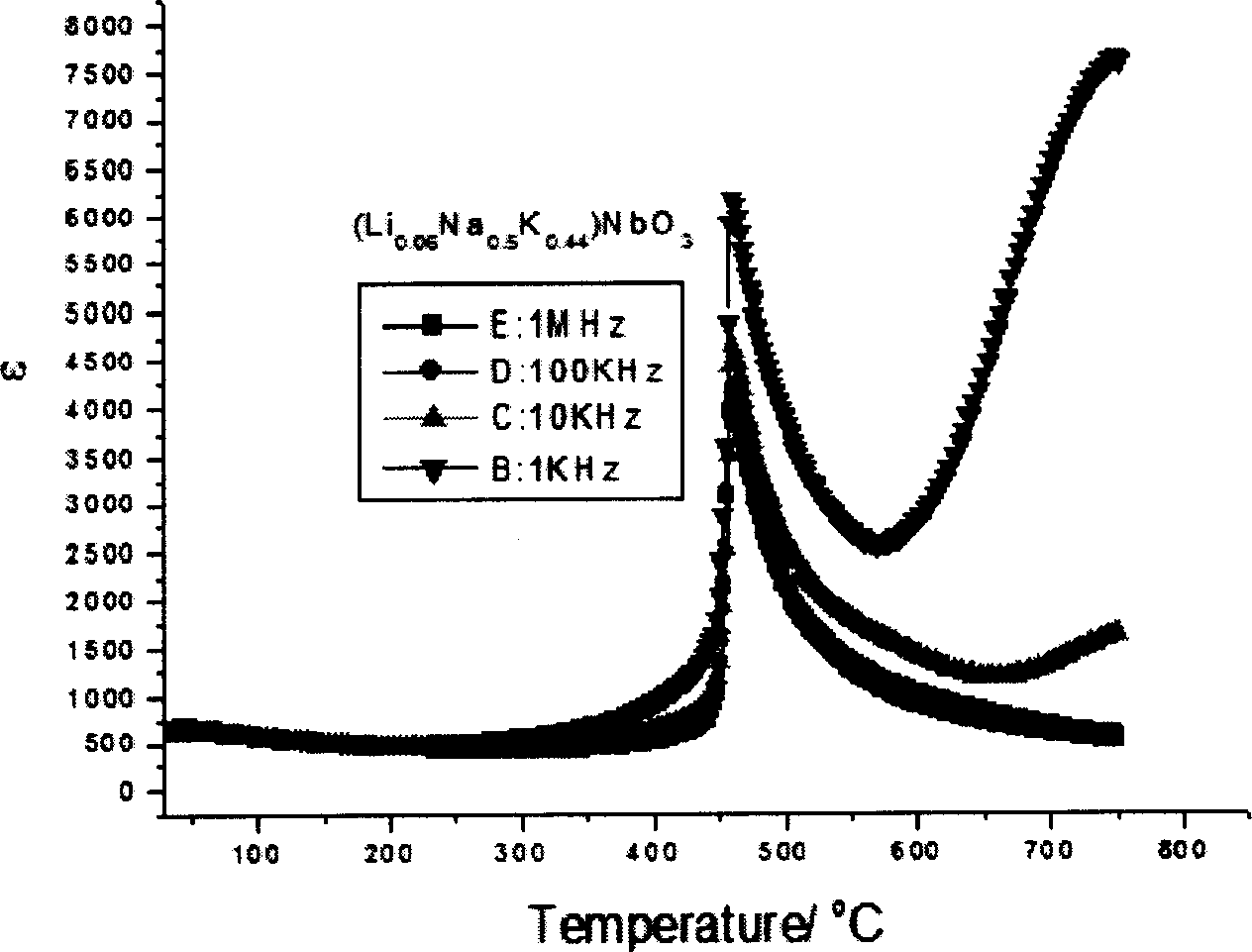

Lead-less lithium sodium potassium niobate piezoelectric ceramic with high curie point and its prepn

A lead-free piezoelectric and ceramic technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of staff health damage and surrounding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Formula: by the general formula (1-u)[(1-z)(Li x Na y K 1-x-y )NbO 3 +zMTiO 3 ]+uMnO 2 The lead-free piezoelectric ceramics indicated, when x=0.03, y=0.15, z=0, u=0, it is (Li 0.03 Na 0.15 K 0.82 )NbO 3

[0021] sintering

Embodiment 2

[0023] Formula: when x=0.03, y=0.25, z=0, u=0, it is (Li 0.03 Na 0.25 K 0.72 )NbO 3

[0024] The preparation process is as described above, and the performance parameters of the obtained lead-free piezoelectric ceramics are as follows:

[0025] sintering

Embodiment 3

[0027] Formula: when x=0.02, y=0.15, z=0, u=0, it is (Li 0.02 Na 0.15 K 0.83 )NbO 3

[0028] sintering

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com