Preparation method of cylindrical strontium sodium niobate crystallite powder

A technology of sodium strontium niobate and microcrystalline powder, which is applied in the fields of chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of powder morphology damage, etc., and achieve easy control of the process, high purity, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

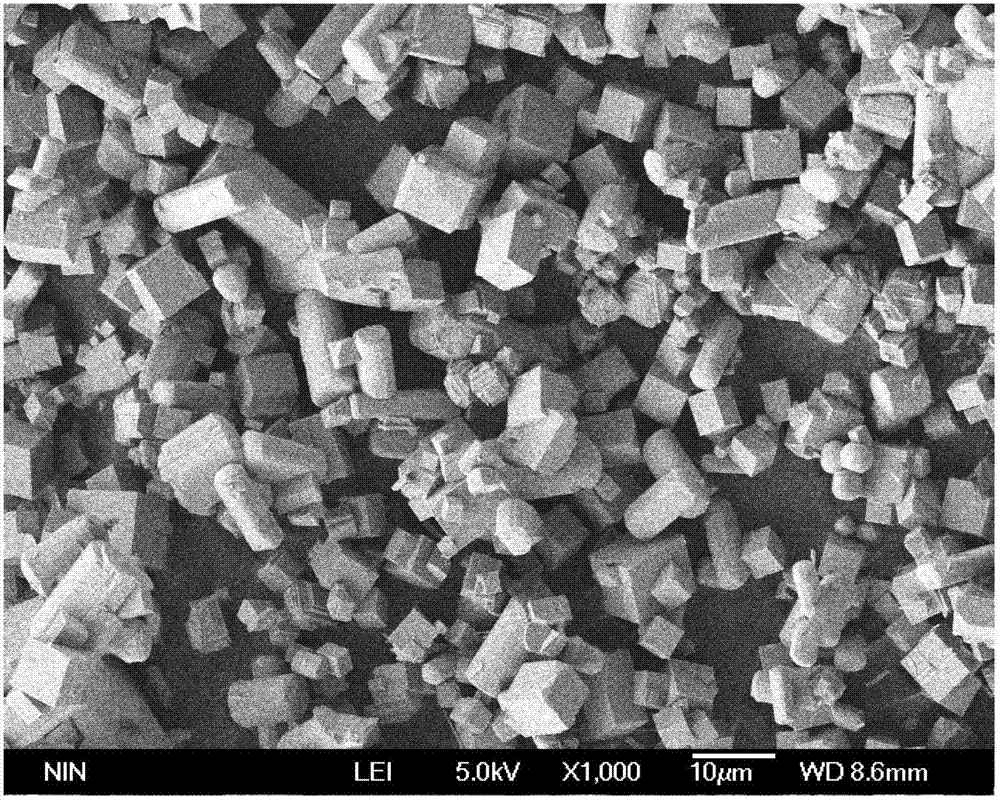

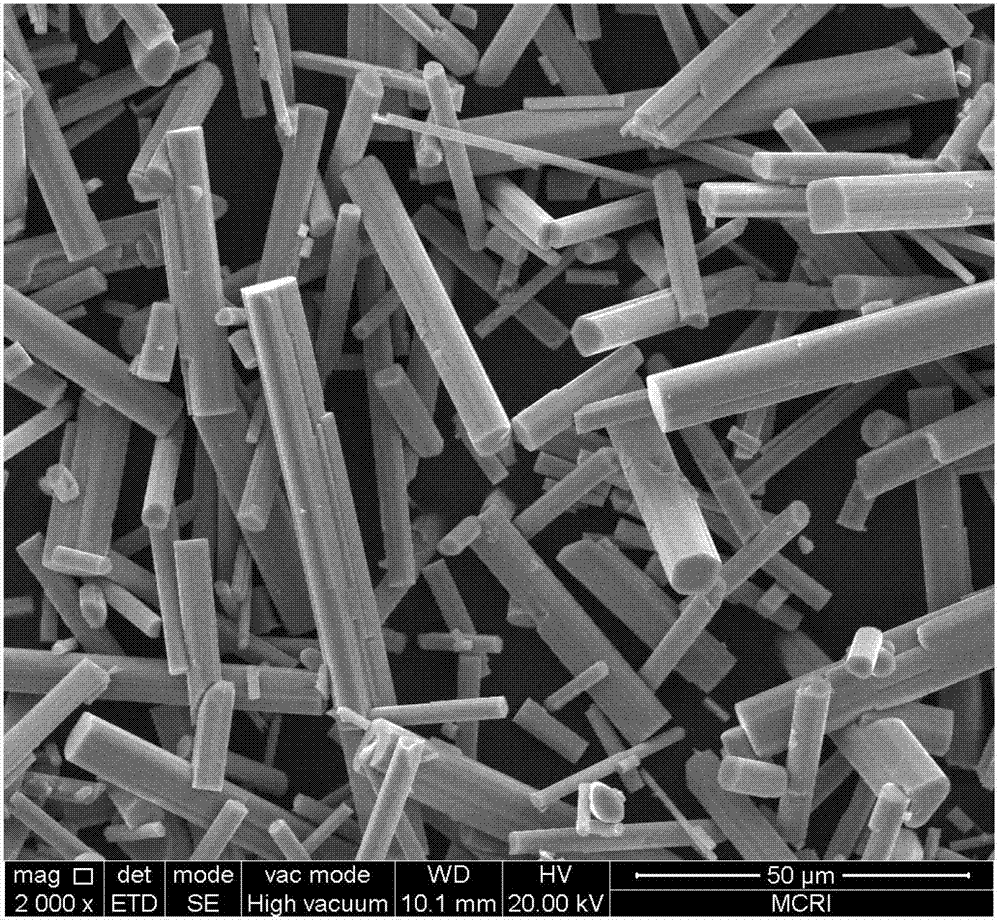

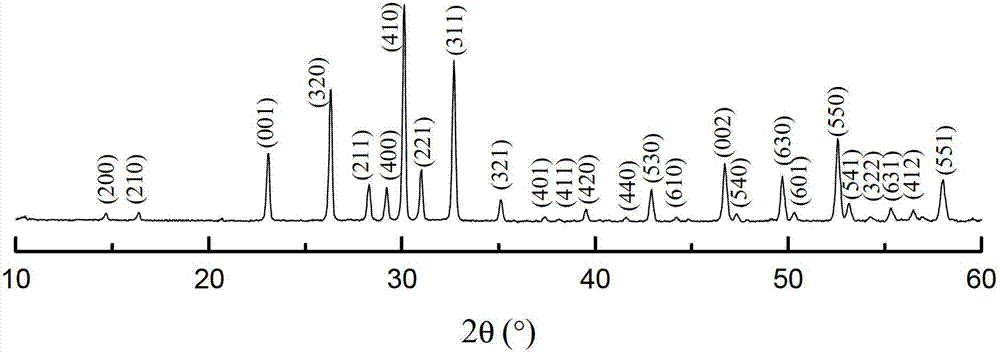

[0019] This embodiment is a preparation method of columnar sodium strontium niobate microcrystalline powder, and its specific process is:

[0020] Step 1: Ingredients. The composition of the sodium strontium niobate is: Sr 2 NaNb 5 o 15 . The analytically pure strontium carbonate and niobium pentoxide powders are weighed and mixed in a molar ratio of 1:1.25 to obtain an oxide mixture formed of strontium carbonate and niobium pentoxide. Weigh and mix sodium chloride and potassium chloride in a molar ratio of 1:1 to obtain the desired molten salt. The obtained oxide mixture is mixed with molten salt to obtain a raw material mixture; the mass ratio of the molten salt to the oxide mixture is 5:1. The weighed raw material mixture is placed in a nylon ball mill jar.

[0021] Step 2: Ball milling. Add absolute ethanol to a nylon ball mill jar and mill on a ball mill for 12 hours. The mass ratio of the absolute ethanol to the raw material mixture placed in the nylon ball mill ...

Embodiment 2

[0026] This embodiment is a preparation method of columnar sodium strontium niobate microcrystalline powder, and its specific process is:

[0027] Step 1: Ingredients. The composition of sodium strontium niobate is designed to be: Sr 2 NaNb 5 o 15 . The analytically pure strontium carbonate and niobium pentoxide powders are weighed according to a molar ratio of 1:1.25 to obtain an oxide mixture formed of strontium carbonate and niobium pentoxide. Sodium chloride and potassium chloride are weighed in a molar ratio of 1:1 to obtain the desired molten salt. The mass ratio of the molten salt to the oxide mixture is 4:1 to obtain a raw material mixture. The weighed raw material mixture is placed in a nylon ball mill jar.

[0028]Step 2: Ball milling. Add absolute ethanol to a nylon ball mill jar and mill on a ball mill for 12 hours. The mass ratio of the absolute ethanol to the raw material mixture placed in the nylon ball mill jar is 1.5:1.

[0029] Step 3: Dry. The ball...

Embodiment 3

[0033] This embodiment is a preparation method of columnar sodium strontium niobate microcrystalline powder, and its specific process is:

[0034] Step 1: Ingredients. The composition of sodium strontium niobate is designed to be: Sr 2 NaNb 5 o 15 . The analytically pure strontium carbonate and niobium pentoxide powders are weighed according to a molar ratio of 1:1.25 to obtain an oxide mixture formed of strontium carbonate and niobium pentoxide. Sodium chloride and potassium chloride are weighed in a molar ratio of 1:1 to obtain the desired molten salt. The mass ratio of the molten salt to the oxide mixture is 3:1 to obtain a raw material mixture. The weighed raw material mixture is placed in a nylon ball mill jar.

[0035] Step 2: Ball milling. Add absolute ethanol to a nylon ball mill jar and mill on a ball mill for 12 hours. The mass ratio of the absolute ethanol to the raw material mixture placed in the nylon ball mill jar is 1.5:1.

[0036] Step 3: Dry. The bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com