Optical switching method capable of using electronic control quadratic electro-optical effect for deflecting incident light

A secondary electro-optic and incident light technology, applied in the optical field, can solve problems such as difficult practical application, and achieve the effects of low cost, broad application prospects and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

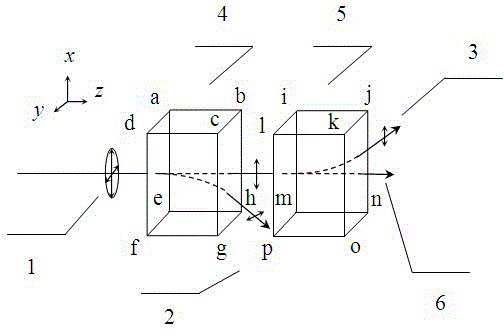

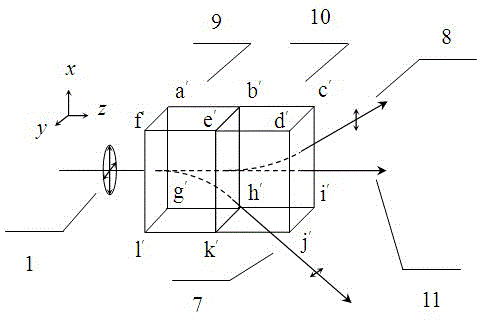

[0031] Specific implementation mode one: combine figure 1 In this embodiment, an optical switch method for realizing deflection of incident light by using the electronically controlled secondary electro-optic effect, the specific process is as follows:

[0032] Step 1. Cut two pieces of potassium tantalum niobate crystals grown by the pulling method with a Curie temperature near room temperature (temperature range of 10-30 degrees Celsius) along the crystal axes of [100], [010] and [001] Cuboid, then polished on all sides. The temperature of the potassium tantalum niobate crystal should be controlled within 20 degrees higher than its Curie temperature.

[0033] Step 2. Correspond the [100], [010] and [001] crystal axes of the two crystals to the x, y, and z axes of the Cartesian coordinate system, and place them in sequence along the z axis. At this time, the z axis is the entire optical system The optical symmetry axes of the two crystals in the middle are the first...

specific Embodiment approach 2

[0037] Specific embodiment two: this embodiment is a further description of specific embodiment one, the size of the first crystal 4 used in step one is 5.00 (ab) × 2.00 (ae) × 1.50 (ad) cubic millimeters, the second crystal 4 The dimensions of the crystal 5 are 5.00(ij)×2.00(il)×1.50(im) cubic millimeters.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment is a further description of Embodiment 1. The Curie temperature of the potassium tantalum niobate crystal used in step 1 is 20 degrees Celsius, and the crystal temperature is 22 degrees Celsius.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com