Novel high-energy-storage and high-efficiency sodium niobate-based ceramic material and preparation method thereof

A ceramic material and sodium niobate-based technology, applied in the field of sodium niobate-based ceramic materials and their preparation, can solve problems such as harming human health and the environment, and achieve increased energy storage density, maximum polarization strength and breakdown field. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

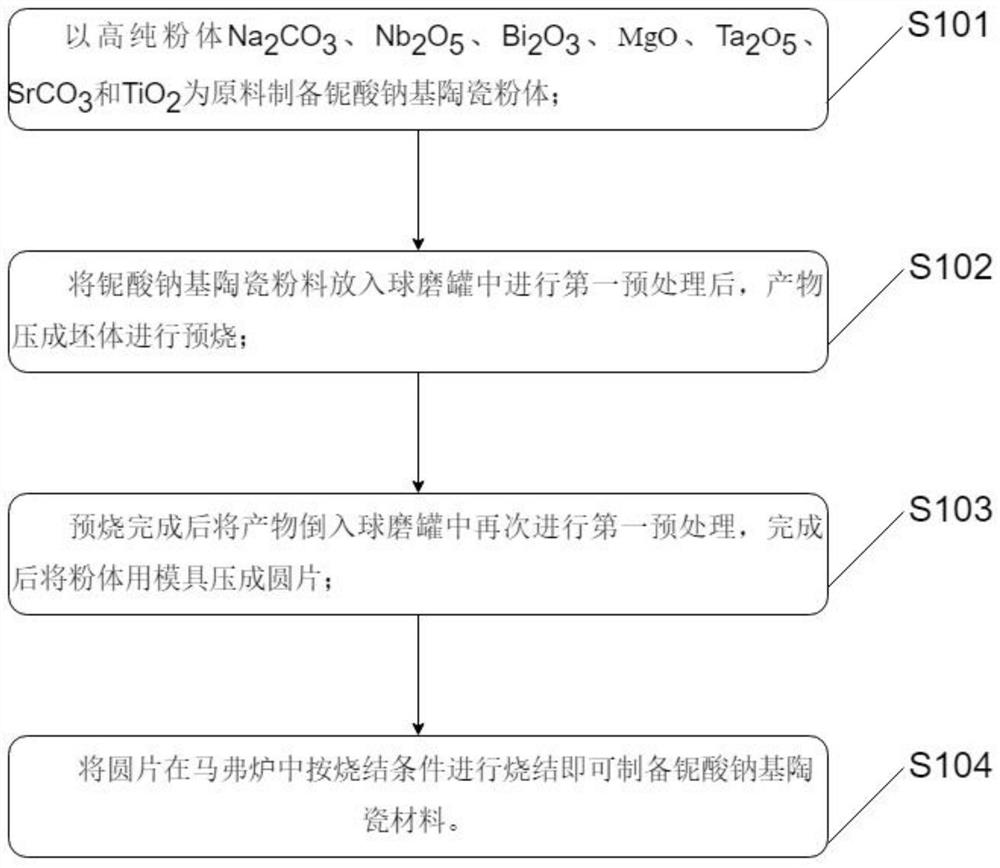

[0038] The present invention also proposes a method for preparing a sodium niobate-based ceramic material, including the novel high-energy-storage, high-efficiency sodium niobate-based ceramic material, and also includes the following steps:

[0039] S101 uses high-purity powder Na 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 , MgO, Ta 2 o 5 , SrCO 3 and TiO 2 Preparation of sodium niobate-based ceramic powder as raw material;

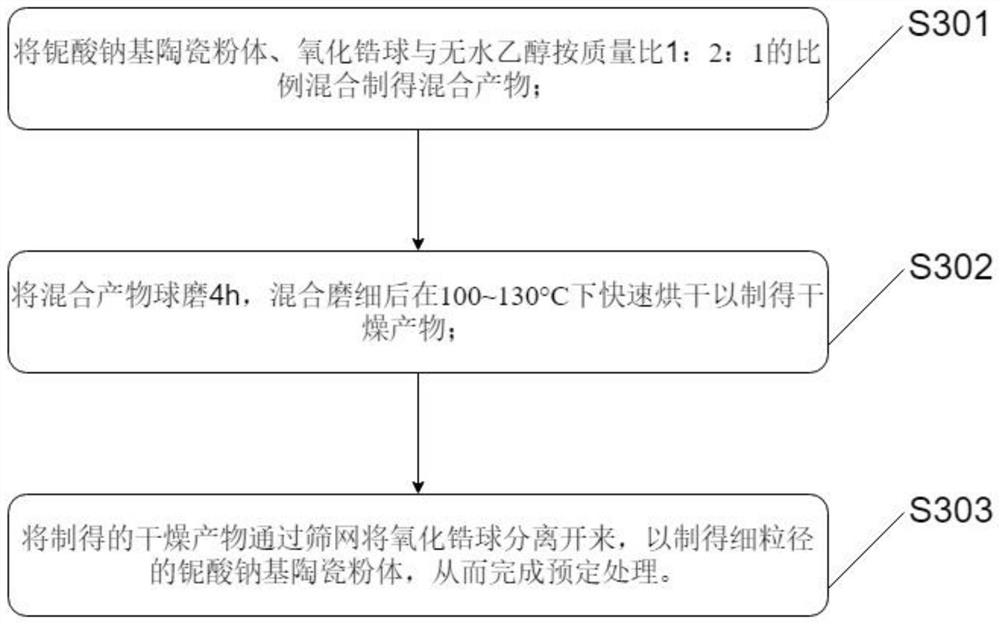

[0040] S102 Put the sodium niobate-based ceramic powder into a ball mill tank for predetermined treatment, and press the product into a green body for pre-sintering;

[0041] S103 After the pre-burning is completed, the product is poured into a ball mill tank for predetermined treatment again, and the powder is pressed into a disc with a mold after completion;

[0042] S104 The sodium niobate-based ceramic material can be prepared by sintering the disc in a muffle furnace according to the sintering conditions.

[0043] Further, the high-purity powder Na 2 ...

specific Embodiment 1

[0059] Prepare high-purity powder Na with purity ≥ 99% 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 , MgO, Ta 2 o 5 , SrCO 3 and TiO 2 as raw material,

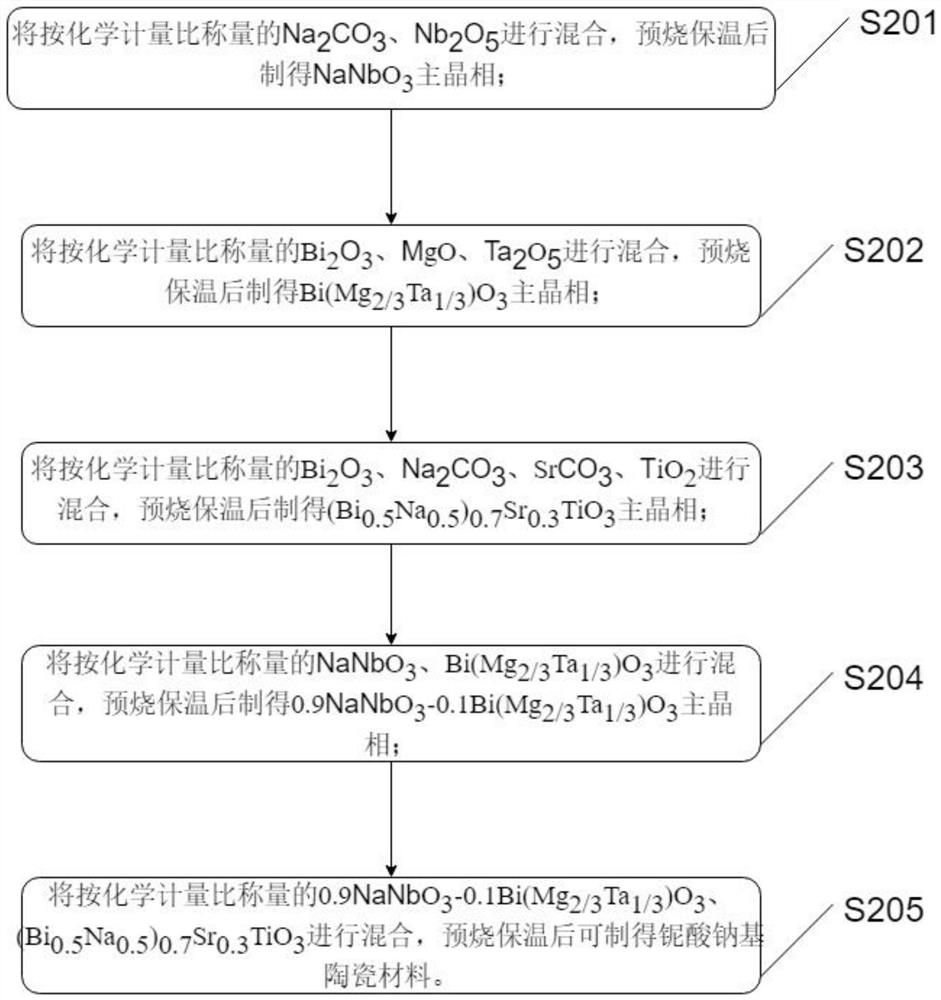

[0060] Na, which will be weighed stoichiometrically 2 CO 3 , Nb 2 o 5 Mixed, pre-fired and kept warm to obtain 0.9 mole percent NaNbO 3 main crystal phase;

[0061] Bi will be weighed stoichiometrically 2 o 3 , MgO, Ta 2 o 5 Mixed, pre-fired and kept warm to obtain 0.1 mole percent Bi(Mg 2 / 3 Ta 1 / 3 )O 3 main crystal phase;

[0062] Bi will be weighed stoichiometrically 2 o 3 、Na 2 CO 3 , SrCO 3 、TiO 2 Mix, make 0 mole percent (Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 TiO 3 main crystal phase;

[0063] NaNbO will be weighed stoichiometrically 3 , Bi(Mg 2 / 3 Ta 1 / 3 )O 3 Mixed, pre-fired and kept warm to obtain 0.9NaNbO 3 -0.1Bi(Mg 2 / 3 Ta 1 / 3 )O 3 main crystal phase;

[0064] 0.9NaNbO weighed according to the stoichiometric ratio 3 -0.1Bi(Mg 2 / 3 Ta 1 / 3 )O 3 , 0 mole percent (Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 TiO 3 M...

specific Embodiment 2

[0067] According to the composition formula of the prepared sodium niobate-based ceramic powder is (0.9)[0.9NaNbO 3 -0.1Bi(Mg 2 / 3 Ta 1 / 3 )O 3 ]-0.1mol% (Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 TiO 3 Weigh each high-purity powder, and the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com