Low temperature synthesized no-lead piezoelectric Mg doped sodium potassium niobate ceramic and its prepn process

A potassium-sodium niobate-based, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of reducing the pressureless sintering temperature, lead-free piezoelectric ceramics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

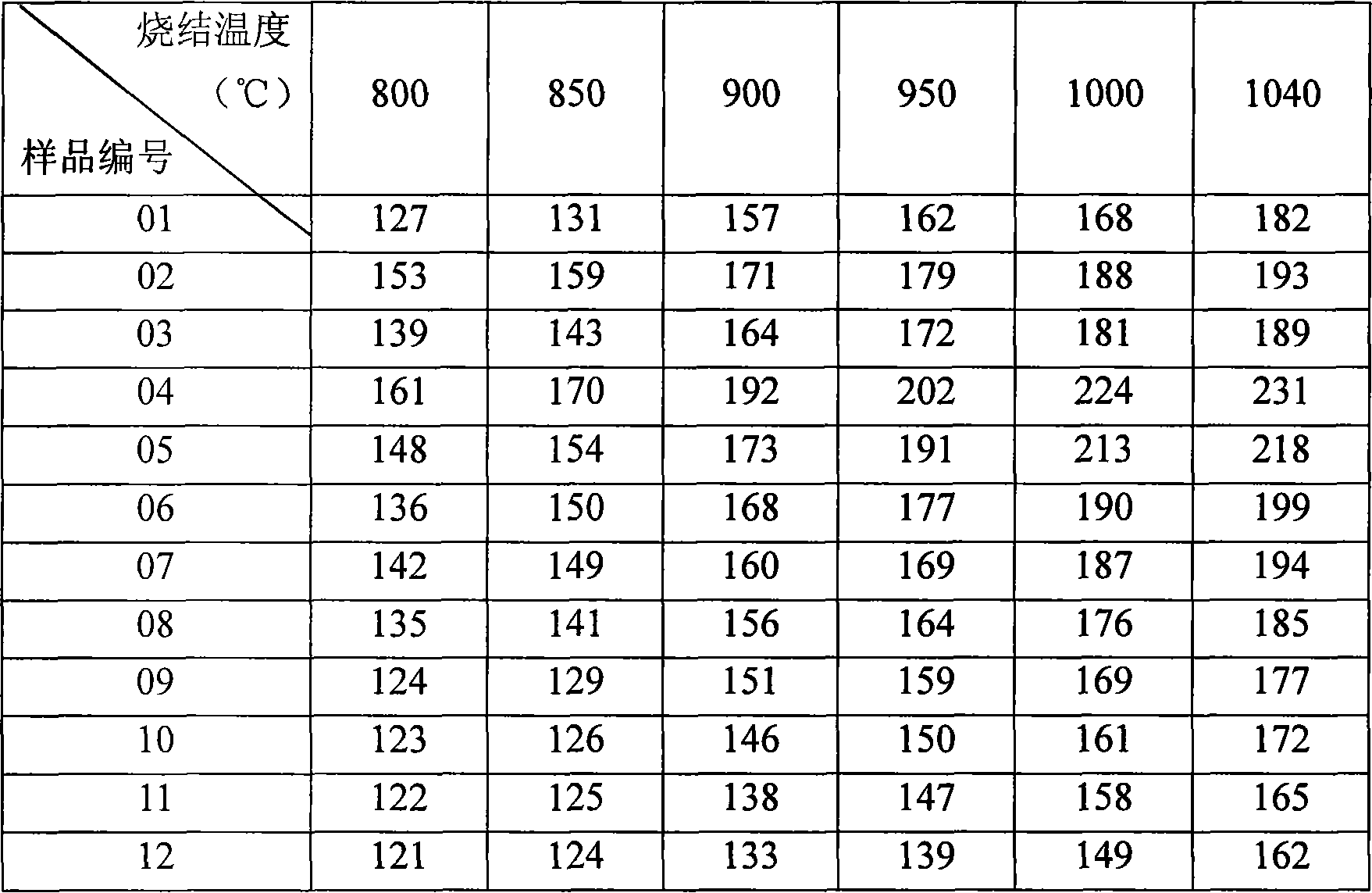

[0019] According to (Na 0.263 K 0.772 Li 0.057 )NbO 3 +0.044MgO (a=0.263, b=0.772, c=0.057, x=0.044) formula, weigh 0.3195 grams of Na with electronic balance 2 CO 3 , 1.2227 g K 2 CO 3 , 0.0483 g Li 2 CO 3 , 2.9122 g Nb 2 o 5 and 0.0406 g of MgO, using absolute ethanol as a medium, grinding and mixing with a planetary ball mill for 8 hours at a speed of 100 rpm, and drying the slurry at 50° C. to obtain a dry powder. The dry powder was subjected to 500°C and kept for 9 hours to synthesize niobate. Take 0.3 grams of powder and put it into a Φ10mm mold, and press it into shape. The shaped discs were sintered in a programmed temperature-controlled box-type furnace, sintered at 1040° C., kept for 1 hour, and cooled to room temperature to obtain ceramic discs. After grinding with 600-mesh fine sandpaper, coat the two surfaces with baked silver electrodes to make a silver ceramic sheet, put it into the polarization device, heat the silicone oil to 100°C, keep it at 5kV / ...

Embodiment 2

[0021] According to (Na 0.539 K 0.467 Li 0.114 )NbO 3 +0.187MgO (a=0.539, b=0.467, c=0.114, x=0.187) formula, weigh 0.7163 grams of Na with electronic balance 2 CO 3 , 0.8092 g K 2 CO 3 , 0.1056 g Li 2 CO 3 , 2.7093 g Nb 2 o 5 and 0.1977 g of MgCO 3 , using absolute ethanol as the medium, grinding and mixing the materials with a planetary ball mill for 4 hours at a rotation speed of 250 rpm, and drying the slurry at 120° C. to obtain dry powder. The dry powder was subjected to temperature at 650°C for 4 hours to synthesize niobate. Take 0.3 grams of powder and put it into a Φ10mm mold, and press it into shape. The shaped discs were put into a programmed temperature-controlled box furnace for sintering at 960° C., kept for 2 hours, and cooled to room temperature to obtain ceramic discs. After grinding with 600-mesh fine sandpaper, coat the two surfaces with baked silver electrodes to make a silver ceramic sheet, put it into the polarization device, heat the silicon...

Embodiment 3

[0023] According to (Na 0.539 K 0.467 Li 0.001 )NbO 3 +0.187MgO (a=0.674, b=0.318, c=0.001, x=0.3) formula, weigh 0.7199 grams of Na with electronic balance 2 CO 3 , 0.8132 g K 2 CO 3 , 0.009 g Li 2 CO 3 , 2.7229 g Nb 2 o 5 and 0.0380 g of basic magnesium carbonate, using absolute ethanol as a medium, grinding and mixing with a planetary ball mill for 1 hour at a speed of 450 rpm, and drying the slurry at 200° C. to obtain dry powder. The dry powder was subjected to 900°C and kept for 1 hour to synthesize niobate. Take 0.3 grams of powder and put it into a Φ10mm mold, and press it into shape. The shaped discs were sintered in a programmed temperature-controlled box furnace, sintered at 800° C., kept for 4 hours, and cooled to room temperature to obtain ceramic discs. After grinding with 600-mesh fine sandpaper, coat the two surfaces with baked silver electrodes to make a silver ceramic sheet, put it into the polarization device, heat the silicone oil to 200°C, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com