Low-temperature sintered potassium sodium niobate lead-free piezoelectric ceramic and preparation method thereof

A potassium sodium niobate, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of potassium sodium niobate-based lead-free piezoelectric ceramics. and other problems, to achieve the effect of controllable stoichiometric ratio, small fluctuation of chemical composition and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

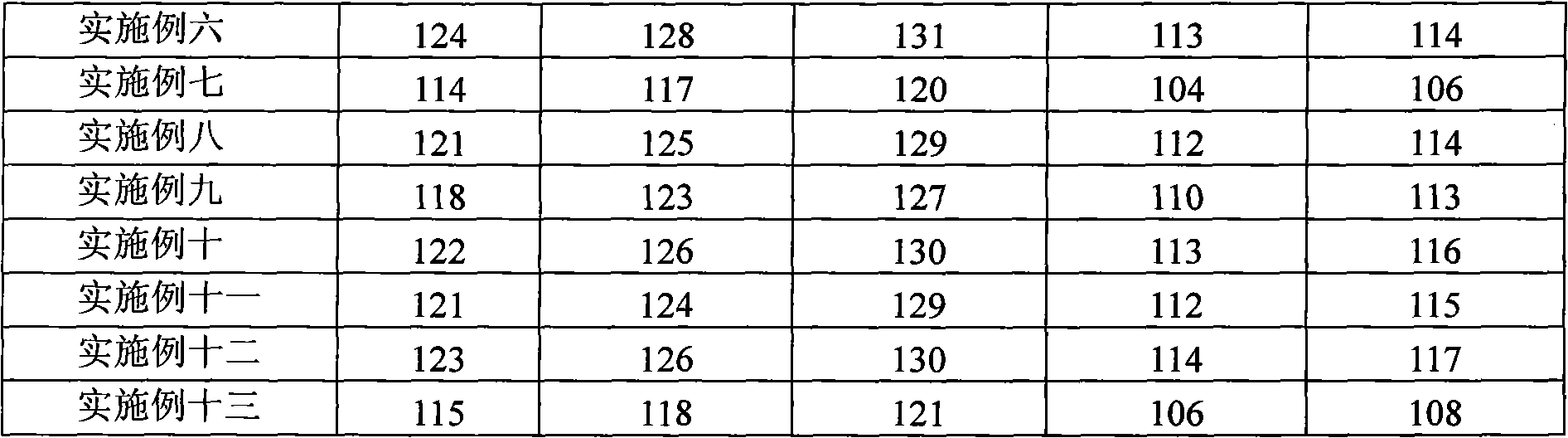

Examples

Embodiment 1

[0033] The preparation method of potassium sodium niobate lead-free piezoelectric ceramics of the present embodiment is as follows:

[0034] (1) Preparation of frit

[0035] According to the composition of the frit shown in Table 2, mix the ingredients evenly, melt at 1100°C, keep warm for 20 minutes, and ball mill for 6 hours with water as the medium after quenching, and dry to obtain the frit;

[0036] (2) Preparation of potassium sodium niobate lead-free piezoelectric ceramic pre-fired green body

[0037] (2-1) The carbonate of K, Na, the oxide compound of Nb are weighed batching according to the parameter shown in Table 1;

[0038](2-2) Add the prepared raw materials into a ball mill with absolute ethanol as the medium, ball mill the mixture for 8 hours, and obtain the mixed powder after drying;

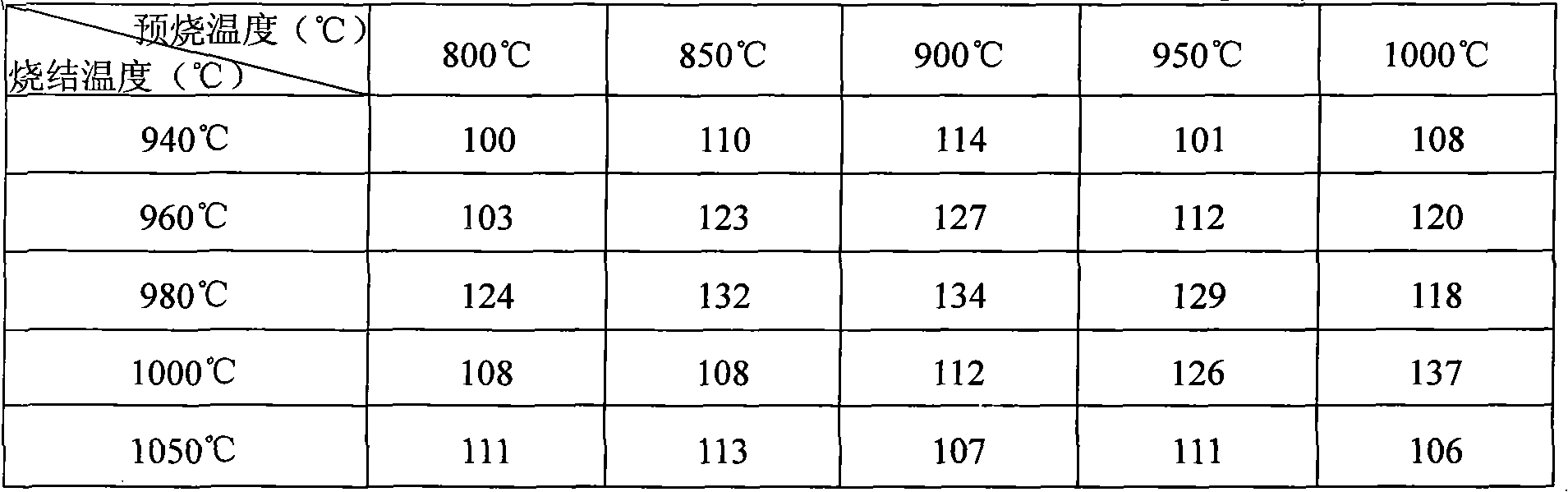

[0039] (2-3) Pre-fire the mixed powder in the air at 800, 850, 900, 950, and 1000°C respectively, keep it warm for 4 hours, and cool with the furnace to synthesize potassium so...

Embodiment 2

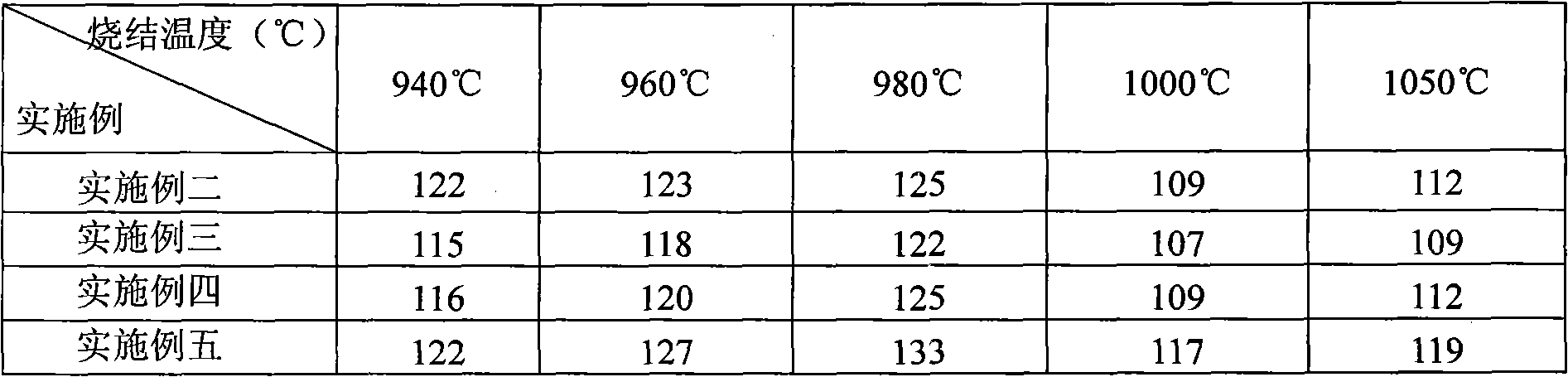

[0047] The preparation method of potassium sodium niobate lead-free piezoelectric ceramics of the present embodiment is as follows:

[0048] (1) Preparation of frit

[0049] According to the composition of the frit shown in Table 2, mix the ingredients evenly, melt at 1000°C, keep the temperature for 30 minutes, and ball mill for 10 hours with water as the medium after quenching, and dry to obtain the frit;

[0050] (2) Preparation of potassium sodium niobate lead-free piezoelectric ceramic pre-fired green body

[0051] (2-1) The carbonate of K, Na, the oxide compound of Nb are weighed batching according to the parameter shown in Table 1;

[0052] (2-2) Add the prepared raw materials into a ball mill with absolute ethanol as the medium, ball mill the mixture for 12 hours, and obtain the mixed powder after drying;

[0053] (2-3) Pre-fire the mixed powder in the air at 800°C, keep it warm for 3 hours, and cool with the furnace to synthesize potassium sodium niobate powder;

...

Embodiment 3

[0058] The preparation method of potassium sodium niobate lead-free piezoelectric ceramics of the present embodiment is as follows:

[0059] (1) Preparation of frit

[0060] According to the composition of the frit shown in Table 2, mix the ingredients evenly, melt at 1200°C, keep the temperature for 60 minutes, and ball mill with water for 14 hours after quenching, and dry to obtain the frit;

[0061] (2) Preparation of potassium sodium niobate lead-free piezoelectric ceramic pre-fired green body

[0062] (2-1) The carbonate of K, Na, the oxide compound of Nb are weighed batching according to the parameter shown in Table 1;

[0063] (2-2) Add the prepared raw materials into a ball mill with absolute ethanol as the medium, ball mill the mixture for 16 hours, and obtain the mixed powder after drying;

[0064] (2-3) Pre-fire the mixed powder in the air at a temperature of 850° C., keep it warm for 5 hours, and cool with the furnace to synthesize potassium sodium niobate powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com