Sodium potassium niobate-sodium bismuth zirconate titanate lead-free piezoelectric ceramic

A bismuth sodium zirconate titanate-based, lead-free piezoelectric technology is applied in the field of potassium sodium niobate-bismuth sodium zirconate titanate lead-free piezoelectric ceramics, which can solve the problem of high material cost and hinder the practical application of lead-free piezoelectric ceramics. process and other issues, to achieve the effect of low price, promotion of practical process, and high-voltage electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

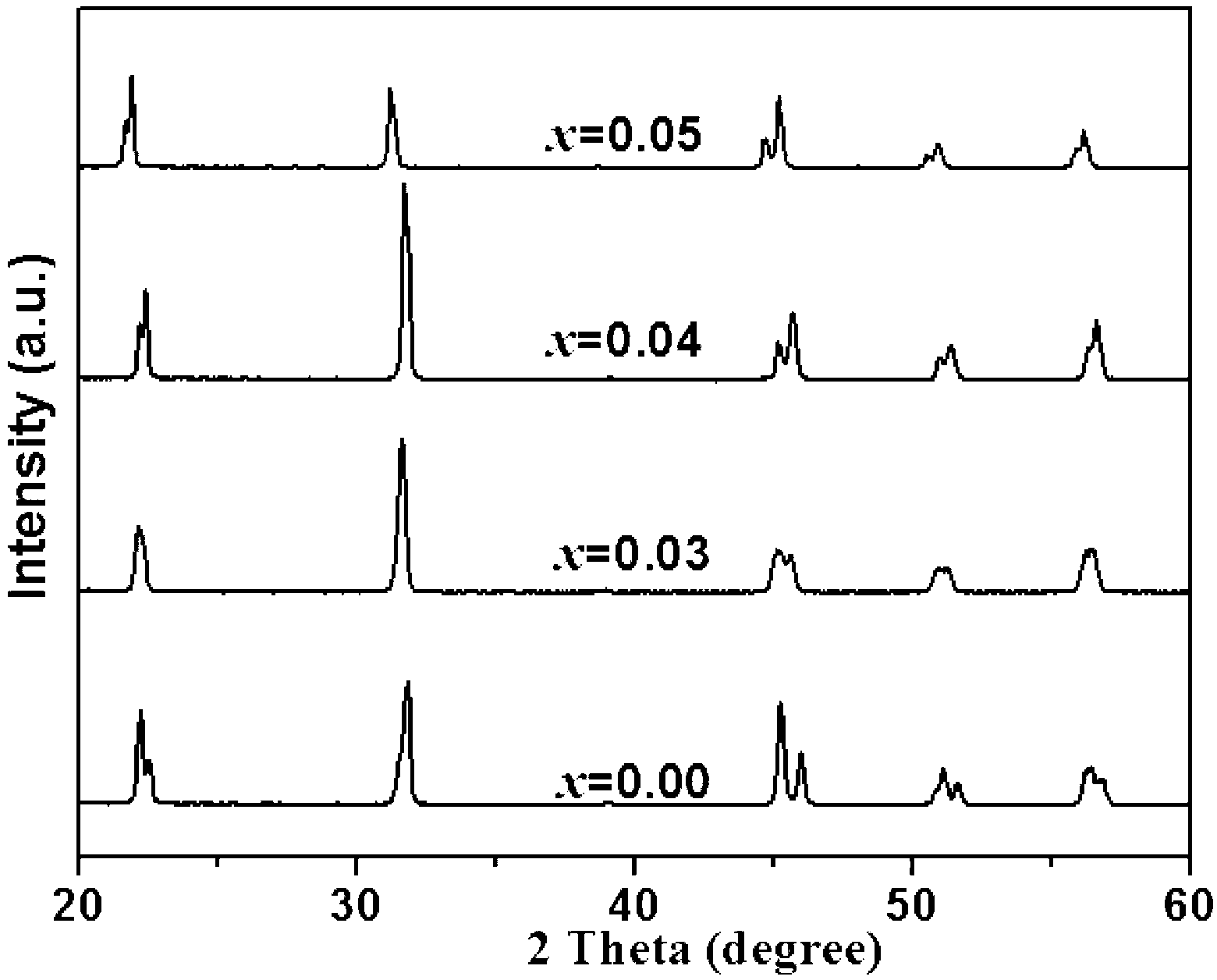

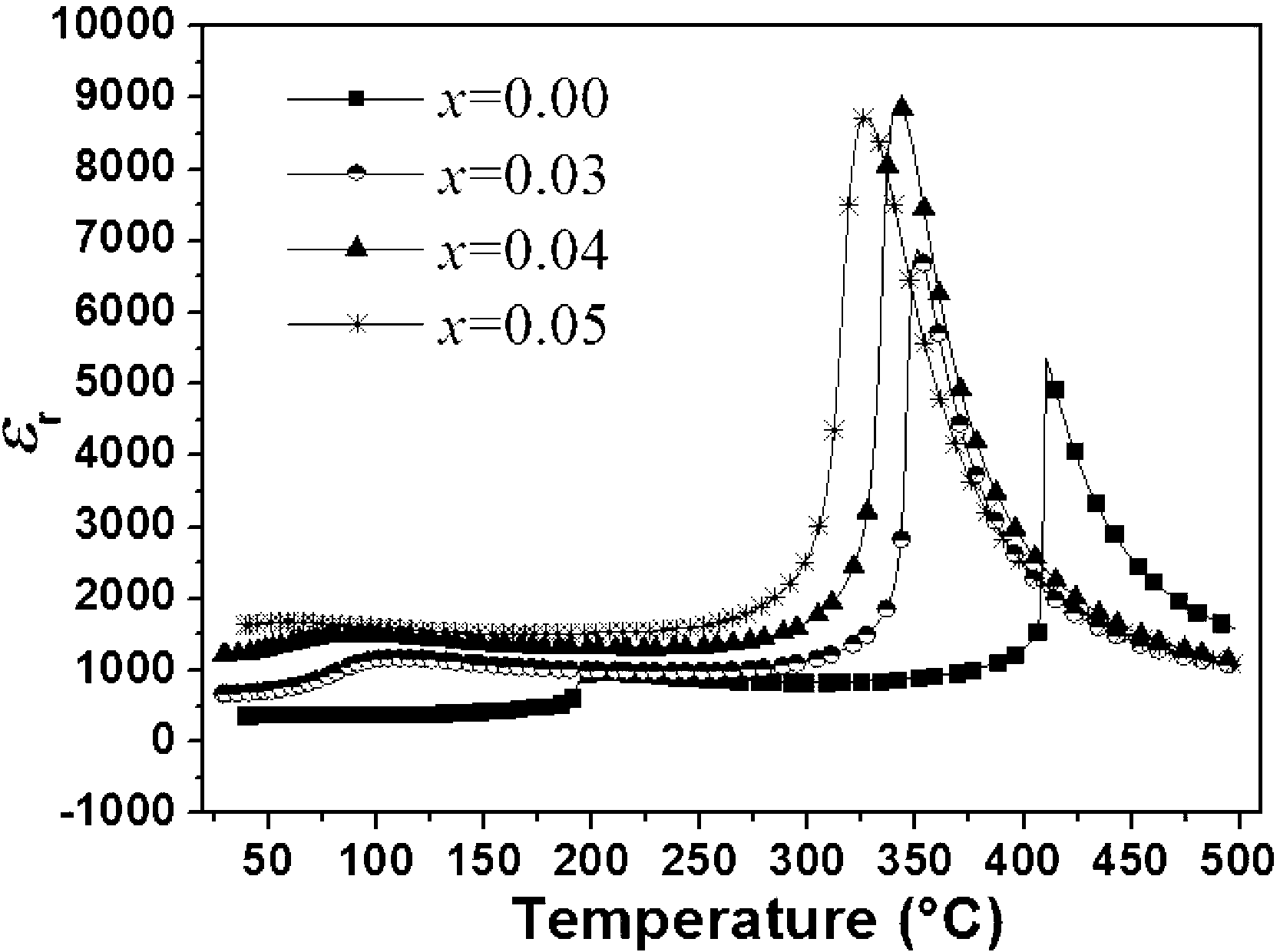

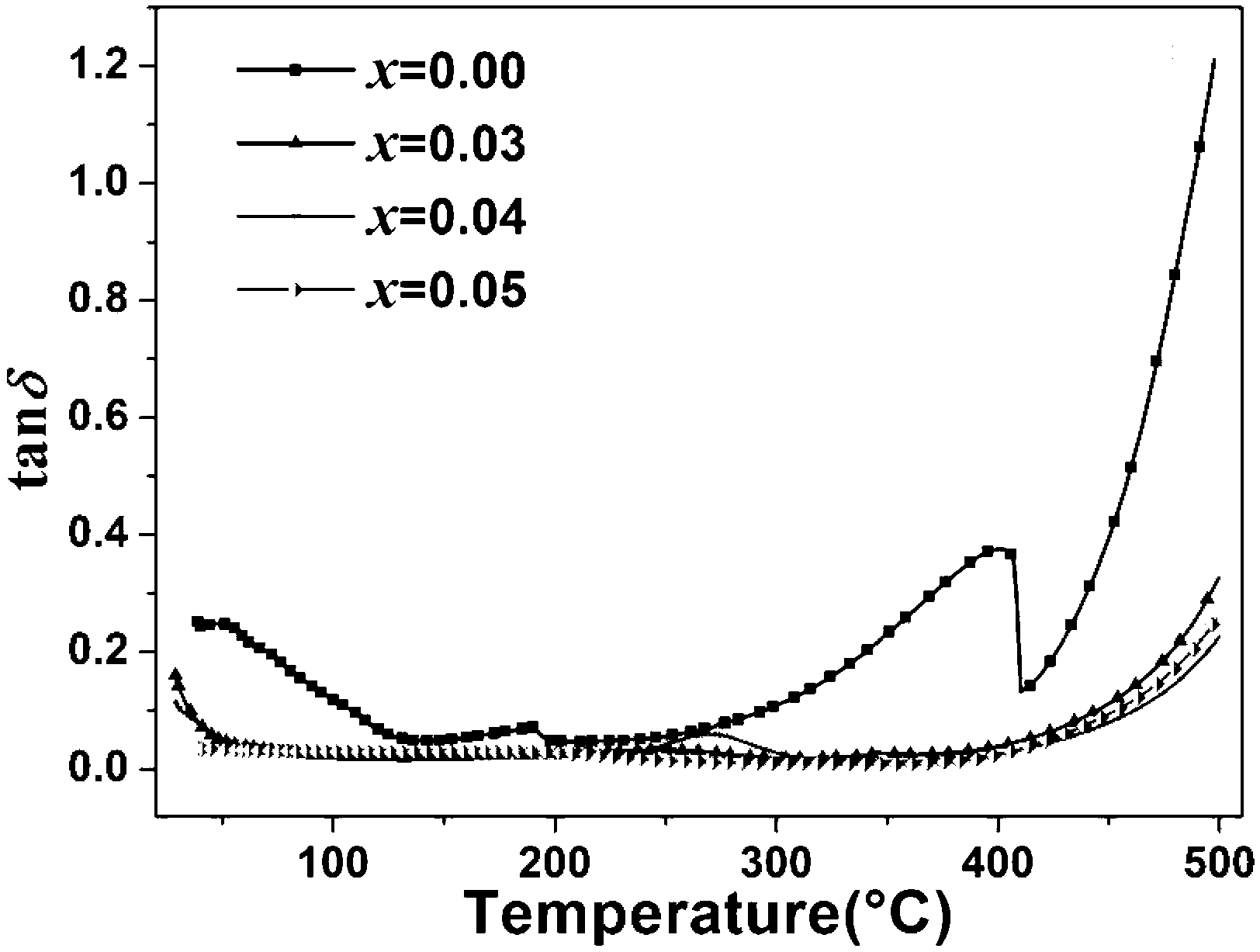

[0020] Formula: by general formula (1-x)K 0.5 Na 0.5 NbO 3 -x Bi 0.5 Na0.5 ZrO 3 Lead-free piezoelectric ceramics represented by , where x=0, 0.03, 0.04 or 0.05;

[0021] Preparation process: Analytical pure Na 2 CO 3 , K 2 CO 3 , Nb 2 o 5 , Bi 2 o 3 and ZrO 2 As raw materials, according to the chemical formula of the corresponding formula for batching. Use absolute ethanol as the ball milling medium for the prepared raw materials, dry them with rolling ball mill for 24 h, and then dry them to obtain dry powders. Pre-calcine the obtained dry powders at 850 °C for 6 h to synthesize niobate compounds, and then pre-calcine A good powder is added with a concentration of 8 wt% polyvinyl alcohol aqueous solution to granulate. The consumption of the polyvinyl alcohol aqueous solution is limited to meet the granulation requirements. Pressed under pressure into small discs, and discharged glue. Finally, it was sintered at 1100°C for 3 h, and the sintered ceramic sheet wa...

Embodiment 2

[0026] Formula: by the general formula 0.95K 0.5 Na 0.5 NbO 3 -0.05Bi 0.5 Na 0.5 Zr 1-y Ti y o 3 Lead-free piezoelectric ceramics represented by , where y=0.1, 0.2 or 0.3;

[0027] Preparation process: Analytical pure Na 2 CO 3 , K 2 CO 3 , Nb 2 o 5 , Bi 2 o 3 , TiO 2 and ZrO 2 As raw materials, according to the chemical formula of the corresponding formula for batching. Use absolute ethanol as the ball milling medium for the prepared raw materials, dry them with a rolling ball mill for 24 h, and then dry them to obtain dry powders. Pre-calcine the obtained dry powders at 870 ° C for 5 h to synthesize niobate compounds, and then pre-calcine A good powder is added with a concentration of 8 wt% polyvinyl alcohol aqueous solution to granulate. The consumption of the polyvinyl alcohol aqueous solution is limited to meet the granulation requirements. Pressed under pressure into small discs, and discharged glue. Finally, sinter at 1100°C for 2.5 h. The sintered ce...

Embodiment 3

[0032] Formula: from the general formula 0.95K u Na v NbO 3 -0.05Bi 0.5 Na 0.5 ZrO 3 Lead-free piezoelectric ceramics represented by , where 0.40≤u≤0.55, 0.45≤v≤0.60, and u+v=1.

[0033] Preparation process: Analytical pure Na 2 CO 3 , K 2 CO 3 , Nb 2 o 5 , Bi 2 o 3 and ZrO 2 As raw materials, according to the chemical formula of the corresponding formula for batching. Use absolute ethanol as the ball milling medium for the prepared raw materials, dry them with rolling ball mill for 24 h, and then dry them to obtain dry powders. Pre-calcine the obtained dry powders at 850 °C for 6 h to synthesize niobate compounds, and then pre-calcine A good powder is added with a concentration of 8 wt% polyvinyl alcohol aqueous solution to granulate. The consumption of the polyvinyl alcohol aqueous solution is limited to meet the granulation requirements. Pressed under pressure into small discs, and discharged glue. Finally, it was sintered at 1100°C for 3 h, and the sintere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com