Multi-element sodium-potassium niobate series lead-free piezoelectric ceramic and preparing method

A potassium sodium niobate, lead-free piezoelectric technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of insufficient electrical performance and distance , to achieve excellent piezoelectric and electromechanical coupling properties, inhibit grain growth, and increase sintered density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Carry out each step successively according to above-mentioned embodiment mode, wherein

[0044] In step 1, take values according to x=0, z=0.03, w=0.5, f=0, g=0, u=0, n=0, t1=0 and t2=0,

[0045] The general formula of the composition is expressed as: 0.97 (Na 0.5 K 0.5 )NbO 3 +0.03(Bi 0.5 K 0.5 )TiO 3

[0046] In step 2, the calcination temperature is 900°C, and the calcination time is 5 hours;

[0047] In step 4, the sintering temperature of the green body is 1080° C., and the sintering time is 2 hours.

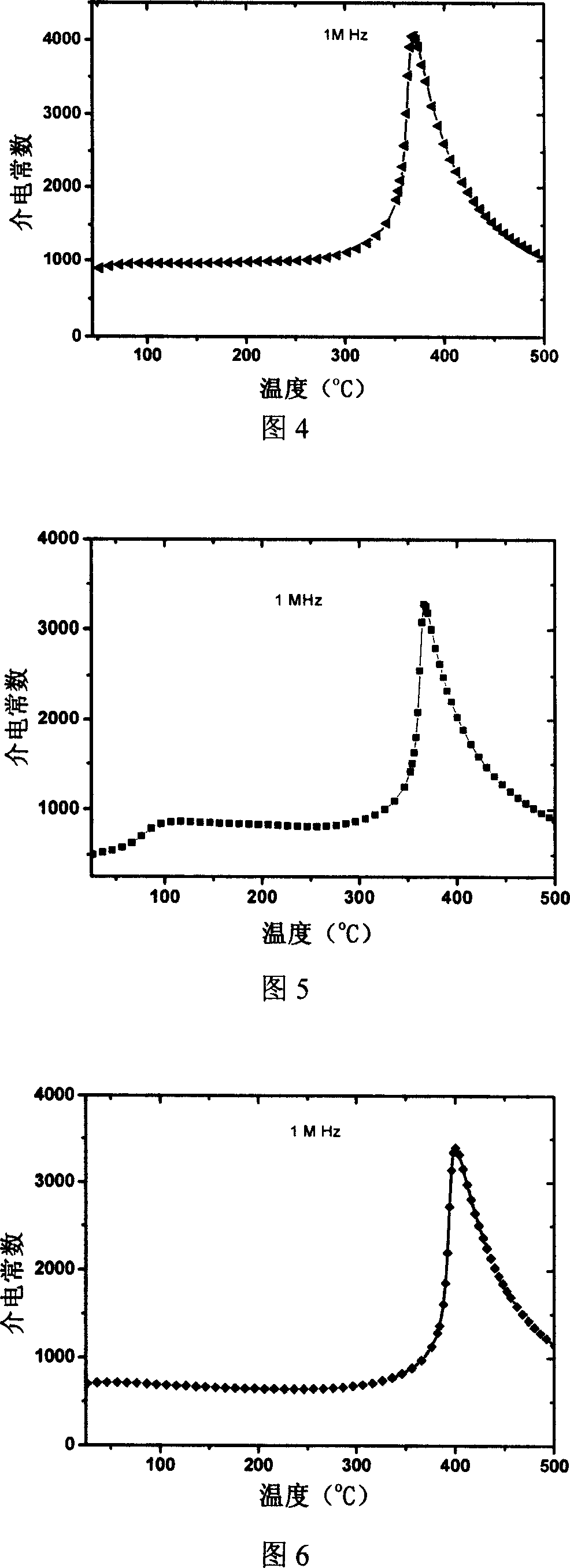

[0048] The scanning electron microscope photo of the obtained natural surface of the sample is shown in Figure 1, the dielectric-temperature characteristic curve of the sample is shown in Figure 4, and other relevant physical performance data:

[0049] Density (g / cm 2 ) Grain size (μm) ε 33 / ε o (1kHz) d 33 (pC / N)k p (%)

[0050] 4.31 3.2 850 191 45

Embodiment 2

[0051] Embodiment 2: Carry out each step successively according to above-mentioned embodiment mode, wherein

[0052] In step 1, take values according to x=1, z=0.02, w=0.5, u=0, n=0, g=0, f=0, t1=0 and t2=0,

[0053] The general formula of the composition is expressed as: 0.98 (Na 0.5 K 0.5 )NbO 3 +0.02(Bi 0.5 Na 0.5 )TiO 3

[0054] In step 2, the calcination temperature is 850°C, and the calcination time is 5 hours;

[0055] In step 4, the sintering temperature of the green body is 1090° C., and the sintering time is 2 hours.

[0056] The scanning electron microscope photo of the obtained natural surface of the sample is shown in Figure 2, the dielectric-temperature characteristic curve of the sample is shown in Figure 5, and other relevant physical performance data:

[0057] Density (g / cm 2 ) Grain size (μm) ε 33 / ε o (1kHz) d 33 (pC / N)k p (%)

[0058] 4.33 2.2 600 185 43

Embodiment 3

[0059] Embodiment 3: Carry out each step successively according to above-mentioned embodiment mode, wherein

[0060] In step 1, values are selected according to x=1, z=0.0192, w=0.5, u=0, n=0.0008, g=0, f=0, t1=0.025 and t2=0.025,

[0061] The general formula of the composition is expressed as: 0.98 (Na 0.475 K 0.475 Li 0.05 )NbO 3 +0.02(Bi 0.48 Na 0.48 Ba 0.04 )TiO 3

[0062] In step 2, the calcination temperature is 950°C, and the calcination time is 5 hours;

[0063] In step 4, the sintering temperature of the green body is 1080° C., and the sintering time is 2 hours.

[0064] The scanning electron microscope photo of the obtained natural surface of the sample is shown in Figure 3, the dielectric-temperature characteristic curve of the sample is shown in Figure 6, and other relevant physical performance data:

[0065] Density (g / cm 2 ) Grain size (μm) ε 33 / ε o (1kHz) d 33 (pC / N)k p (%)

[0066] 4.36 2.5 700 235 47

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com