Method for preparing potassium niobate sodium base leadless piezoelectric ceramic thin sheet and application thereof in buzzer

A potassium-sodium niobate-based, ceramic sheet technology, which is applied in the field of materials, can solve the problems of inability to prepare piezoelectric ceramic components and less research on lead-free piezoelectric ceramic materials, and achieve good electroacoustic performance, uniform crystal grains, and electrical properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

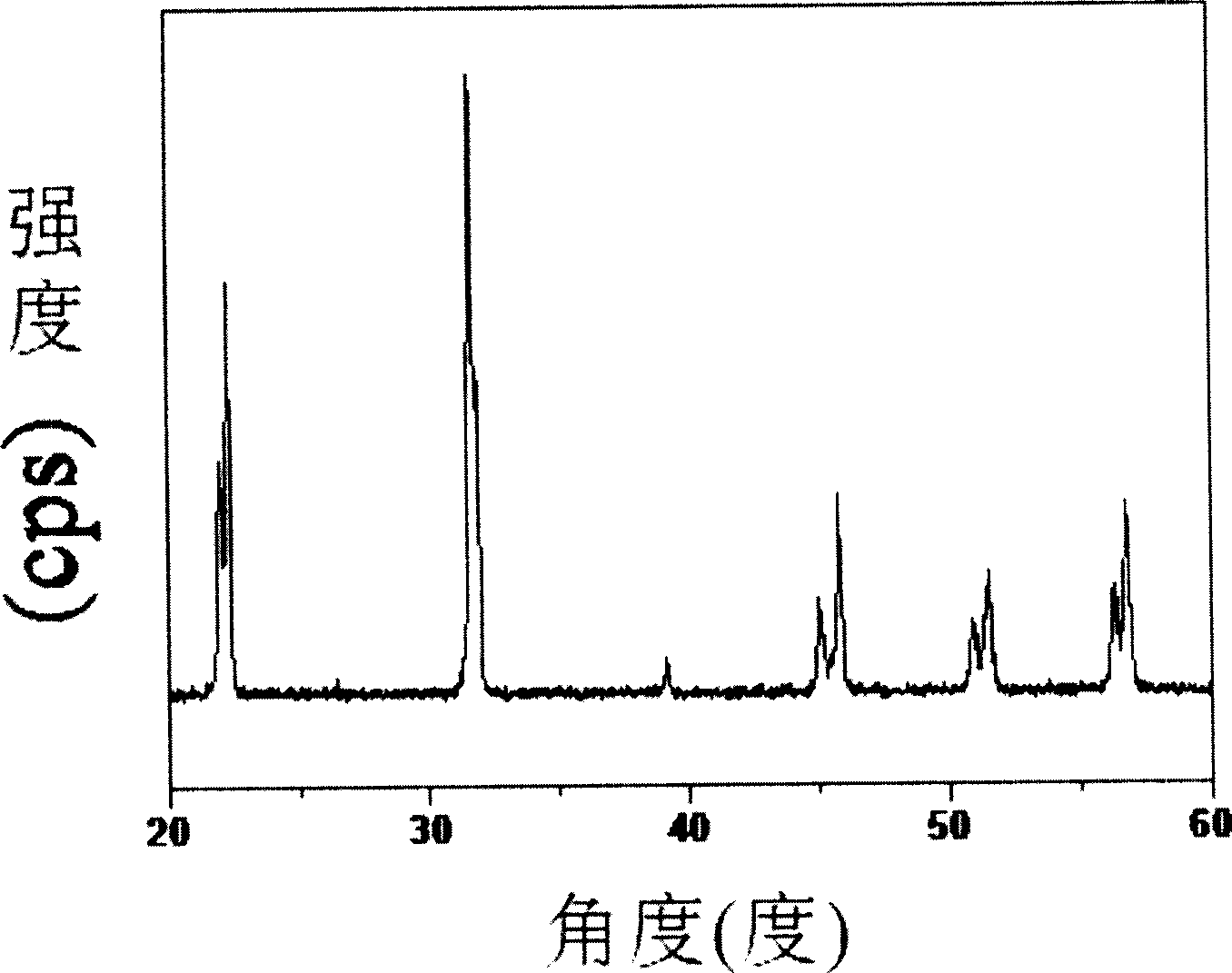

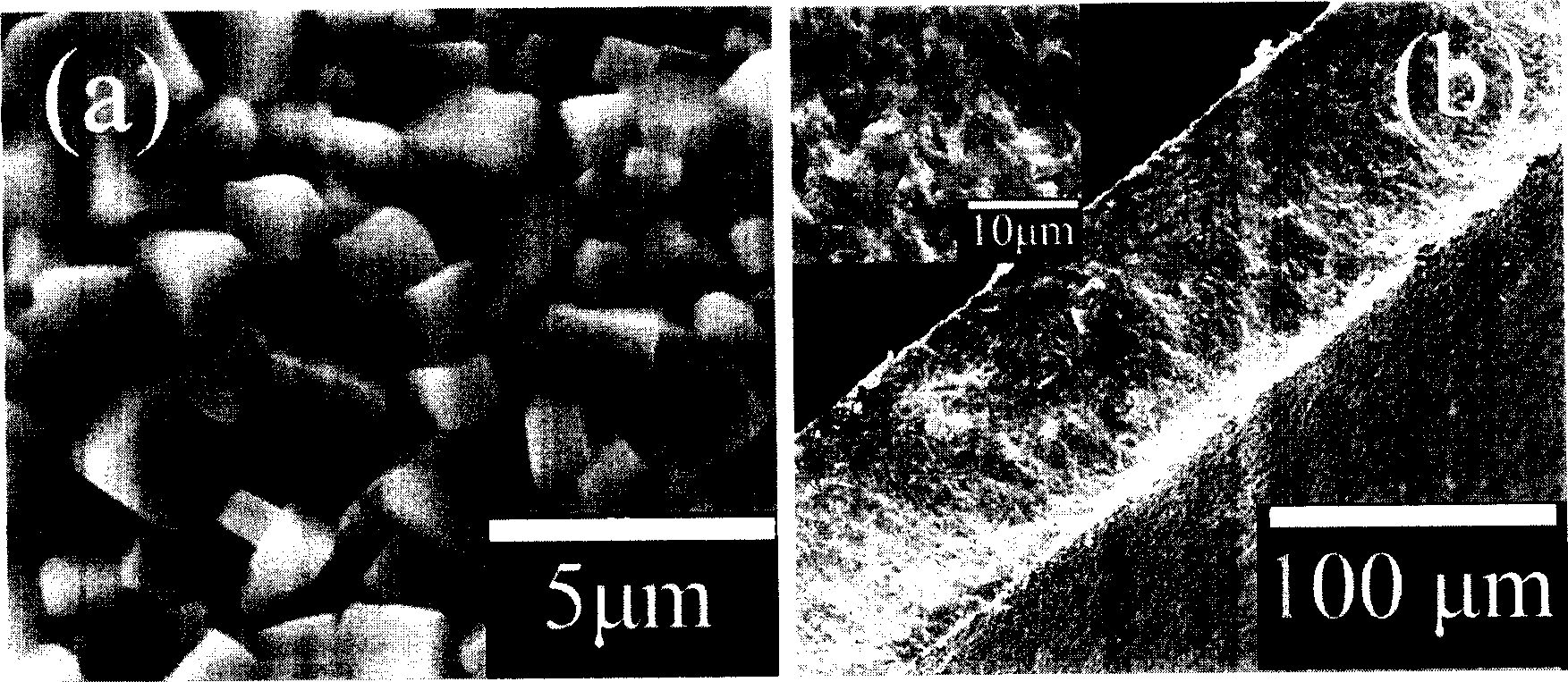

[0041] To prepare the general formula as (K 0.44 Na 0.52 Li 0.04 )(Nb 0.80 Ta 0.20 )O 3 The used raw material 500g of the sodium potassium niobate-based lead-free piezoelectric ceramic sheet is an example and its preparation method is as follows:

[0042] 1. Raw material pretreatment

[0043] Raw material Na 2 CO 3 、K 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 、 Ta 2 o 5 Put it into a petri dish, put the petri dish into an oven, and bake it at 200°C for 4 hours to remove the moisture adsorbed in the raw materials.

[0044] 2. Mixed raw materials

[0045] The raw material after raw material pretreatment process step 1 is processed according to general formula (K 0.44 Na 0.52 Li 0.04 )(Nb 0.80 Ta 0.20 )O 3 The proportioning ratio is weighed, batching 500g, wherein:

[0046] 99.8% pure Na 2 CO 3 65.60kg

[0047] 99% pure K 2 CO 3 72.97kg

[0048] 98% pure Li 2 CO 3 3.58kg

[0049] Nb with a purity of 99.9% 2 o 5 252.86kg

[...

Embodiment 2

[0071] To prepare the general formula as (K 0.44 Na 0.52 Li 0.04 )(Nb 0.80 Ta 0.20 )O 3 The used raw material 500g of the sodium potassium niobate-based lead-free piezoelectric ceramic sheet is an example and its preparation method is as follows:

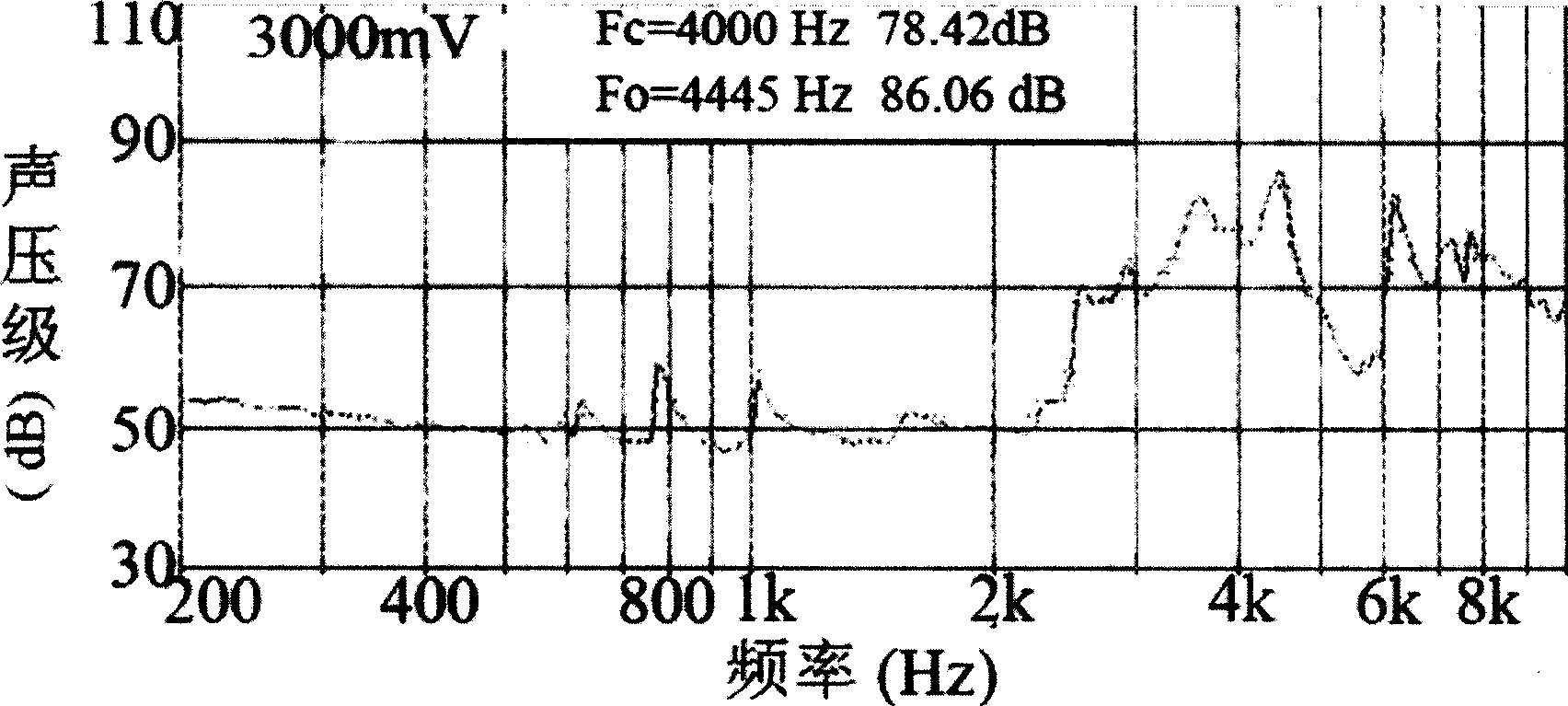

[0072] In the process step 2 of mixing raw materials, the raw materials used and their weight proportions are the same as those in Example 1. In pulping process step 4, 75g alcohol and mass concentration are 30% polyvinyl butyral solution 225g to join in the 225g calcined powder prepared in calcining process step 3, alcohol and mass concentration are 30% polyvinyl butyral solution The mass ratio of polyvinyl butyral solution to calcined powder is 1:3:3, and other steps in this process are the same as in Example 1. In step 5 of the casting process, the slurry prepared in step 4 of the pulping process is poured on the casting machine, cast into a film with a thickness of 70 μm, and the film is cut into a size of 10 × 15 cm 2 Th...

Embodiment 3

[0074] To prepare the general formula as (K 0.44 Na 0.52 Li 0.04 )(Nb 0.80 Ta 0.20 )O 3 The used raw material 500g of the sodium potassium niobate-based lead-free piezoelectric ceramic sheet is an example and its preparation method is as follows:

[0075] In the process step 2 of mixing raw materials, the raw materials used and their weight proportions are the same as those in Example 1. In pulping process step 4, 75g alcohol and mass concentration are 375g of polyvinyl butyral solution 375g joined in the 375g calcined powder prepared in calcining process step 3, alcohol and mass concentration are 30% The mass ratio of polyvinyl butyral solution to calcined powder is 1:5:5, and other steps in this process are the same as in Example 1. In step 5 of the casting process, the slurry prepared in the step 4 of the pulping process is poured on the casting machine, and cast into a film with a thickness of 60 μm, and the film is cut into a size of 10 × 15 cm 2 The small diaphrag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com