Sodium-potassium niobate series substituted by bismuth-base calcium-titanium ore and preparing method

A potassium sodium niobate, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., to improve piezoelectric and electromechanical coupling performance, reduce sintering temperature, and improve sintering The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The specific steps of the preparation method are:

[0046] 1. Take Na 2 CO 3 , K 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 , Ta 2 o 5 , Sb 2 o 5 , Bi 2 o 3 , Fe 2 o 3 , Sc 2 o 3 , Al 2 o 3 And metal oxide and carbonate for doping are raw materials, according to formula (1) batching;

[0047] 2. The prepared raw materials are mixed with absolute ethanol for 6-18 hours, and then dried to obtain dry powder; the obtained dry powder is calcined in an alumina crucible at a temperature of 800-950°C for 2-6 hours; repeated ball milling The mixing and calcination process is done once to complete the pre-calcination synthesis;

[0048] 3. After the pre-synthesized powder is ground, it is still finely ground for 24 hours with absolute ethanol as the medium. After the dried powder passes through a 120 mesh sieve, it is formed into a green body under a pressure of 50-200MPa;

[0049] 4. The formed green body is sintered in the air under normal pressure by buried powder met...

Embodiment 1

[0052] Embodiment 1: Carry out each step successively according to above-mentioned embodiment mode, wherein,

[0053] Using (1-n)(Na 0.5 K 0.5 )NbO 3 +nBiFeO 3 For the piezoelectric ceramics composed of , the pre-calcination temperature is 900° C. and the time is 5 hours. After two calcinations, ball mill again for 24 hours with absolute ethanol as the ball milling medium. The formed body is then sintered in the range of 1080-1130° C. for 2 hours.

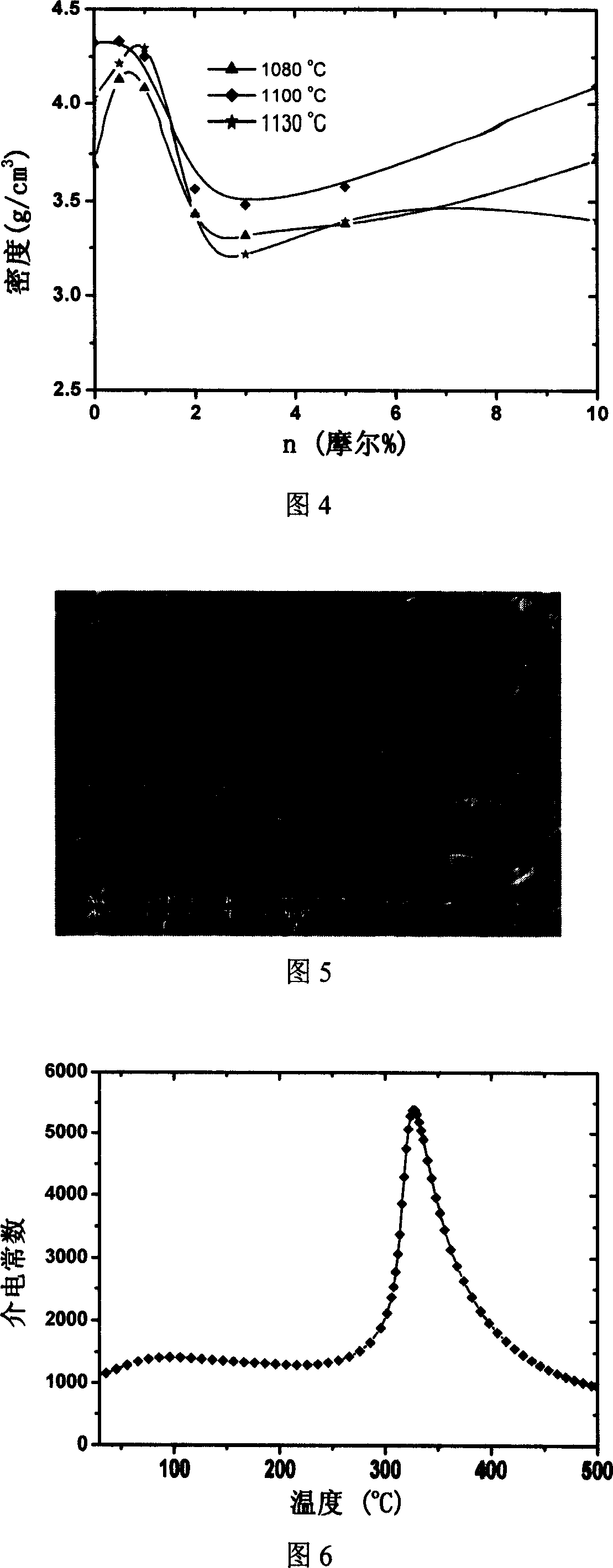

[0054] The scanning electron micrograph of the natural surface of the sample with n=0.01 after sintering at 1100°C for 2 hours is shown in Figure 1, and its dielectric-temperature characteristic curve is shown in Figure 2.

[0055] The X-ray diffraction patterns of the two composition samples when n=0.01 and 0.02 are shown in FIG. 3 .

[0056] The density changes of samples with different n sintered under three different temperature conditions are shown in Figure 4.

[0057] When n=0.01 and the sintering temperature is 1100°...

Embodiment 2

[0060] Embodiment 2: Carry out each step successively according to above-mentioned embodiment mode, wherein

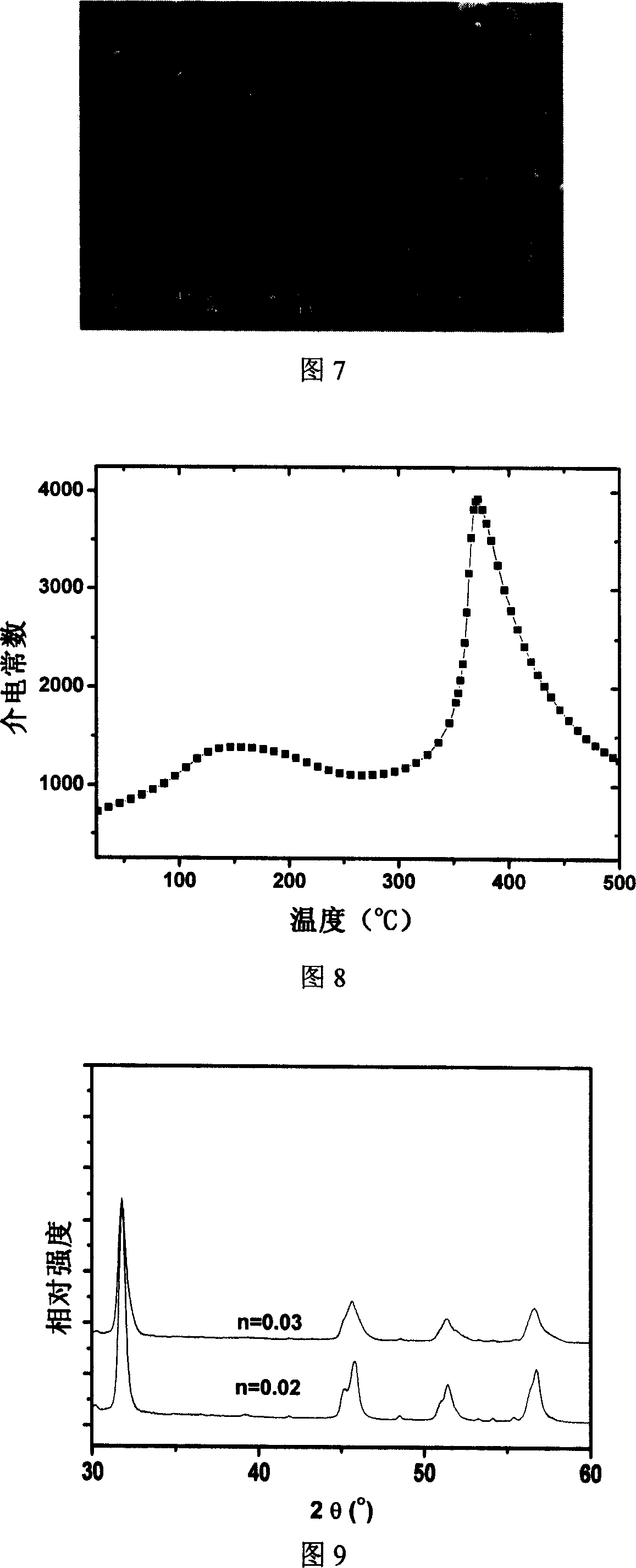

[0061] Using (1-n)(Na 0.5 K 0.5 )NbO 3 +nBiScO 3 And n=0.02 is the piezoelectric ceramic whose composition is, the pre-calcination condition is 850° C., and the time is 6 hours. After two calcinations, ball mill again for 24 hours with absolute ethanol as the ball milling medium. Then the molded green body was sintered at 1110°C for 3 hours. The scanning electron microscope photo of the natural surface of the sample is shown in Figure 5, and the dielectric-temperature characteristic curve of the sample is shown in Figure 6. Other relevant physical performance data are listed in Table 2:

[0062] Table 2

[0063] density

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com