Method for preparing sodium niobate powder

A technology of sodium niobate and powder, which is applied in chemical instruments and methods, niobium compounds, sustainable manufacturing/processing, etc., can solve the problems of long powder cycle, save energy, shorten reaction time, and increase heating rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, Nb 2 o 5 Be raw material, NaOH is mineralizer, carry out according to the following steps:

[0041] 1) preheating

[0042] First, turn on the power of the microwave instrument to preheat for 20-40 minutes;

[0043] 2) Weigh raw materials, mix

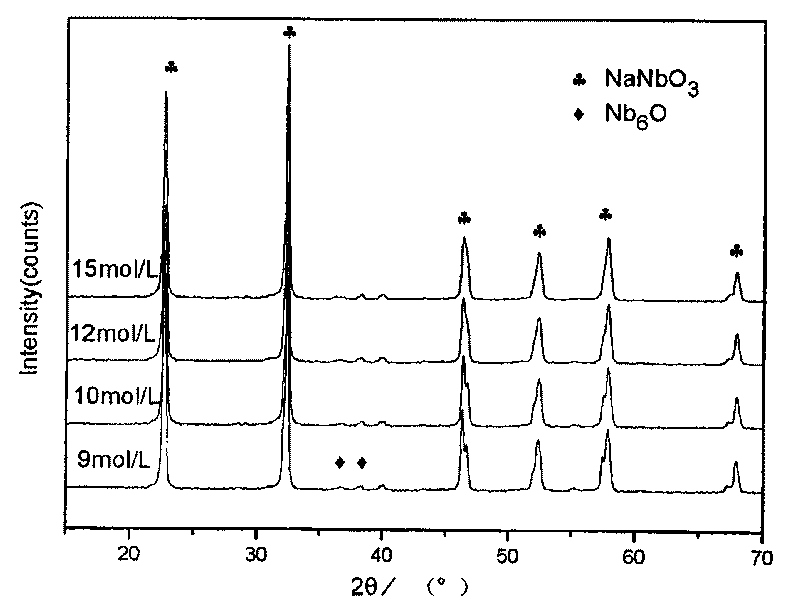

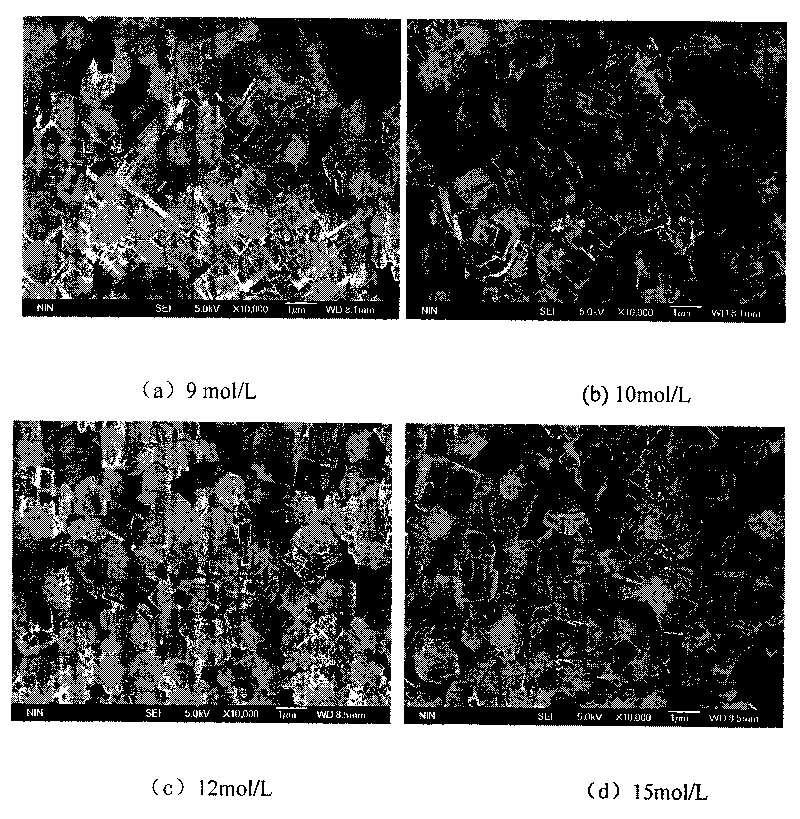

[0044] Weigh four 1.33g portions of Nb 2 o 5 , to prepare aqueous NaOH solutions with concentrations of 9mol / L, 10mol / L, 12mol / L and 15mol / L, respectively. Four copies of Nb 2 o 5 Mix with NaOH aqueous solutions of different concentrations in a beaker, stir with a glass rod to dissolve completely;

[0045] 4) Heating

[0046] Pour the solution in each beaker into the reaction kettle of the MDS-8 multi-flux airtight microwave instrument, the filling degree reaches 55%; fill the kettle, set the heating curve, the heating temperature is 210°C, and the reaction time is 30min;

[0047] 5) cooling

[0048] After the heating is completed, wait until the kettle is cooled below 100°C, take out the kettle to coo...

Embodiment 2

[0054] In this example, Nb 2 o 5 Be raw material, NaOH is mineralizer, carry out according to the following steps:

[0055] 1) preheating

[0056] First, turn on the power of the microwave instrument to preheat for 40 minutes;

[0057] 2) Weigh raw materials, mix

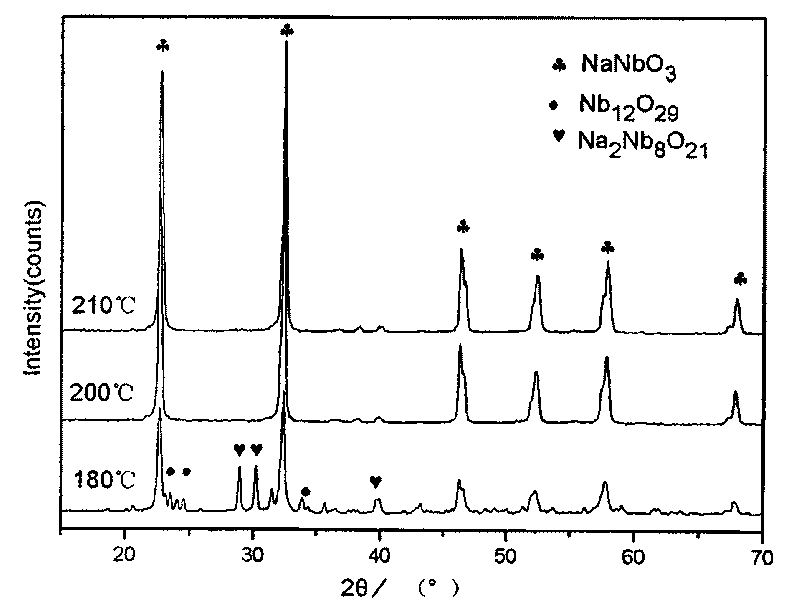

[0058] Weigh three 1.33g Nb 2 o 5 , prepare three NaOH aqueous solutions with concentrations all of 10mol / L. Will Nb 2 o 5 and NaOH aqueous solution were mixed in a beaker, stirred with a glass rod to dissolve completely;

[0059] 4) Heating

[0060] Pour the mixed solution into the reaction kettle of the MDS-8 multi-flux airtight microwave instrument, and the filling degree reaches 55%; fill the kettle, set the heating curve, and keep the temperature at 180°C, 200°C and 210°C for 30 minutes to prepare the powder body.

[0061] 5) cooling

[0062] After the heating is completed, wait until the kettle is cooled below 100°C, take out the kettle to cool, open it, pour out the supernatant, and pour the remai...

Embodiment 3

[0068] In this example, Nb 2 o 5 And NaOH is raw material, and KOH is mineralizer, carries out according to the following steps:

[0069] 1) preheating

[0070] First turn on the power of the microwave instrument to preheat for 20 minutes;

[0071] 2) Weigh raw materials, mix

[0072] Weigh two 1.33g Nb 2 o 5 , and then weighed 1.54g and 3.08g KOH respectively, and prepared two NaOH aqueous solutions with a concentration of 9mol / L. Will Nb 2 o 5 , KOH and NaOH aqueous solution are mixed (wherein the concentration of KOH is 0.5mol / L and 1.0mol / L respectively), stir with glass rod to make it dissolve completely;

[0073] 4) Heating

[0074] Pour the solution in each beaker into the reaction kettle of the MDS-8 multi-flux airtight microwave instrument, the filling degree reaches 55%; fill the kettle, set the heating curve, the heating temperature is 210°C, and the reaction time is 30min;

[0075] 5) cooling

[0076] After the heating is completed, wait until the kettle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com