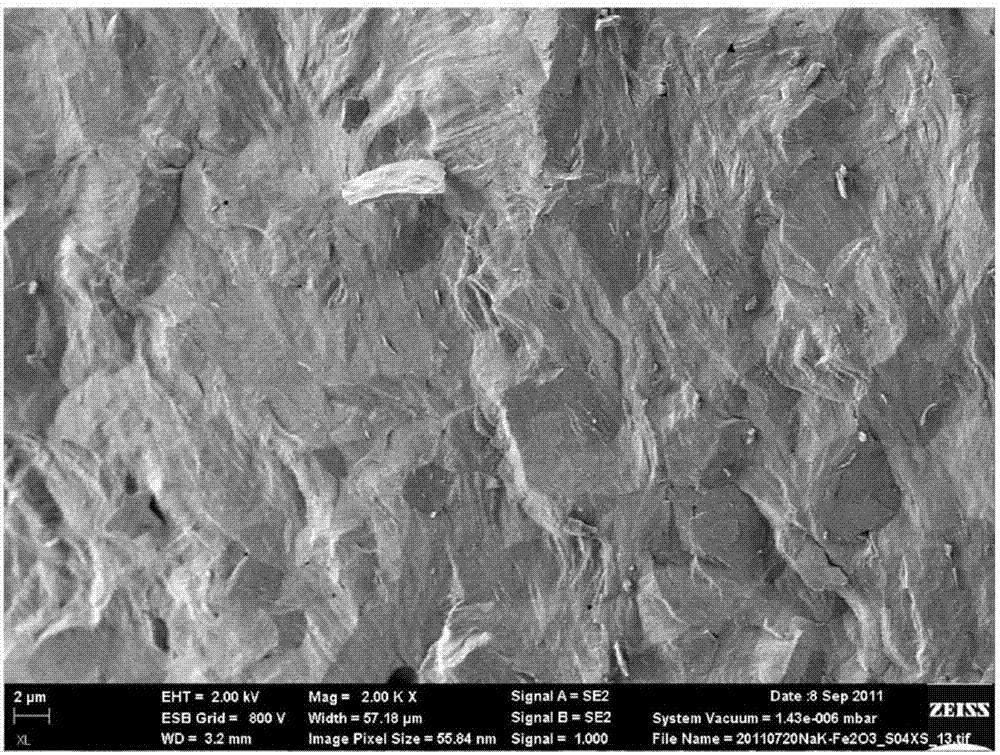

Embodiment 2

[0096] (1), purchase chemically pure Li from the market 2 CO 3 、K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , Sb 2 o 3 、 Ta 2 o 5 , MnO 2 As raw material, according to the chemical formula [Li of potassium niobate base lead-free piezoelectric ceramic material of the present invention 0.06 (K 0.47-x Na 0.47+x )][(Nb 0.893 Sb 0.057 Ta 0.05 ]O 3 +y MnO 2 , where x=0.03, y=0.0008 take the raw material; put the weighed raw material in the ball mill jar, add the dehydrated alcohol accounting for 80% of the total weight of the above raw material, and mix it on the planetary ball mill at a speed of 150r / min And grind for 2h;

[0097] (2), put the mixed material after ball milling in the crucible after drying at 80°C, pre-burn at 900°C, and keep it for 3.5h; After water ethanol, grind at a speed of 150r / min for 4h;

[0098] (3), dry the finely ground pre-fired synthetic powder at 80°C, add an appropriate amount of binder, place it in a mold, and press it into the required ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com