Crystal oriented ceramics and production method of same

A technology of crystallographic orientation and ceramics, applied in chemical instruments and methods, manufacturing/assembly of piezoelectric/electrostrictive devices, niobium compounds, etc., can solve problems such as damage to piezoelectric properties and inability to realize composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

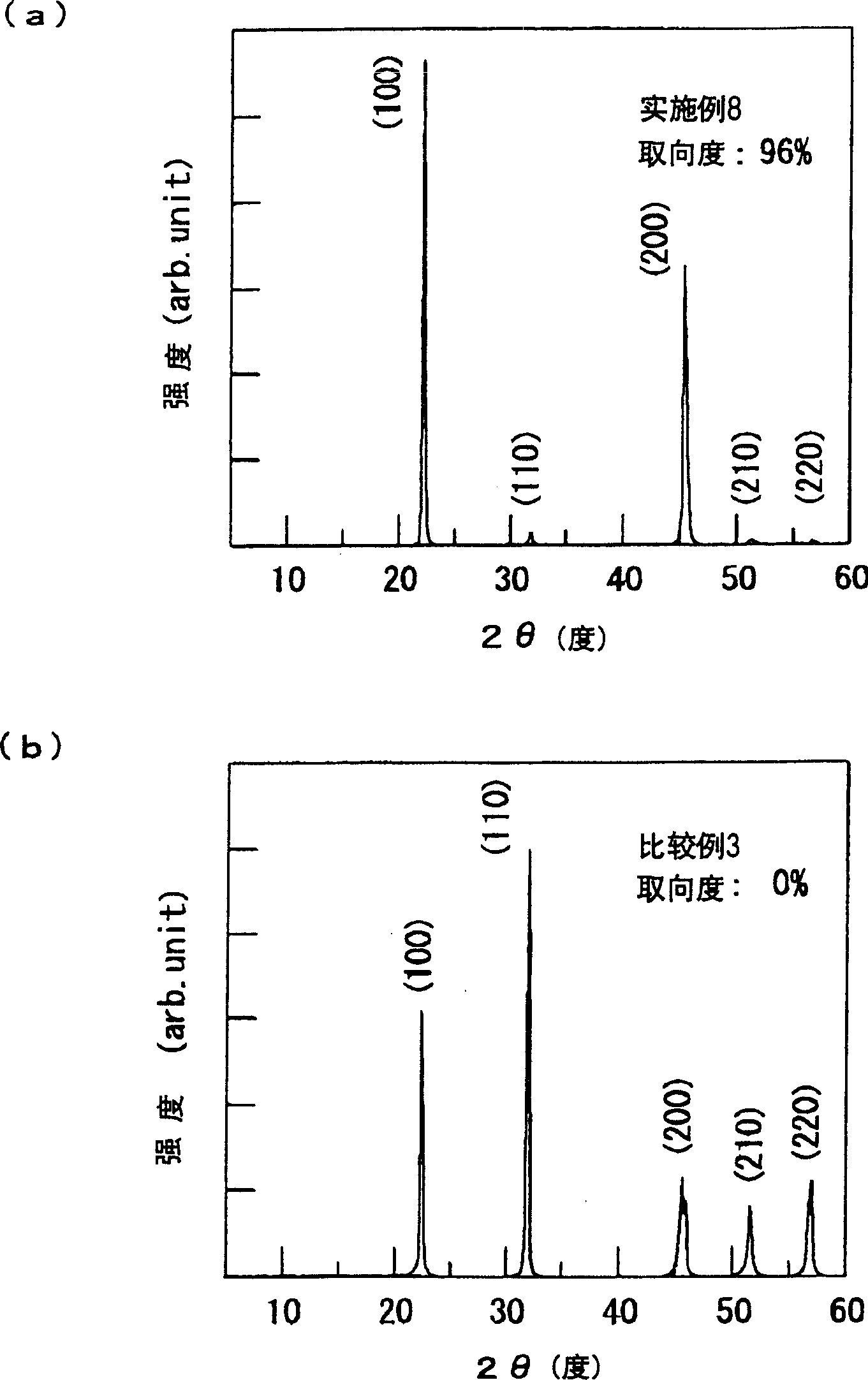

Embodiment 1

[0174] (1) Synthesis of NN plate powder

[0175] Bi according to the stoichiometric ratio 2.5 Na 3.5 Nb 5 o 18 (hereinafter, referred to as "BINN5") composition, weighing Bi 2 o 3 Powder, Na 2 CO 3 Powder and Nb 2 o 5 powder, which is wet mixed. Then, 50% by weight of NaCl was added as a flux to this raw material, and dry mixing was performed for 1 hour.

[0176] Then, the prepared mixture was put into a platinum crucible and heated at 850°C for 1 hour. After the flux was completely dissolved, it was further heated at 1100°C for 2 hours to synthesize BINN5. In addition, the temperature increase rate was 200° C. / hour, and the temperature decrease was cooling in the furnace. After cooling, the flux was removed from the reactants by hot water washing to obtain BINN5 powder. The obtained BINN5 powder is a plate-shaped powder with {001} plane as the growth plane.

[0177] Then, add the amount of Na required for NN synthesis to this BINN5 plate powder 2 CO 3 The powde...

Embodiment 2

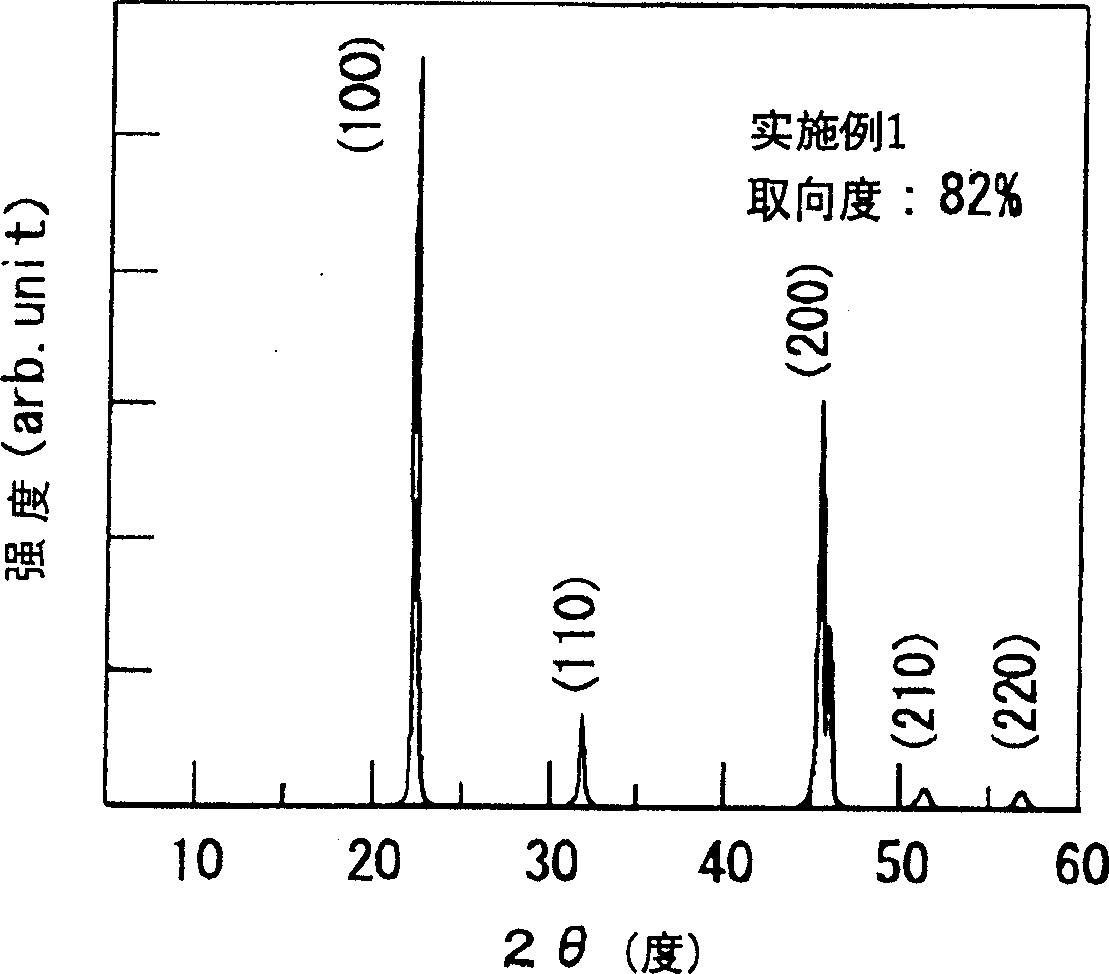

[0188] Except that the sintering temperature of the plate-shaped molded body after degreasing is 1125° C., according to the same steps as in Example 1, a 0.02 (K 0.5 Na 0.5 ) 0.98}{Nb 0.94 Sb 0.06}O 3 Composition of crystalline oriented ceramics. For the obtained crystal-oriented ceramics, under the same conditions as in Example 1, the density of the sintered body, the average degree of orientation, and the piezoelectric properties were evaluated.

[0189] The relative density of the crystal-oriented ceramics prepared in this embodiment is above 95%. In addition, the quasi-cubic {100} planes are oriented parallel to the band planes, and the average orientation degree of the quasi-cubic {100} planes measured by the Lotgering method reaches 82%. In addition, the evaluation results of the piezoelectric properties at room temperature: d 31 93.2pm / V, k p 0.588 and g 31 It was 16.5×10-3 Vm / N, which was 1.40 times, 1.35 times and 1.79 times higher than the non-oriented sint...

Embodiment 3

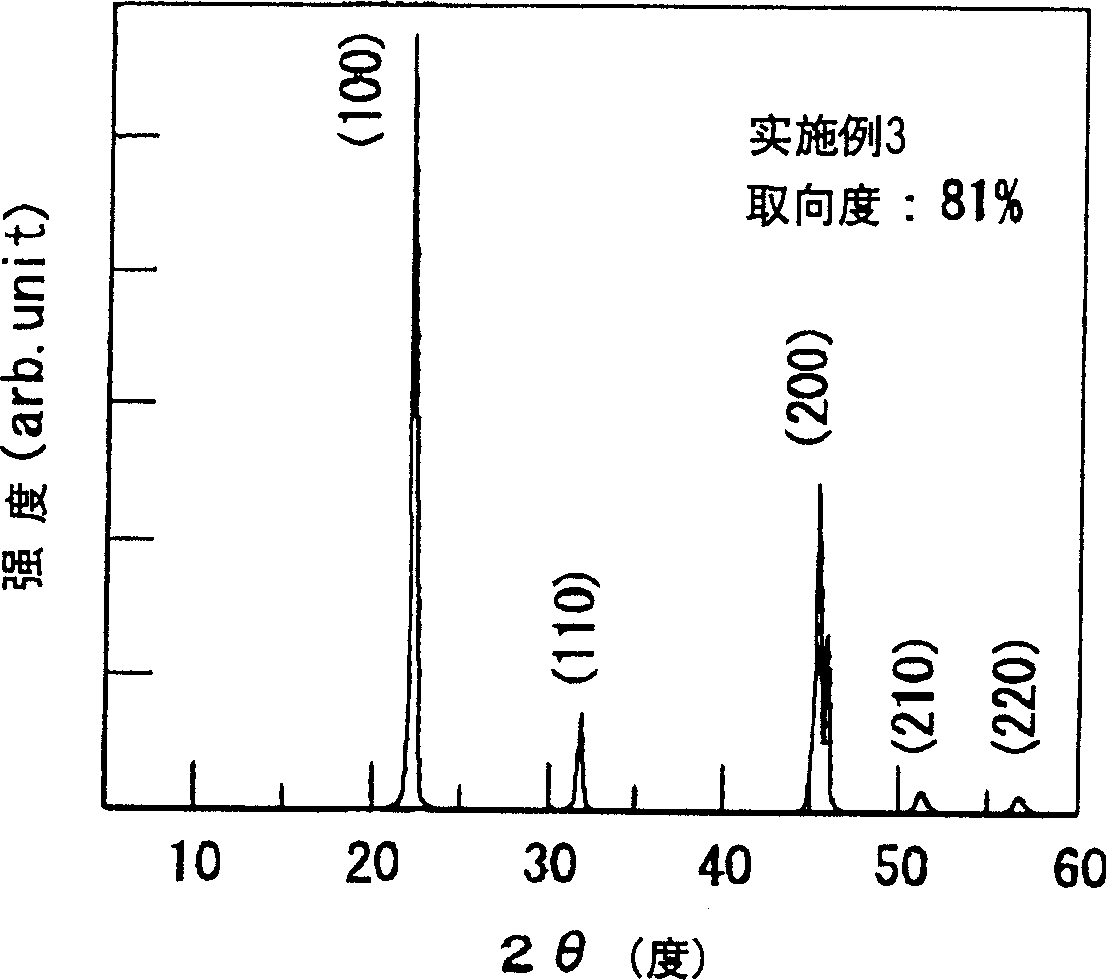

[0191] In addition to pressing {Li 0.02 (K 0.5 Na 0.5 ) 0.98}{Nb 0.88 Ta 0.10 Sb 0.02}O 3 The composition is matched with the initial raw materials, and the calcining temperature of the plate-shaped molded body after degreasing is 1125° C., according to the same steps as in Example 1, the production has {Li 0.02 (K 0.5 Na 0.5 ) 0.98}{Nb 0.88 Ta 0.10 Sb 0.02}O 3 Composition of crystalline oriented ceramics. For the obtained crystal-oriented ceramics, under the same conditions as in Example 1, the density of the sintered body, the average degree of orientation, and the piezoelectric properties were evaluated.

[0192] The relative density of the crystal-oriented ceramics prepared in this embodiment is above 95%. In addition, the quasi-cubic {100} planes are oriented parallel to the band shape, and the average orientation degree of the quasi-cubic {100} planes measured by the Lotgering method reaches 81%. In addition, the evaluation results of the piezoelectric pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com